Double die pressing type stand for optical imaging lens

An optical imaging and molding machine technology, applied in the field of molding, can solve the problems of low production efficiency and unreasonable structural design, and achieve the effects of simple structure, novel design and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described below in conjunction with specific embodiments.

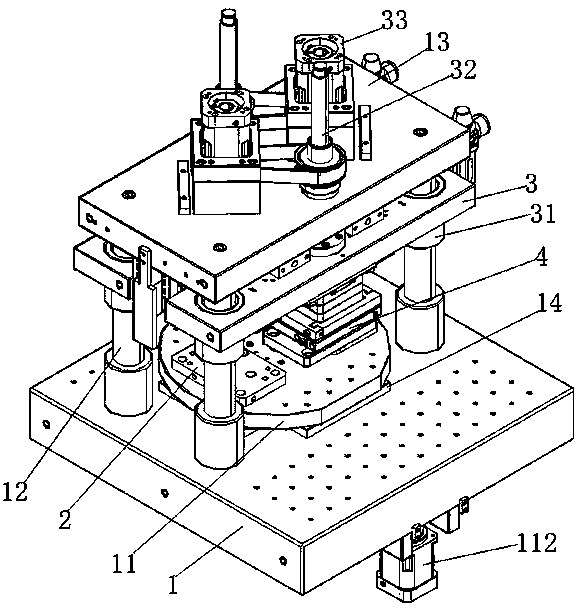

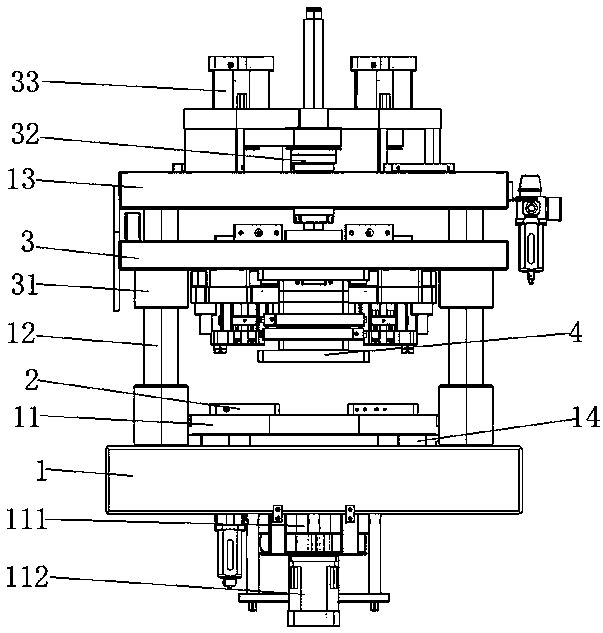

[0014] Such as Figure 1-2 As shown, a dual-mode pressing machine for optical imaging lenses includes a horizontally arranged working machine 1, and the upper end of the working machine 1 is equipped with a horizontally arranged rotating seat 11 and several vertically arranged guides. column 12, and the lower end of the rotating base 11 is connected with the rotating shaft 111 that runs through the lower end surface of the working machine 1, the rotating shaft 111 is connected with the rotating motor 112 installed at the bottom of the working machine 1, and the upper end of the rotating base 11 is equipped with two The lower mold base 2 arranged horizontally, the upper end of the guide post 12 is set with two molding plates 3, and the molding plate 3 is set on the upper end of the guide post 12 through the guide sleeve 31, and the upper end of the guide post 12 is equipped with an ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap