Modular Security Cash Counter with Tear Gas Module

A tear gas, modular technology, applied in similar counters, store counters, home appliances, etc., can solve the problem of no way to stop criminals from illegal activities, achieve rapid and effective illegal activities, simple structure, and increase the effect of spray angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

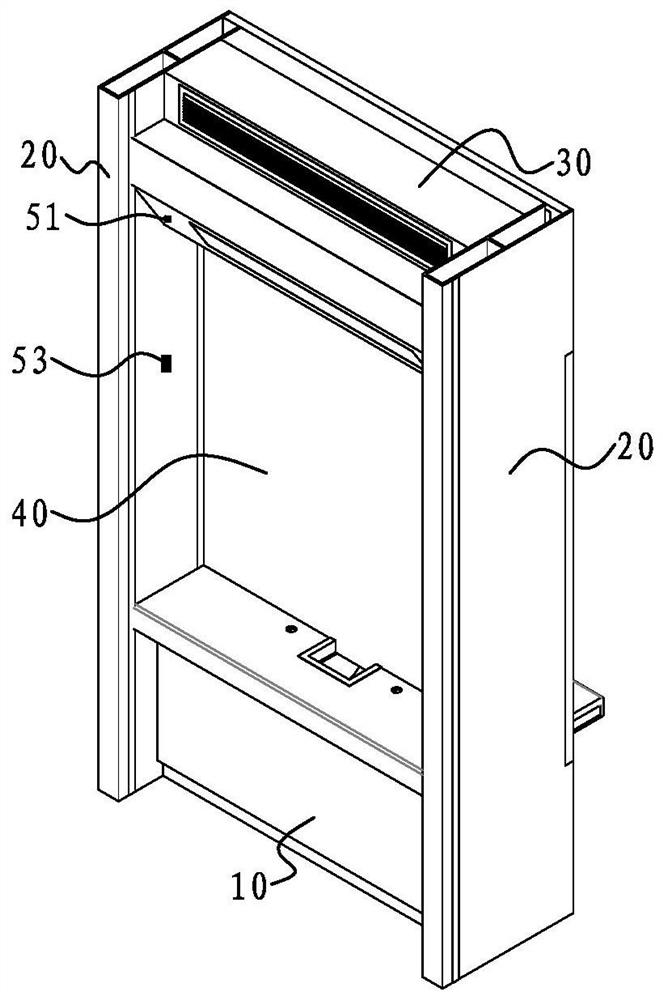

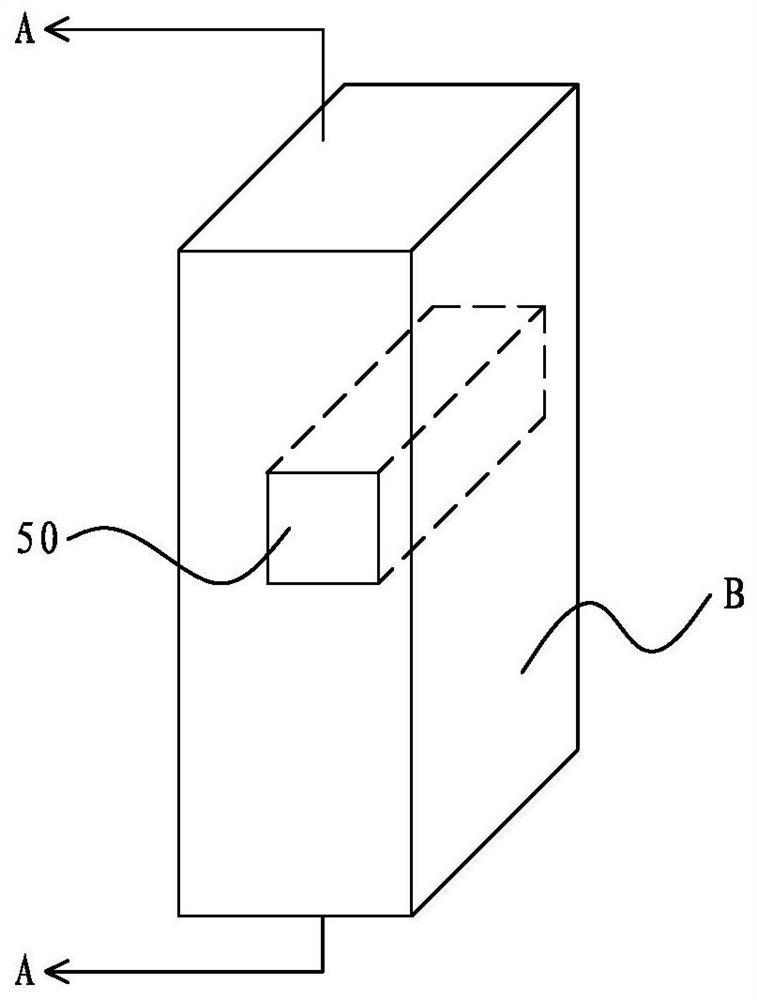

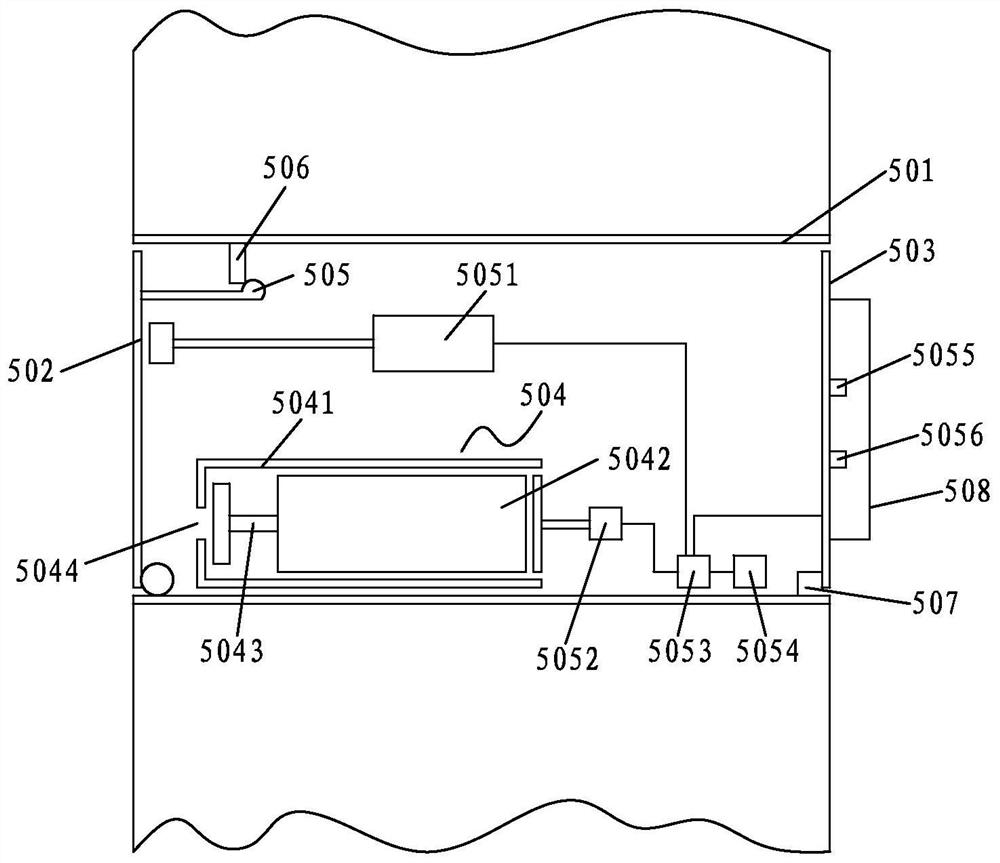

[0046] Please refer to figure 1 , figure 2 and Figure 8 , as a non-limiting embodiment, the modular security cash counter provided by Embodiment 1 of the present invention includes: a base structure module 10, a column structure module 20, a counter structure module 30, a bulletproof glass module 40, and a plurality of Tear Gas Module (detailed later). Among them, the tear gas module 50 can be installed in figure 2 In any one of the column structure module 20 or the cabinet head structure module 30 represented by B, for example, a tear gas module 51 can be set in the lower left corner and the lower right corner of the front face of the cabinet head structure module 30; or, choose A tear gas module 52 is respectively arranged on the left edge and the right edge of the bottom end surface of the cabinet head structure module 30 towards the counter top; or, the middle and upper parts of the sides adjacent to the bulletproof glass module 40 of each column structure module 20 ...

Embodiment approach 2

[0054] In this non-limiting example, as Figure 7 As shown, the tear gas injection device 504 of the tear gas module arranged at the front end of the column structure module also includes a base 5046 connected to the inner bottom wall of the outer frame 501 through a spherical hinge 5045, and the firing slot 5041 is fixedly connected to the base 5046 Above, the first driving mechanism 5051 is fixed on the inner top wall of the outer frame 501 through a bracket, the second driving mechanism 5052 is fixed on the base 5046 through a bracket, and the control circuit board 5053 and the battery pack 5054 are fixed on the base 5046 . Moreover, the rear end of the base 5046 is connected with a direction adjusting rod 5047 extending out of the tailgate 503 . Thus, the staff can rotate the base 5046 through the direction adjustment lever 5047, thereby adjusting the spraying angle of the tear gas. In this non-limiting embodiment, it is optional to place the tear gas module 50 on only on...

Embodiment approach 3

[0056] In order to strengthen the prevention of illegal acts of dangerous elements and facilitate the operation and control of the tear gas module by the staff, the firing button 5055 and the indicator light 5056 of the tear gas module of the cabinet structure module and the bulletproof glass module 40 are not arranged on the tailgate. 503, but extend through the control line to the teller's operable area located inside the counter, such as the control room or a more remote area for manual mode control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com