LED neon lamp strip with back wires

A technology of LED neon lights and neon lights, which is applied in the parts of lighting devices, safety devices of lighting devices, semiconductor devices of light-emitting components, etc., can solve the problems of poor cascading performance, complicated installation and use, etc. The effect of wrapping and fixing and improving practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

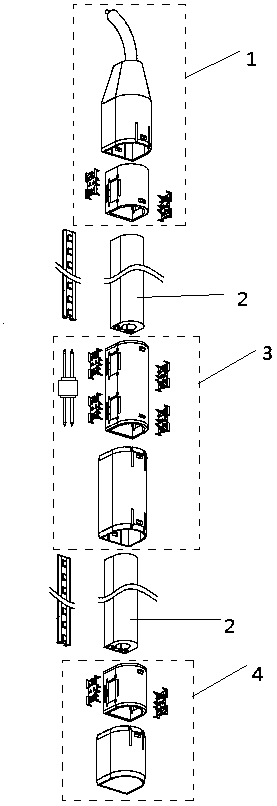

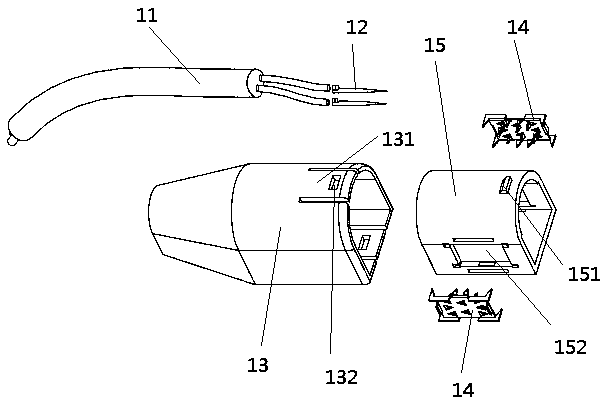

[0024] combine figure 1 As shown, the present invention provides an LED neon light strip with a back line, which includes an input end assembly (1), a neon light strip body (2), a middle end connection assembly (3) and a tail end assembly (4).

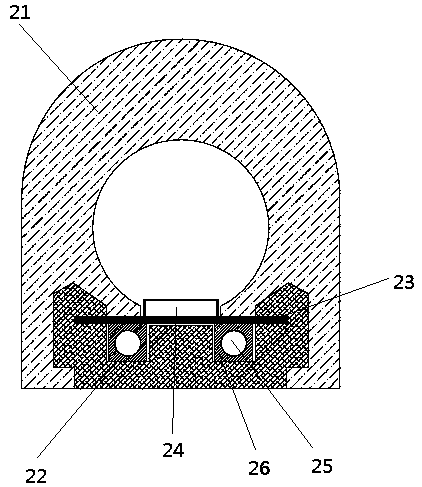

[0025] Such as figure 1 , figure 2 with Figure 7As shown, the neon light strip body is composed of two neon light strips, the neon light strip includes inclusions, FPC (23), LED (24), back line (25) and insulating colloid (26), and the inclusions use Milky white silica gel (21) and transparent silica gel (22) are made of two materials through extrusion molding, which are elongated structures that penetrate inside. The outer top surface of the milky white silica gel (21) is a curved surface structure, and the transparent The outer bottom surface of the silica gel (22) has a planar structure, the hollow structure inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com