Sludge drying equipment

A sludge drying and equipment technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor drying effect and low drying efficiency, and achieve the effect of simple structure, preventing drying effect, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

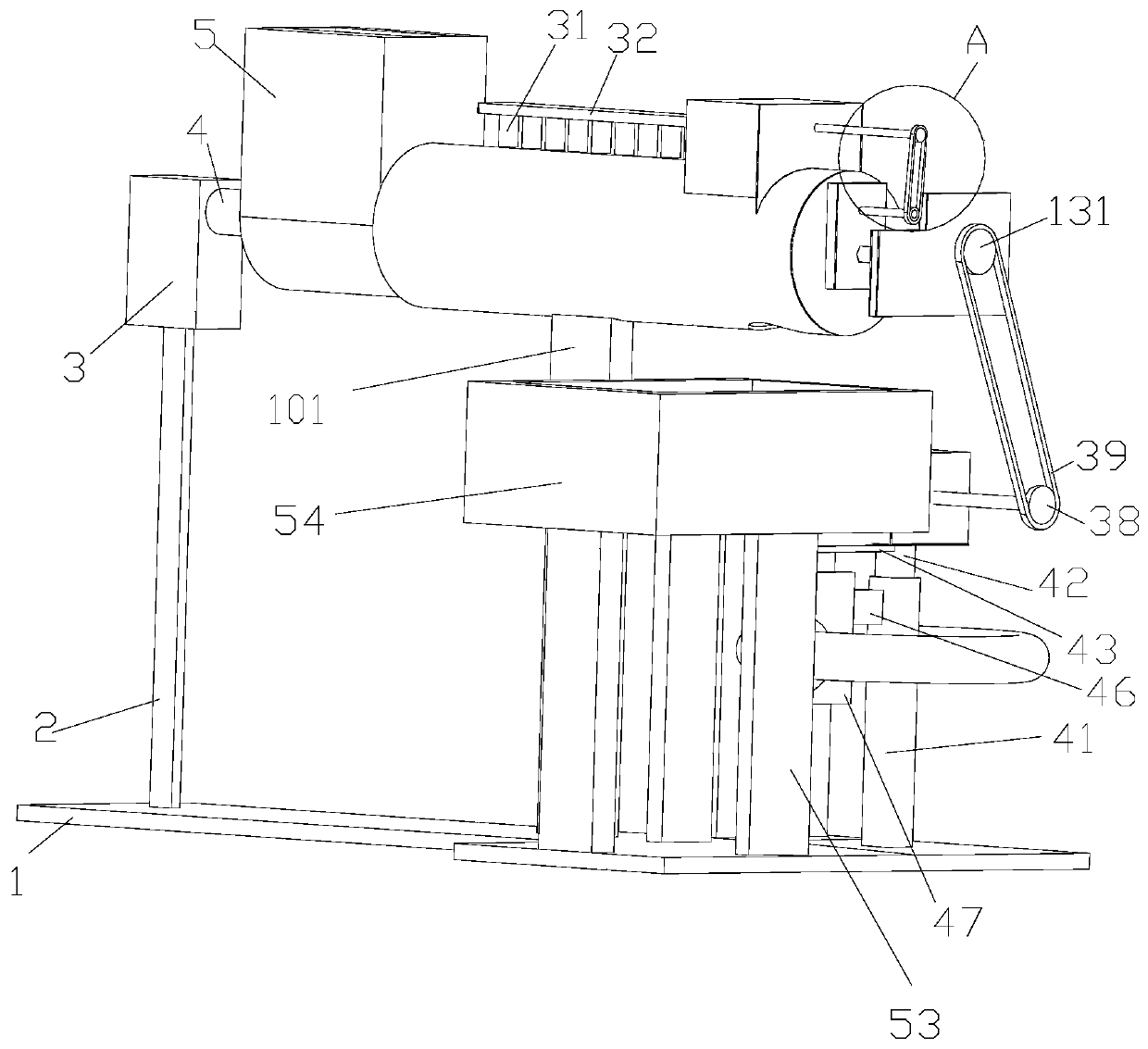

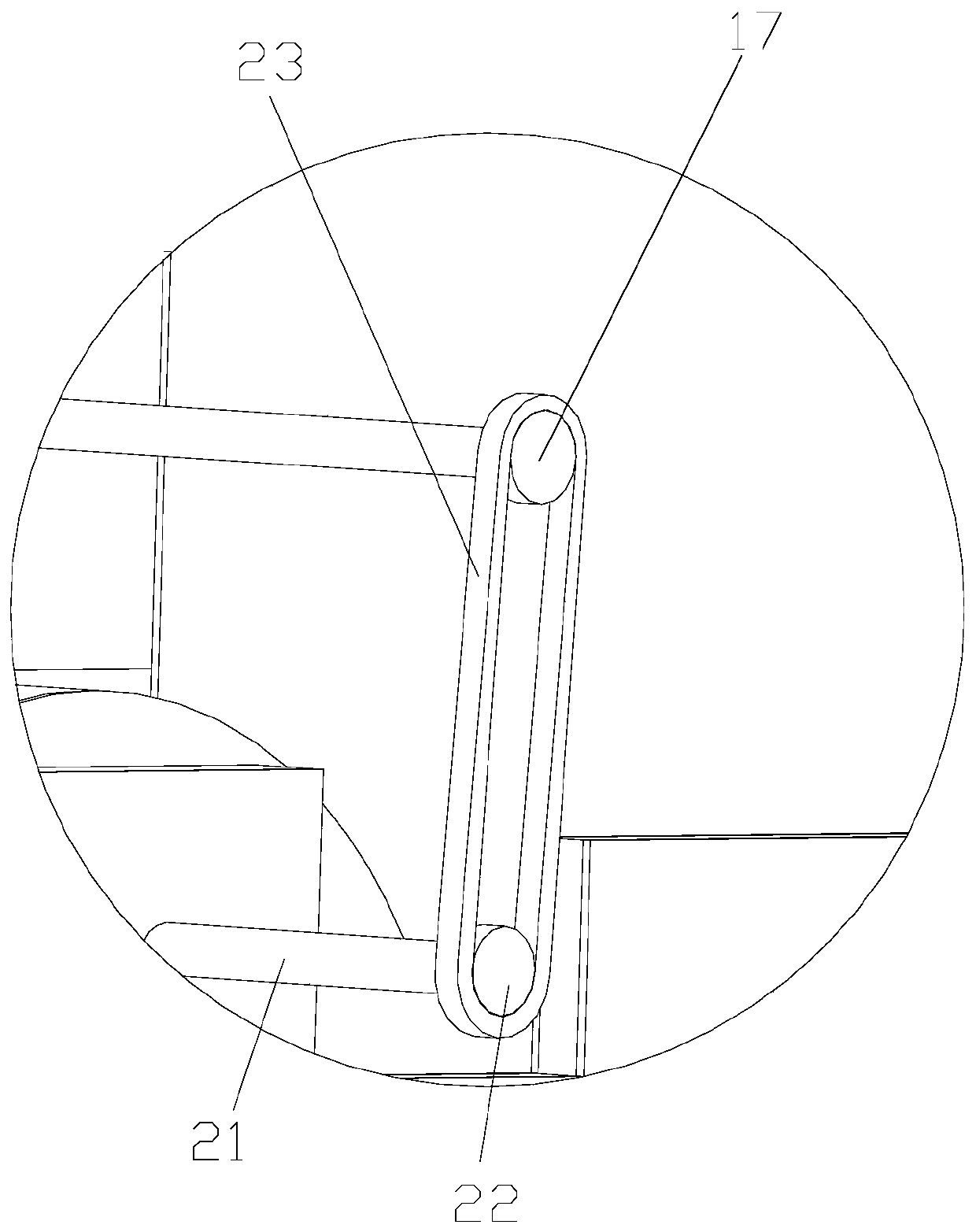

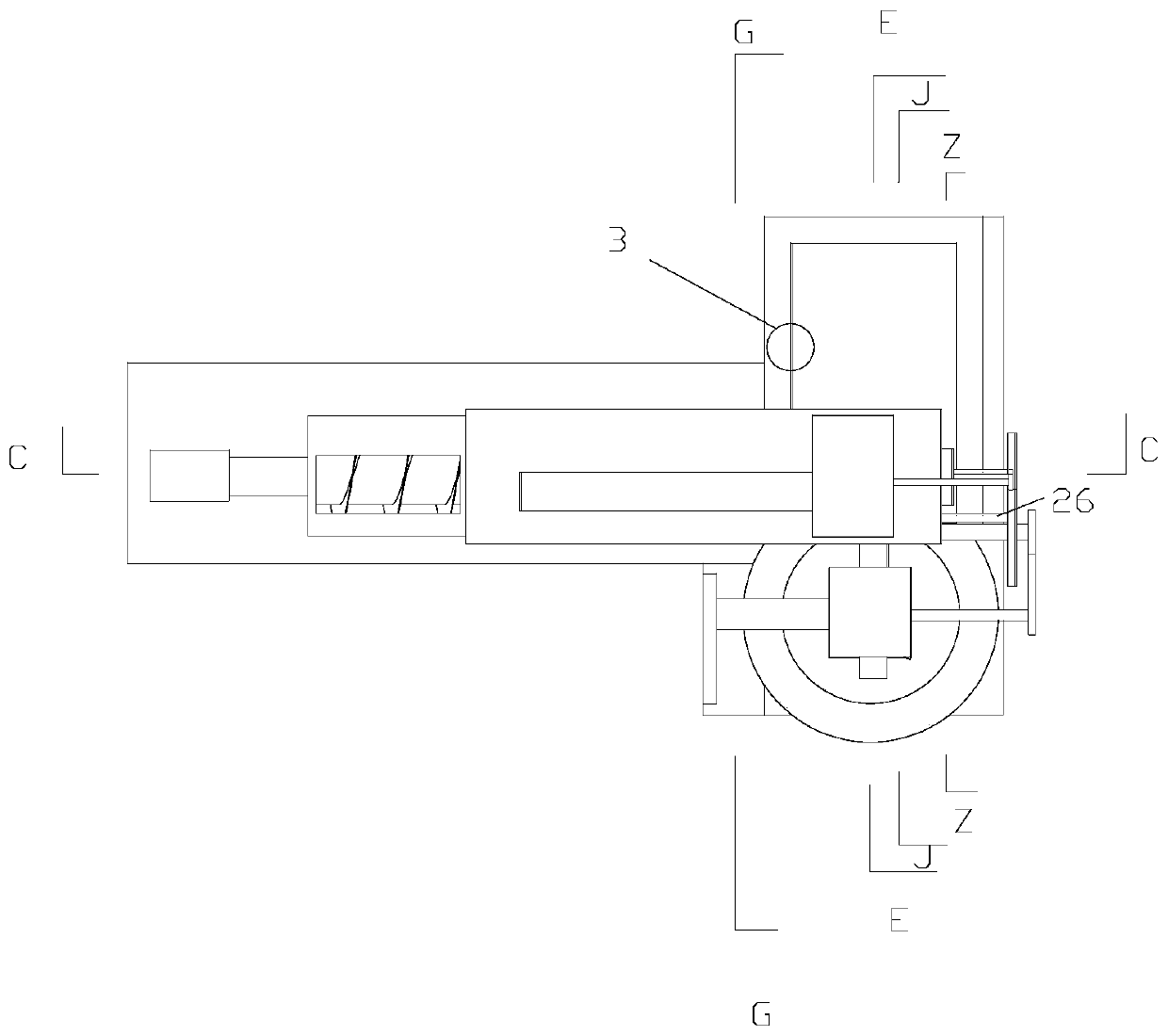

[0031] Such as Figure 1-14 As shown, a sludge drying equipment includes a machine base 1, a first vertical plate 2 fixedly arranged on the upper surface of the machine base 1, a transmission device arranged on the upper surface of the first vertical plate 2, and a fan installed on the transmission device The device, the turning device fixedly arranged on the right side of the upper surface of the machine base 1, is characterized in that: the transmission device includes a steam engine 3 fixedly arranged on the upper surface of the first vertical plate 2, and a steam pipe connected to the right end surface of the steam engine 3 4. It is connected to the crushing shell 5 arranged on the right end of the steam pipe 4, the crushing space 6 which is set in the crushing shell 5 and opens upward, and connected to the spiral shell 7 arranged on the right end wall of the crushing space 6. In the screw space 8 in the screw housing 7, the screw feeding shaft 9 that is arranged on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com