Jig for positioning steel sheet, steel sheet positioning method and electronic product

A positioning method and steel sheet technology, applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, casing/cabinet/drawer parts, etc., can solve the problems of large horizontal space requirements and complex molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

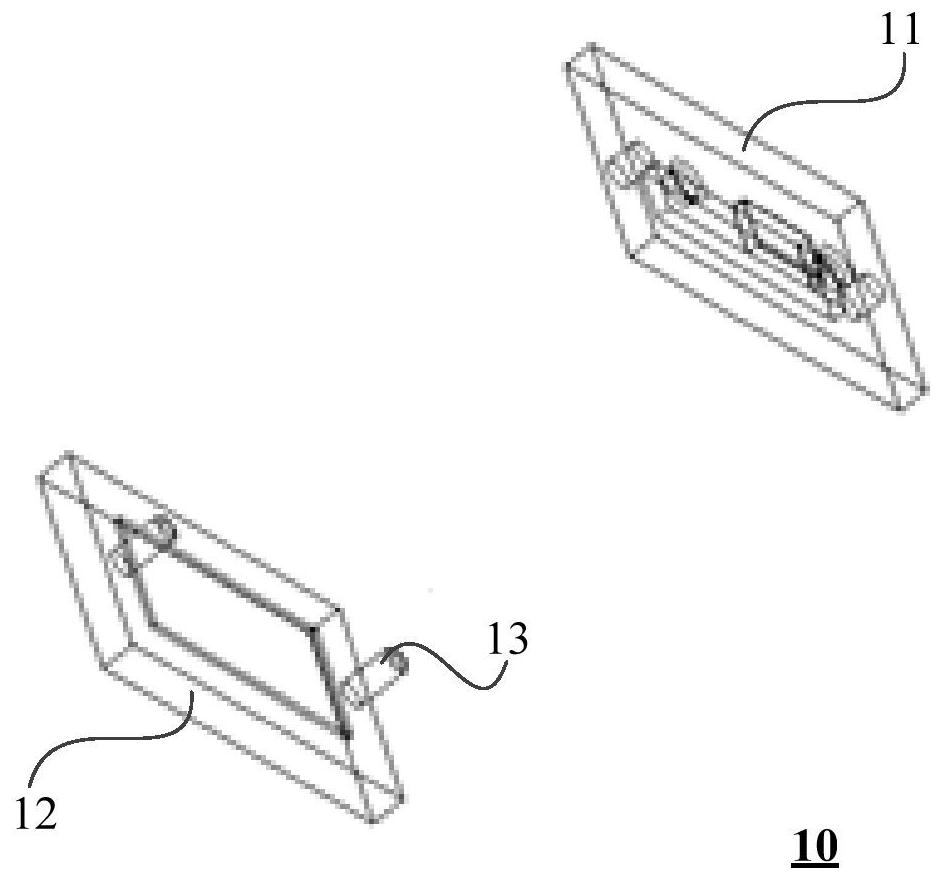

[0077] figure 1 An exploded view of a jig for positioning steel sheets provided by an embodiment of the present application. This embodiment provides a jig for positioning steel sheets, such as figure 1 As shown, the jig 10 includes: an upper cover 11 , a lower cover 12 and a positioning guide 13 .

[0078] Wherein, the upper cover plate 11 is provided with a first groove (not shown), and the first groove is used for positioning the steel sheet. A second groove (not shown) is provided on the lower cover plate 12, and the second groove is used for positioning and fixing the substrate. The lower cover plate 12 cooperates with the upper cover plate 11 through the positioning guide 13 to position the steel sheet to the compacted body located on the upper part of the compacted matrix.

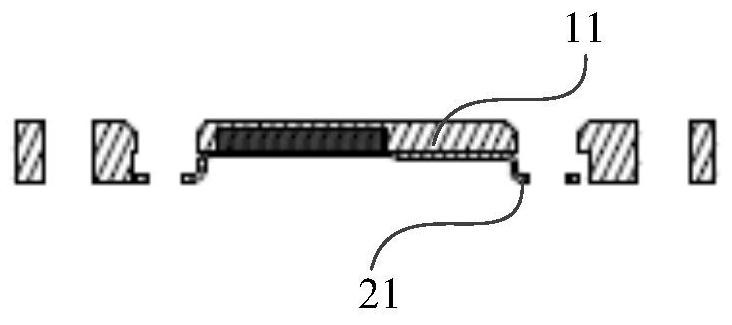

[0079] In actual application, the steel sheet 21 is fixed and positioned on the upper cover plate 11, such as Figure 2A , Figure 2B and Figure 2C shown. in, Figure 2A A front view cross-...

Embodiment 2

[0087] On the basis of the above embodiments, in a possible implementation manner, the positioning guide 13 is arranged on the lower cover plate 12, such as figure 1 or Figure 3A , Figure 4A and so on. Or, the positioning guide 13 is independent of the lower cover 12 and the upper cover 11, and the positioning guide 13 is connected with the lower cover 12 by welding, or the positioning guide 13 is connected with the upper cover 11 by welding. .

[0088] When the positioning guide 13 is disposed on the lower cover 12 , the positioning guide 13 and the lower cover 12 can be integrally formed. In this case, optionally, the upper cover plate 11 is provided with a positioning portion that cooperates with the positioning guide 13 . Wherein, the positioning guide member 13 is, for example, a positioning guide post, etc. At this time, the upper cover plate 11 is provided with structures such as a positioning hole or a positioning groove that cooperate with the positioning guide ...

Embodiment 3

[0091] still refer to Figure 4A and Figure 4B , the first groove 22 is provided with an adsorption device 41 , and the upper cover plate 11 is fixed and positioned by the adsorption device 41 to position the steel sheet 21 . Wherein, the adsorption device 41 may at least include any one of a magnet, an air suction device, and the like. That is to say, the adsorption device 41 in the embodiment of the present application includes but not limited to a magnet and a suction device.

[0092] When the adsorption device 41 is a magnet, if the fastener 42 used to fix the steel sheet 21 and the compressed body 32 is a magnetic fastener, the magnetic fastener may cause a positional deviation due to the magnetic attraction force, so , the fastener 42 at this time may specifically be a non-magnetic fastener, such as a non-magnetic screw, or a fastener including a non-magnetic bolt and a non-magnetic nut, and the like. By setting the fasteners as non-magnetic fasteners, the influence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com