Intelligent paint spraying machine for furniture manufacturing

A technology for furniture manufacturing and painting machines, applied in painting booths, spraying devices, etc., can solve the problems of uneven paint surface, poor quality of finished products, low efficiency, etc., achieve uniform paint surface, ensure paint effect, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

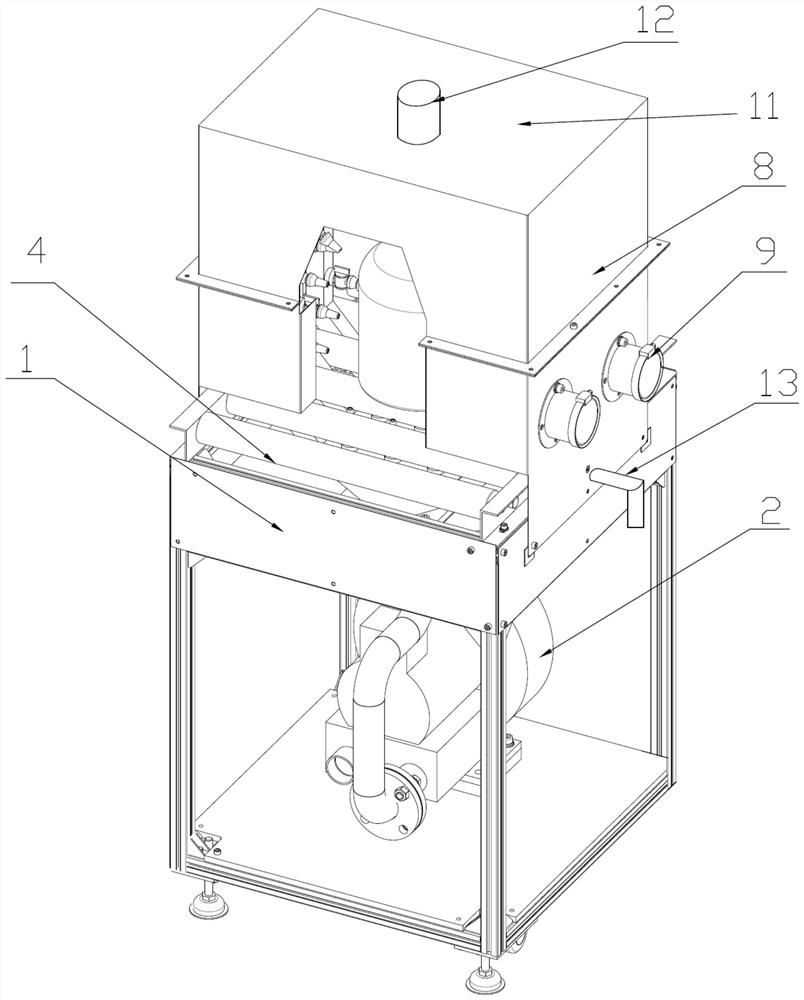

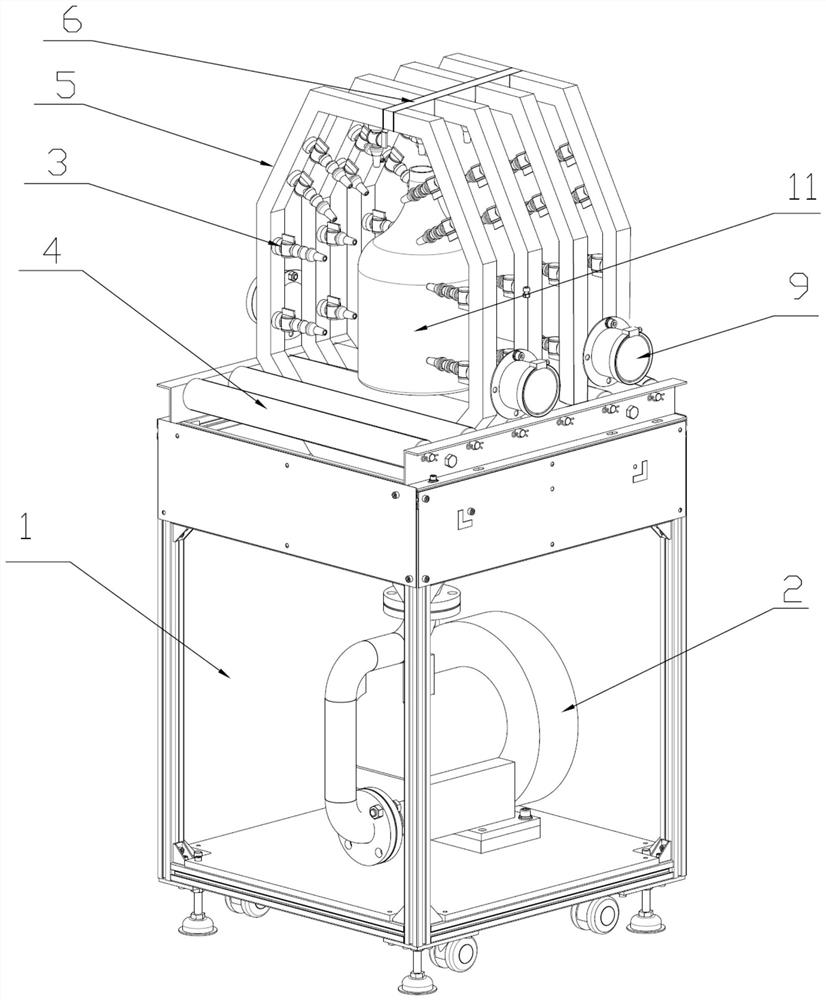

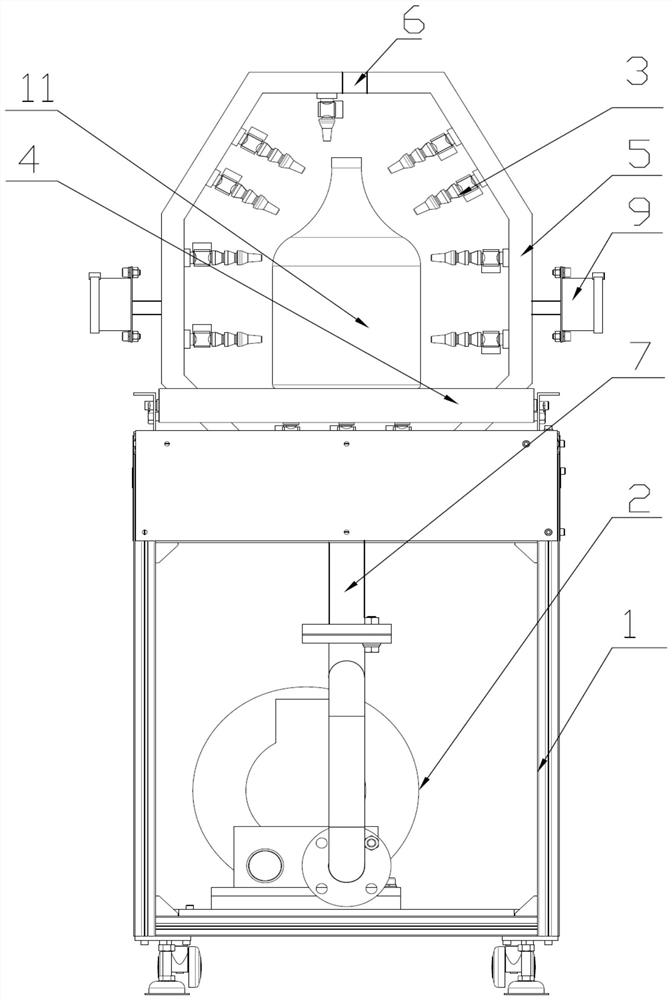

[0018] refer to Figure 1-Figure 4 , an intelligent paint spraying machine for furniture manufacturing, comprising a frame 1, a paint spray gun 2 installed in the frame 1 and a nozzle 3 communicated with the paint spray gun 2, the orientations of the nozzles 3 are all different, and the top surface of the frame 1 A conveying roller 4 is provided, and the conveying roller 4 can convey the ornament, and the nozzle 3 is aimed at the ornament 11 for painting. Described frame 1 top is provided with the arc-shaped paint pipe 5 that group is arranged side by side on the periphery of conveying roller 4, and the number of each group of paint pipe 5 is two and distributes axisymmetrically according to central axis 6, and described paint The top of the pipe 5 is hinged with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com