Device capable of accurately measuring carbon powder output

A technology of precise measurement and output, applied in the field of toner, which can solve the problems of easily affecting the surrounding environment and difficult cleaning of toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] as attached figure 1 to attach Figure 7 Shown:

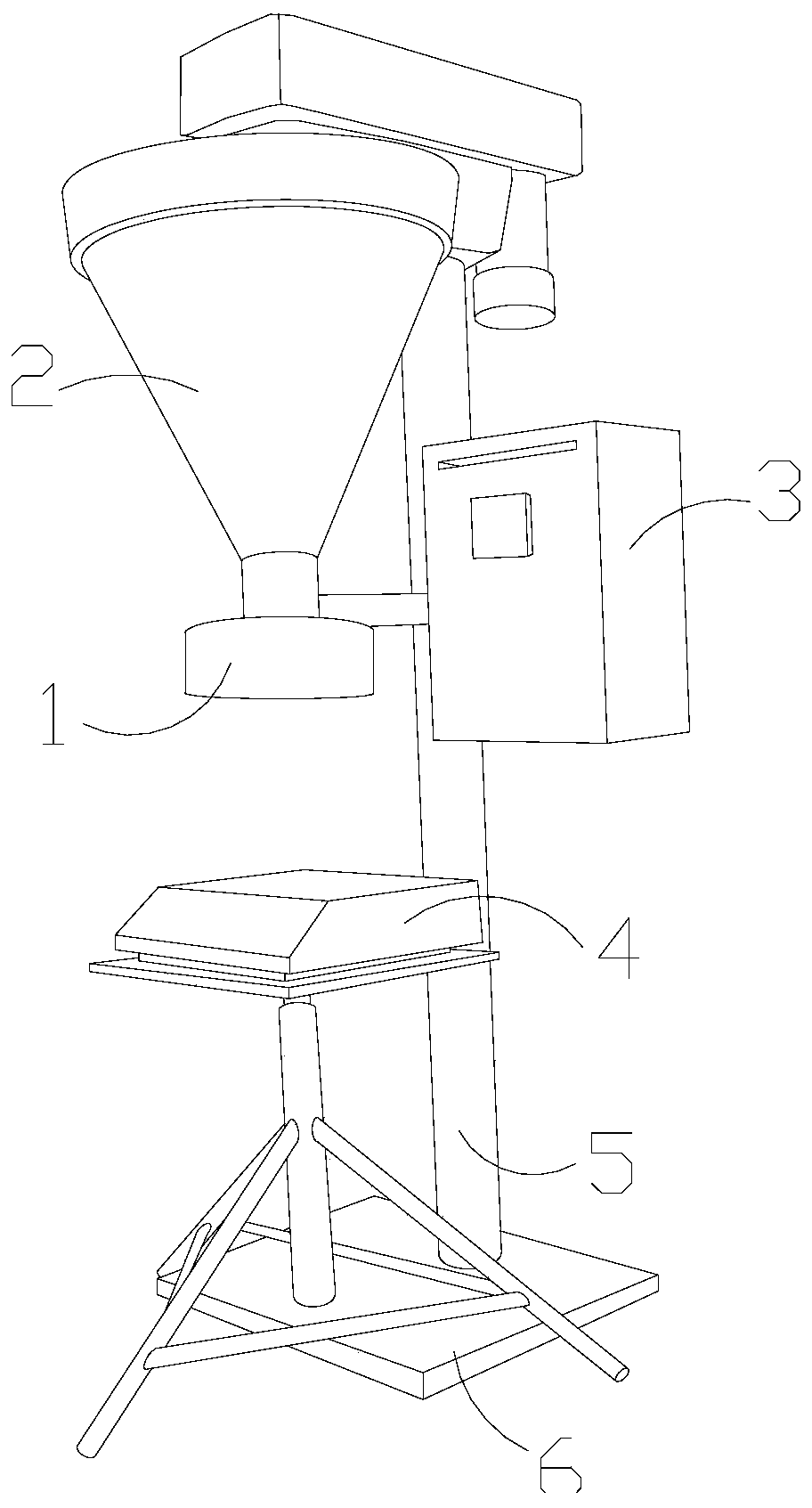

[0030] The present invention provides a device for accurately measuring the output of carbon powder. The structure includes a measuring carbon powder output port 1 , a powder storage tank 2 , a control box 3 , an operating table 4 , a support rod 5 , and a fixed base 6 .

[0031] The top of the measuring carbon powder output port 1 is connected to the bottom of the powder storage tank 2, the control box 3 is welded to the outer surface of the support rod 5, the bottom of the support rod 5 is vertically connected to the fixed base 6, and the placement operation The platform 4 is located above the fixed base 6 .

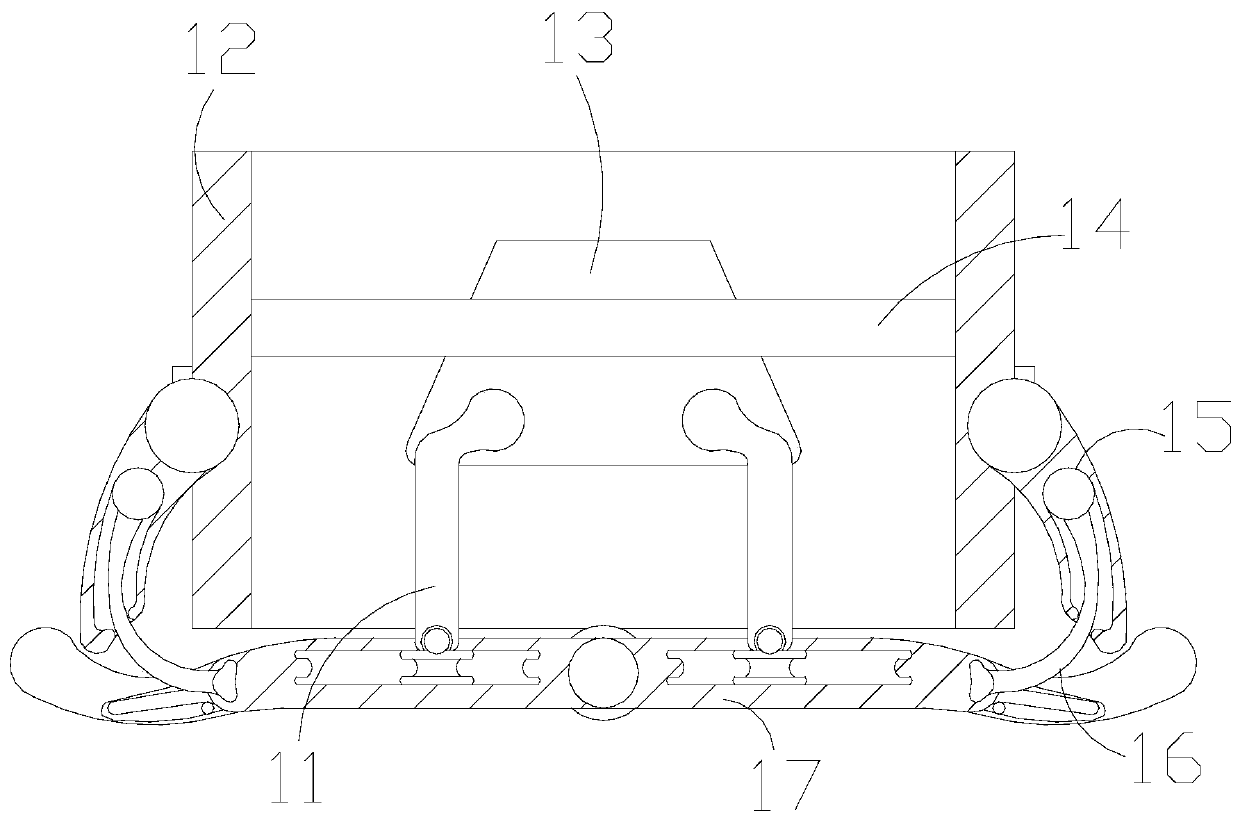

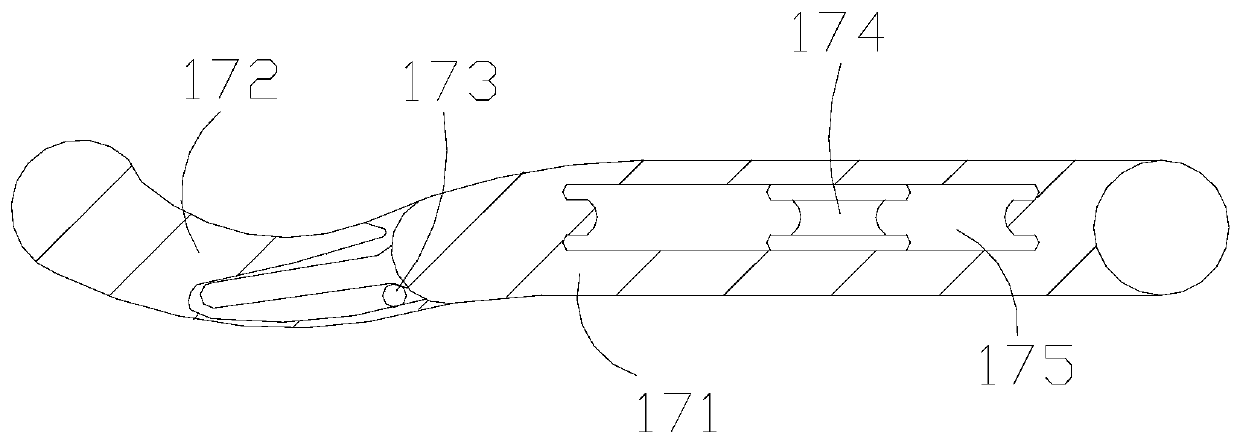

[0032] The measuring toner output port 1 includes a movable support rod 11, a partition case 12, a stamping cone 13, a force ring 14, a magnetic return strip 15, a slip-limiting rope 16, and an anti-floating blocking rod 17. The movable support rod 11 and The anti-floating blocking rod 17 is connected, the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com