Small-scale movable computer vision automatic navel orange separator

A computer vision and automatic sorting technology, applied in the field of fruit navel orange sorting and grading equipment, small mobile navel orange computer vision automatic sorting machine, can solve the problem of no automatic sorting and feeding mechanism, can not be applied to large-scale production practice and other problems , to achieve the effect of simple mechanical system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

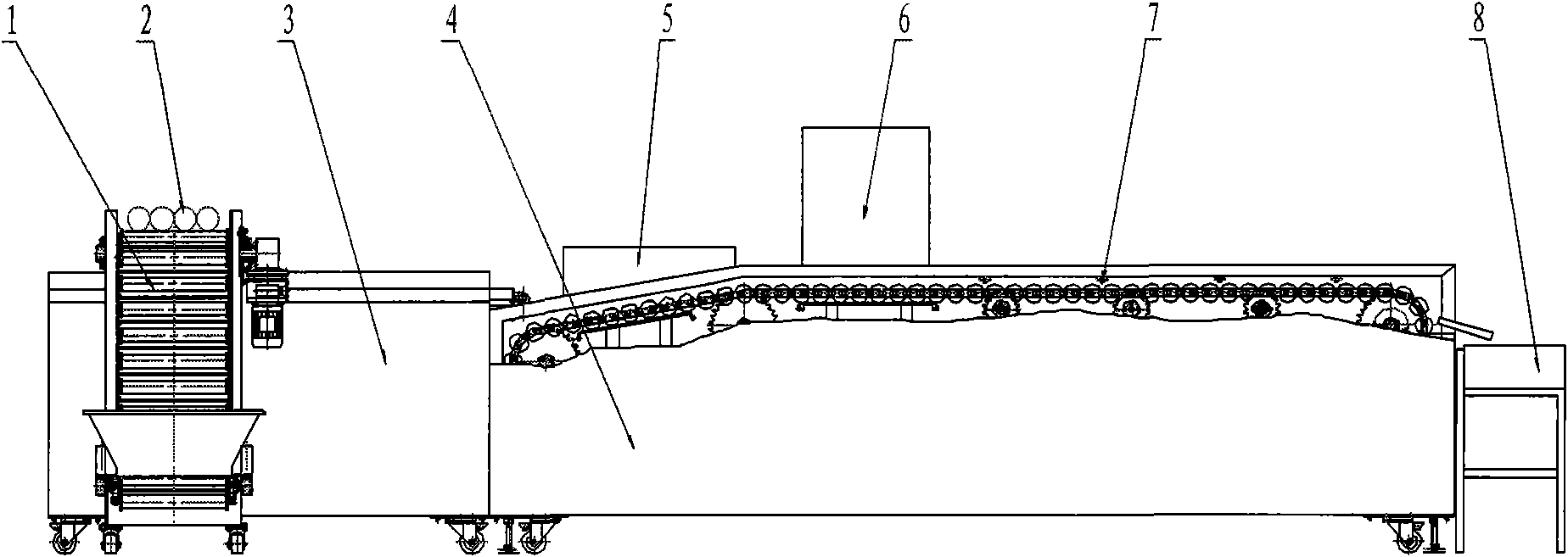

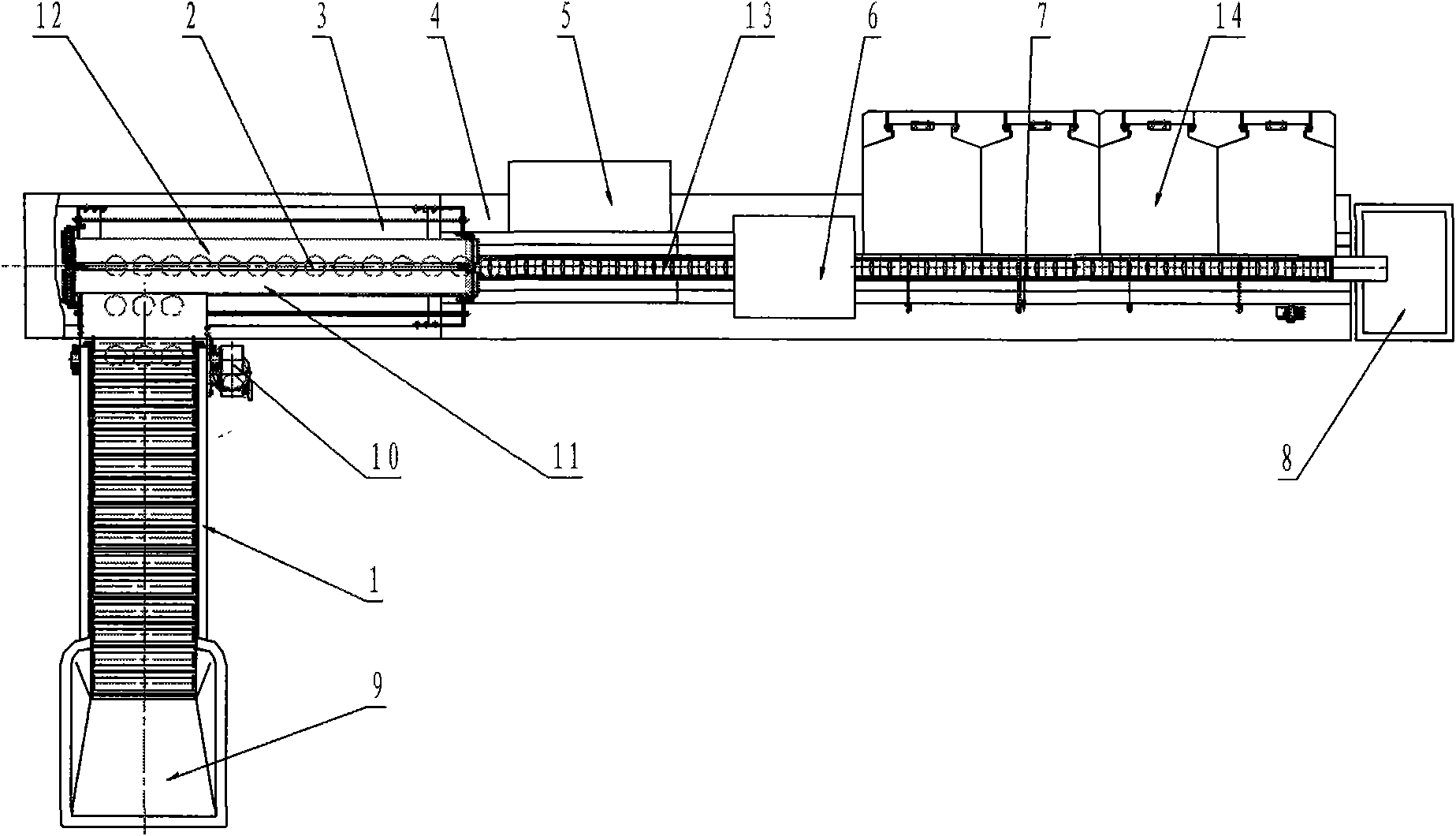

[0024] Such as figure 1 , 2 As shown, the sub-device of the present invention consists of navel orange staggered feeding mechanism 1, differential speed pair rubbing automatic arrangement mechanism 3, conveying line 4, computer and machine, light and electric automatic control box 5, computer vision system and camera photoelectric box Part 6 is composed of grading air blowing actuator 7.

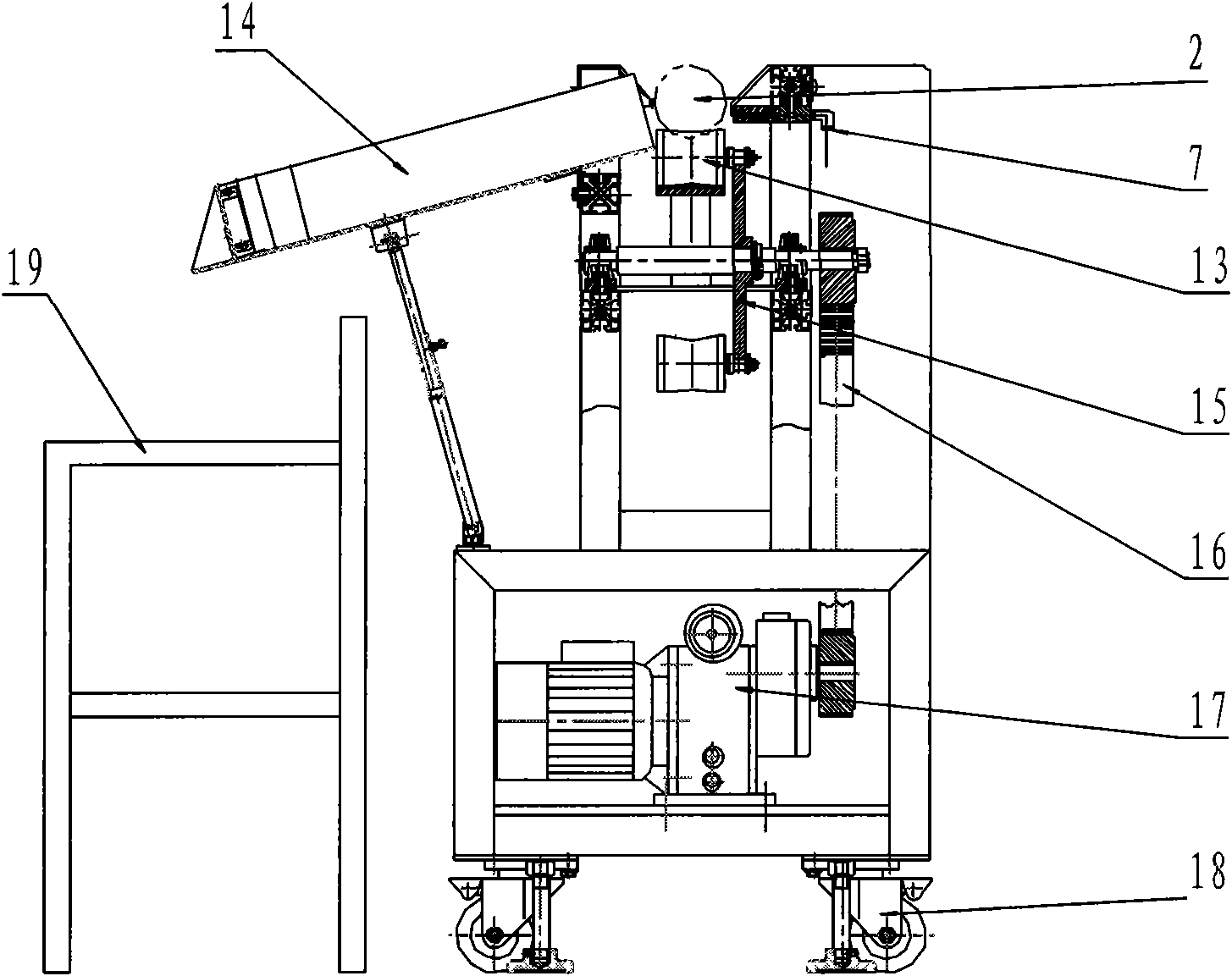

[0025] (1) The staggered feeding mechanism 1 is at one end of the sorting machine, such as Figure 4 and Figure 5 As shown, it includes a feed hopper 9, a frame body 20, an inclined feeding frame 24, a continuously variable speed changer 10 and a transmission chain part 27. The feeding hopper 9 is installed on the feeding position on the lower part of the left side of the frame body 20 . Drive chain adjusting devices 26 are installed on both sides of the lower left side of the frame body 20 , which can adjust the degree of tightness of the drive chain part 27 . The continuously variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com