High-pressure spraying device for dust removal

A high-pressure injection and consistent technology, applied in the field of dust removal, can solve the problems of small injection angle and low injection efficiency, and achieve the effect of large injection angle, high injection efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

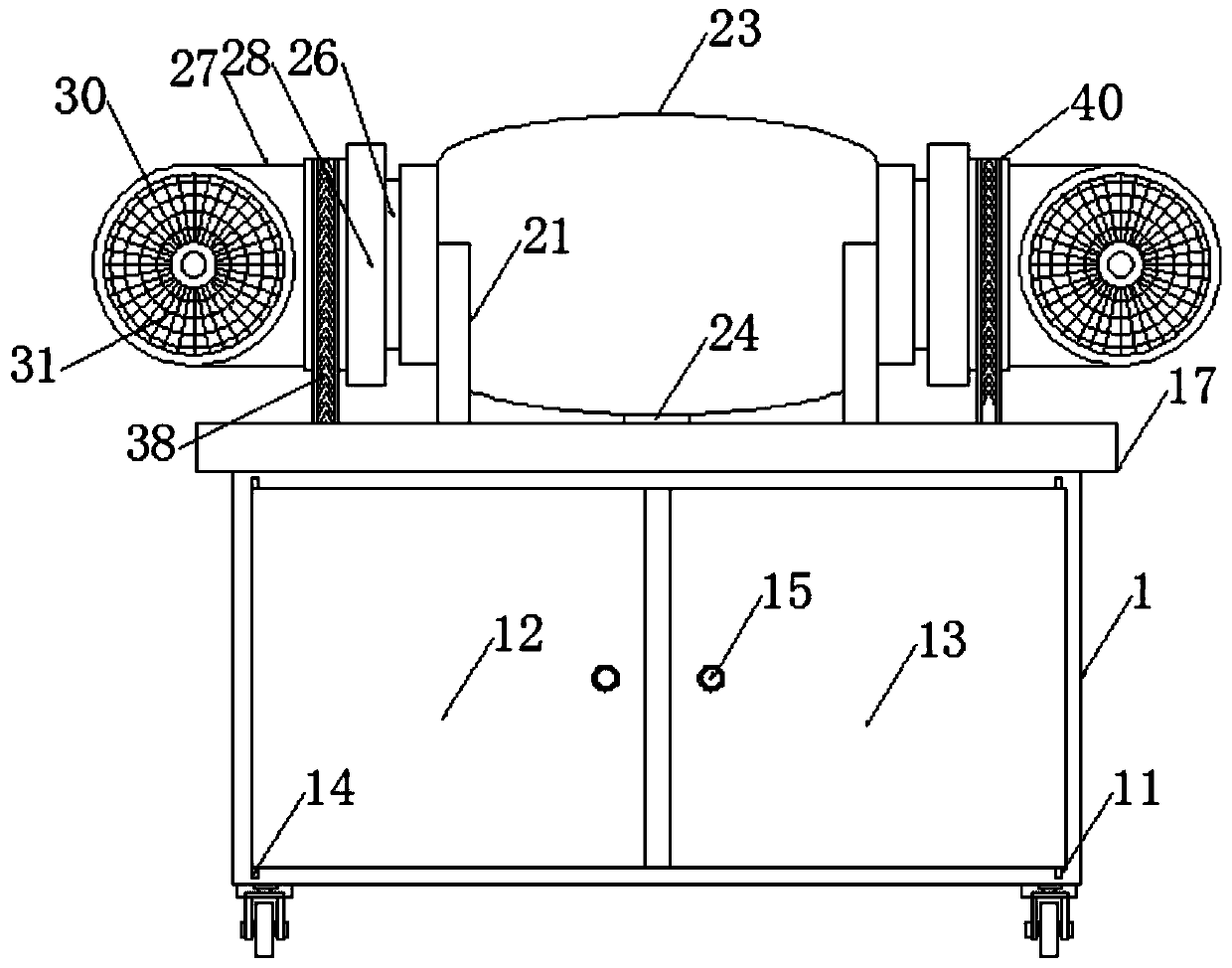

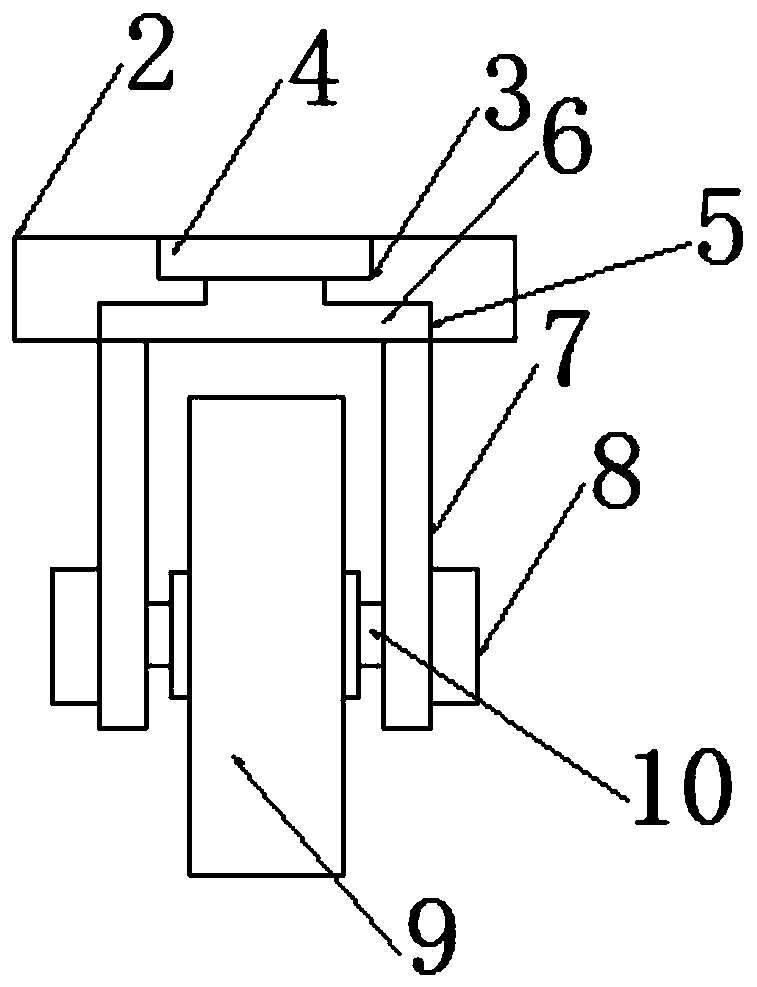

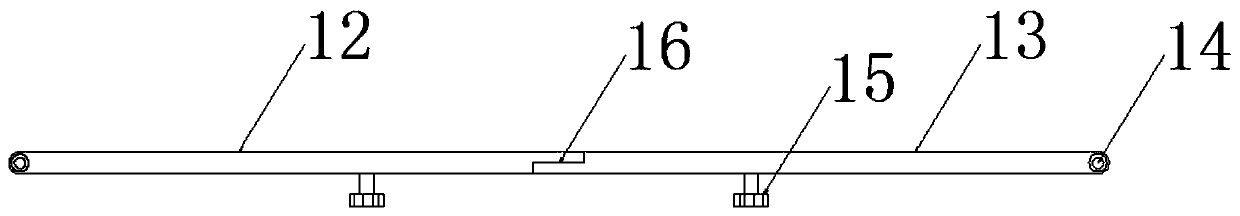

[0026] like Figure 1-8 As shown, this specific embodiment adopts the following technical solutions: a high-pressure spraying device for dust removal, including a protection box 1, and two shaft grooves 11 are provided on the upper top edge and the lower bottom edge of the mouth of the protection box 1, The four rotating shaft grooves 11 are of the same specification and are arranged correspondingly. The opening position of the protection box 1 is provided with a first box door 12 and a second box door 13. The first box door 12 and the second box door A rotating shaft 14 is respectively fixedly installed on the edge of the upper and lower ends of the door 13, and the four rotating shafts 14 are adapted to the four rotating shaft grooves 11 respectively and are arranged correspondingly. The first box door 12 and the second The box doors 13 are all rotated with the protective box 1 through two rotating shafts 14 and two rotating shaft grooves 11, and the first box door 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com