Method and system for evaluating health state of industrial equipment, equipment and storage medium

A technology for industrial equipment and health status, applied in the fields of instruments, electrical digital data processing, hardware monitoring, etc., can solve the problems of unconsidered, unable to fully reflect the health status of industrial equipment, and low accuracy of model prediction results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

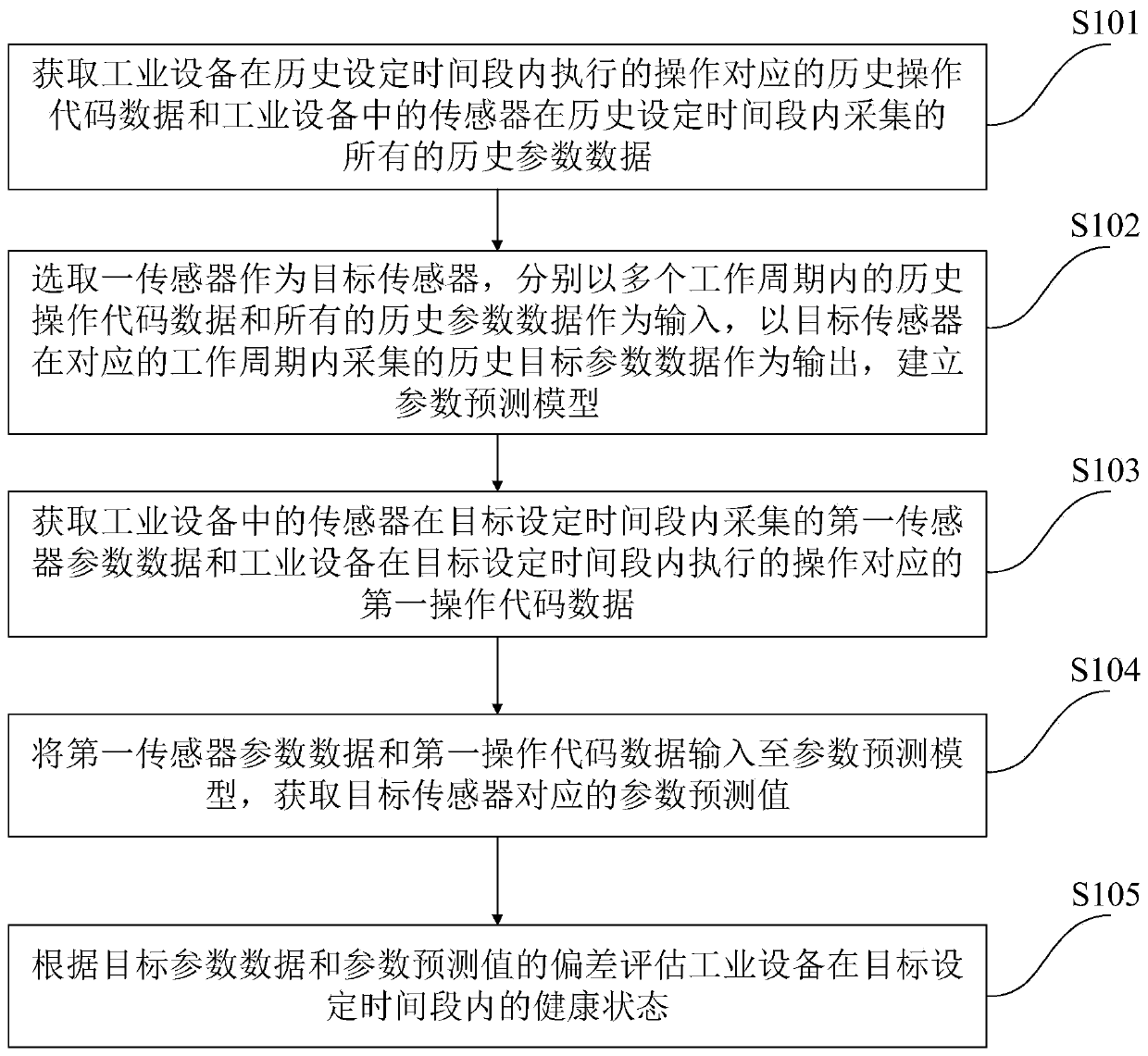

[0078] Such as figure 1 As shown, the assessment method of the health state of the industrial equipment of the present embodiment includes:

[0079] S101. Obtain the historical operation code data corresponding to the operations performed by the industrial equipment within the historically set time period and all historical operating parameter data collected by the sensors in the industrial equipment within the historically set time period;

[0080] Among them, the historical operation parameter data is continuous data, and the historical operation code data is discrete data; the historical setting time period includes multiple working cycles;

[0081] In order to ensure that the industrial equipment completes the specified operation in each working cycle, it is necessary to write the operation code in advance and store it in the corresponding storage device, where the historical operation code data is collected from the storage device by the data acquisition system.

[0082]...

Embodiment 2

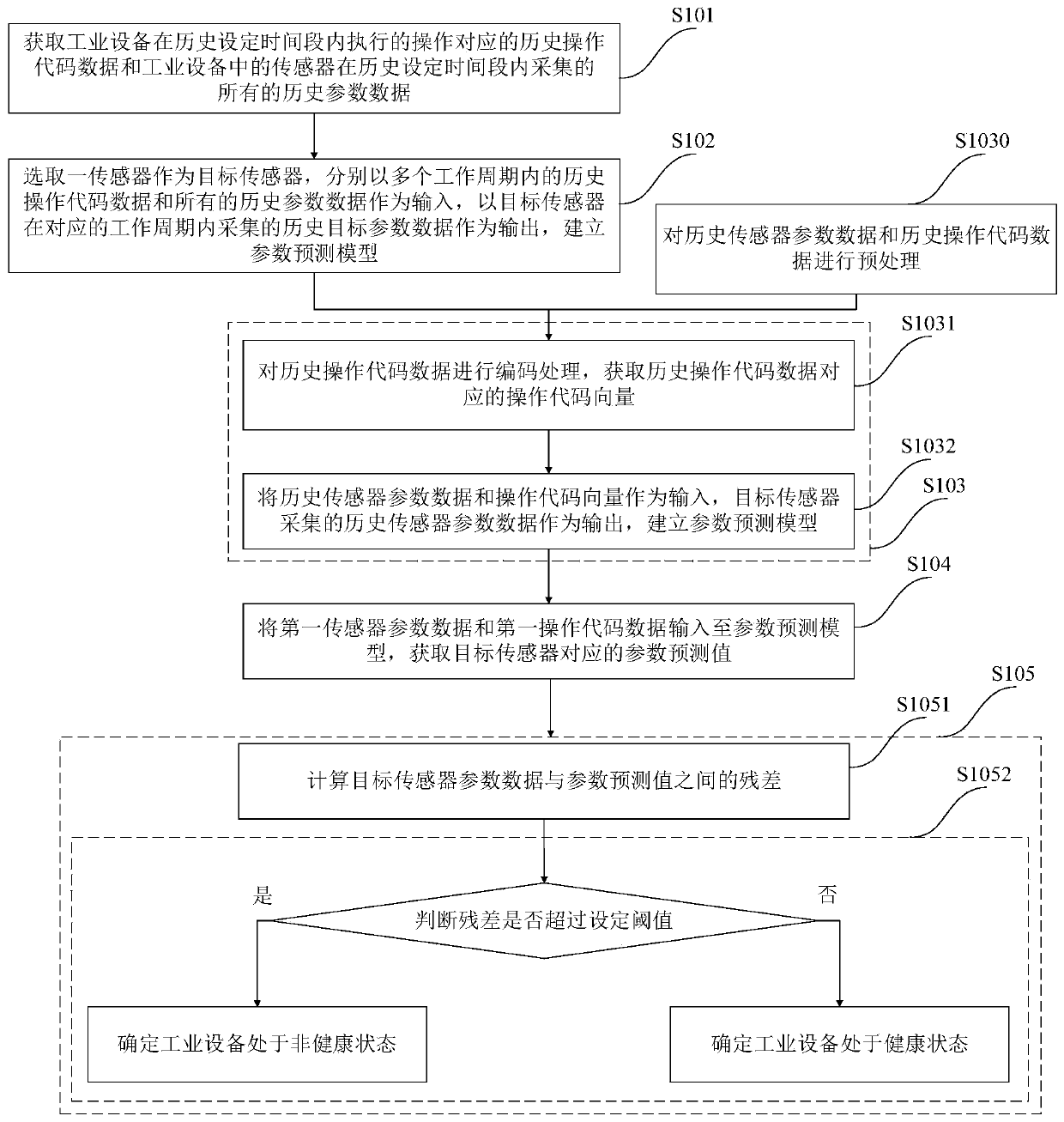

[0090] Such as figure 2 As shown, the method for evaluating the health status of industrial equipment in this embodiment is a further improvement to Embodiment 1, specifically:

[0091] After step S101, before step S103 also includes:

[0092] S1030. Perform preprocessing on historical operating parameter data and historical operation code data.

[0093] Among them, the preprocessing includes removing some abnormal data in the historical operating parameter data and historical operating code data, such as data obtained when a sensor fails.

[0094] In this embodiment, the data acquisition system is used to obtain historical operating parameter data and historical operation code data. The data acquisition system here is an existing device that can obtain target data from a certain device. The specific type, model, etc. No special request.

[0095]In addition, for the historical operating parameter data and historical operating code data collected by the same data acquisitio...

Embodiment 3

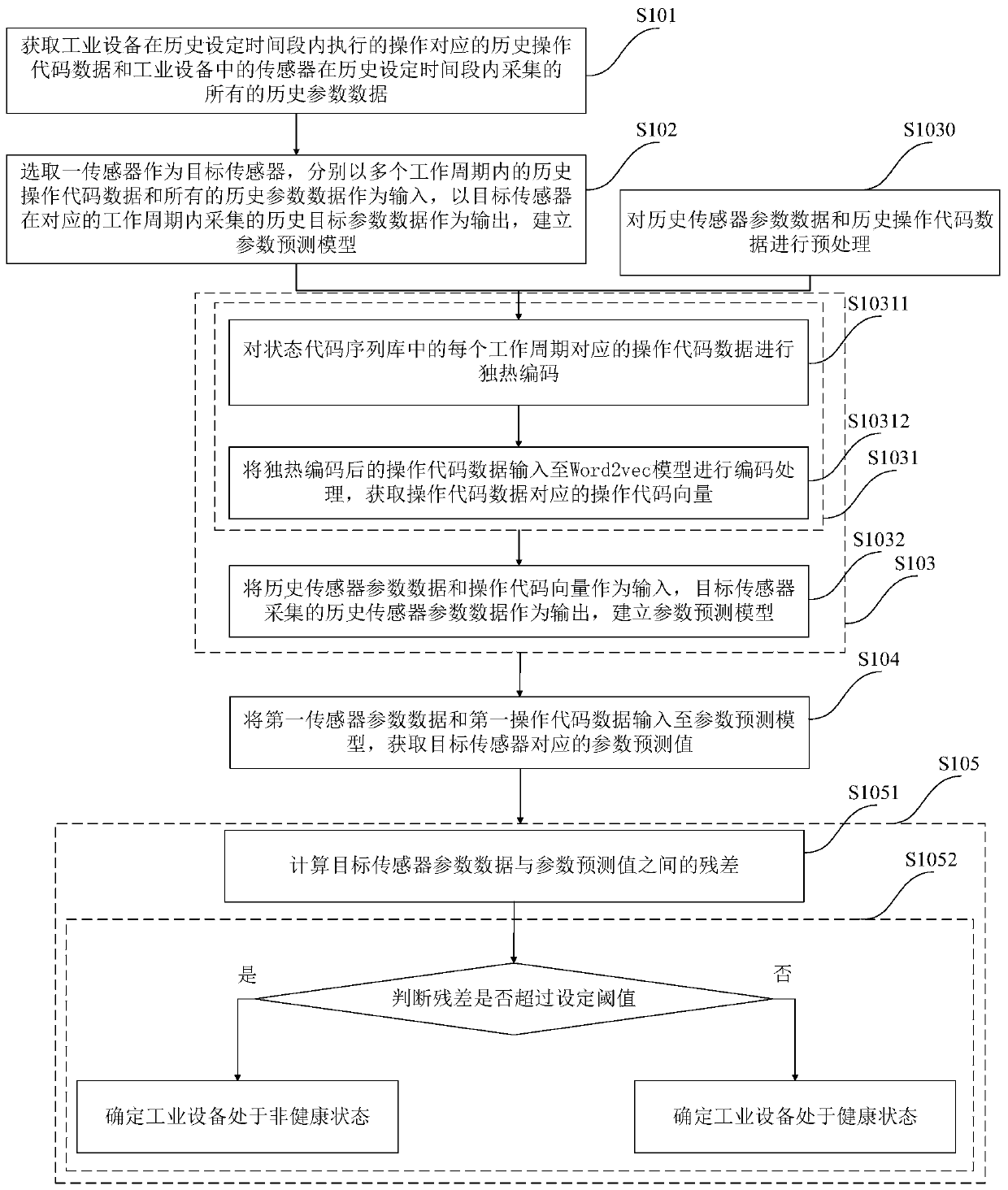

[0107] Such as image 3 As shown, the method for evaluating the health status of industrial equipment in this embodiment is a further improvement to Embodiment 2, specifically:

[0108] The historical operation code data corresponding to each working cycle constitutes a state code sequence, and the multiple state code sequences corresponding to the historical setting time period constitute a state code sequence library.

[0109] Examples of industrial equipment include excavators, wind turbines, and the like. For an excavator, it can be used as a working cycle from start-up to shutdown; for a wind turbine, every natural day can be used as a working cycle.

[0110] Industrial equipment such as excavators or wind turbines will perform a series of operations in each work cycle, and each operation corresponds to its own historical operation code data. In chronological order (from the beginning to the end of the work cycle), each work The historical operation code data for a seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com