Bagging machine

A bagging machine and bag technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of unfavorable bagging, low efficiency, easy loosening and falling of parts, etc., and achieve the effect of improving the degree of automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

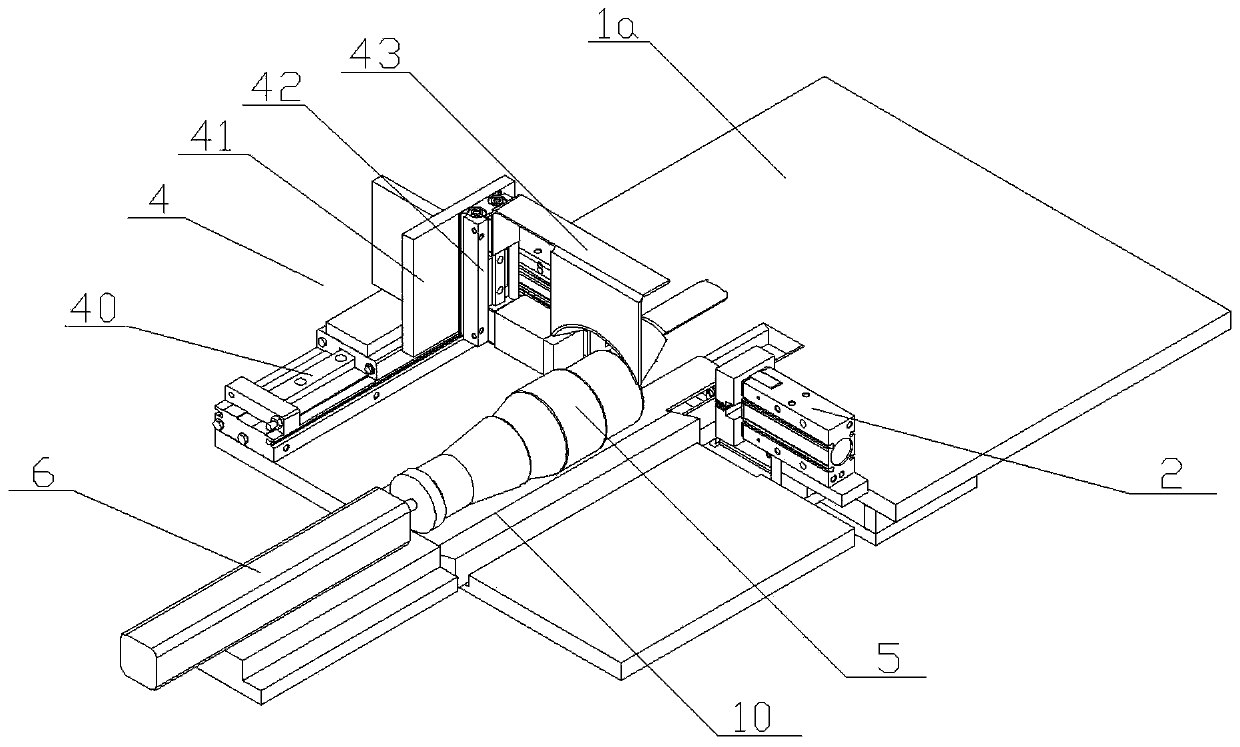

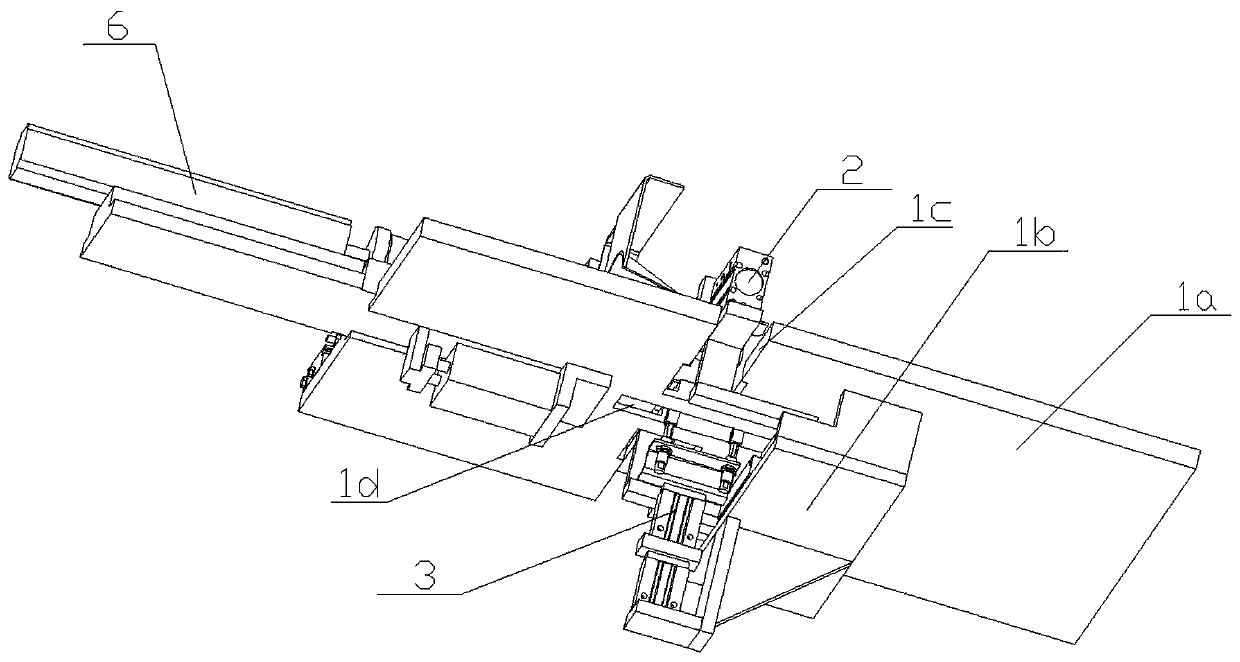

[0033] Such as figure 2 and image 3 As shown, the bagging machine corresponding to a preferred embodiment of the present invention includes a platen 1a, a bottom plate 1b, a bag clamping assembly 2, a suction cup assembly 3, a bag opening assembly 4 and a pushing assembly 6. The bottom plate 1b is disposed below the platform 1a.

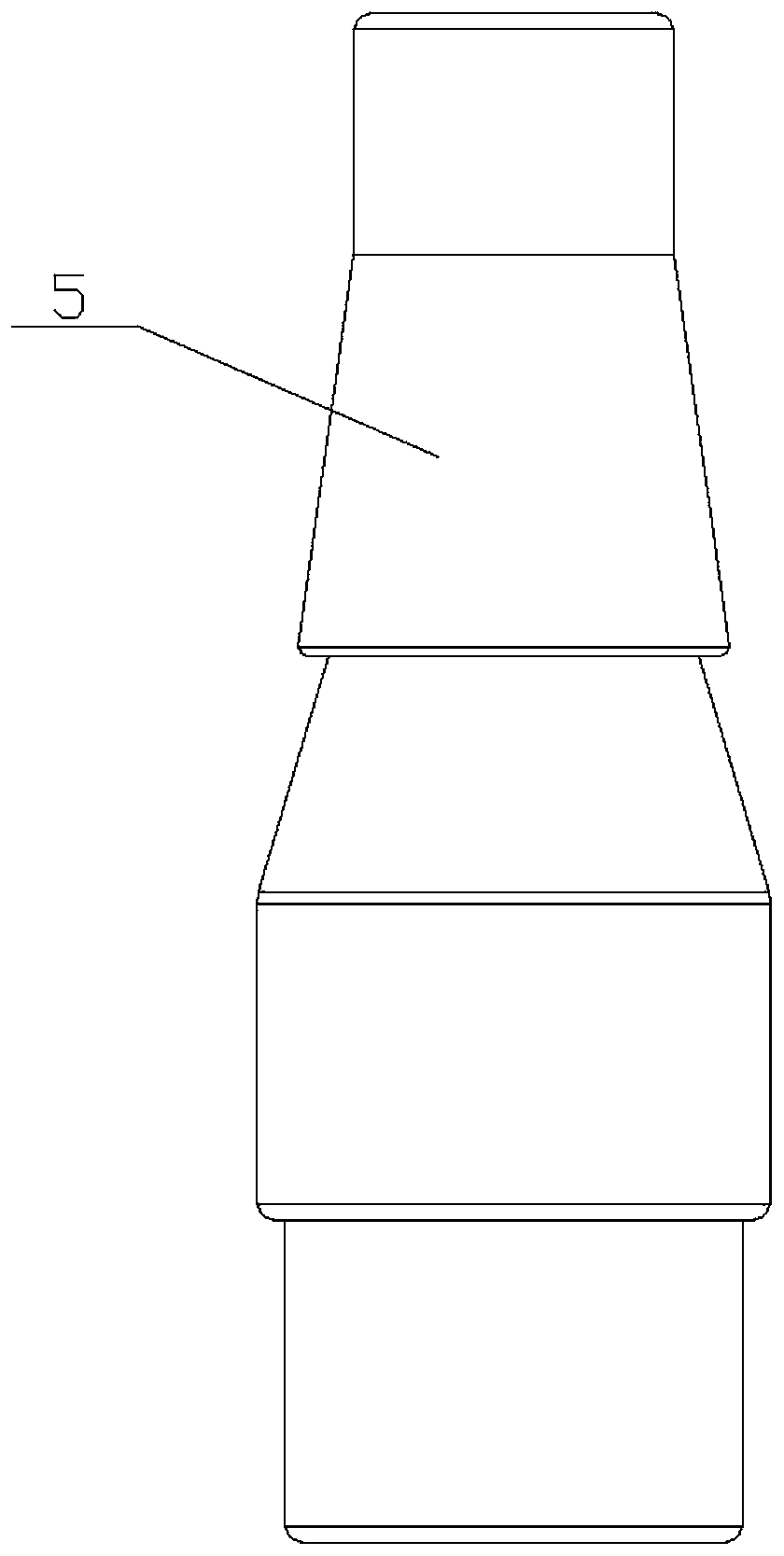

[0034] further reference Figure 4 and Figure 5 , The platen 1a is provided with a guide seat 10, the guide seat 10 is provided with a guide groove 11, the bottom of the guide groove 11 is an arc surface 11a, and both sides are inclined surfaces 11b connected with the arc surface 11a. The product 5 is horizontally placed in the guide groove 11, and when it is pushed into the bag 50 on the guide groove 11, its components will not fall off due to the effect of gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com