Steel trestle static load test evaluation method considering non-elastic deformation

An evaluation method and technology of static load test, applied in the direction of elasticity test, mechanical component test, machine/structural component test, etc., can solve problems such as uneconomical, unsafe, material and energy waste, and reduce waste of resources , the calibration coefficient is accurate, and the effect of improving safety

Active Publication Date: 2019-08-06

GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

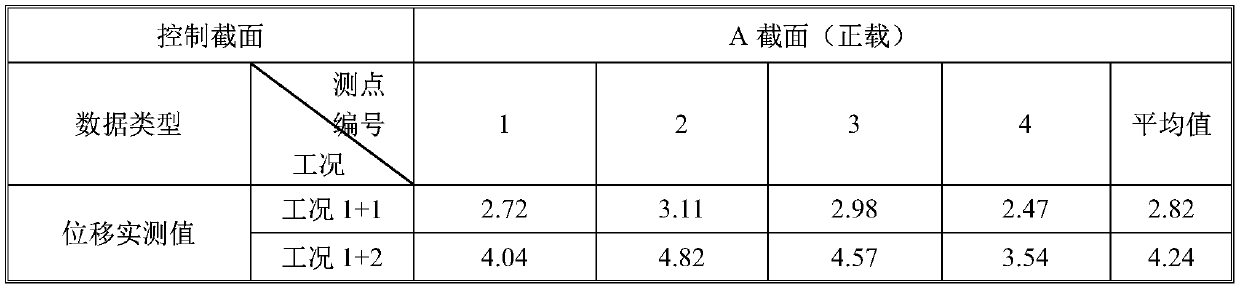

The characteristics of its structure itself lead to large residual values of strain and displacement after unloading, so that the relative residual strain S 应变 and the relative residual displacement S 位移 Too large, so that its value does not meet the specification requirements

Third, in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

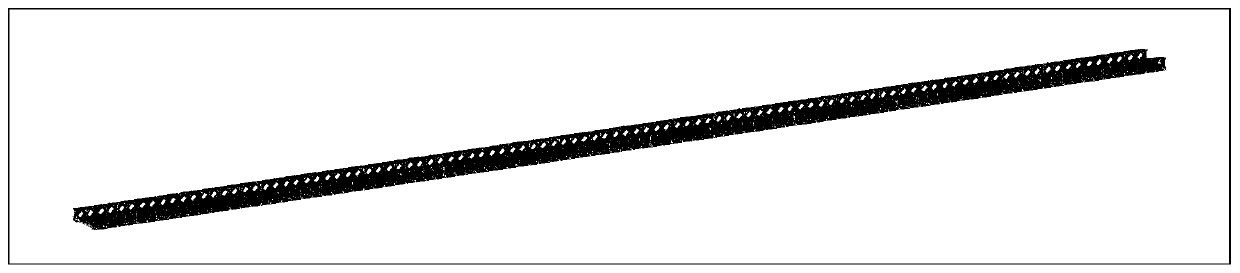

The invention provides a steel trestle static load test evaluation method considering non-elastic deformation and belongs to the bridge bearing capacity test technology field. The method is characterized by using a partial loading amount to eliminate non-elastic deformation of a steel trestle, and finding a starting point of an elastic phase in a test process according to a displacement change value; and then, using a verification coefficient of a bridge effect change value caused by a residual loading amount to evaluate a bearing capacity of the steel trestle, wherein the bridge effect changevalue includes a strain change value and a displacement change value. By using the method, structural characteristics of the steel trestle are fully considered, the bearing capacity of the steel trestle can be effectively and objectively evaluated and misjudgment is reduced. A test can be performed by using a test loading vehicle after proper prepressing, resource wastes can be reduced, test safety is increased, and the method can be widely used in the field where the bearing capacity of the steel trestle is evaluated through a static load test.

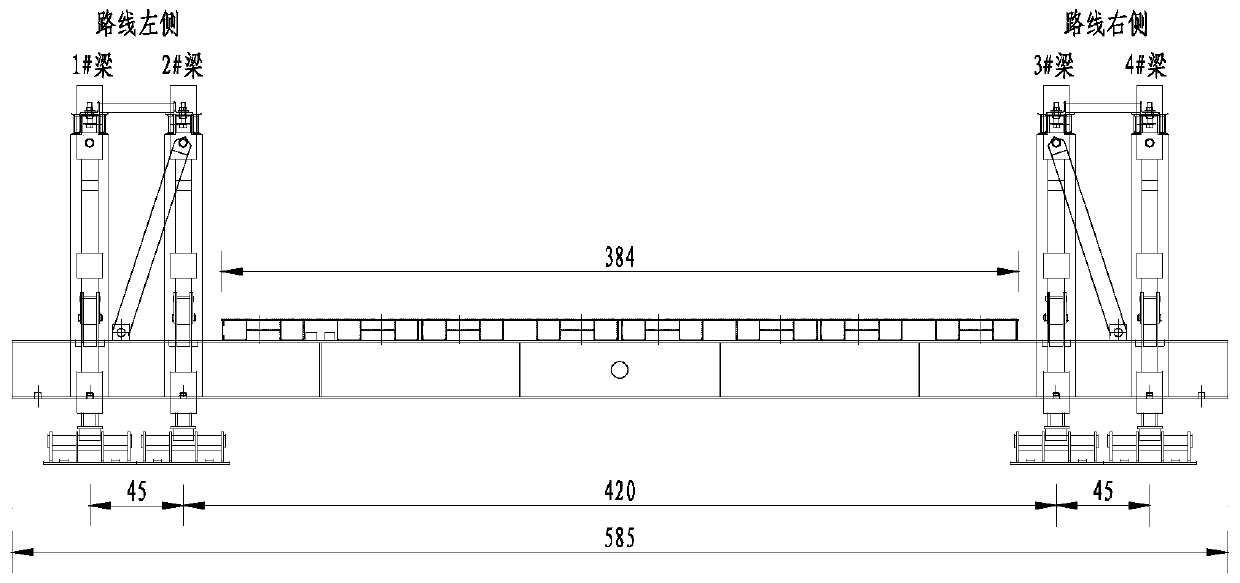

Description

[0001] 【Technical field】 [0002] The invention relates to the technical field of bridge bearing capacity tests, in particular to a static load test evaluation method for steel trestle bridges considering inelastic deformation. [0003] 【Background technique】 [0004] In the field of bridge construction, before the bridge is officially completed, there are often needs for flow of people and cargo transportation on both sides of the bridge. At this time, a steel trestle bridge is generally erected not far from the bridge to meet the needs of bridge construction. After the steel trestle is erected, it is often necessary to pass a static load test to evaluate whether the bearing capacity of the steel trestle meets the design requirements. It is very necessary to find an effective method for evaluating the static load test of the steel trestle. [0005] The current general practice of static load test evaluation of steel trestle bridges is: (1) Theoretical calculation: Calculate th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00G01M5/00

CPCG01M5/0008G01M5/005G01M13/00

Inventor 杨雨厚鞠玉财唐洪泉彭曦陈仕湘郝天之李增科王海华韦昊黄铁

Owner GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com