Intelligent painting device for building wall

A building wall, intelligent technology, applied in construction, machine tools suitable for grinding workpiece planes, building structures, etc., can solve the problem of inability to realize automatic movement of the painting mechanism, save manpower, material resources and time, and improve work efficiency. , the effect of reducing work intensity and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further detailed explanation through specific implementation mode below:

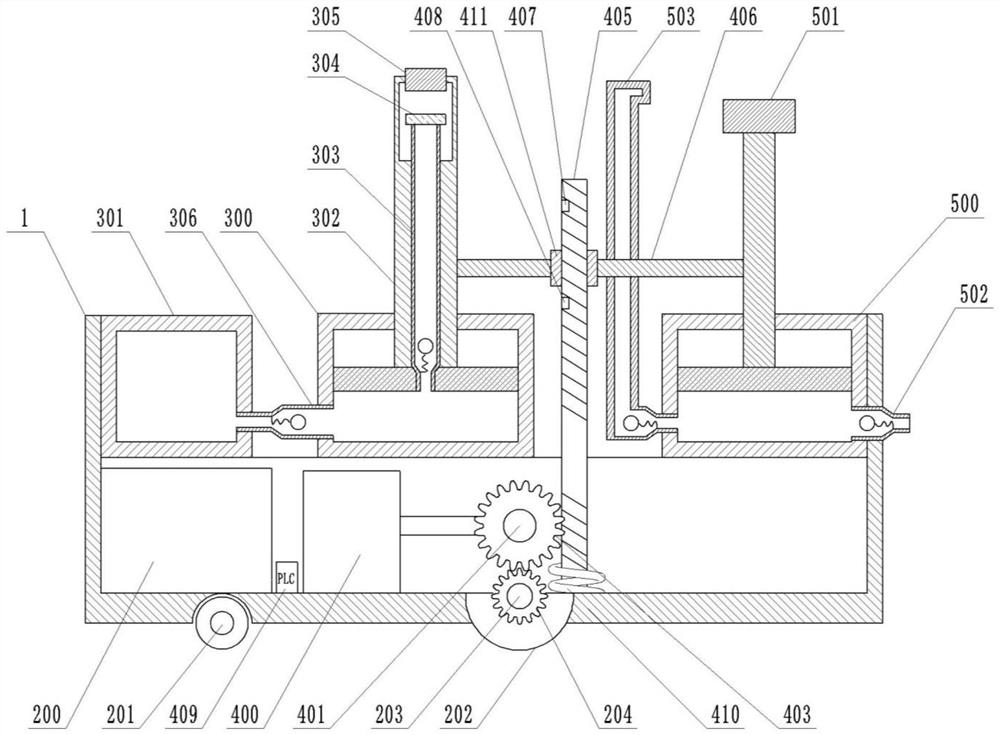

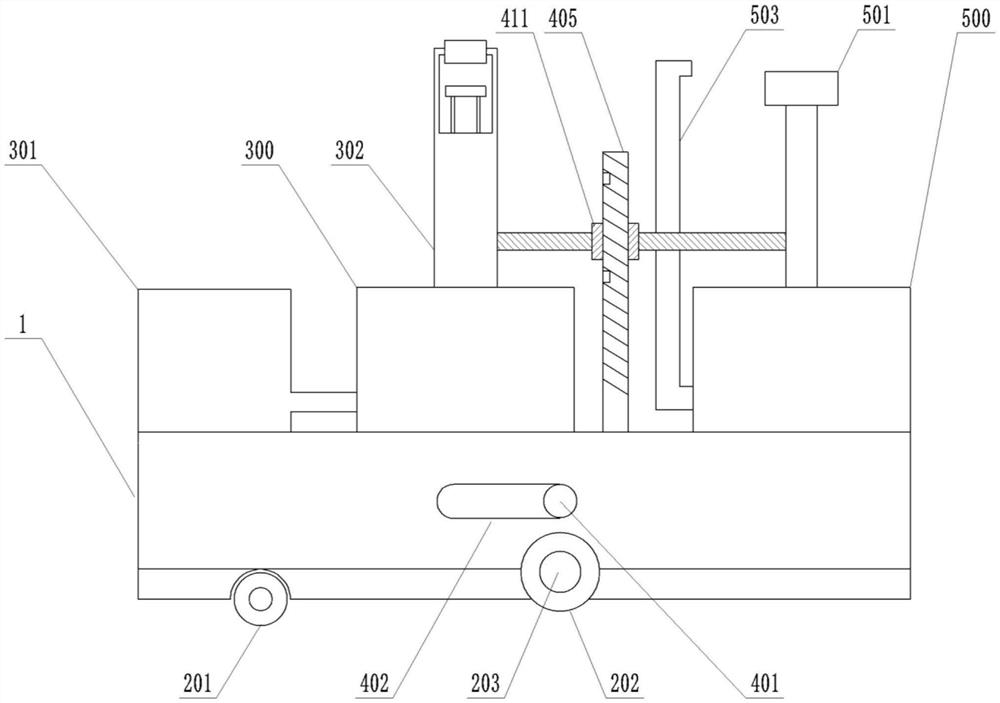

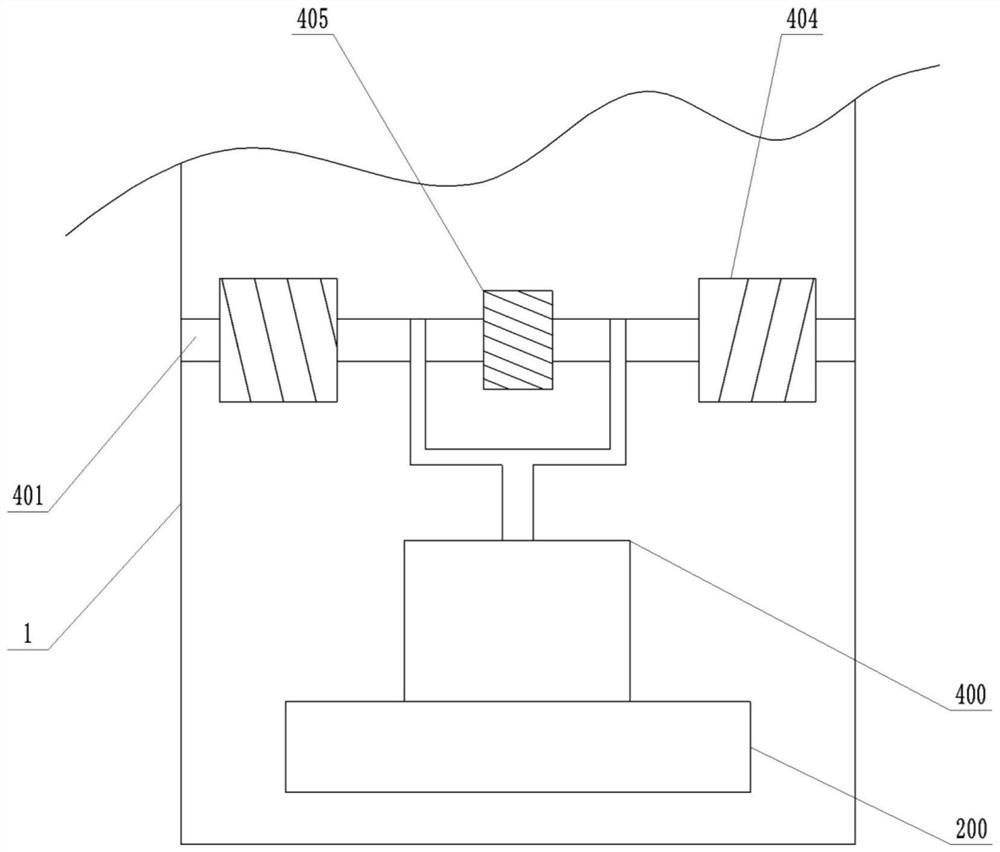

[0033] The reference numerals in the drawings of the description include: frame 1, driving motor 200, driving wheel 201, driven wheel 202, rotating shaft 203, first gear 204, painting cylinder 300, paint bucket 301, first painting rod 302, paint spraying tube 303, nozzle 304, painting roller 305, paint inlet pipe 306, second painting rod 307, hydraulic cylinder 400, moving rod 401, chute 402, worm wheel 403, second gear 404, reciprocating ball screw 405, lifting plate 406, The first pressure sensor 407, the second pressure sensor 408, the PLC controller 409, the torsion spring 410, the nut 411, the grinding cylinder 500, the first frosted plate 501, the air inlet pipe 502, the first air outlet pipe 503, the second sanded plate 504 , the second air outlet pipe 505 .

[0034] The embodiment is basically as attached Figure 1-2 Shown:

[0035] An intelligent painting device for building walls inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com