A reciprocating paint spraying machine

A paint sprayer, reciprocating technology, applied in the field of paint sprayers, can solve problems such as poor track operation, uneven paint spraying, and poor gas flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

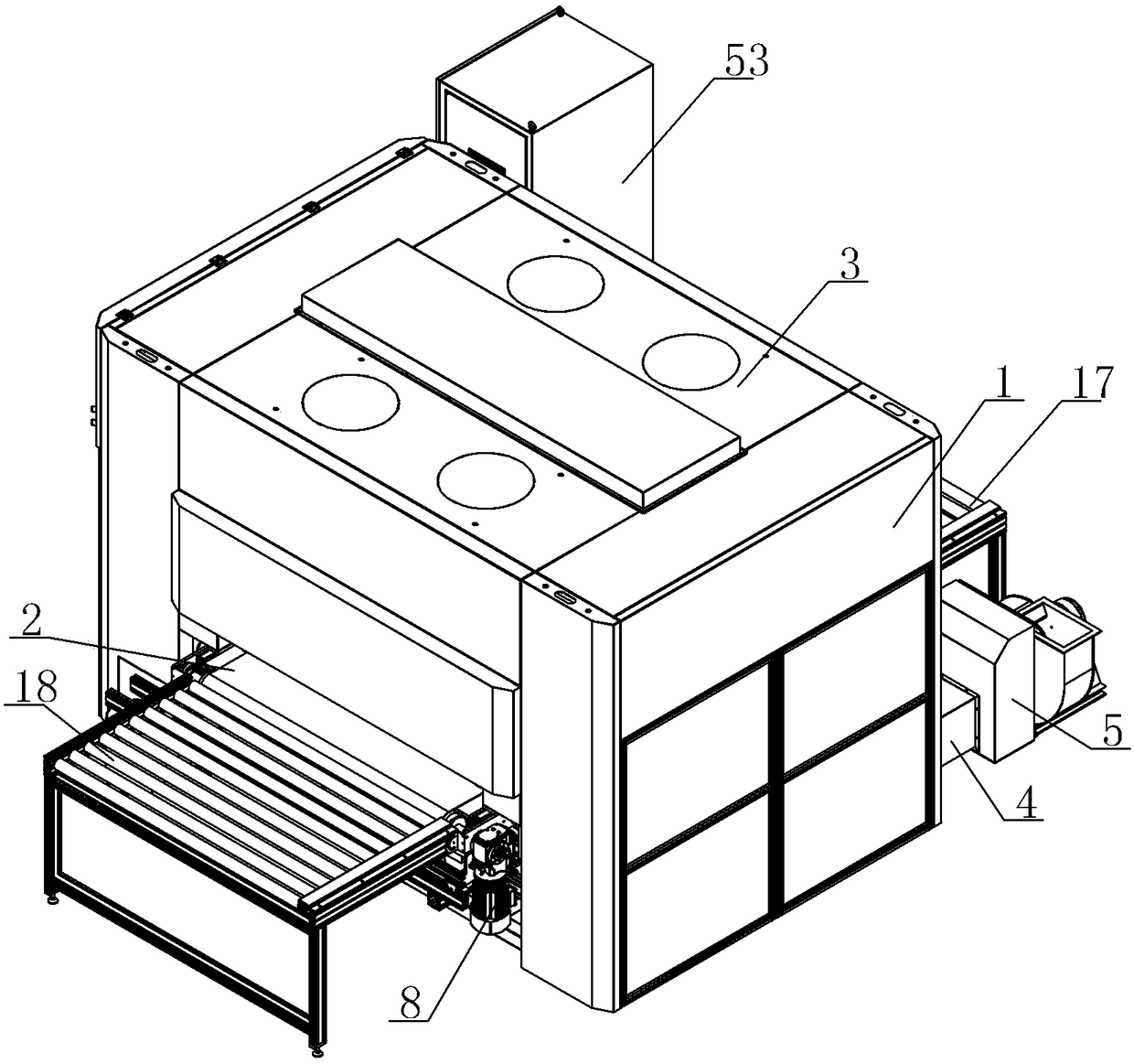

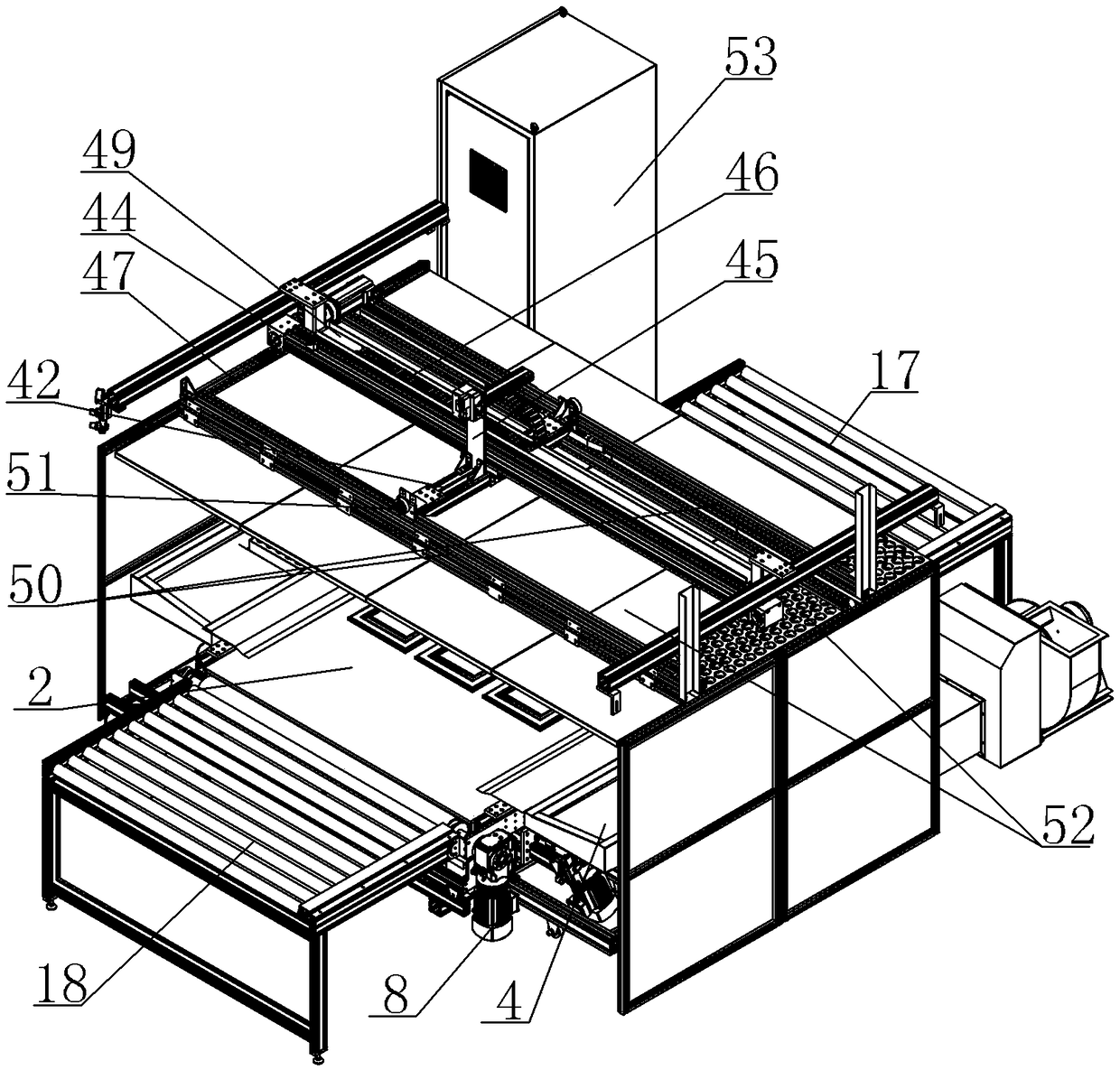

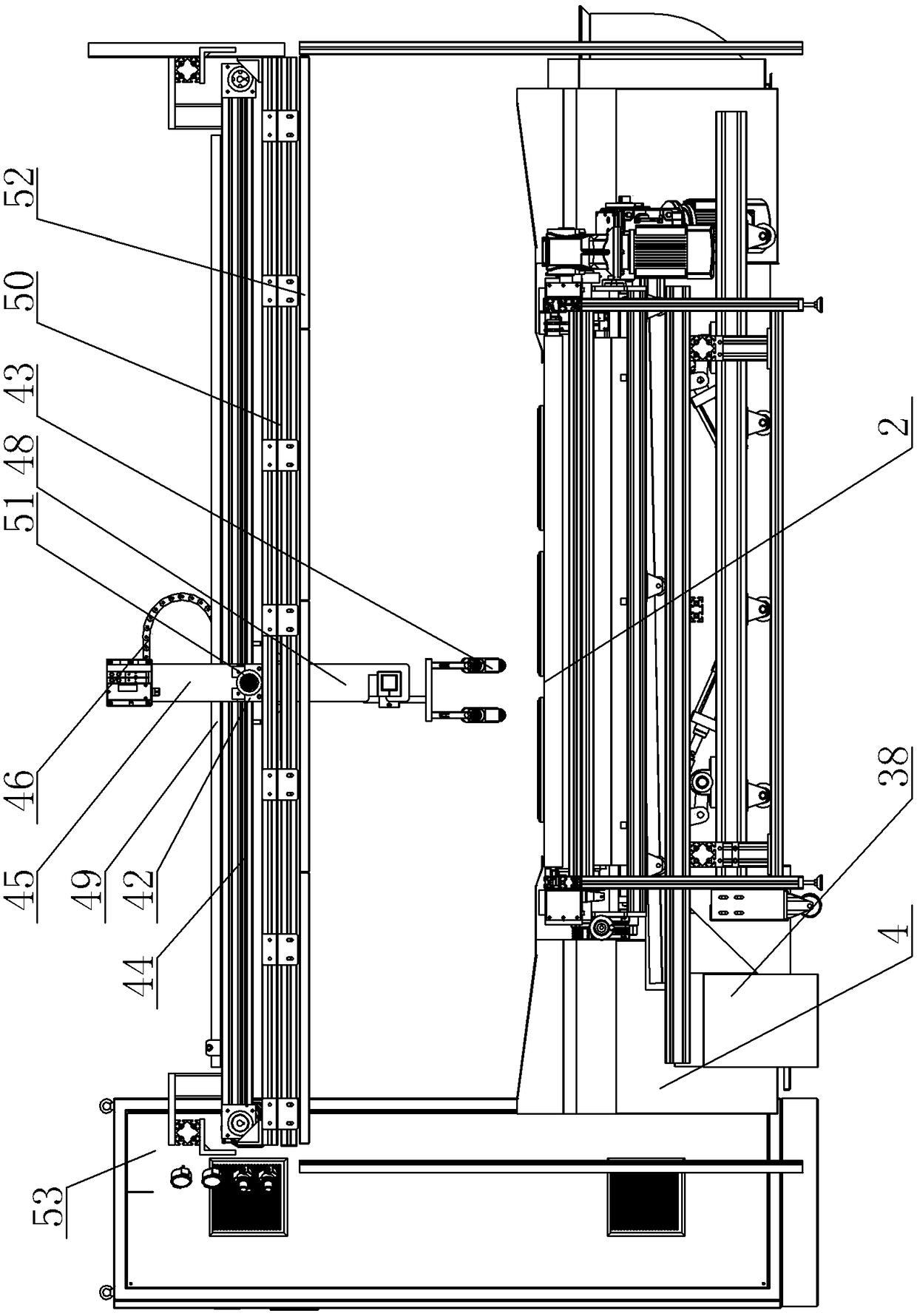

[0030] A reciprocating paint sprayer, see Figure 1 to Figure 9 : It includes a box structure 1, a material conveyor belt 2 is arranged inside the box structure 1, a spray gun structure is arranged above the material conveyor belt 2, and a front bottom wheel scraper structure is arranged directly below the front end of the material conveyor belt 2, and the material conveying There is a bottom scraper structure directly below the middle of the belt 2. The box structure 1 is located directly above the spray gun structure and is equipped with a high-pressure blower 3. The lower part of the box structure 1 is also provided with an air filter box 4. The entrance of the air filter box 4 Opened in the box structure 1, the outlet of the air filter box 4 is externally connected to the centrifugal exhaust fan 5 through the pipeline, and the centrifugal exhaust fan 5 is used to discharge the paint mixed gas in the machine.

[0031] The front end and rear end of the material conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com