Compact high-resolution optical fiber imaging system

A high-resolution, imaging system technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of increased light loss, small magnification of the imaging part, and large conjugate distance, so as to reduce the machine space and improve the imaging resolution. , The effect of reducing the welding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

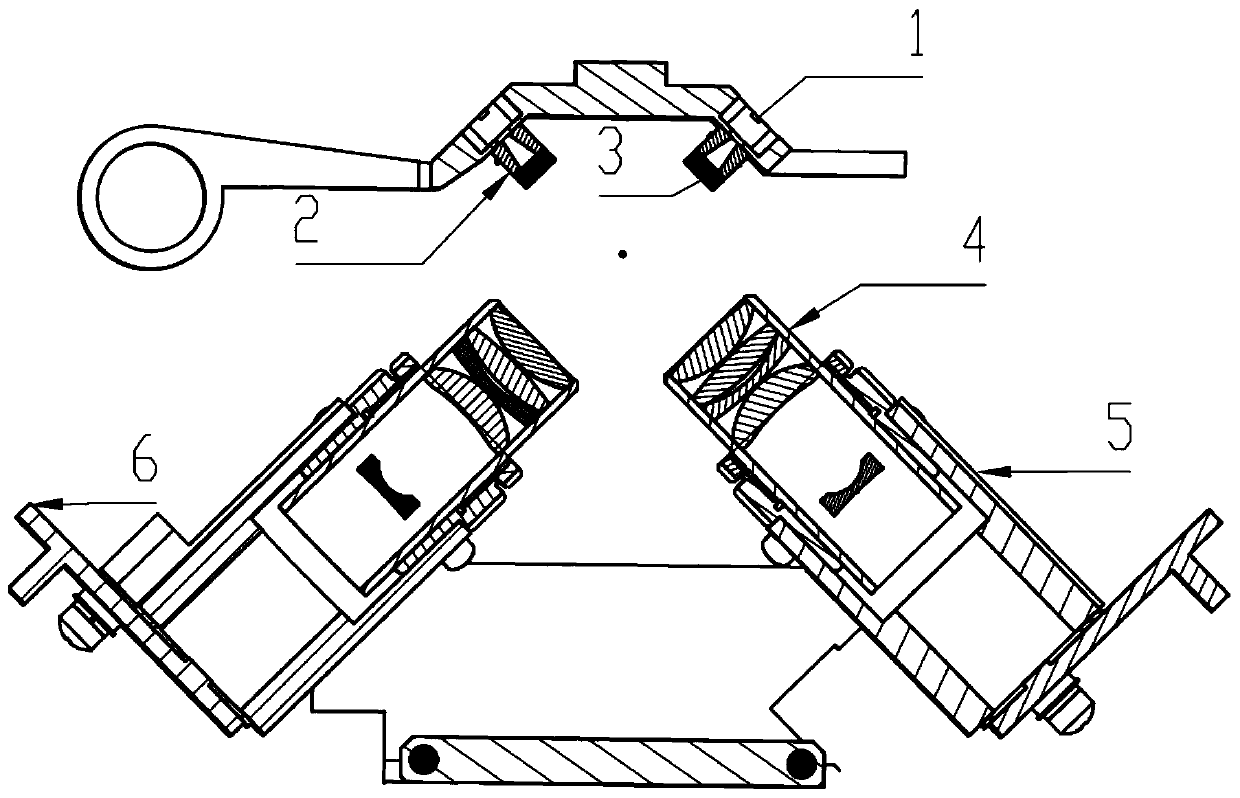

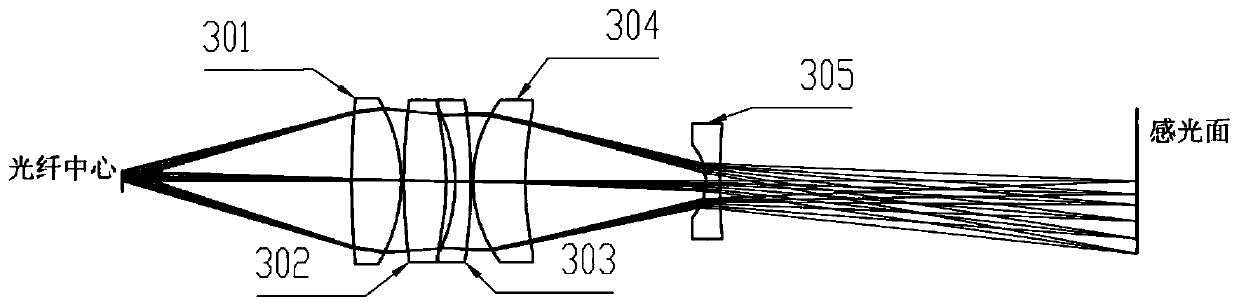

[0028] Such as figure 1 As shown in Fig. 1, a compact high-resolution optical fiber imaging system includes two parts: optical fiber illumination optical path Ⅰ and optical fiber imaging optical path Ⅱ.

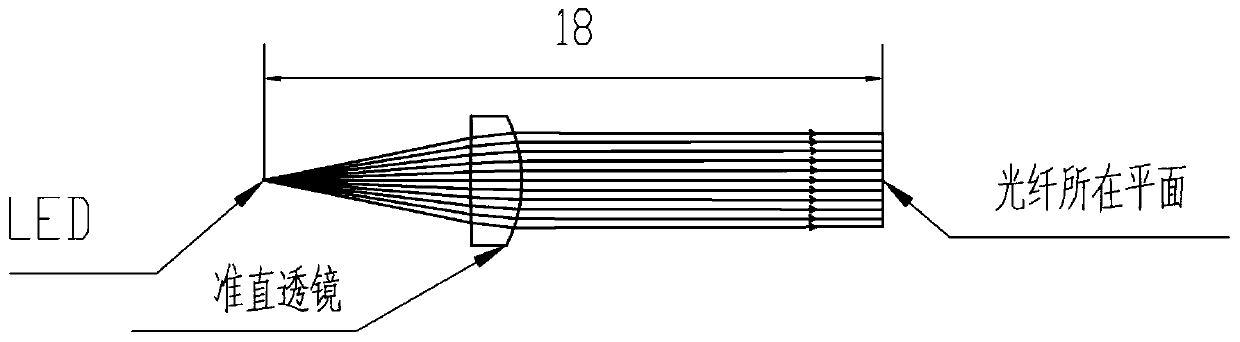

[0029] The optical fiber lighting path I adopts the direct lighting method, which includes the LED light source 1 and the light guide tube 2 respectively. Compared with the traditional reflective lighting method, it can reduce the loss of light energy caused by the long reflection path. Because the LED light source 1 emits light The area is very small, here we can approximate it as a point light source, the light guide tube 2 is cylindrical, the length is 7.5mm, the internal light hole is tapered, used for the transmission of the light beam, the front end is attached to the light source, and the rear end is fixed. Straight lens 3, the radial c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com