Patents

Literature

50results about How to "Affect the drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

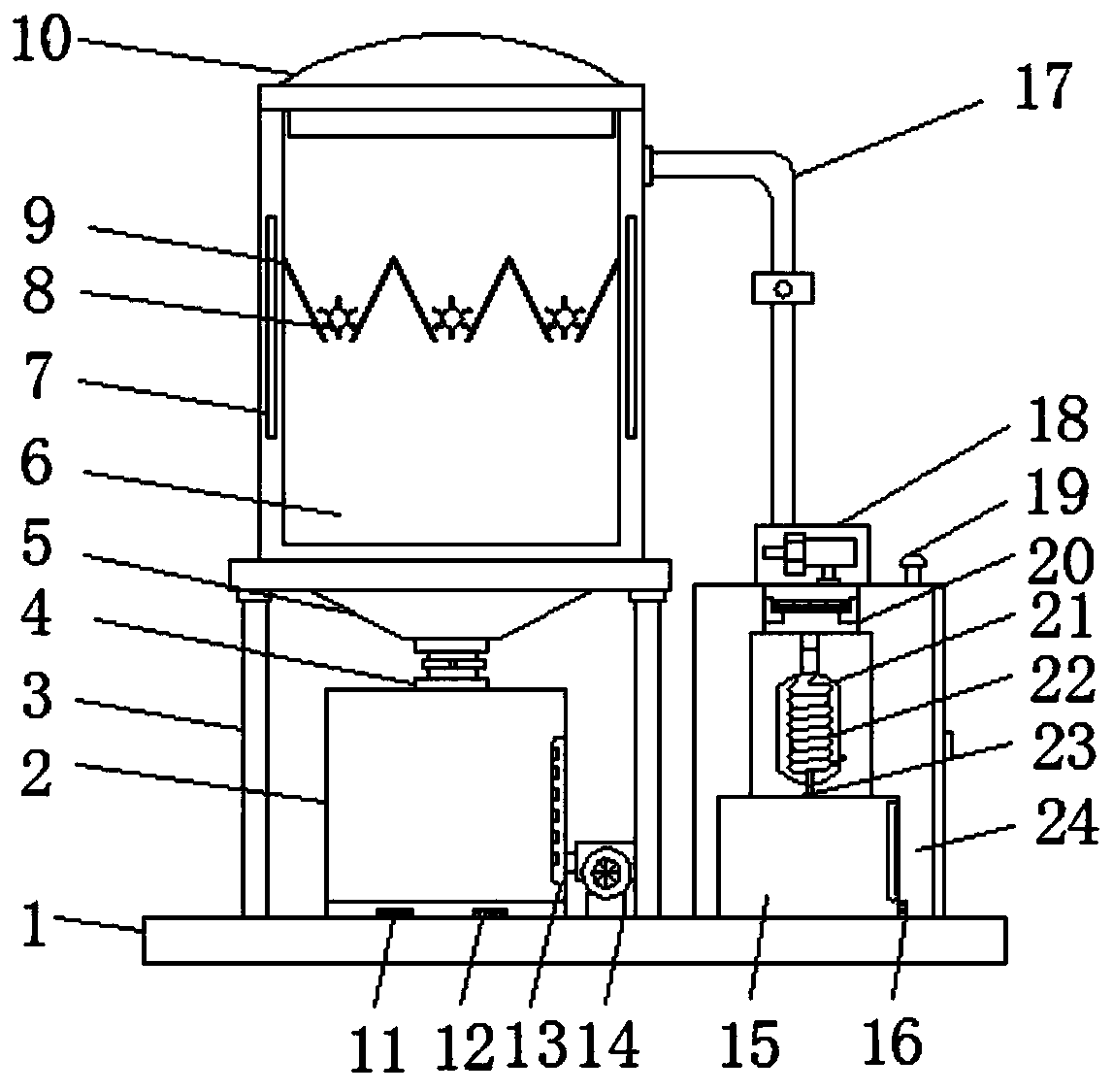

Drying device with disinfecting and deodorizing functions for down feather production

InactiveCN107606903APlay a sealing roleAvoid damageDrying solid materials without heatDrying gas arrangementsUv disinfectionWater flow

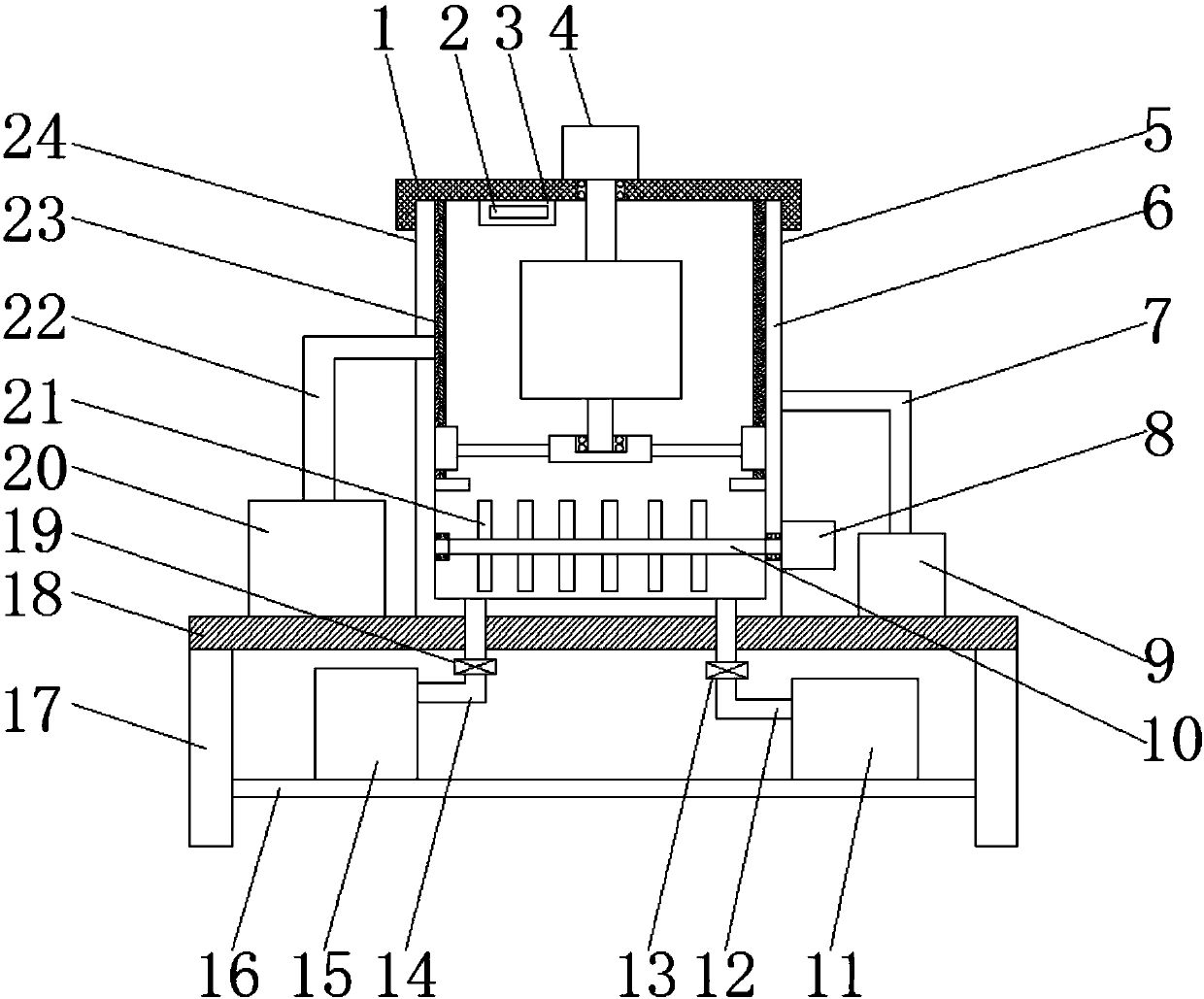

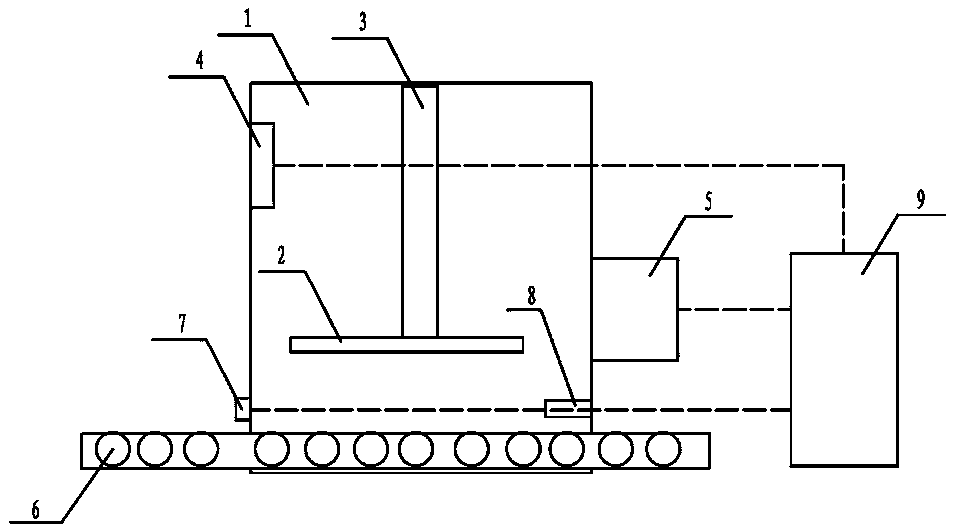

The invention discloses a drying device with disinfecting and deodorizing functions for down feather production. The device comprises a drying cage, a hot air blower, an ultraviolet disinfection lamp,a valve and an ozone generation device, wherein the drying cage is arranged for conveniently recycling down feather after drying, and thus the down feather recycling efficiency is greatly improved; hot air is blown out by using the hot air blower and enters a cavity through an air inlet pipe, thus the down feather in a box body is dried, and the situation that the quality of the down feather is influenced due to the damage to the down feather caused by direct contact between the down feather and a heat source is avoided; the ultraviolet disinfection lamp is arranged for disinfecting the downfeather in the box body, so that the quality of the down feather is improved; the valve is opened to enable water on the bottom of the inner side of the box body to enter a waste water collecting boxthrough a water outlet pipe, thus the drying speed of the down feather in the box body is further accelerated, and meanwhile, the pollution to the environment caused by the waste water flowing everywhere is avoided; and the ozone generation device is used for generating ozone, and the ozone enters the box body through a guide pipe to deodorize the down feather.

Owner:安徽芙芮雅羽绒有限公司

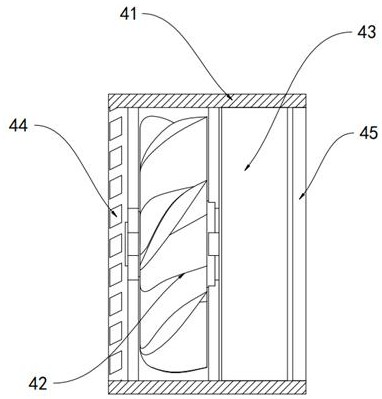

Traditional Chinese medicine drying and sterilizing device and use method thereof

ActiveCN108981318ANovel structural designEasy to useDrying gas arrangementsDrying chambers/containersUltravioletEngineering

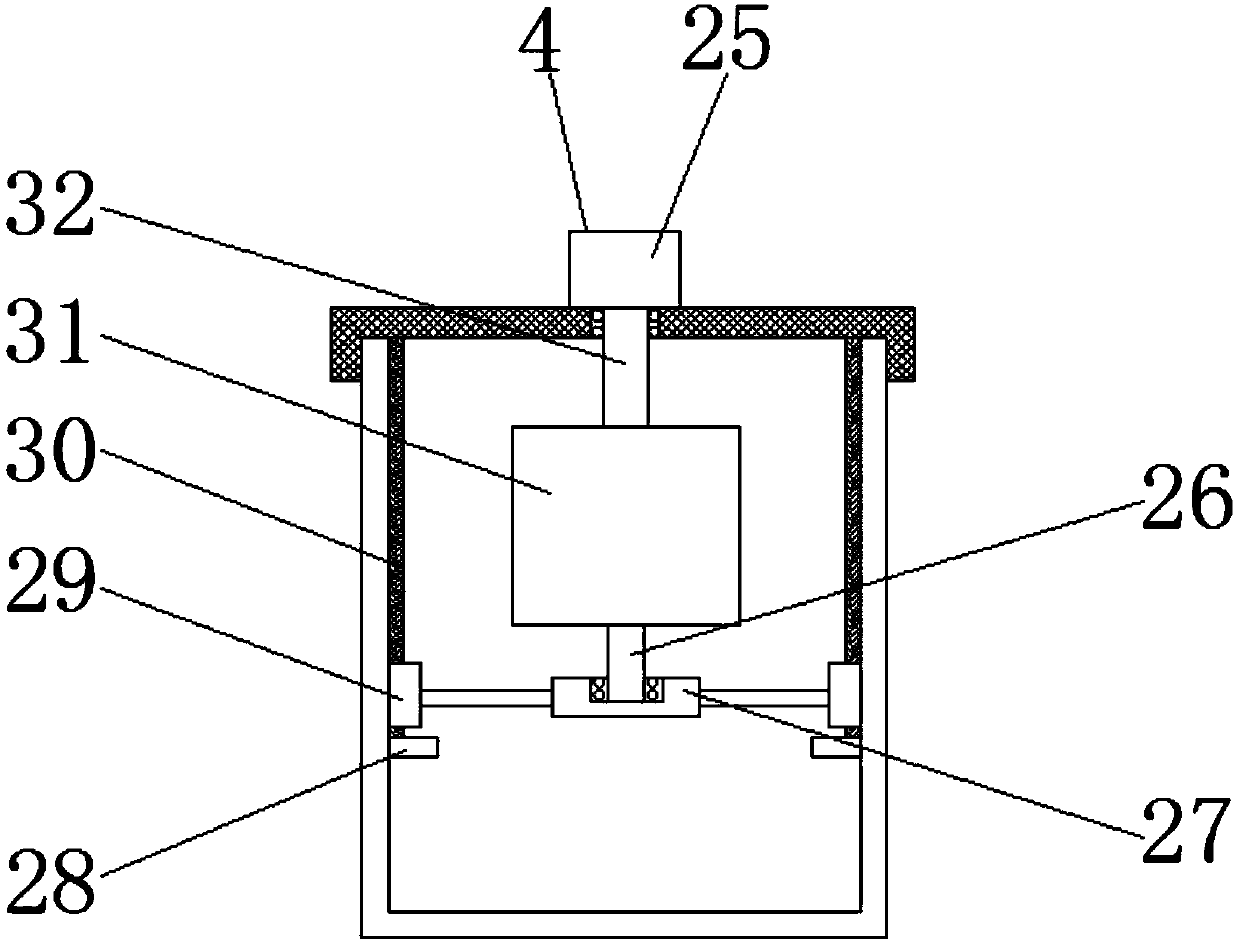

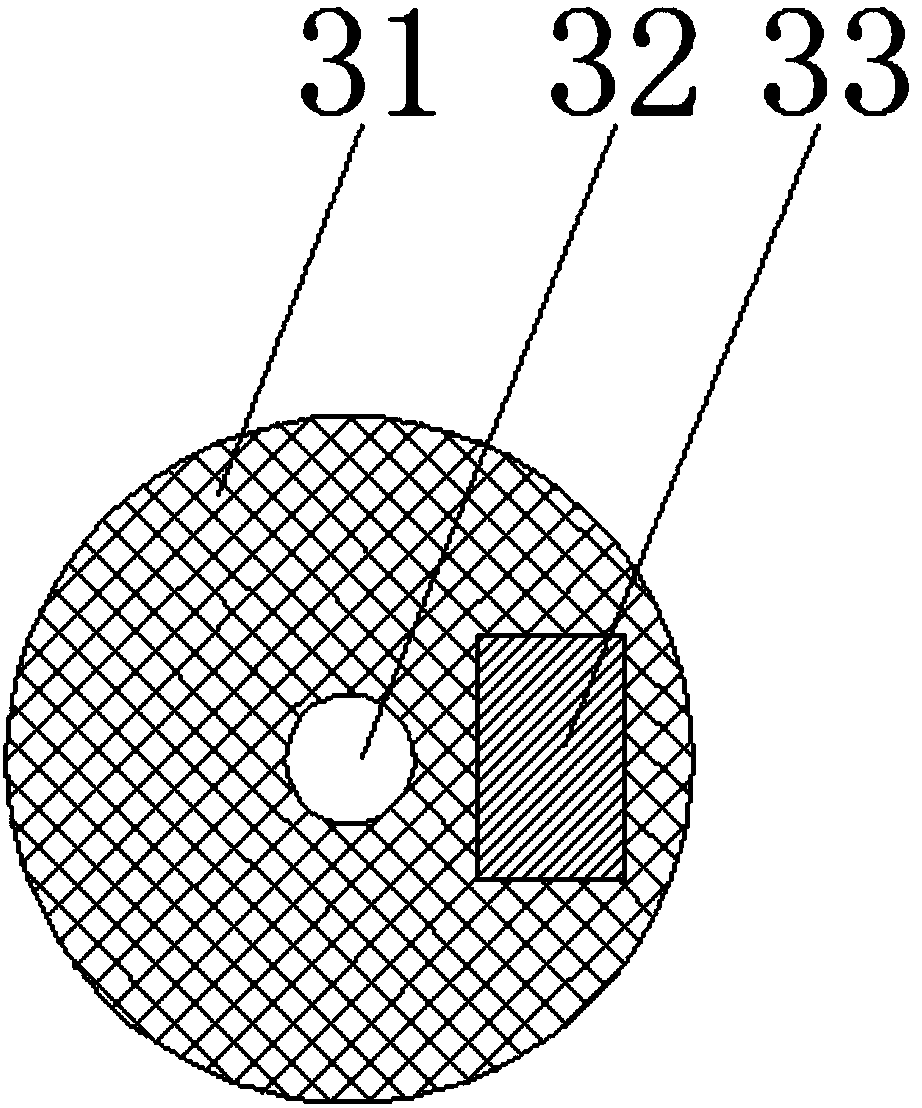

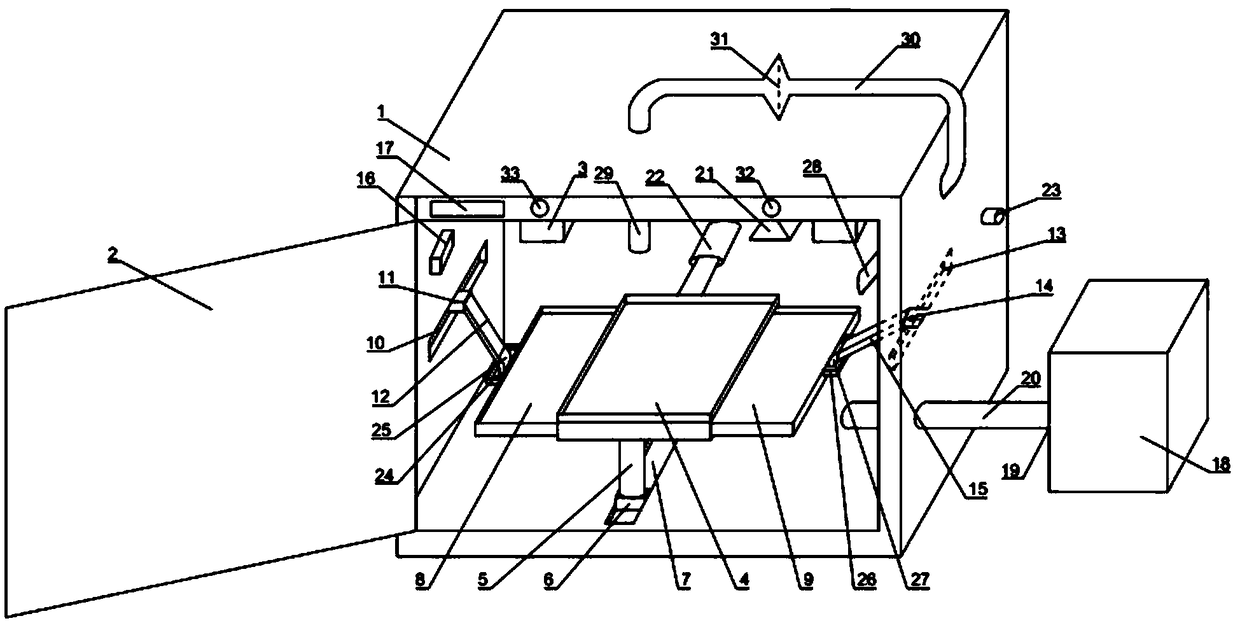

The invention discloses a traditional Chinese medicine drying and sterilizing device and a use method thereof. The traditional Chinese medicine drying and sterilizing device comprises a box body and afront box door, wherein the front box door is fixed on the front frame of the box body through hinges; a plurality of ultraviolet lamps are arranged on the inner side of the top of the box body; a stretchable device is arranged on the rear side surface of the box body; a main drying plate is fixedly connected to the front side of the stretchable device; a support column is fixedly connected to the bottom of the main drying plate; a first sliding block is arranged at the bottom of the support column; a first sliding groove is formed on the inner side of the bottom of the box body; the supportcolumn is connected with the first sliding groove through the first sliding block in a sliding manner; a first auxiliary drying plate drawn along the left-right direction is arranged on the left sidesurface of the main drying plate; and a second auxiliary drying plate drawn along the left-right direction is arranged on the right side surface of the main drying plate. The traditional Chinese medicine drying and sterilizing equipment is novel in structural design and convenient to use, and can rapidly and uniformly dry various traditional Chinese medicines and kill residual bacteria in varioustraditional Chinese medicines.

Owner:JIAMUSI UNIVERSITY

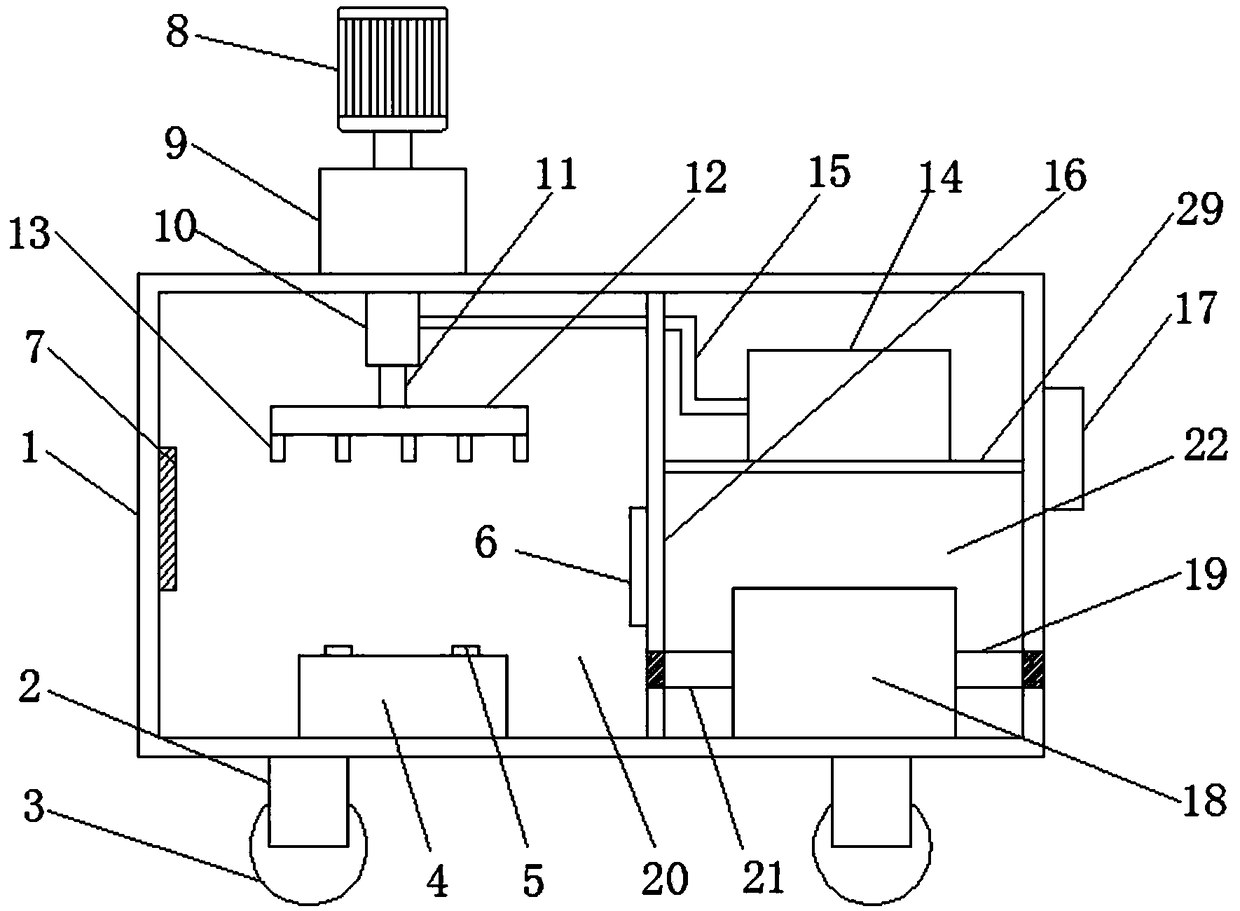

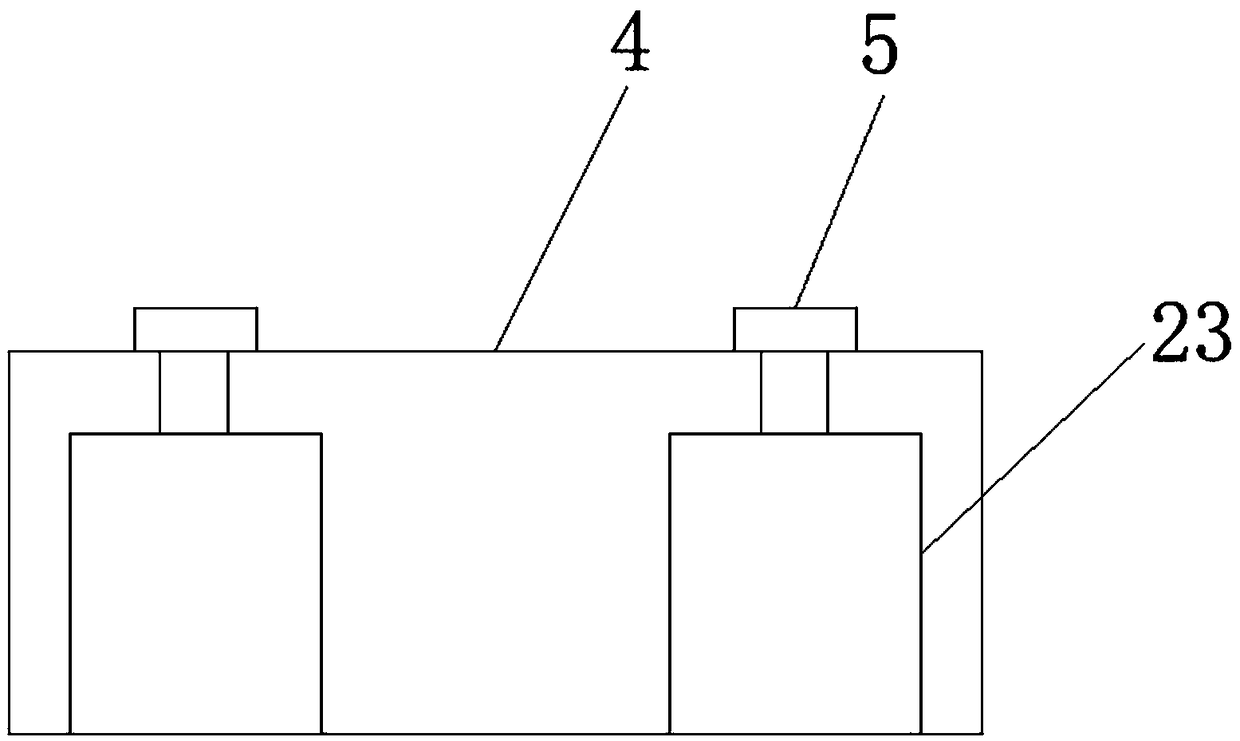

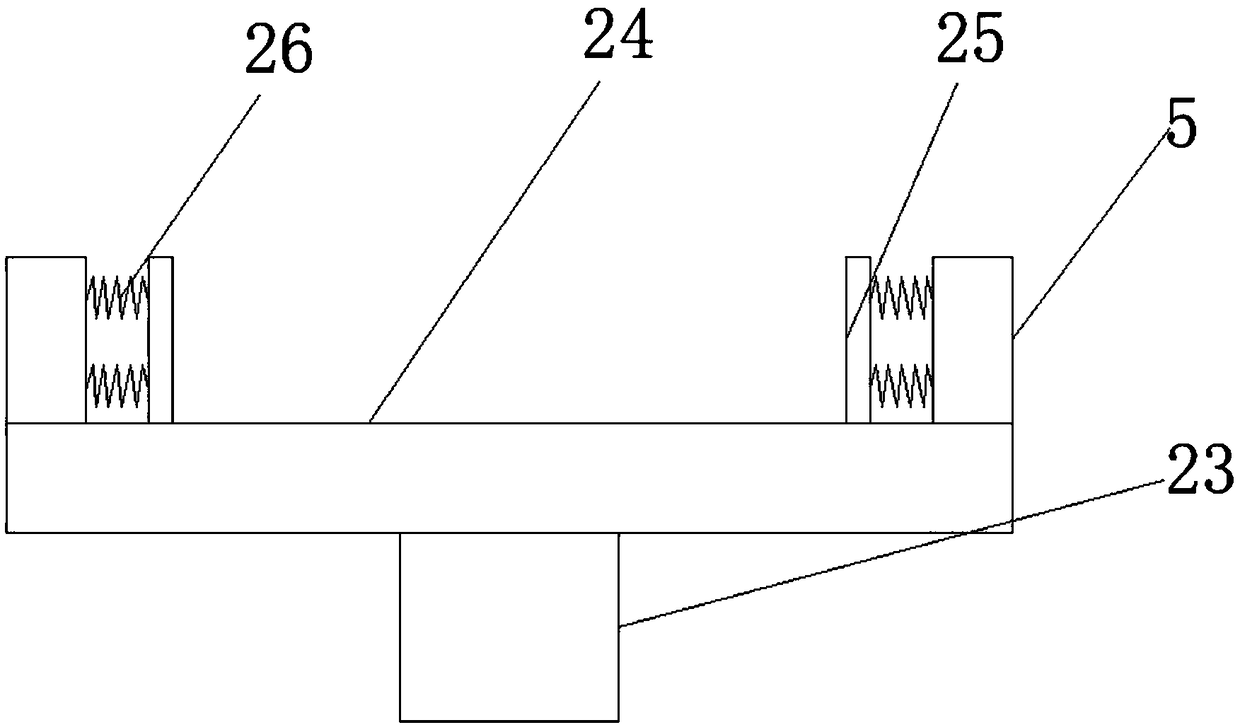

Drying device for shoe processing

PendingCN108851368AImprove heating uniformityEmission reductionShoemaking devicesReduction driveAgricultural engineering

Owner:郑新

Tidal range automatic drying cultivation method for laver culture

InactiveCN107027619AQuality improvementIncrease productionDrying solid materials with heatCultivating equipmentsEngineeringBalance performance

Owner:LIANYUNGANG HAIZHILIN COMPOUND MATERIALS +1

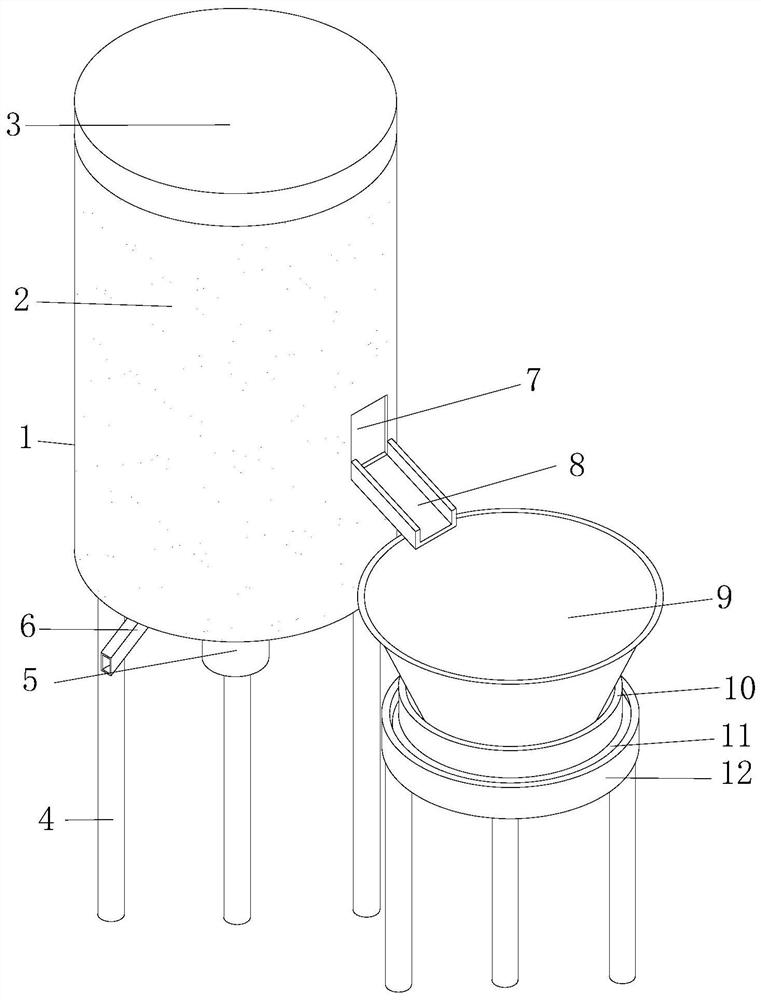

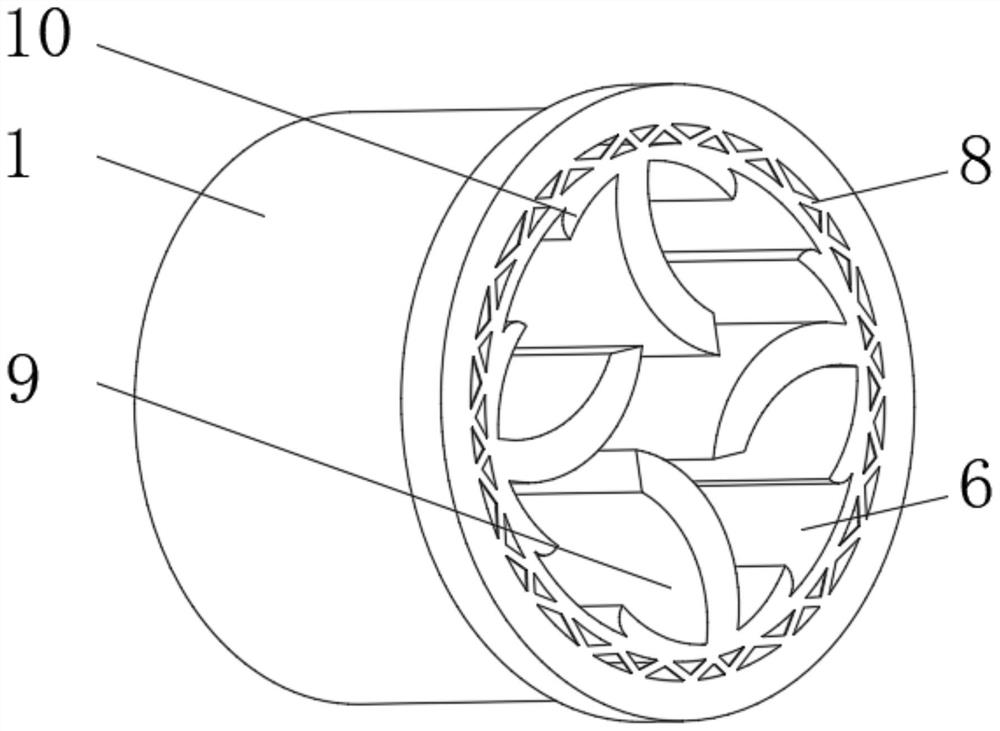

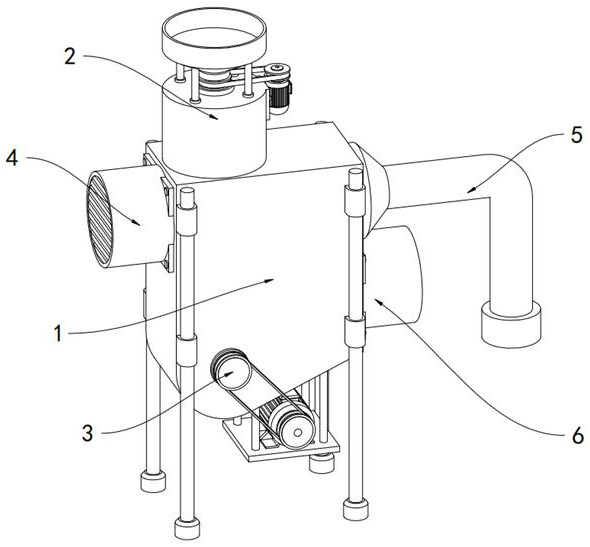

Rapid drying device for formed chemical fertilizers

ActiveCN112595057APrevent fertilizer cakingImprove drying efficiencySievingScreeningFertilizerElectric machinery

The invention relates to the technical field of chemistry, and discloses a rapid drying device for formed chemical fertilizers. The rapid drying device for the formed chemical fertilizers comprises adrying barrel, wherein the outer surface of the drying barrel is fixedly connected with a heat preservation and insulation pad; the upper end of the drying barrel is provided with a heating hole; an electric heating pipe is movably clamped in the heating hole; the upper end of the drying barrel is provided with a sealing cover; supporting legs are fixedly connected to the lower end of the drying barrel; a motor is fixedly connected to the lower surface of the drying barrel; a discharging port is formed in the outer surface of the drying barrel; and a blocking plate is arranged in the discharging port. According to the rapid drying device for the formed fertilizers, the fertilizers in the drying barrel is turned up and down, so that the fertilizers can form a material curtain, the fertilizers at the bottom can be in uniform contact with heat, the caking phenomenon caused by non-uniform heating due to fertilizer accumulation is avoided, the heating efficiency of the fertilizer is improved, the drying speed is increased, the drying time is saved, and the production efficiency is improved.

Owner:江西瑞思博新材料有限公司

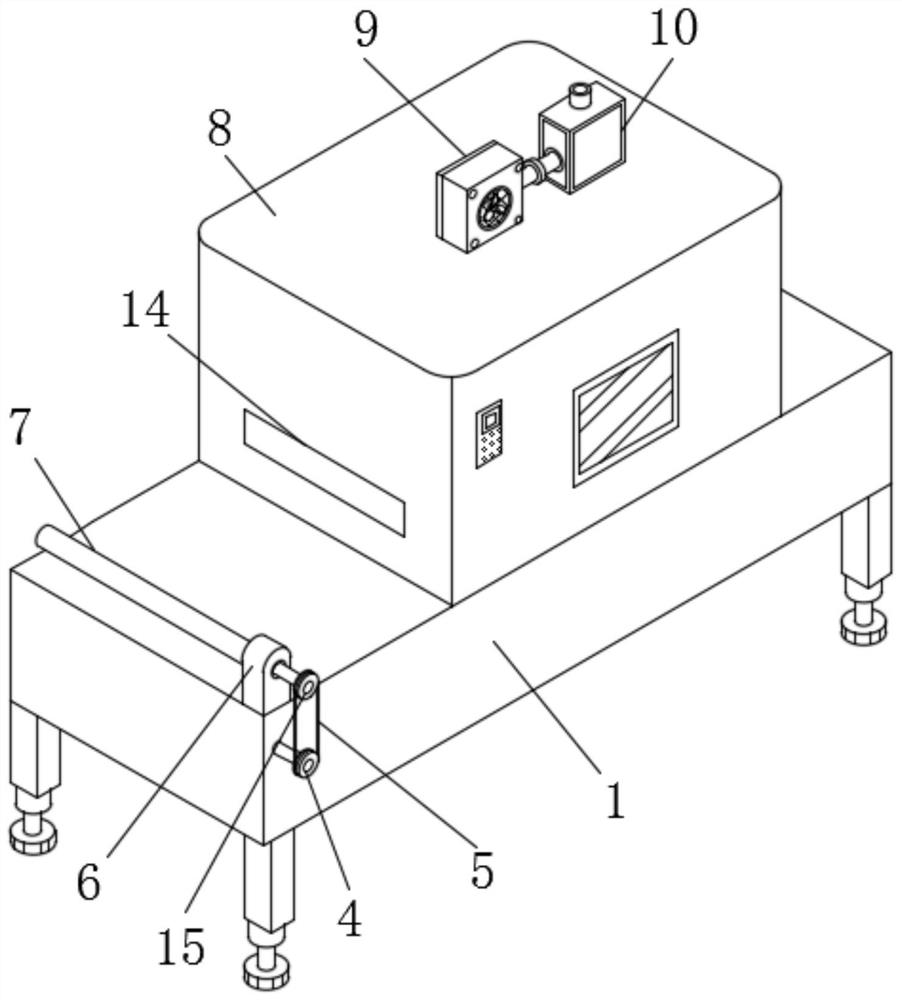

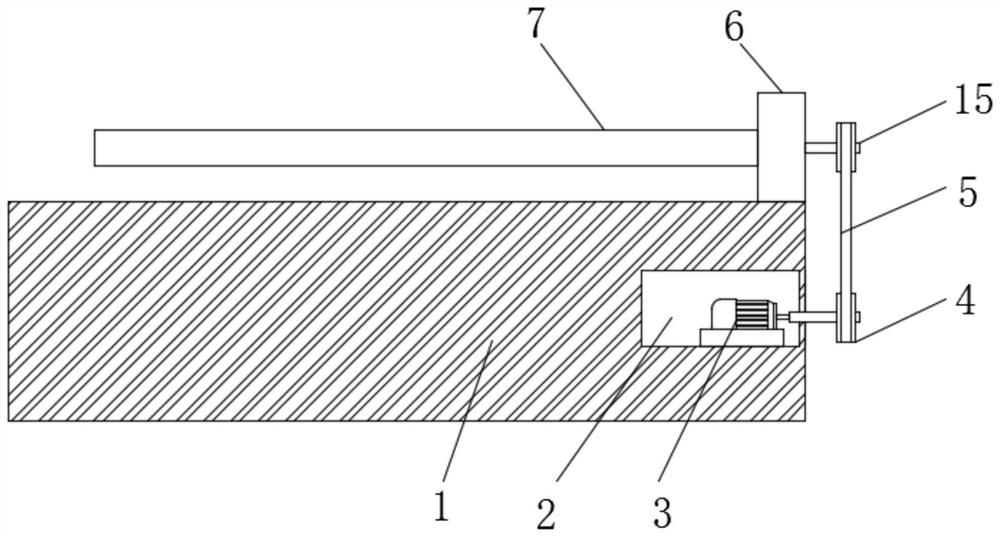

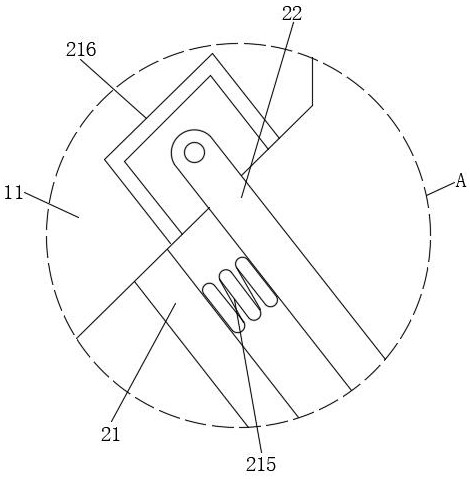

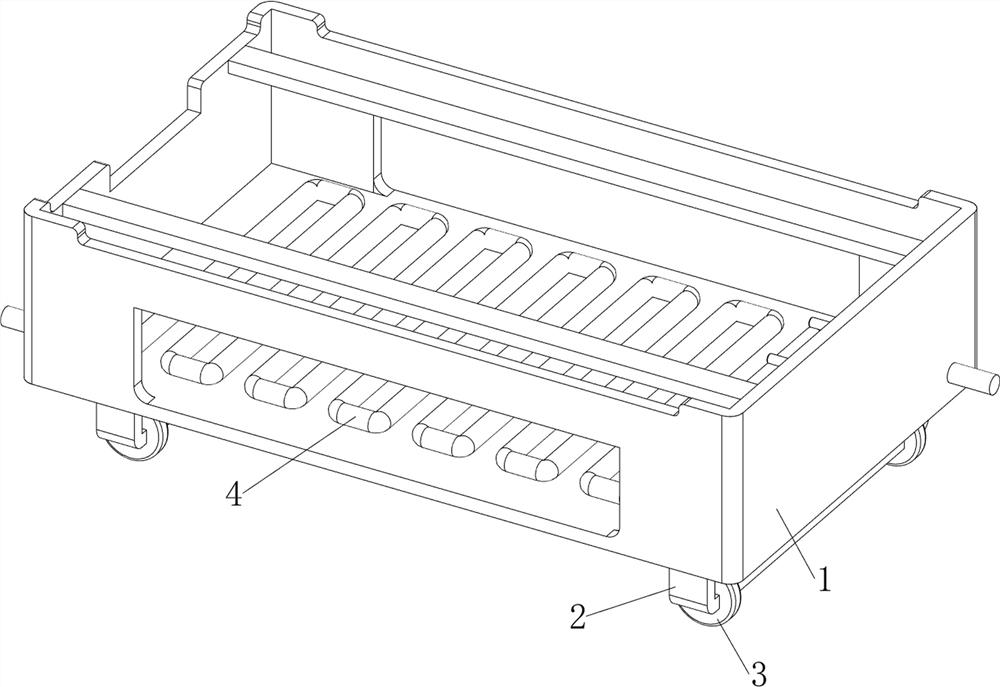

Rolling supporting mechanism for drying printed and dyed silk fabrics

InactiveCN112553815AEasy to rewindAffect the drying effectLiquid/gas/vapor removalWebs handlingDrive wheelElectric machinery

The invention discloses a rolling supporting mechanism for drying printed and dyed silk fabrics. The rolling supporting mechanism comprises a workbench and a cavity; a first motor is fixedly installedin the cavity formed in the workbench; a driving wheel is arranged at an output end of the first motor; the surface of the driving wheel is in transmission connection with a first conveying belt; a mounting block is arranged on the upper surface of the workbench; a cloth rolling roller is inserted into the mounting block; and a drying box is arranged on the upper surface of the workbench. Throughthe arrangement of the first motor, the cloth rolling roller, an electric telescopic rod and a pressing plate, after the cloth is dried, the cloth rolling roller is driven by the first motor to rollcloth by a second cloth conveying belt, so that the dried cloth is convenient to roll; and in the winding process, the electric telescopic rod is controlled to downwards make the pressing plate tightly attached to the cloth to be matched with tension formed by the cloth winding roller, the cloth can be flattened, the situation that the cloth wrinkles after being dried, and the cloth drying effectis affected is prevented, and the practicability of the device is improved.

Owner:王旭川

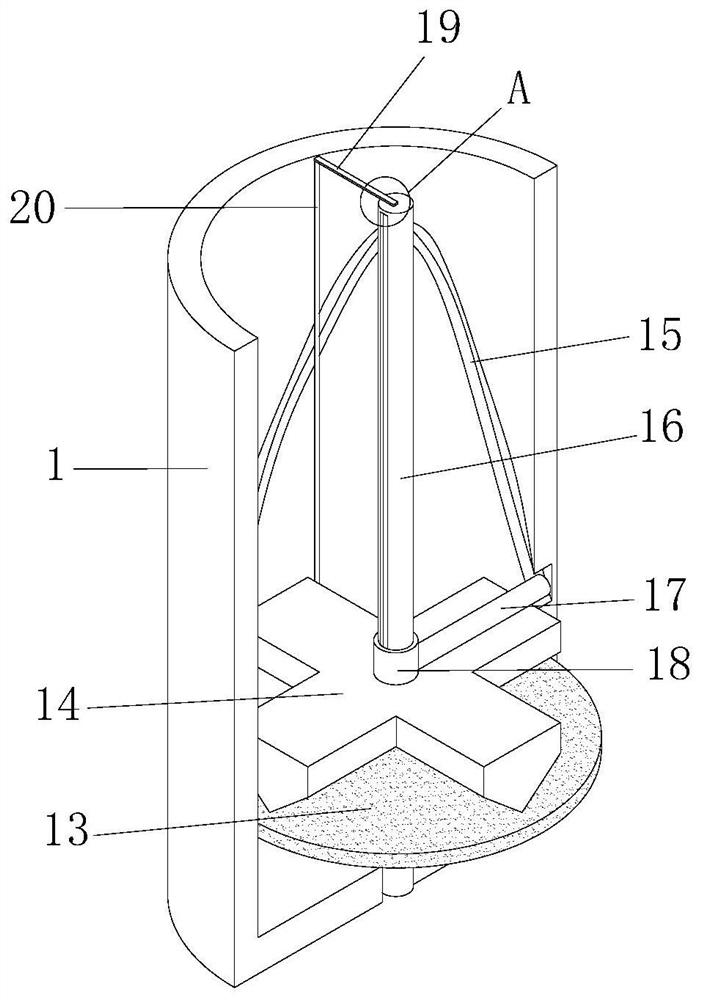

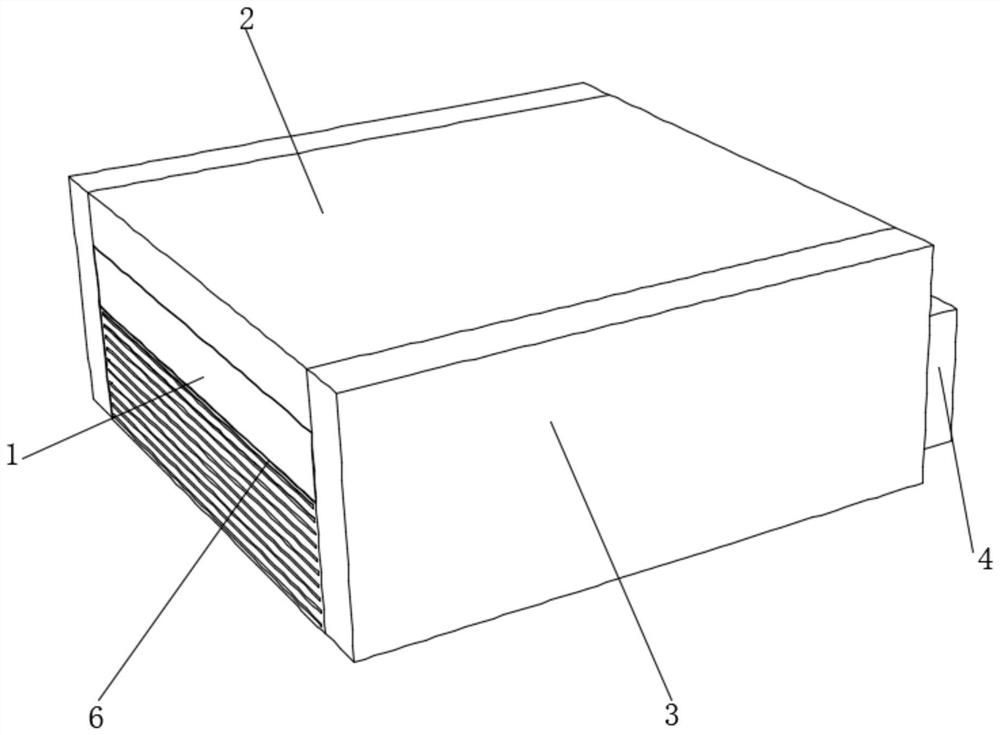

Dried flower drying device

InactiveCN112944825AAffect aestheticsAvoid distortionDrying gas arrangementsDrying chambers/containersEngineeringBud

The invention provides a dried flower drying device, and relates to the technical field of dried flower processing. The dried flower drying device comprises a drying oven, a connecting block, telescopic devices, an air outlet device, a supporting mechanism and a drying mechanism, the connecting block is arranged above the drying oven, the telescopic devices are arranged on the left side and the right side of the connecting block, the two sides of the bottom end of each telescopic device are fixedly connected with the left side and the right side of the drying oven, the air outlet device is arranged at the right end of the drying oven and fixedly connected with the drying oven, and the supporting mechanism is arranged at the position, close to the top end, of the inner part of the drying oven. Flowers are supported through the supporting mechanism to prevent buds and stems of the flowers from deforming in the drying process, the supporting mechanism is fixedly connected with the drying oven, the drying mechanism is arranged at the position, close to the bottom end, of the inner part of the drying oven, the flowers placed in the supporting mechanism are dried through the drying mechanism, the drying mechanism is fixedly connected with the drying oven, and due to the dried flower drying device, the problem that dried flowers cannot be manufactured on a large scale is solved.

Owner:孙凯

Treatment method for accelerating peeling of walnut green seedcases

PendingCN113892622AEasy to handle separatelyShort heating timeDrying gas arrangementsDrying solid materialsFood scienceJuglans

The invention discloses a treatment method for accelerating peeling of walnut green seedcases, and relates to the technical field of epidermis treatment. The treatment method comprises the steps that S1, sorting is conducted, and walnut fruits with cracked green seedcases and walnut fruits with uncracked green seedcases are sorted; S2, the walnut fruits with cracked green husks and the walnut fruits with uncracked green husks are heated and dried, and the heating time of the walnut fruits with cracked green husks is shorter than that of the walnut fruits with uncracked green husks; S3, the heated and dried green walnut fruits are naturally stacked; and S4, green seedcases are removedmanually or mechanically. According to the treatment method for accelerating peeling of the walnut green seedcases, peeling of the walnut green seedcases can be accelerated, the treatment efficiency is improved, and pollution to the fruit surface and the environment can be reduced or avoided.

Owner:云南省林业和草原科学院漾濞核桃研究院

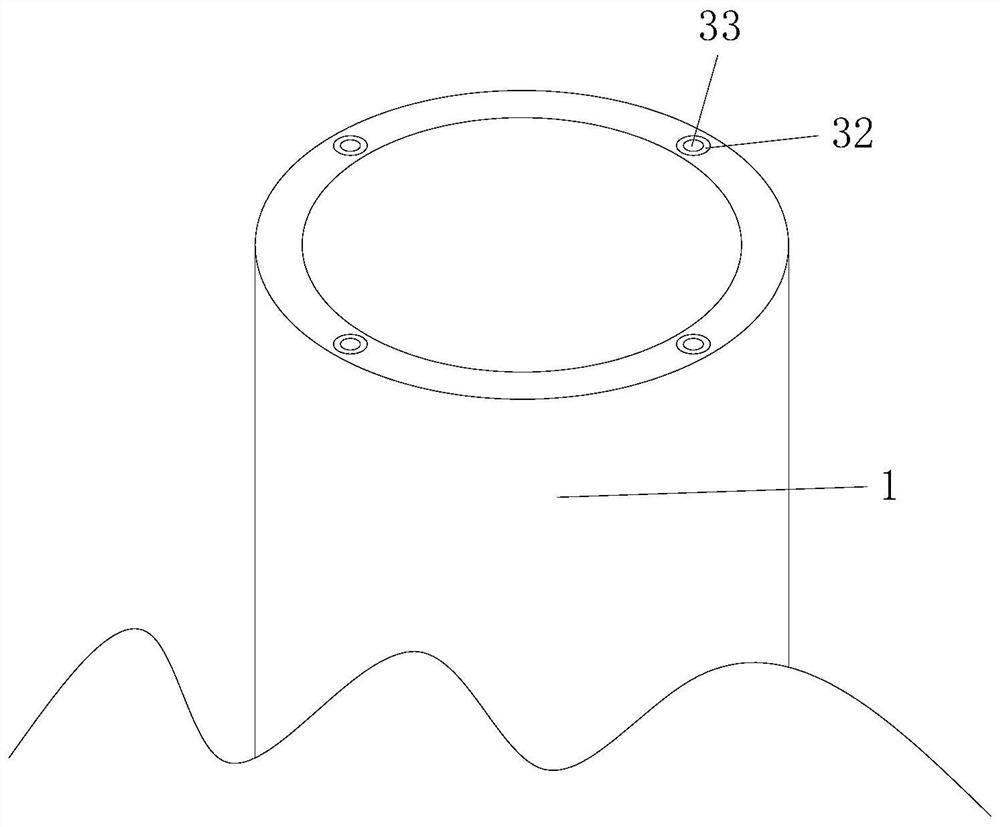

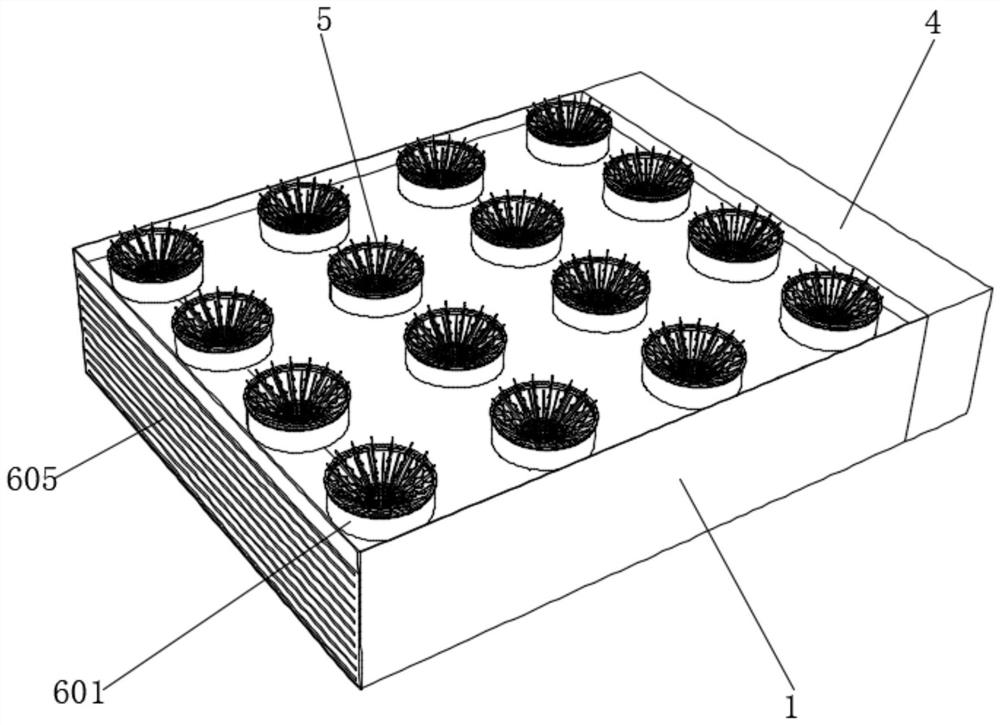

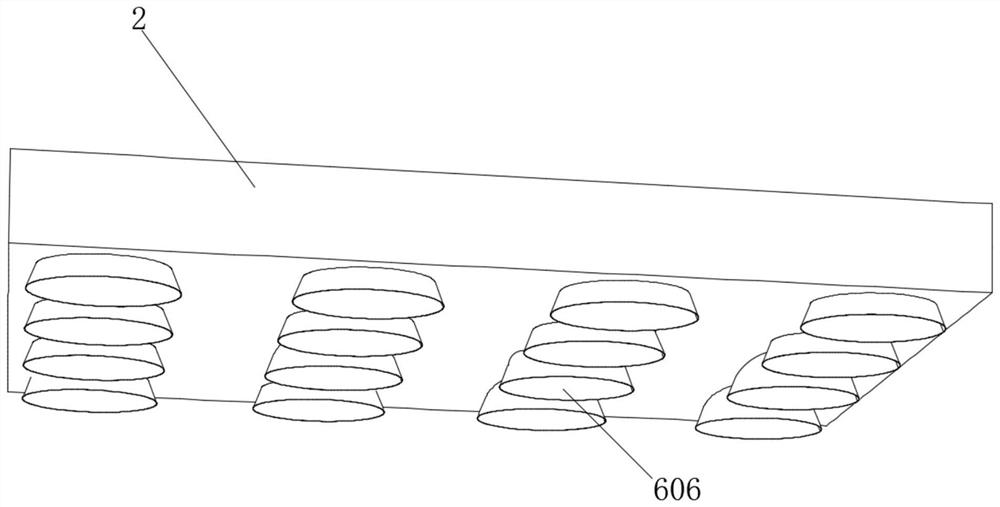

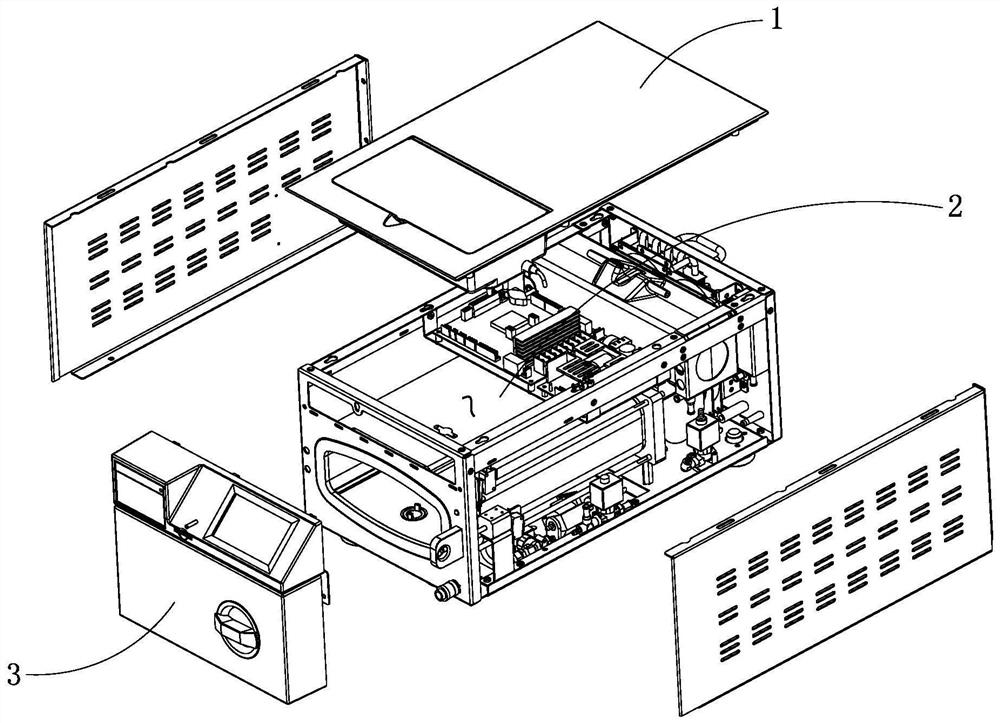

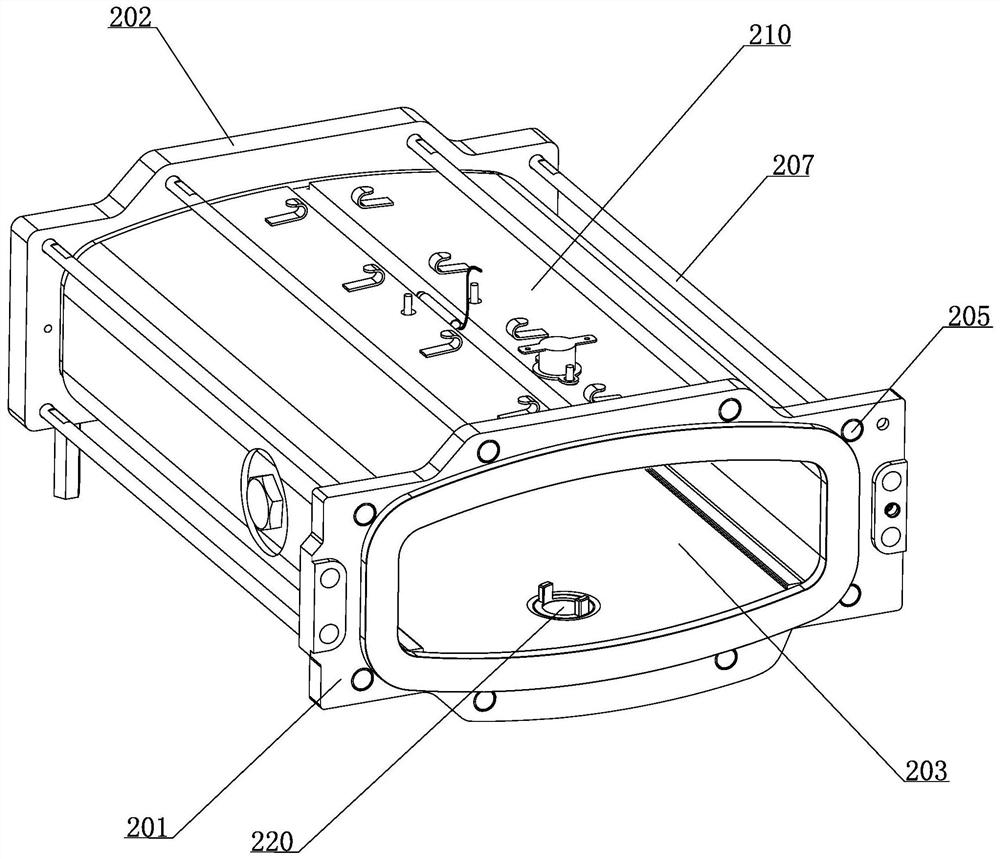

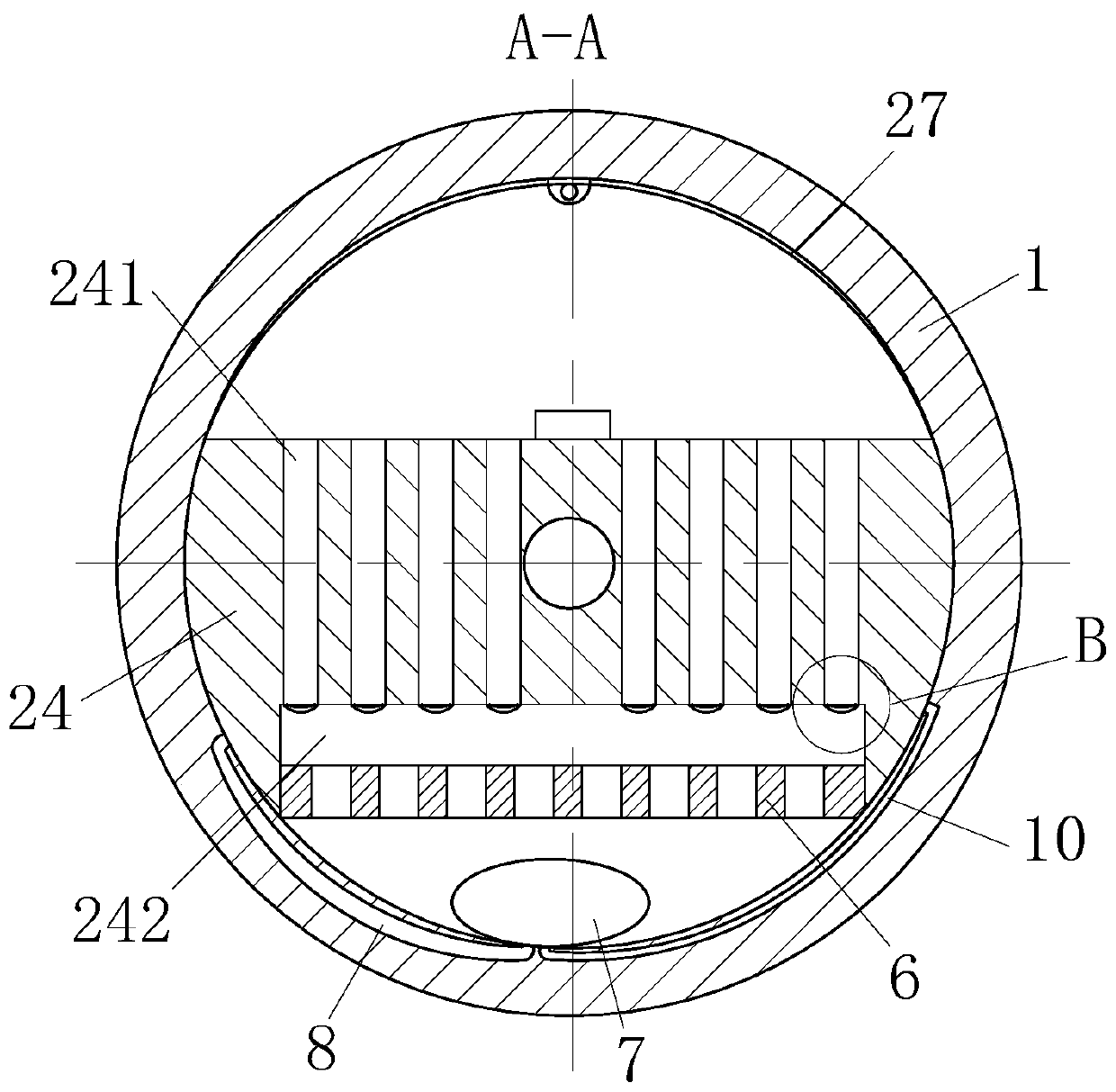

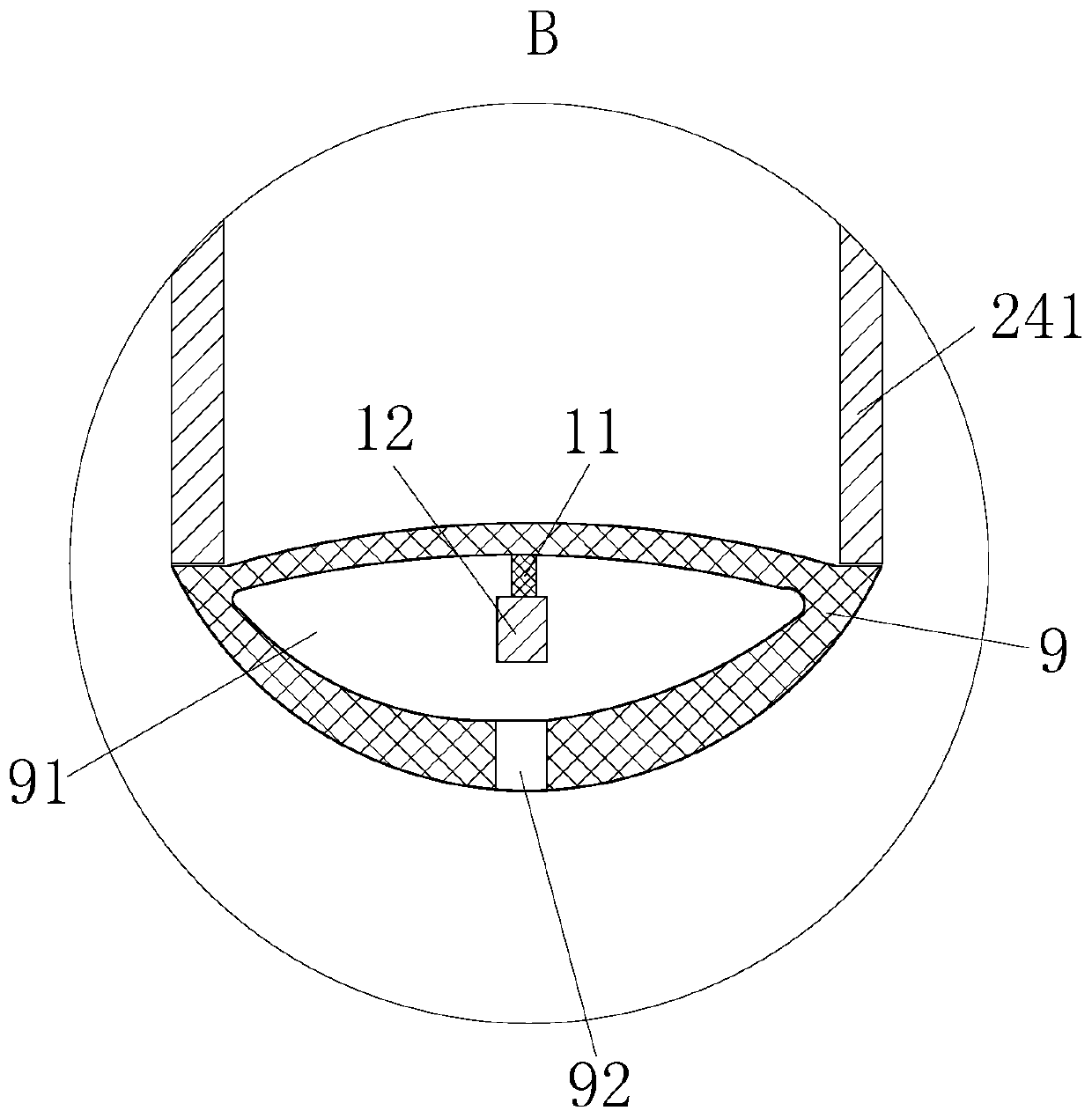

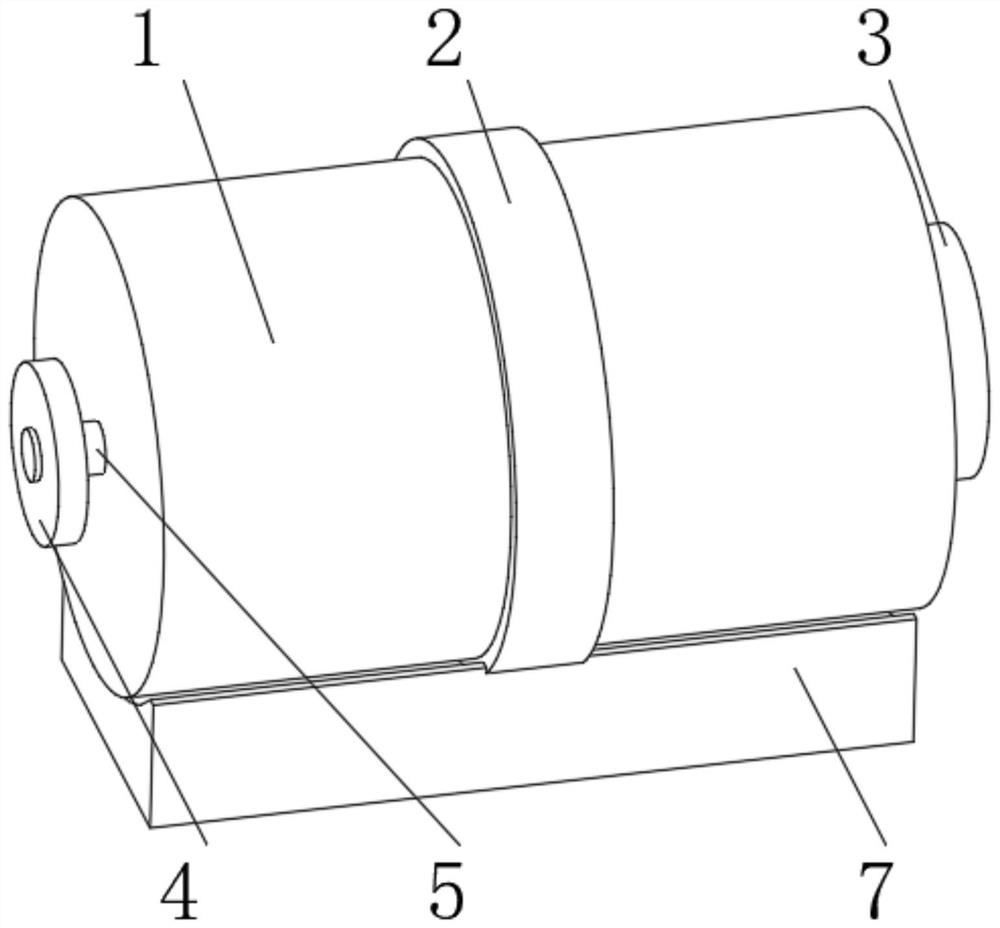

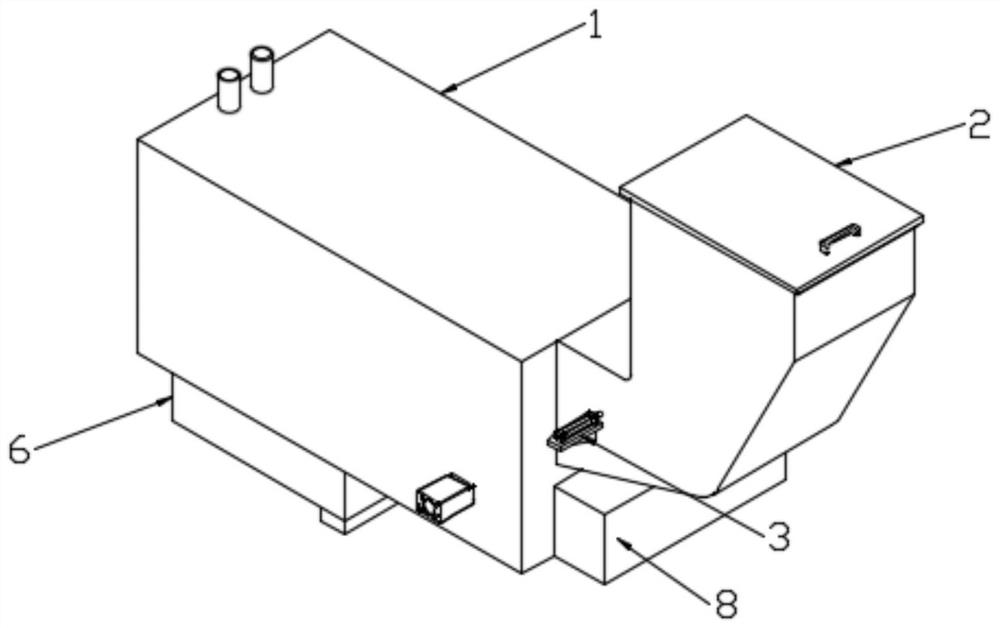

Sterilizer

The invention provides a sterilizer with the following structure that: the sterilizer comprises a shell, a pot body mechanism and a cabin door mechanism; the pot body mechanism comprises a pot body, afront plate and a rear plate; the front plate and the rear plate are in detachable connection to both end faces of the pot body; the cabin door mechanism comprises a door plate main body; the inner lateral surface of the door plate main body is connected with a sealing ring adaptive to an opening on the front plate; the sealing ring is provided with a protruding edge which is distributed in a ring shape along an outer edge of the sealing ring and extends in a radial direction; and a flanging extending inwards is formed at the end part of the protruding edge. The pot body is in detachable connection with the front plate and the rear plate without welding, the mounting process is simple and convenient, mounting efficiency is high, and the sterilizer is safe. In addition, when a pressure inside the pot body is a negative pressure, an attractive force can be applied to the door plate main body, and the door plate main body compresses the sealing ring on the opening of the front plate; andwhen the pressure inside the pot body is a positive pressure, high-pressure steam can enter a gap between the sealing ring and the flanging and apply a pressure to the flanging, so that the flangingis clung to the opening of the front plate, and thus, a better sealing effect is achieved, and air leakage cannot be generated.

Owner:NINGBO LIFE MEDICAL TECH

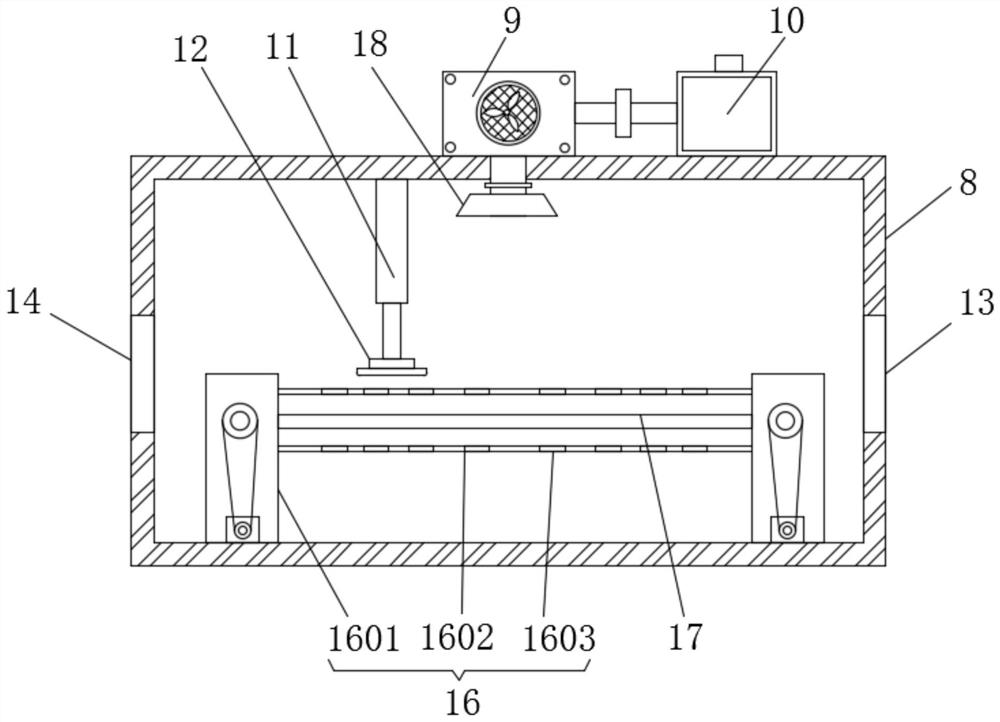

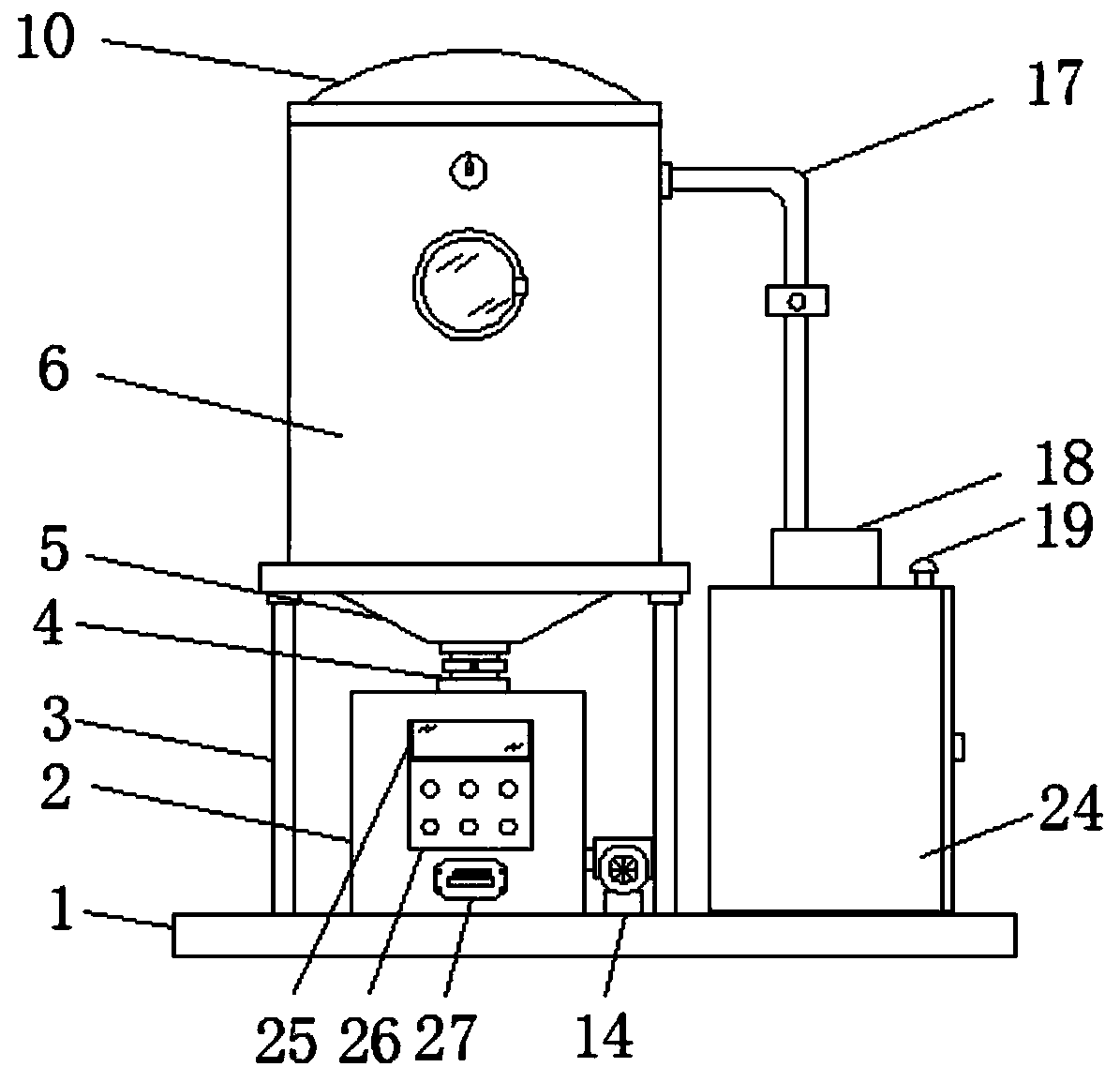

Drying equipment for ultra-soft short plush fabric processing

InactiveCN108413752AEfficient dryingEasy to controlLighting elementsDrying gas arrangementsEngineeringWarm air blower

The invention discloses drying equipment for ultra-soft short plush fabric processing. The equipment comprises a base, a drying box, a support, a conveying belt and a receiving box. The drying box islocated on the surface of the base, the support is located on one side of the base, the conveying belt is located on the top of the support, the receiving box is located on the bottom side of one endof the conveying belt, an observation window is embedded to one side wall of the drying box, a power supply panel is fixed to one side of the observation window, an isolation plate is fixed to an inner cavity of the drying box, an exhaust fan is fixed to the top of the drying box, a warm air blower is fixed to one side of the exhaust fan, and heating rollers are movably connected to the inner cavity of the drying box and located on one side of the isolation plate. The drying equipment is reasonable and novel in design, capable of effectively drying ultra-soft short plush fabric, high in dryingefficiency, high in practicability and suitable for being used and popularized, has a sterilization effect and improves the later-period using effect of the ultra-soft short plush fabric.

Owner:海宁市新益毛绒有限公司

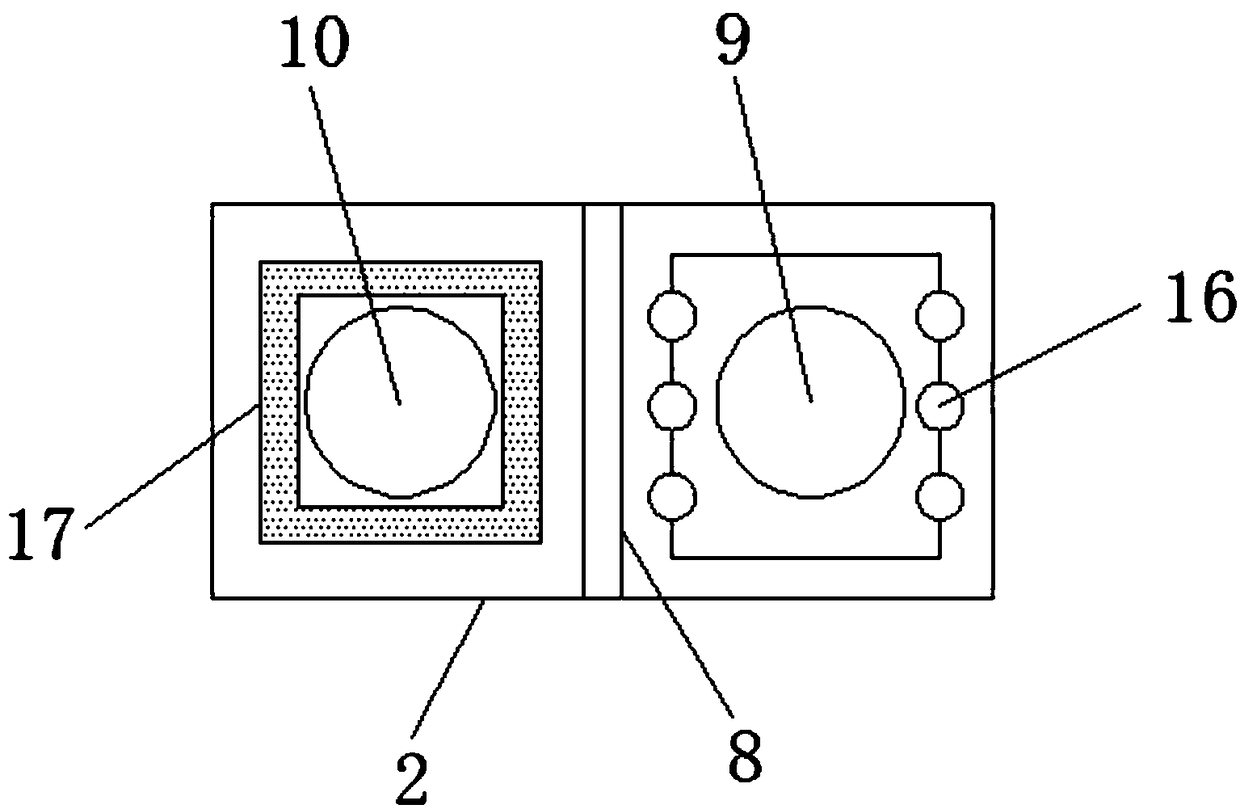

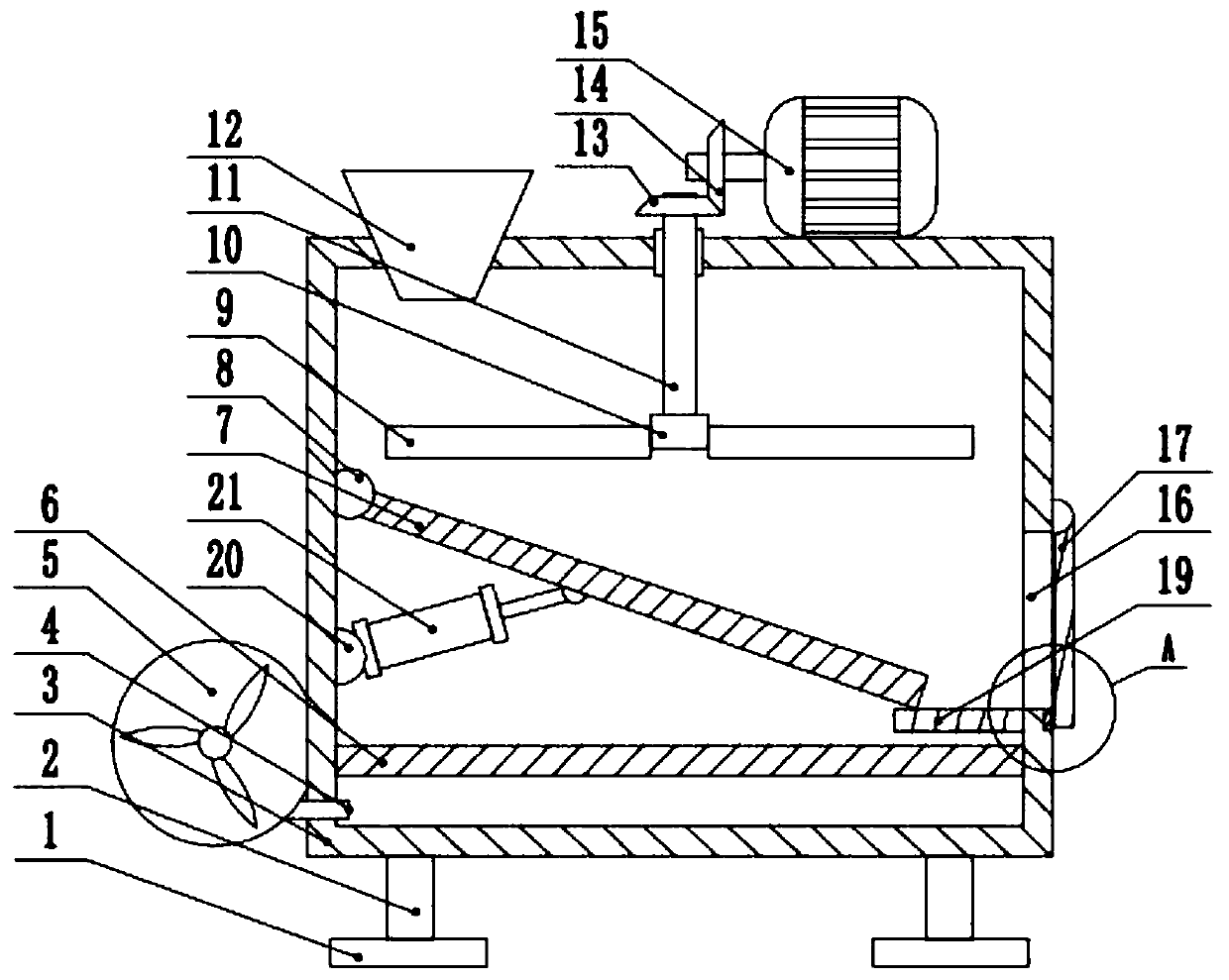

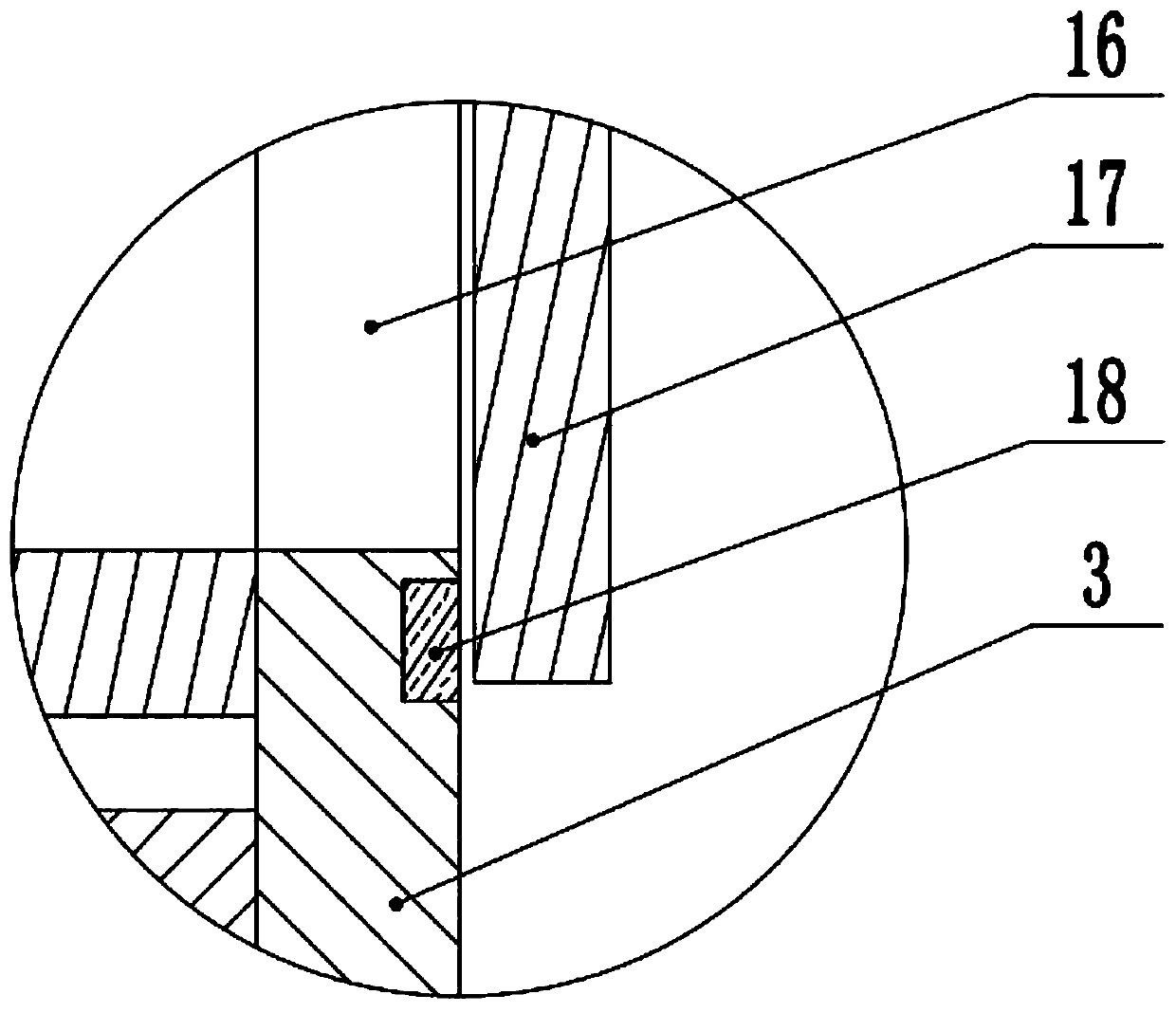

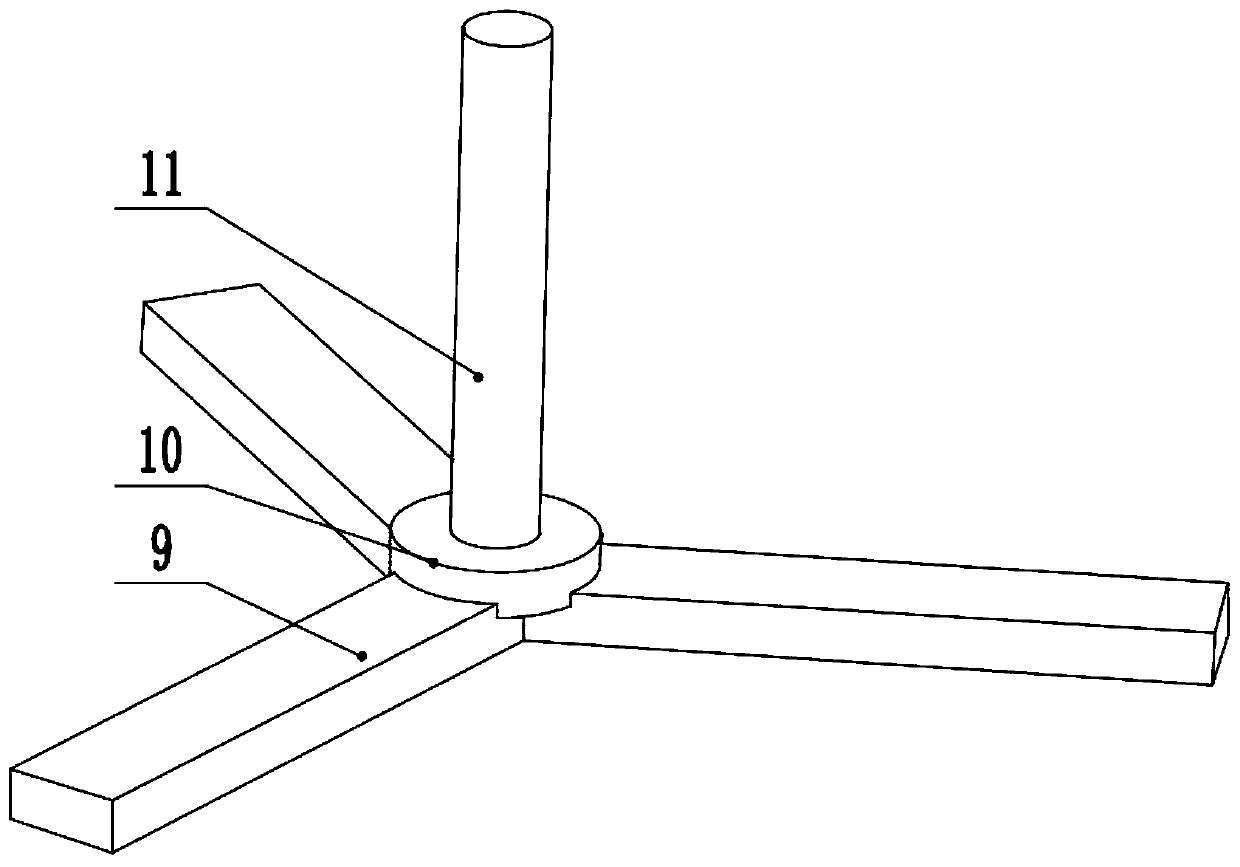

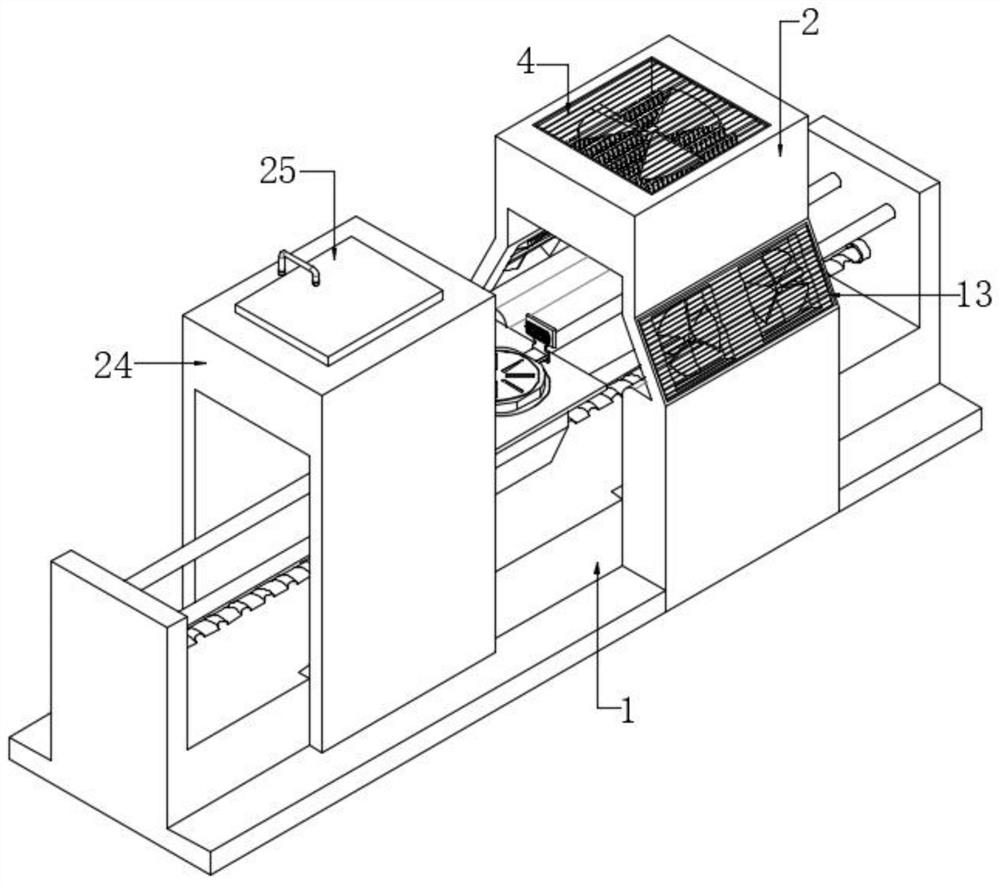

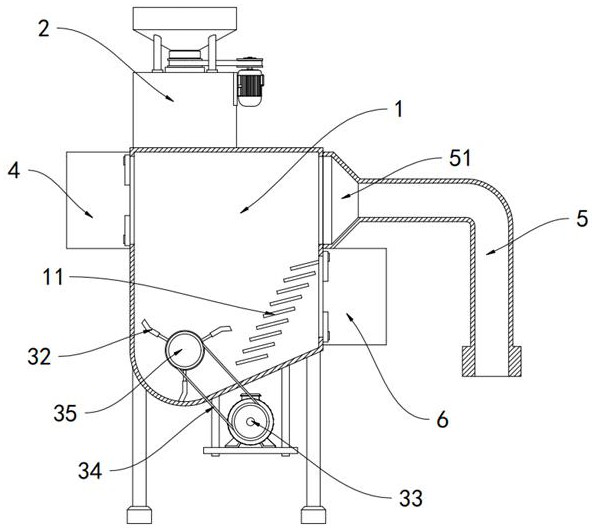

Puffed feed drying device

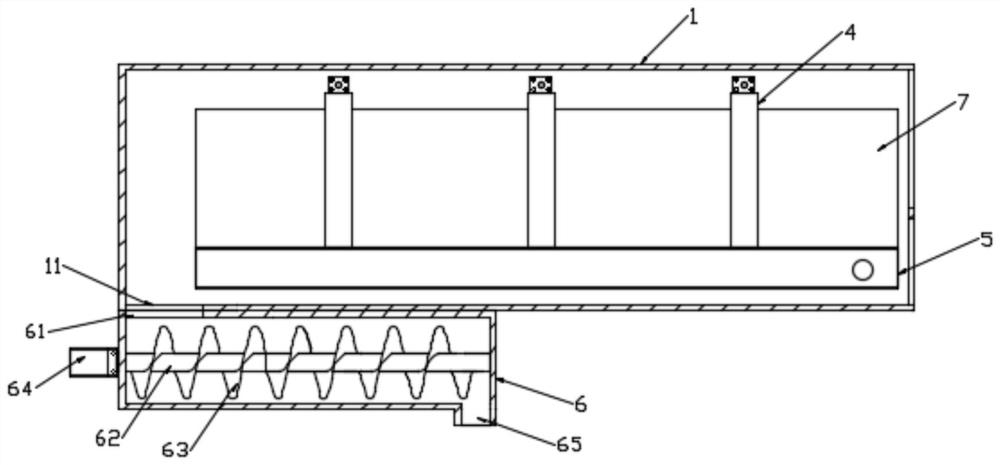

InactiveCN111189308AAffect the drying effectSimple structureDrying gas arrangementsDrying machines with non-progressive movementsAir pumpEngineering

The invention relates to the technical field of feed processing, and discloses a puffed feed drying device. The puffed feed drying device comprises a drying box, wherein the upper part of the left side of the drying box is provided with a feeding inlet, the middle part of the right side of the drying box is provided with a discharging outlet, the left side wall of the drying box is provided with an air pump, the output end of the air pump is connected with the drying box through an air inlet, the bottom of the drying box is provided with a heating plate, the middle part of the inner side of the left side wall of the drying box is provided with a first rotating seat, the first rotating seat is rotationally connected with a ventilating plate, the top of the drying box is rotationally connected with a rotating shaft, the lower end of the rotating shaft is provided with a fixed seat, the side edges of the fixed seat are provided with scraping plates, the upper part of the discharging portis rotationally connected with a baffle plate, and the lower part of the inner side of the left side wall of the drying box is provided with a second rotating seat. According to the puffed feed dryingdevice, the scraping plates which rotate continuously are arranged in the puffed feed drying device, so that feed is spread on the ventilating plate, the situation that feed is caked and affects thedrying effect of the feed is prevented, and the whole device is simple in structure, convenient and fast to operate, and suitable for use and popularization.

Owner:ZOUPING LIBANG FEED

Plate drying method

InactiveCN109405504AAffect the drying effectDrying machines with progressive movementsDrying solid materialsMotor driveEngineering

The invention discloses a plate drying method, and relates to the technical field of plate processing. The plate drying method comprises the steps that (1) a humidity value in a body is set at an electronic control unit, a temperature value of a heater is set, and meanwhile, the drying time is set; (2) a to-be-dried plate is placed on a transporting belt, a control motor of the transporting belt is started, and the control motor drives the transporting belt to convey the plate into the body; and (3) then a lifting rod drives the heater to descend, and the heater presses the plate to bake moisture in the plate out. According to the plate drying method, the problem that in the prior art, the plate is heated unevenly, and consequently the drying effect of the plate is affected can be solved.

Owner:广西霖昇实业有限公司

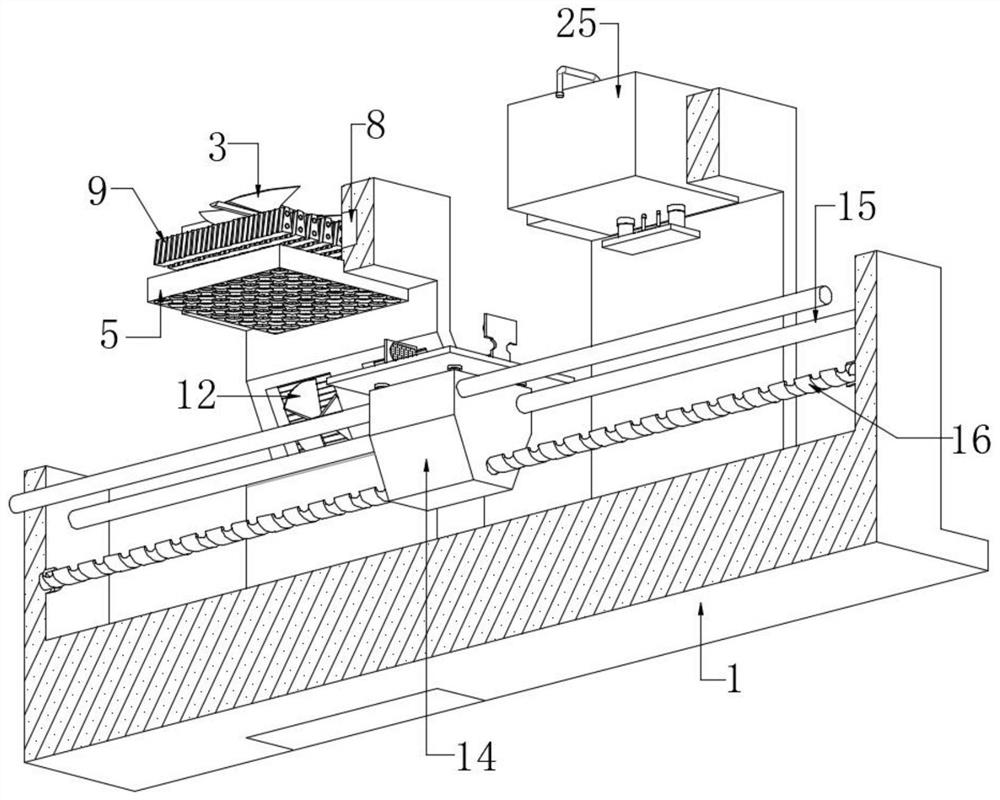

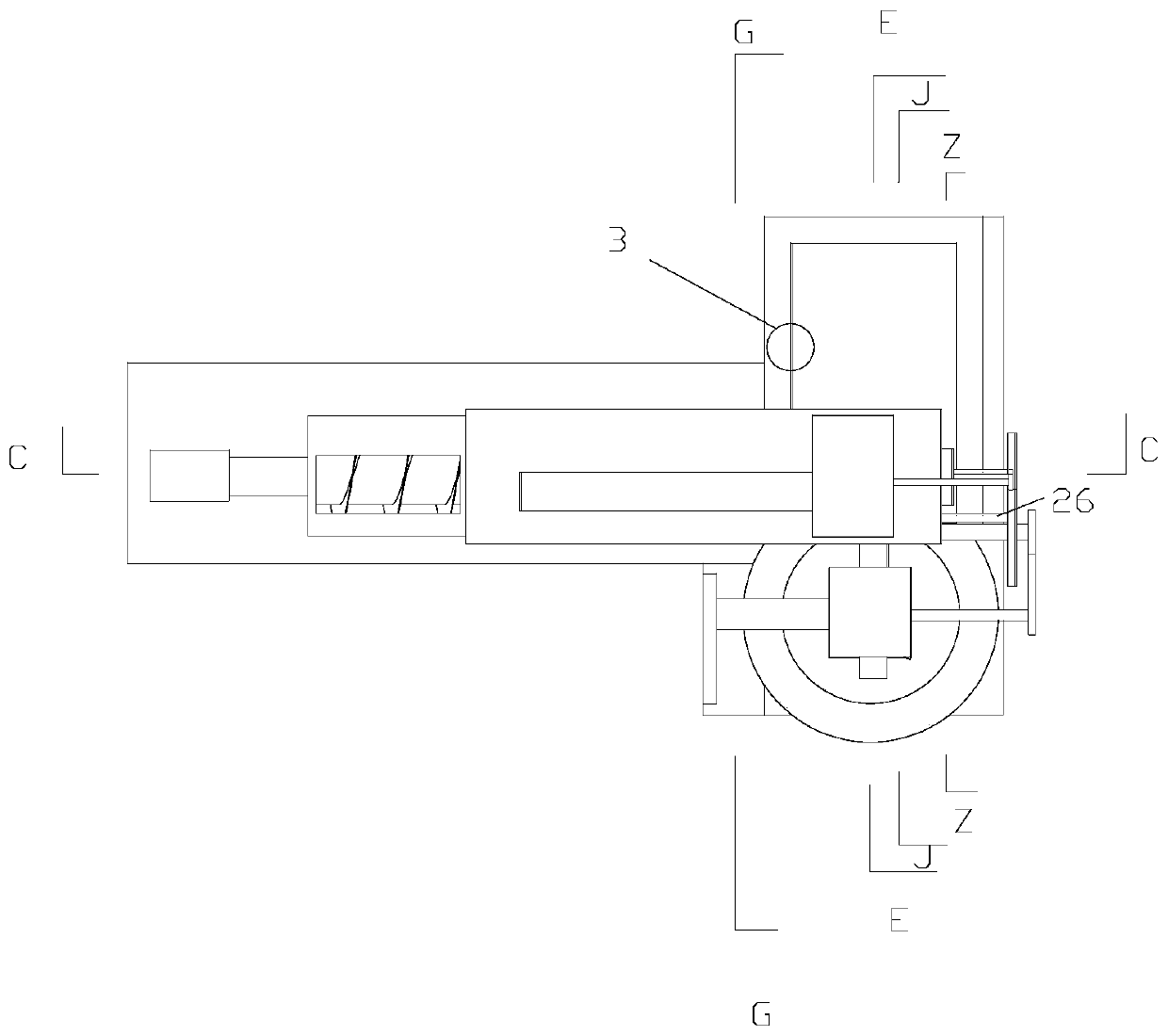

Grain dryer and online moisture detection method thereof

InactiveCN110506789AIncrease the drying heating areaAffect the effect of drying and heatingElectrostatic cleaningSeed preservation by dryingDrive motorPulp and paper industry

The invention belongs to the technical field of grain drying equipment, and particularly relates to a grain dryer and an online moisture detection method thereof. The grain dryer comprises a drying case, a driving motor is arranged on the outer wall of the drying box, and the output end of the driving motor is connected with a stirring shaft; the stirring shaft is rotatably arranged in the dryingbox, and first stirring blocks are uniformly fixed on the stirring shaft; the stirring shaft is uniformly sleeved with the second stirring blocks, and the second stirring blocks are in uniform contactwith the first stirring blocks; a first magnet block is arranged at the end part of the side surface of the first stirring block; a second magnet block is arranged at the end part of the side surfaceof the second stirring block, and the second magnet block and the first magnet block attract each other; when the second stirring block and the first stirring block rotate in a staggered manner, thesoybean grains on the first stirring block and the second stirring block are turned over, so that the drying and heating area of the soybean grains is increased, and the situation that the drying andheating effect of the soybean grains is affected due to uneven stirring of a grain drying device is prevented.

Owner:ANHUI OCEAN AUTOMATION EQUIP

Paint drying device for computer production

InactiveCN109590186AAvoid direct dischargeImprove drying ratePretreated surfacesCoatingsActivated carbonCombined use

The invention discloses a paint drying device for computer production, and belongs to the field of computer production. The paint drying device for computer production includes a drying box, a partition plate is fixedly connected with the interior of the drying box, ventilating holes evenly distributed are formed in the top of the partition plate, a supporting plate is arranged at the position, located below the partition plate, of the interior of the drying box, the bottom of the supporting plate is fixedly connected with the inner bottom wall of the drying box, and drying tables arranged atequal intervals are arranged at the top of the supporting plate. By placing computers on the drying tables, blowing equipment blows the air to the computers by being combined with an air transmissionpipe and a nozzle, the air drying rate is accelerated, meanwhile, through the combined use of an air transmission device and a treatment box, the produced harmful gas can be absorbed through an activated carbon adsorption plate and processed by the process water in the treatment box, the direct discharge of the harmful gas is avoided, the safety and environmental protection are achieved, and the paint drying device is worthy of popularization.

Owner:池州市明永科技服务有限公司

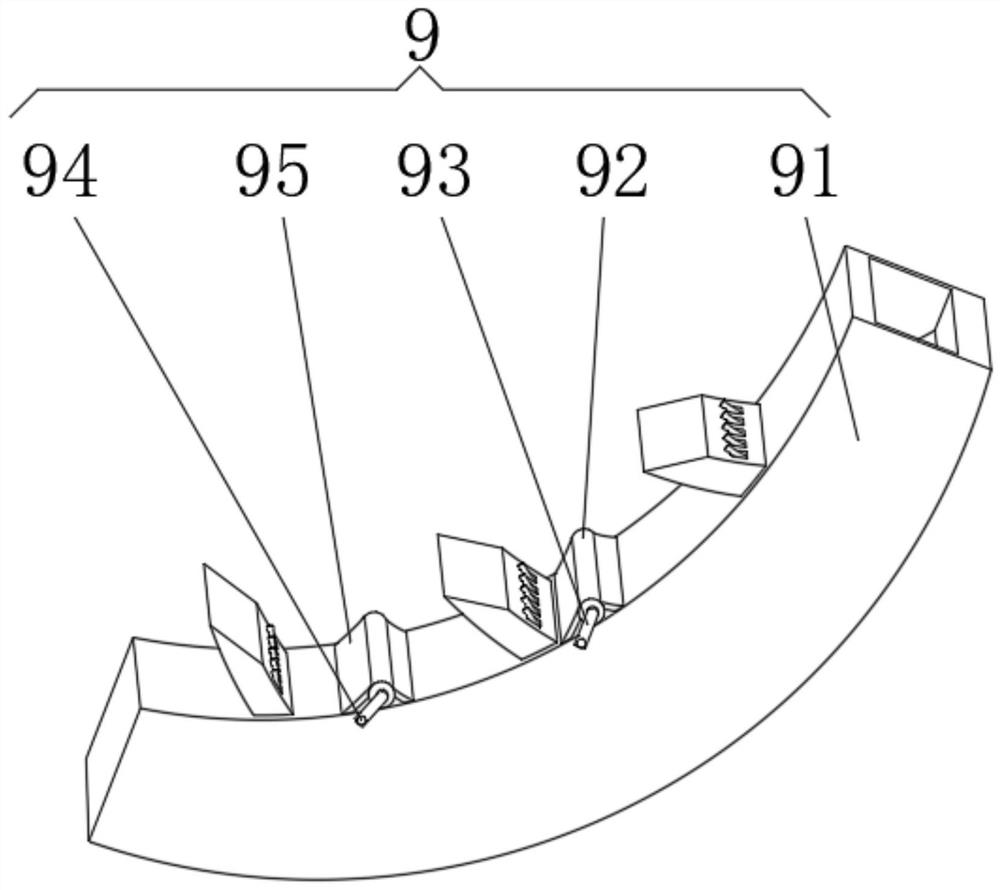

Drying equipment for biomass fuel

PendingCN113758179AAchieve the purpose of mixingAffect the drying effectDrying chambers/containersDrying machines with non-progressive movementsElectric machineProcess engineering

The invention discloses drying equipment for biomass fuel. The drying equipment for the biomass fuel comprises an outer frame; a reinforcing frame is mounted on the outer side of the outer frame; a feeding opening is formed in one side of the outer frame; a driving motor is mounted on the side, far away from the feeding opening, of the outer frame; an output shaft of the driving motor is rotationally connected with a rotating shaft; a rotating frame is fixedly connected to the end, far away from the driving motor, of the rotating shaft; a base is fixedly connected to the bottom of the outer frame; an electric heating wire is mounted in the position, close to the rotating frame, on the inner wall of the outer frame; stirring devices are evenly mounted on the inner wall of the rotating frame; ejection devices are uniformly mounted in the positions, close to the stirring devices, on the inner wall of the rotating frame; and each stirring device comprises an arc-shaped stirring plate. The invention relates to the technical field of drying. According to the drying equipment for the biomass fuel, the purpose of stirring internal straw materials is achieved, the situation that the drying effect is affected due to the fact that the straw materials are moist and agglomerated is prevented, and the straw drying efficiency is effectively improved.

Owner:于坤

Rust removal device for galvanized wire production

PendingCN111910142AGuaranteed firmnessGuaranteed air-drying effectHot-dipping/immersion processesCleaning using liquidsUltrasonic generatorEngineering

The invention discloses a rust removal device for galvanized wire production. The rust removal device comprises a base and an air drying mechanism, universal wheels are arranged at the four corners ofthe lower end of the base, a rust removal bin is fixed to the upper end of the base, an ultrasonic generator is installed in the center of the lower end of the base, and the upper end of the ultrasonic generator is connected with an ultrasonic transducer; and visual glass is arranged in one side of the rust removal bin, and carrying mechanisms are arranged at the two sides of the interior of therust removal bin. The rust removal device for galvanized wire production is provided with sliding rails, the sliding rails extend from the two sides of the interior of the rust removal bin to the twosides of the interior of the air drying bin, the sliding rails fixed to the two sides of the interior of the rust removal bin and the two sides of the interior of the air drying bin are matched with sliding blocks, and therefore a carrier plate can vertically move in the rust removal bin and the air drying bin under the action of hydraulic rods, the situation that in the actual use process, galvanized wires fall off due to the fact that the carrier plate inclines and shakes is avoided, and the actual use effect of the rust removal device is improved.

Owner:TIANJIN ZHAOHONG METAL PROD

Paper product rotary printing mechanism for finished product packaging

InactiveCN113172999AAvoid high kinetic energyReduce kinetic energyNon-rotating vibration suppressionPrinting press partsEngineeringPrinting ink

The invention belongs to the technical field of printing equipment, particularly relates to a paper product rotary printing mechanism for finished product packaging, and provides the following scheme for solving the problems that after rotary printing of existing paper products, a factory mostly adopts an air drying manner to accelerate the drying effect, but printing ink is blown away and fonts are fuzzy due to the fact that the gas flow rate is too large. The mechanism comprises a base, a drying box is fixedly connected to the outer wall of the upper side of the base, a supporting rod is fixedly connected between the inner walls of the two sides of the drying box, and a suction fan is fixedly connected to the outer wall of one side of the supporting rod. A square groove is formed in the outer wall of the upper side of the drying box. The surface of a printed paper product is blown and dried after being heated by external air, rapid air drying of printing ink is accelerated, flowing airflow is blown to alternate air blocking pieces to drive a roller to rotate, the overall kinetic energy of the flowing airflow is reduced, and the situation that the flowing speed of the airflow sucked into the drying box is too large, the printing ink is directly air-dried, consequently, the printing ink is blown away, and printing is fuzzy is avoided.

Owner:峨眉山佳洁纸制品有限责任公司

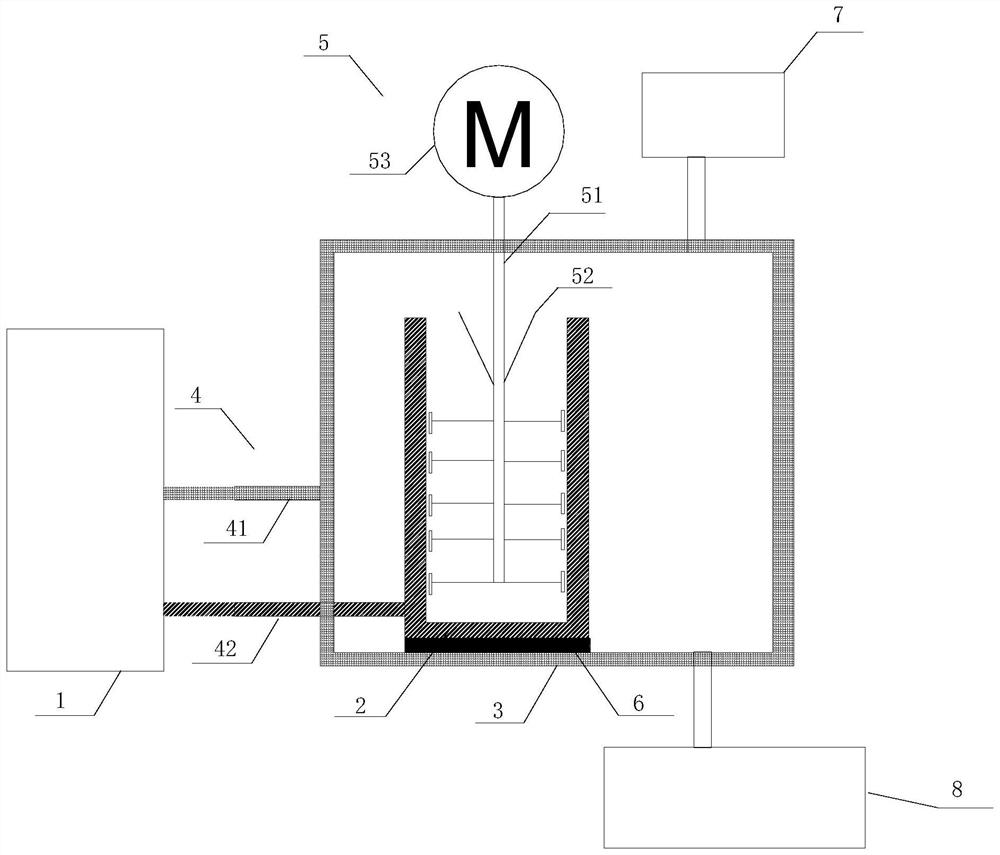

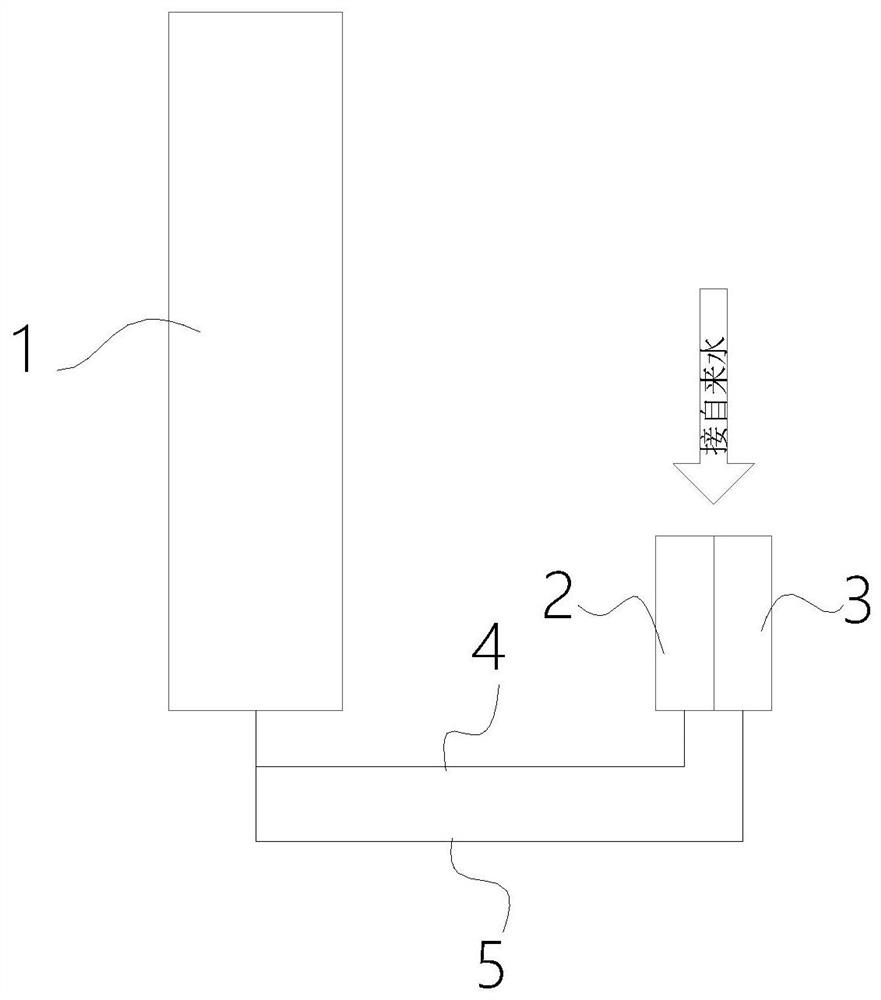

Drying device and system

PendingCN113237300AImprove drying efficiencyImprove dehydration efficiencySteam/vapor condensersDrying solid materialsCondensed waterEngineering

The invention relates to a drying device and system. The drying device comprises a cold and heat source, a heating box, a condensing box and a condensate water return device. The heating box is arranged in the condensing box, a heating jacket and a condensing jacket are correspondingly arranged on the outer wall of the heating box and the outer wall of the condensing box correspondingly, cold water and hot water generated by the cold and heat source communicate with the condensing jacket and the heating jacket through conveying pipelines correspondingly, the upper end of the heating box is open, materials to be heated are contained in the heating box, and the condensate water return device communicates with the condensing box. Cold water and hot water generated by the cold and heat source are supplied to the jacket of the condensing box and the jacket of the heating box correspondingly, then materials in the heating box are heated, steam generated in the heating process overflows from the upper end of the heating box, is condensed and dripped after encountering the inner wall of the condensing box and then is discharged to the condensate water return device, so that water in the heating box is rapidly boiled and condensed, the whole device is in high drying efficiency, and therefore the dewatering efficiency is improved, meanwhile, the structure is simple, and the whole device is efficient and energy-saving.

Owner:广州坤域能源环保科技有限公司

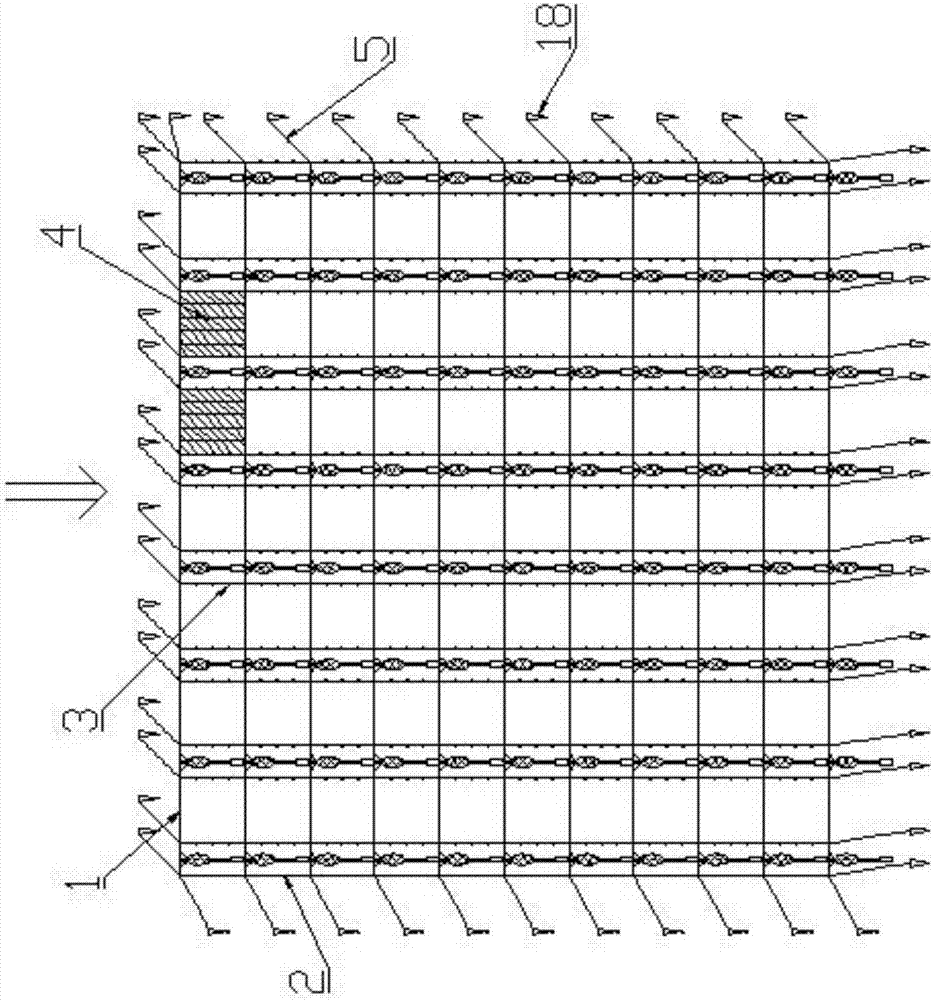

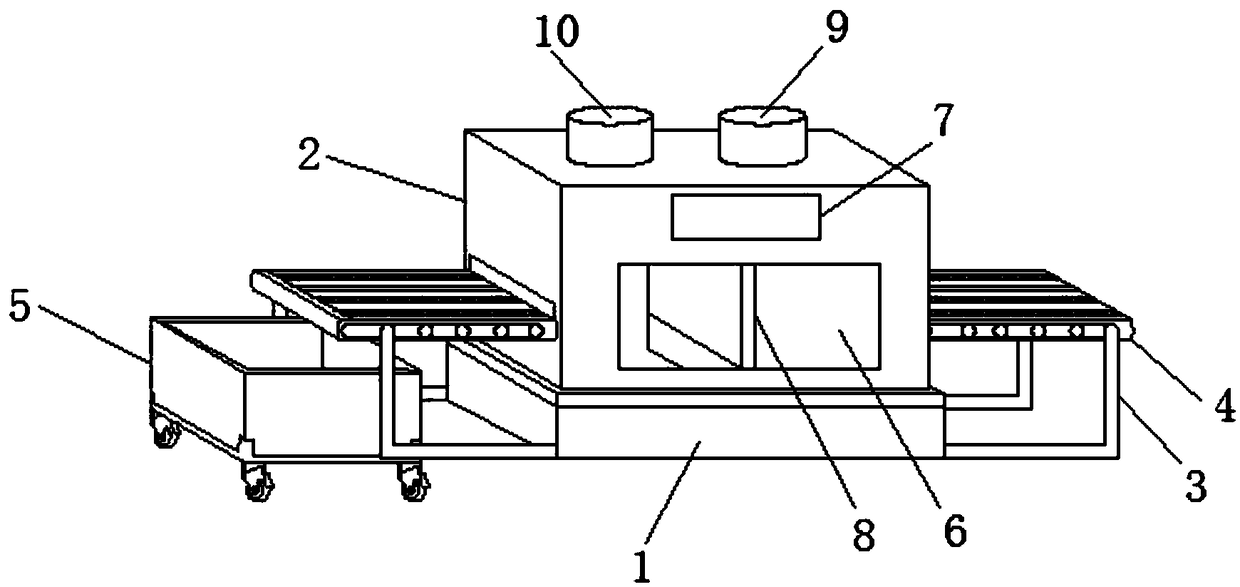

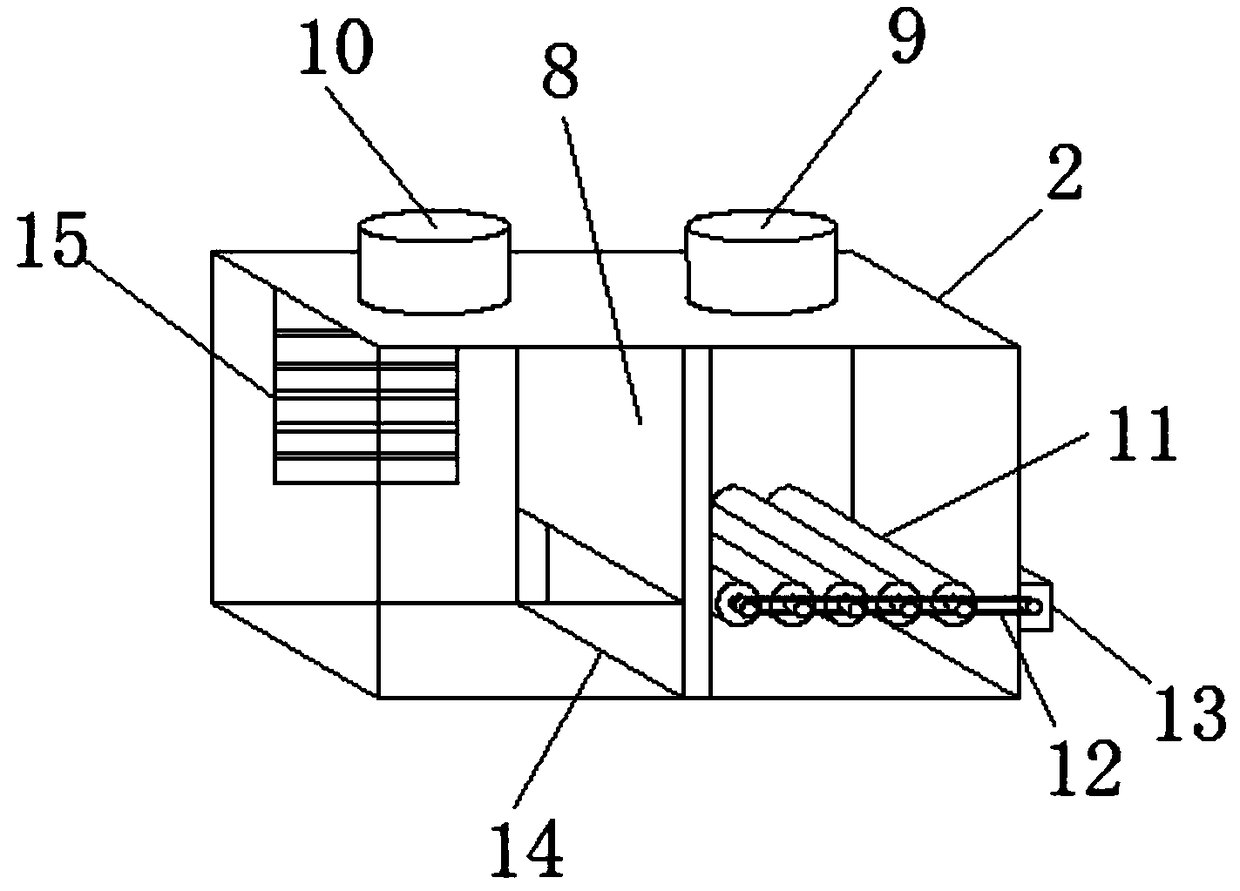

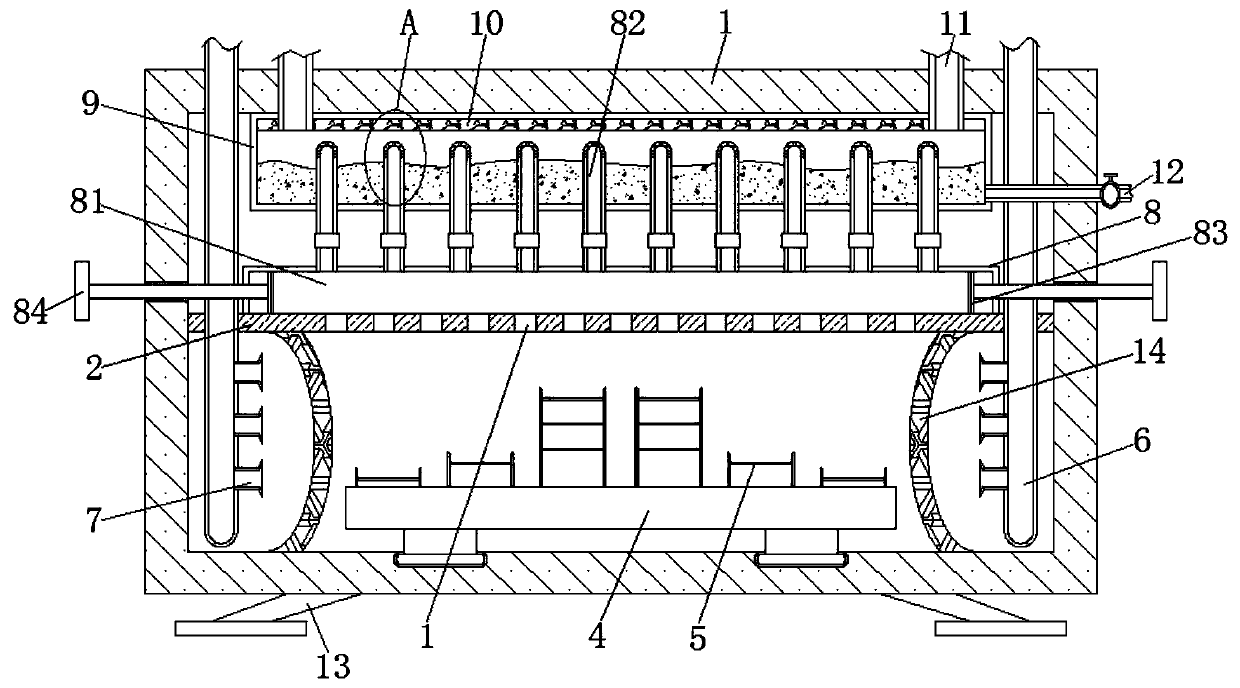

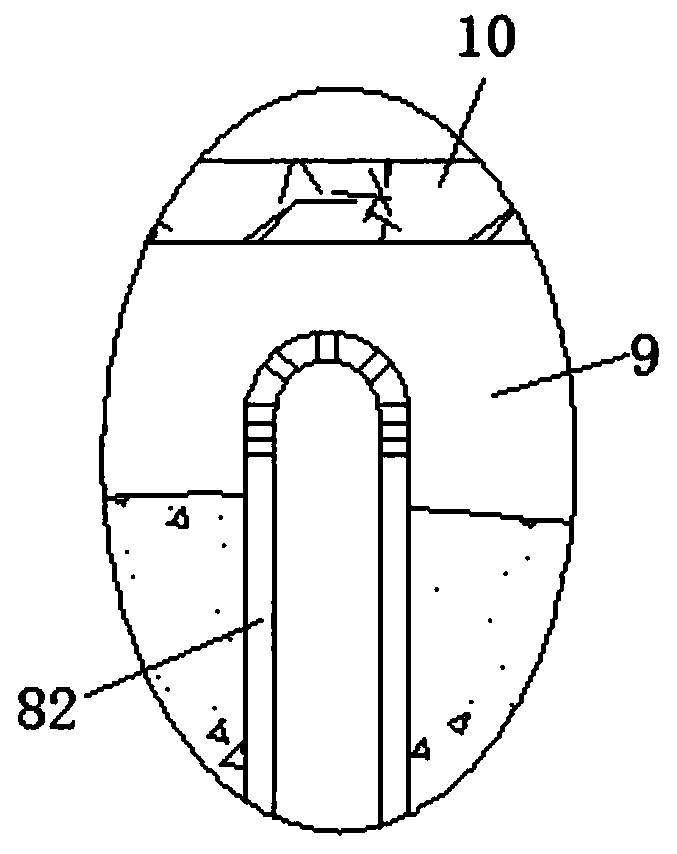

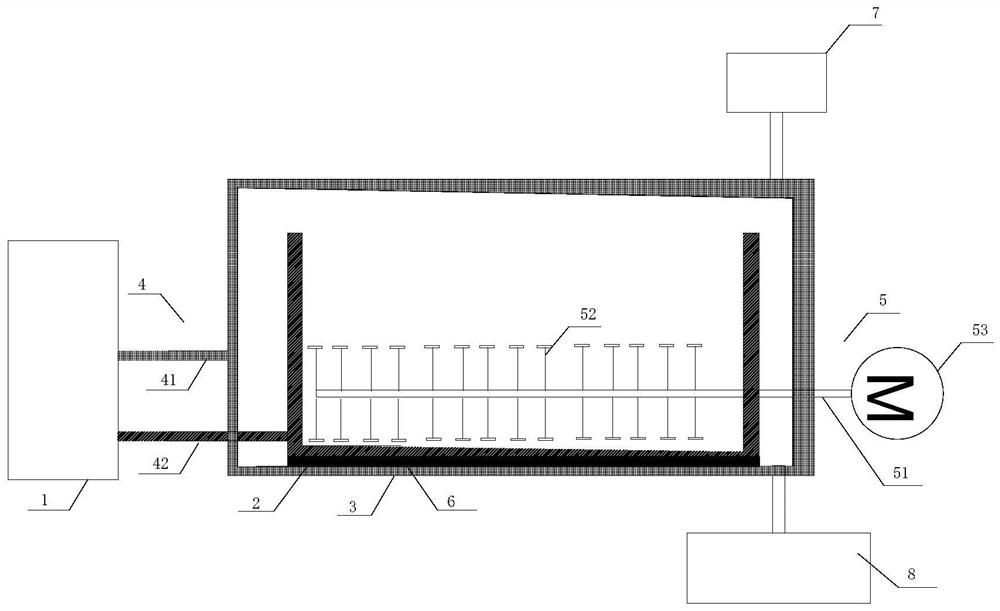

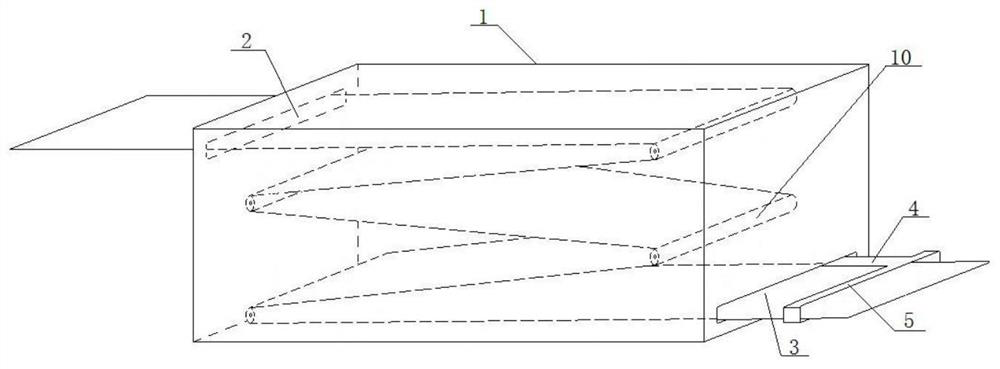

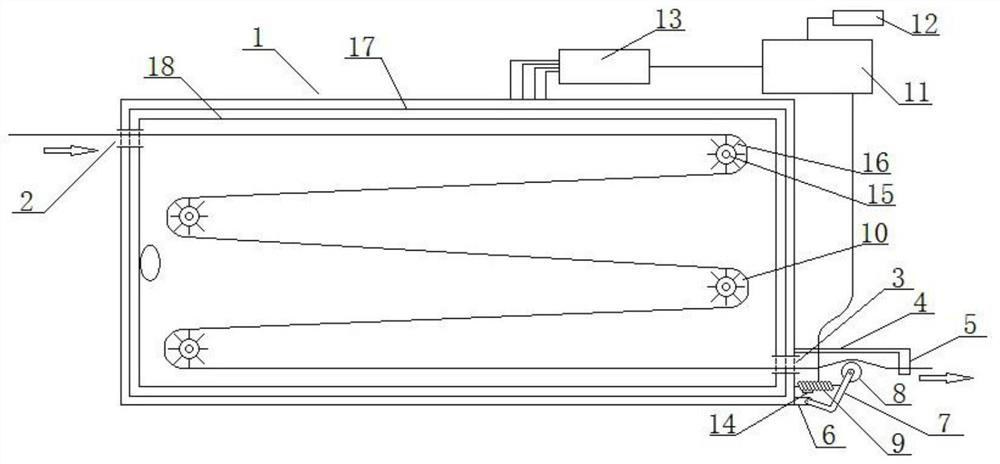

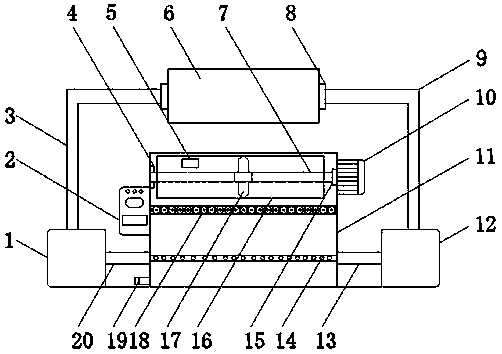

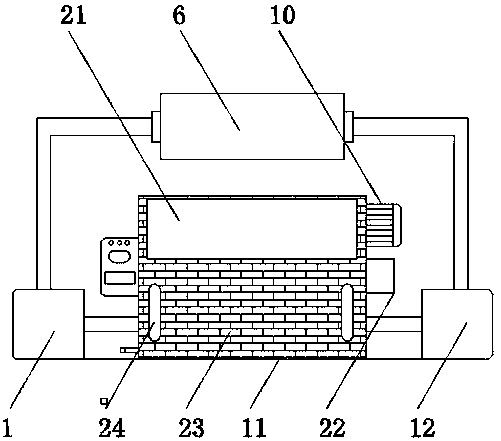

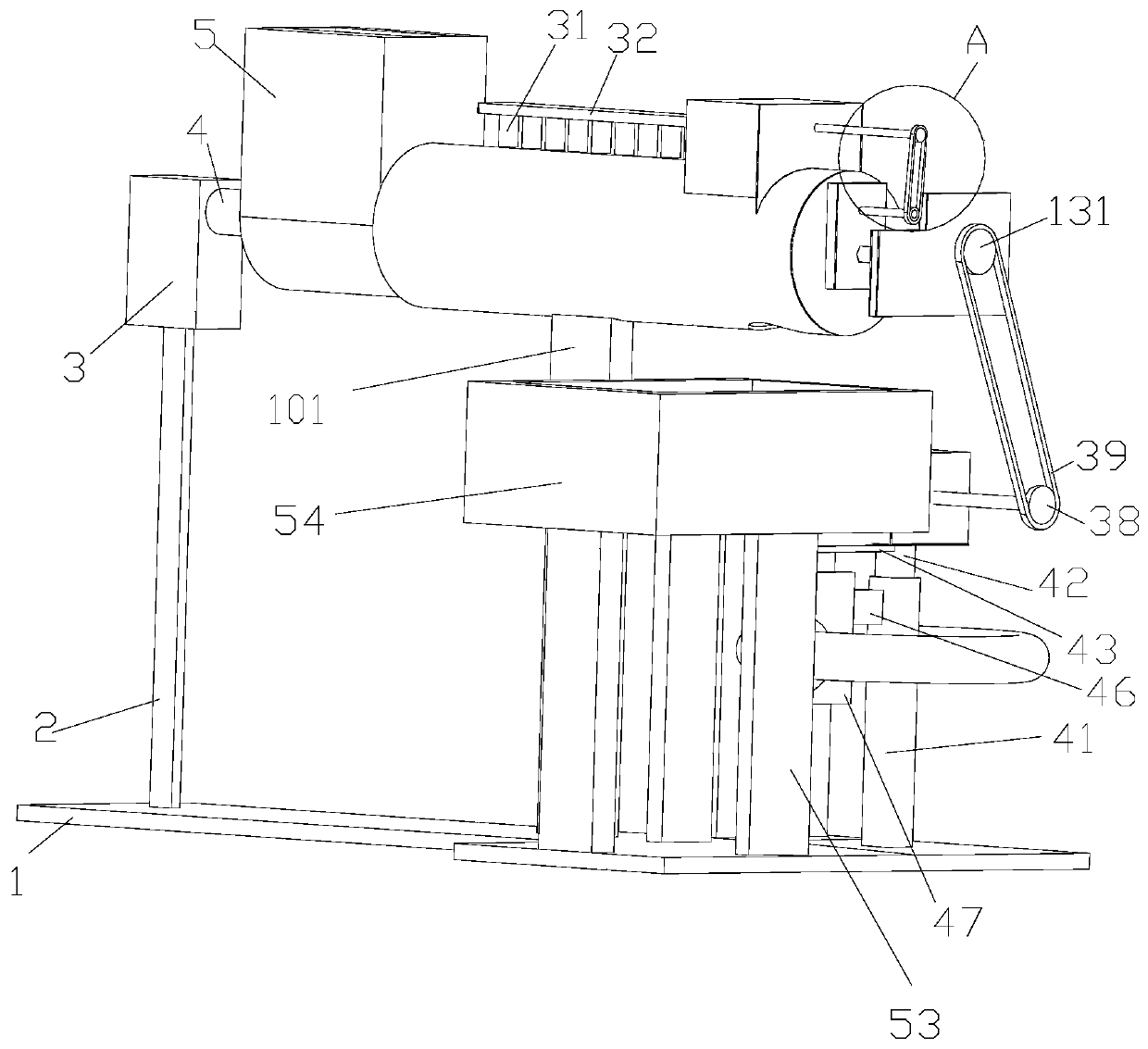

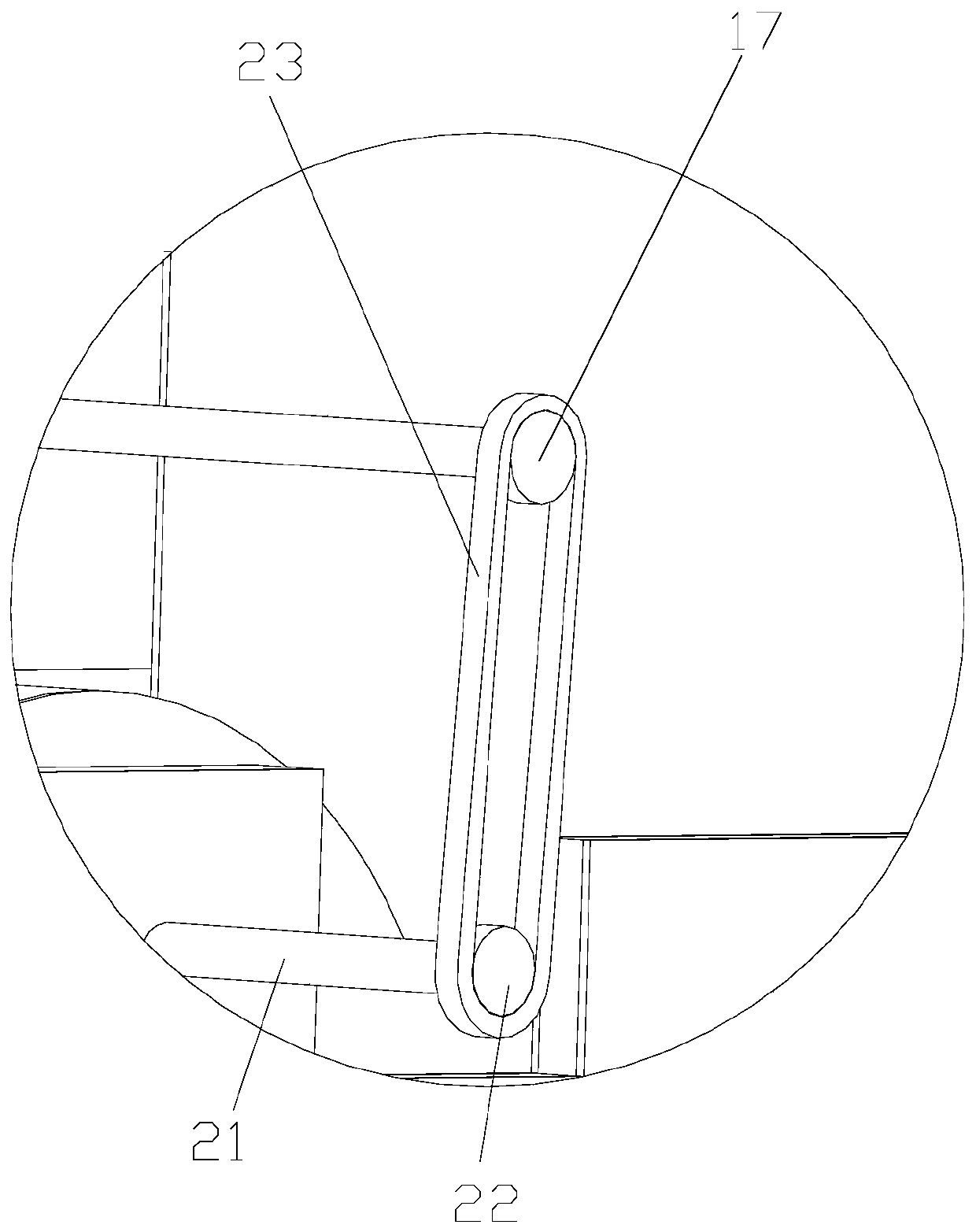

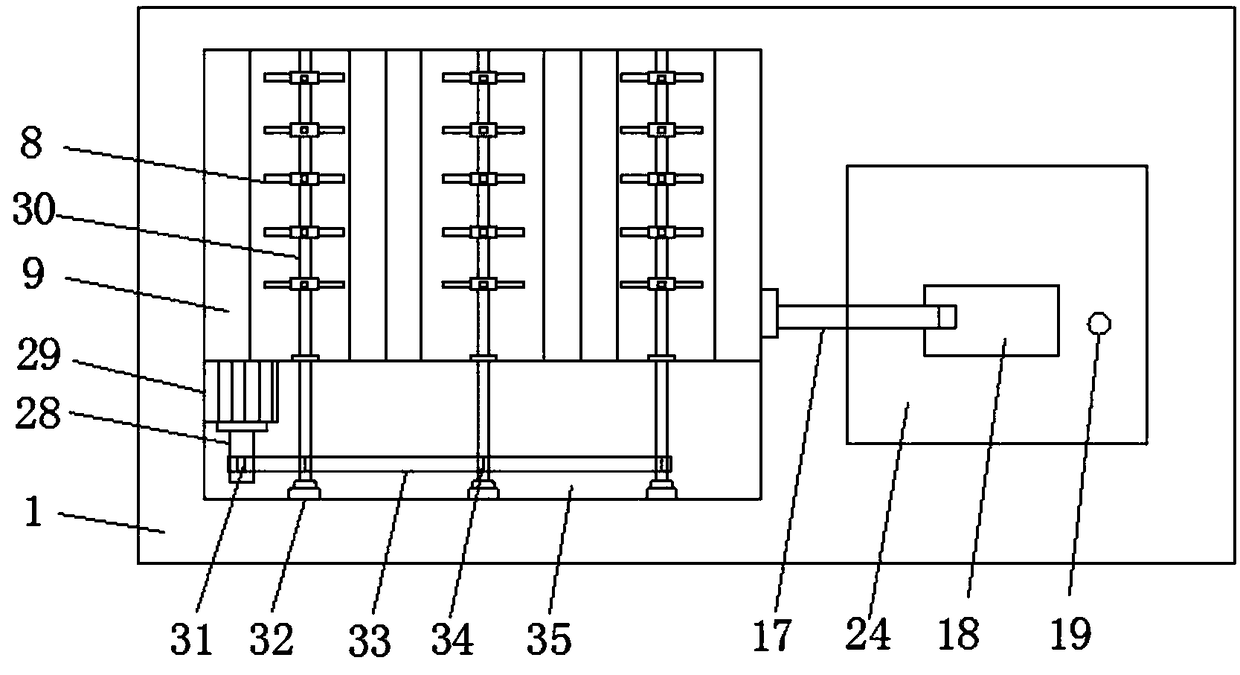

A line type filter cloth oven

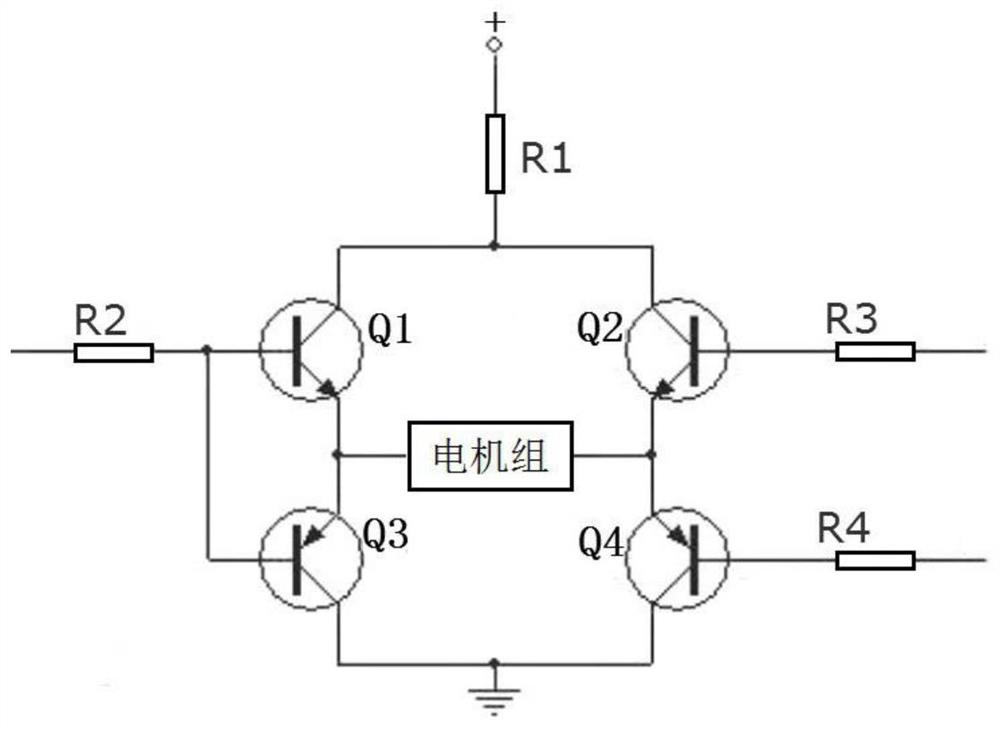

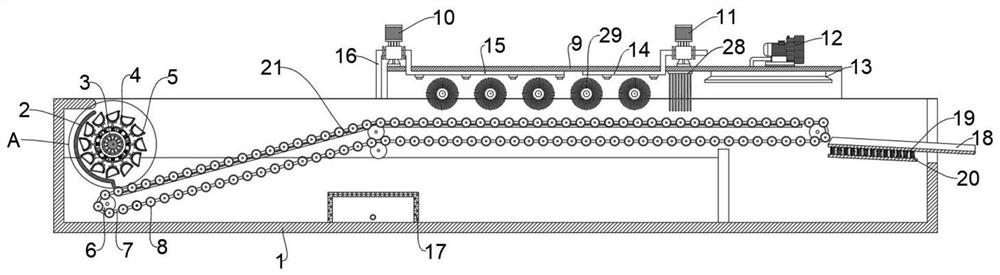

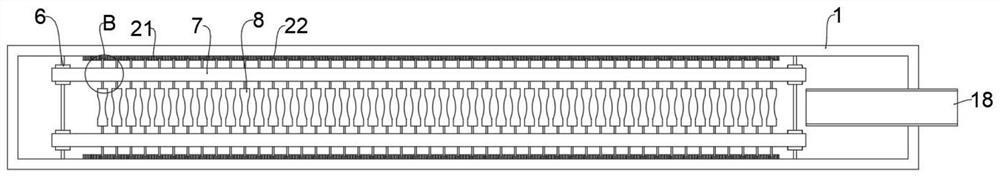

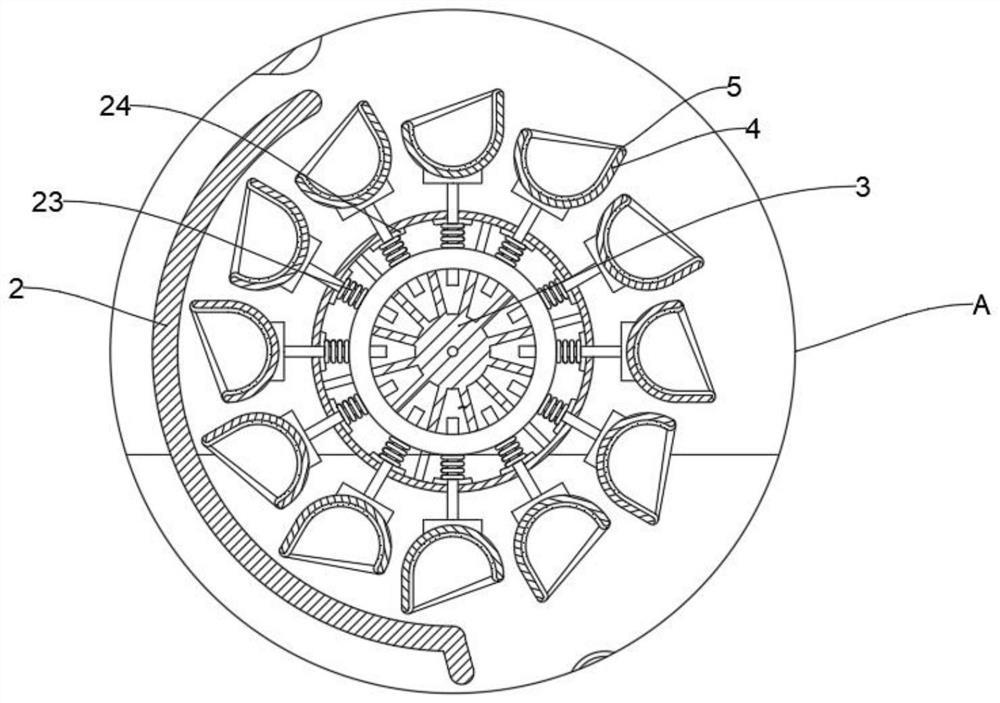

ActiveCN107160606BIncrease distanceExtend drying timeElectronic commutation motor controlDomestic articlesSynchronous motorElectric machine

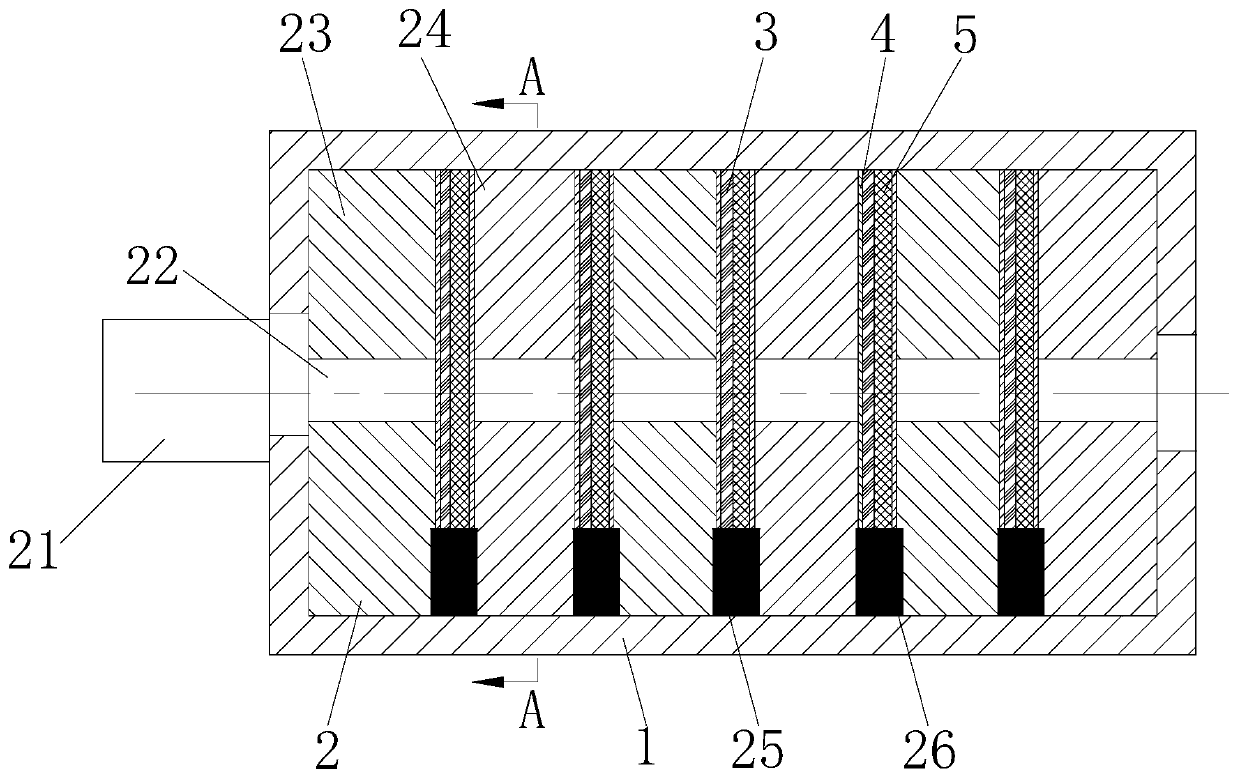

The invention relates to an assembly line type filter cloth drying oven. A multi-linkage rotation mechanism is introduced. Because a plurality of motor electric control rolling shafts (10) are arranged inside a drying oven body (1), the travel distance of filter cloth is increased in the longitudinal direction on the basis of the limited inside space of the drying oven body (1) under the working mode of a filter cloth assembly line, and the drying duration of the filter cloth is prolonged; meanwhile, as for the design of the multiple motor electric control rolling shafts (10), the contact area between the motor electric control rolling shafts (10) and the filter cloth wound around the motor electric control rolling shafts (10) is extremely small, squeezing of objects in contact with the filter cloth on resin on the surface of the filter cloth is avoided to the greatest extent, and accordingly the drying effect of the filter cloth is not affected; and besides, a drive trigger mechanism is arranged in the position, on one side of a filter cloth outlet (3), on the drying oven body (1), by detecting movement of the filter cloth, the motor electric control rolling shafts (10) are synchronously controlled to rotate through a synchronous motor drive circuit (13), smoothness of rotation of the filter cloth in the drying oven is ensured, and therefore the drying efficiency of the filter cloth can be effectively improved.

Owner:JIANGSU LVDI ENVIRONMENTAL PROTECTION FILTER

Manufacturing device and manufacturing method of low-salt high-oil salted duck eggs

InactiveCN113875648AAvoid breakingPrevent smashing intoDrying gas arrangementsDrying chambers/containersBiotechnologySilica gel

The invention discloses a manufacturing device and manufacturing method of low-salt high-oil salted duck eggs, relates to the technical field of making of the salted duck eggs, and aims to solve the problems that the duck eggs are damaged, bacteria easily enter the duck eggs and the duck eggs are rotted when the existing low-salt high-oil salted duck eggs are fed and cleaned, and the duck eggs tend to collide with each other; and the product quality is seriously influenced. A rotary support is installed on one side of the interior of a cleaning box and rotationally connected with the cleaning box, a bearing support is installed in the rotary support and slidably connected with the rotary support through a clamping groove, a silica gel pad is installed at one end of the bearing support, and an anti-collision spring is installed outside the bearing support. The anti-collision spring is connected with the bearing support through the clamping groove, a limiting plate is installed outside the bearing support and connected with the bearing support in a welded mode, and a splash-proof plate is installed on one side of the rotary support.

Owner:合肥田源生态农业科技有限公司

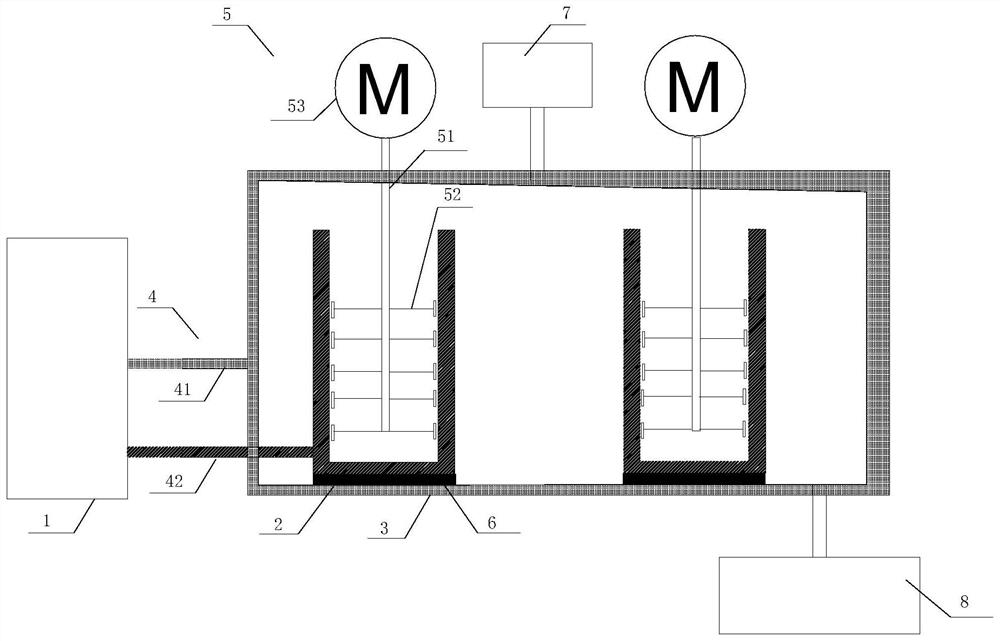

A kind of double hot air blower oven for vegetable processing

ActiveCN106387955BInhibit sheddingAffect the drying effectFood treatmentCooking & bakingHot air oven

Owner:耒阳市丁先生农业发展有限公司

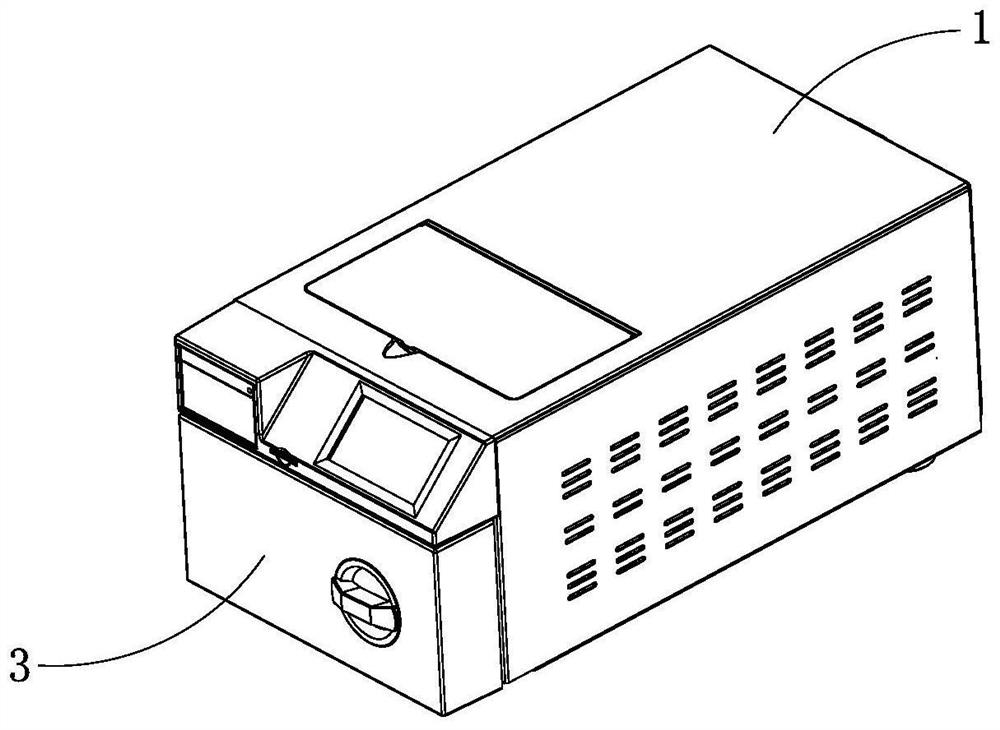

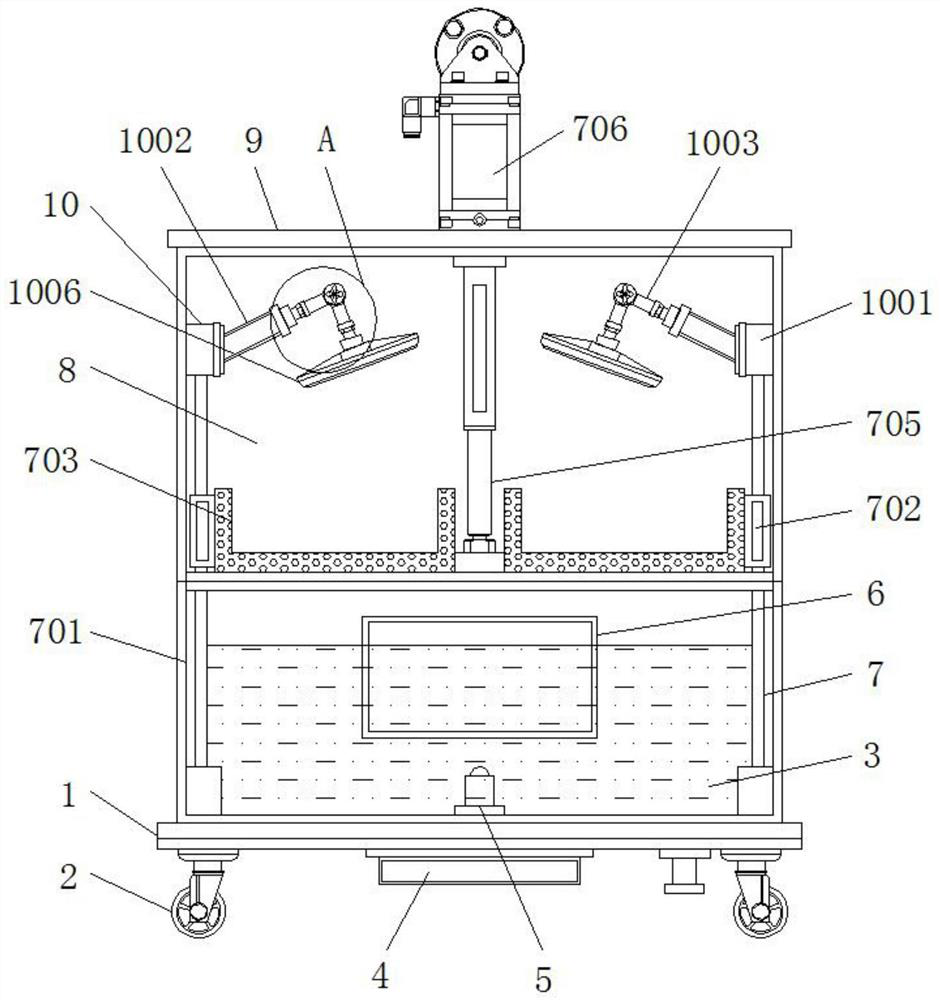

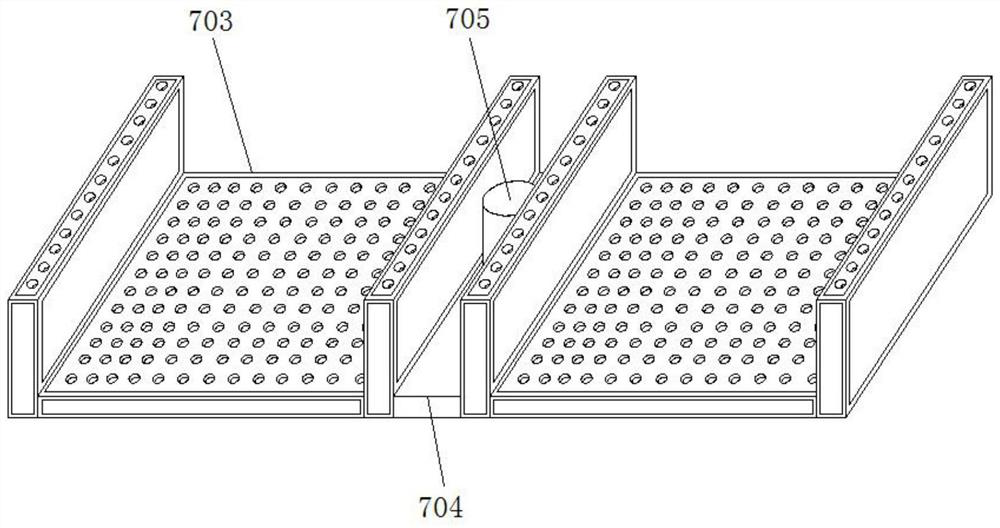

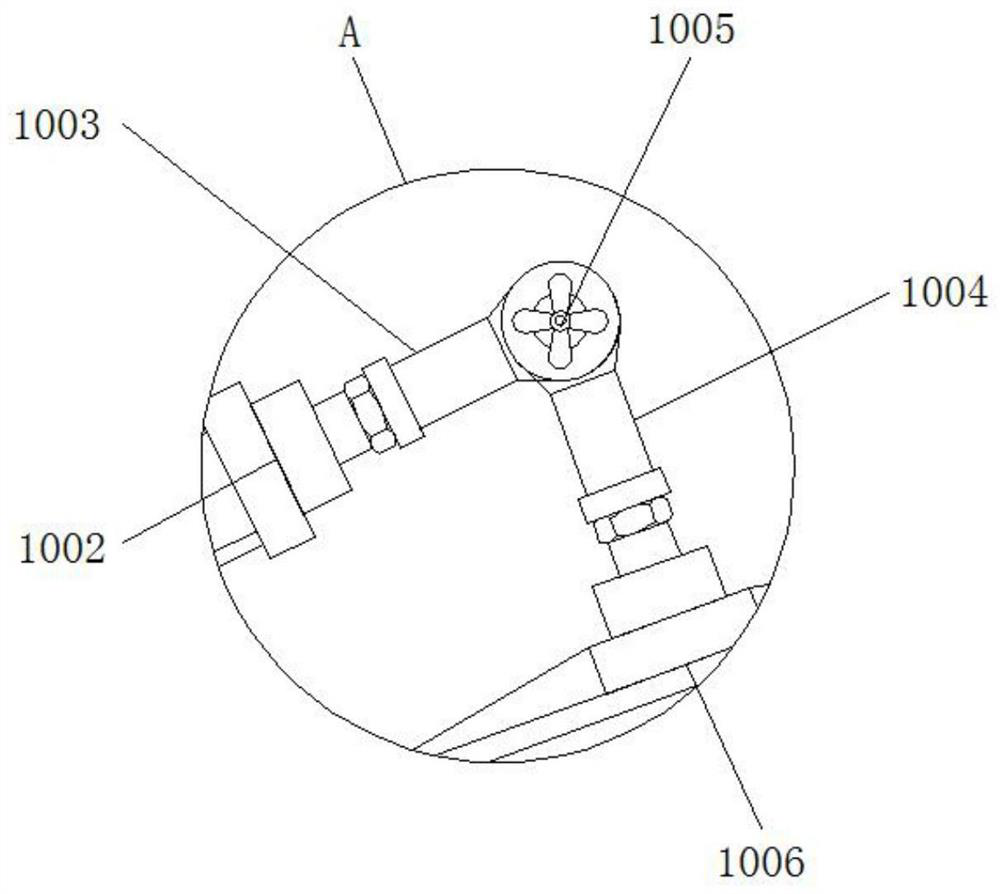

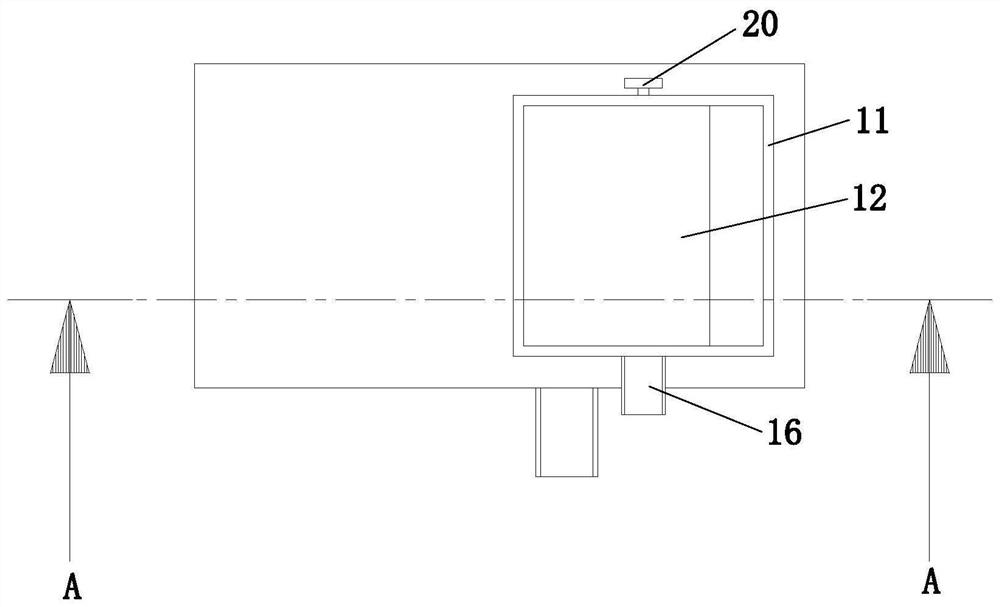

Intelligent drying device for medicine particle manufacturing

InactiveCN113513906AGuaranteed efficiency and effectivenessPrevent drying effectGranular material dryingDrying chambers/containersProcess engineeringPharmacy technology

The invention relates to the technical field of pharmacy, in particular to an intelligent drying device for medicine particle manufacturing. The intelligent drying device comprises a main body, a first controller, a drying plate, a second controller and a third controller, the main body comprises a machine room, the surface of the machine room is fixedly connected with a support frame, and the bottom end of the machine room is fixedly connected with a discharge port; and a drying mechanism is arranged on the inner side of the machine bin and comprises a feeding bin, the feeding bin is fixedly connected to the inner side of the machine bin, a buffer plate is movably connected to the surface of the feeding bin, and a first controller is fixedly connected to the inner side of the feeding bin. Particles in the feeding bin fall into the drying bin, in the falling process, the particles falling into the drying bin from the feeding bin are comprehensively dried through the drying plate, the drying efficiency and effect are guaranteed, medicine particles of different sizes can be automatically adjusted conveniently, the using effect of the dispersing plate in the drying bin is improved, and the drying efficiency of the equipment is improved.

Owner:杭州科永医疗科技有限公司

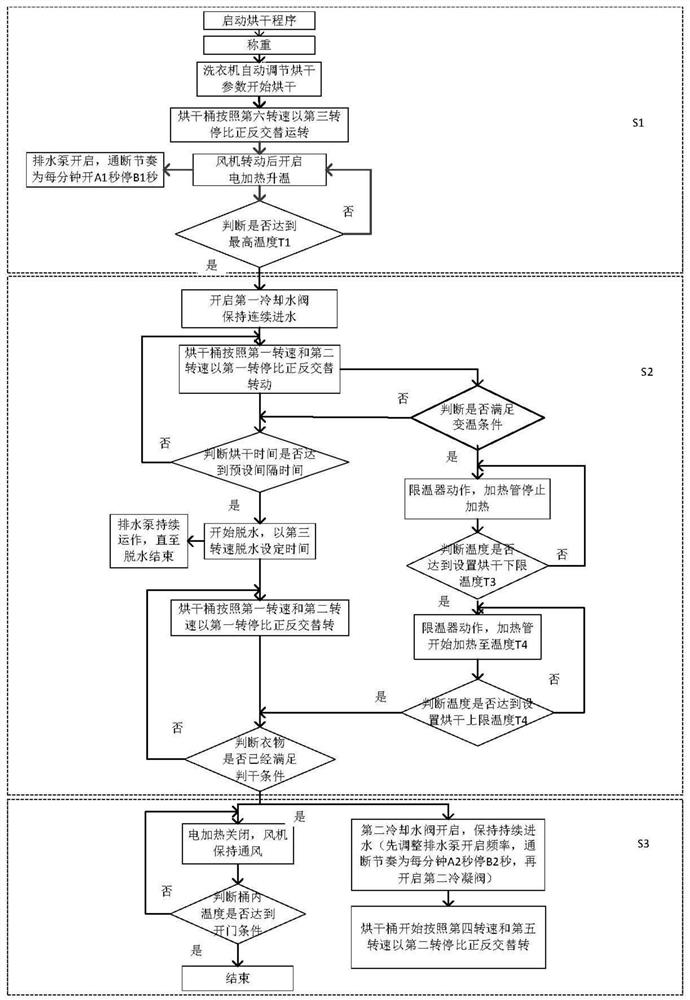

Clothes processing equipment and drying control method thereof

ActiveCN112458718BImprove drying uniformityImprove condensation efficiencyControl devices for washing apparatusTextiles and paperProcess engineeringLaundry

The invention discloses a clothes treatment device and a drying control method thereof. The clothes treatment device comprises a clothes treatment barrel, which is provided with a condenser. One end of the condenser communicates with the clothes treatment barrel, and the other end communicates with at least two cooling The water pipelines are connected, and each of the cooling water pipelines is provided with a cooling water valve that can independently control the opening or closing of the cooling water, so that when the laundry processing tub is in the drying process, the at least two cooling water pipelines can pass through the control The cooling water valve provides the cooling water required by the different drying stages of the condenser. The clothes processing equipment and the drying control method thereof of the present invention have high condensation efficiency in the drying process, short total drying time and good drying uniformity.

Owner:GREE ELECTRIC APPLIANCES INC

Drying equipment applied to flour production

PendingCN114353493AImprove drying efficiencyAffect the drying effectDrying solid materialsDrying machinesProcess engineeringMechanical engineering

The drying equipment applied to flour production comprises a drying box, one side of the drying box communicates with a feeding pipe, guiding mechanisms for guiding the trend of flour are symmetrically arranged on the two sides in the feeding pipe, and a conveying mechanism for conveying the flour is arranged in the drying box; the conveying mechanism comprises two mounting frames and a conveying belt arranged between the two mounting frames, and a plurality of dispersing mechanisms are arranged on the conveying mechanism. A plurality of dispersing mechanisms are arranged on the conveying mechanism, stacked flour is separated through a plurality of guide rods arranged on the dispersing mechanisms in a staggered mode and then evenly laid on the conveying belt, the contact area of the flour and hot air is increased, and the drying efficiency of the flour is improved; and the discharging box arranged at the bottom of the drying box enables the flour on the conveying belt to be fully stirred and dried in the sequential discharging process, the situation that the drying effect of the flour is affected by too much flour is avoided, and meanwhile the drying quality of the flour is improved.

Owner:JIESHOU XIANGYUN FLOUR

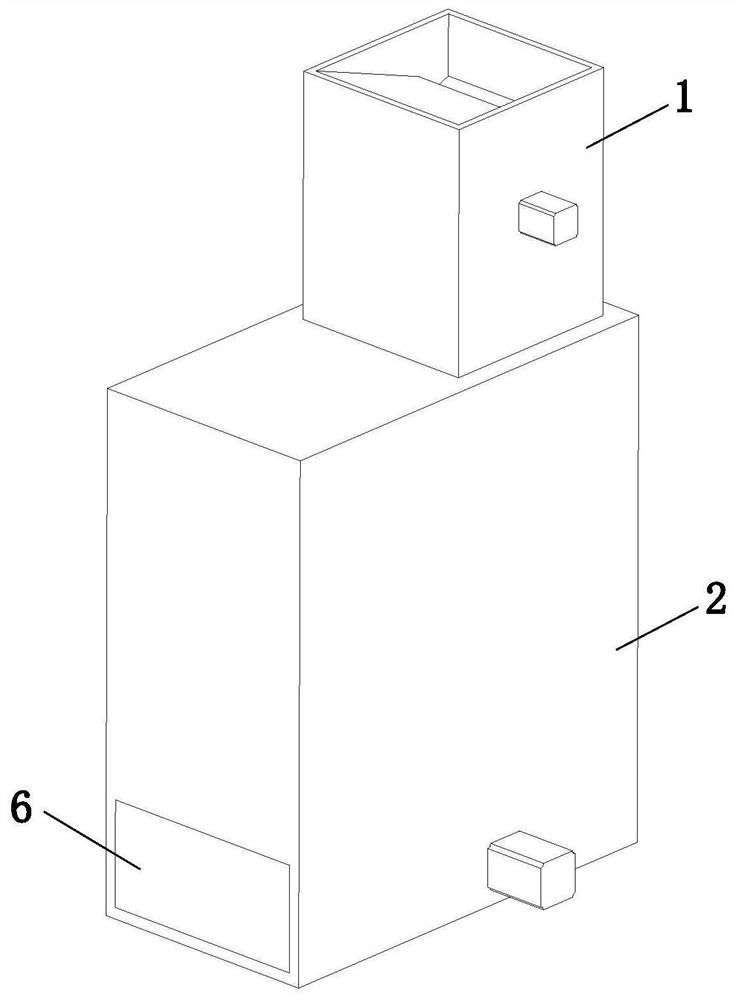

Sludge drying equipment

InactiveCN110127983AAffect the drying effectSimple structureSludge treatment by de-watering/drying/thickeningSludgeSteam engine

The invention discloses sludge drying equipment, the sludge drying equipment is characterized by comprising a machine base, a first vertical plate fixedly arranged on the upper surface of the machinebase, a transmission device arranged on the upper surface of the first vertical plate, a fan device arranged on the transmission device, and a flap device fixedly arranged on the right side of the upper surface of the machine base. The transmission device comprises a steam engine fixedly arranged on the upper surface of the first vertical plate, a steam pipeline communicated with the right end surface of the steam engine, a crushing shell communicated with the right end surface of the steam pipeline, a crushing space arranged in the crushing shell and opening upwards, a spiral shell communicated with the right end wall of the crushing space, a spiral space arranged in the spiral shell, a spiral feeding shaft rotationally arranged on the left end wall of the crushing space, and crushed sludge is dried while being conveyed through the transmission device.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

Drying device for silk-shaped crops

ActiveCN111678313BTo achieve the purpose of shaking and blankingReduce entanglementDrying gas arrangementsDrying solid materialsAgricultural scienceAgricultural engineering

The invention relates to the field of crop processing equipment, and discloses a drying device for filamentous crops, comprising a feeding mechanism, an outer box, an air supply mechanism and a drying mechanism. The driving mechanism and the drying mechanism include a material-bearing cylinder and a supporting round table. The inner and outer walls of the material-bearing cylinder are respectively provided with a continuous inner spiral flow channel and an outer spiral flow channel. The trumpet pressing piece has a horn-like structure, a through-hole group for discharging the filamentous crops is arranged on the bearing cylinder, and a side door is arranged on the side wall of the outer box. The separation of dry and wet filamentous crops during the drying process of filamentous crops prevents the filamentary crops from entanglement, and does not require the existing stirring mechanism to turn the filamentous crops, and the filamentous crops will not be broken and damaged. , to ensure the quality of filamentous crops, strong practicability.

Owner:ANHUI POLYTECHNIC UNIV

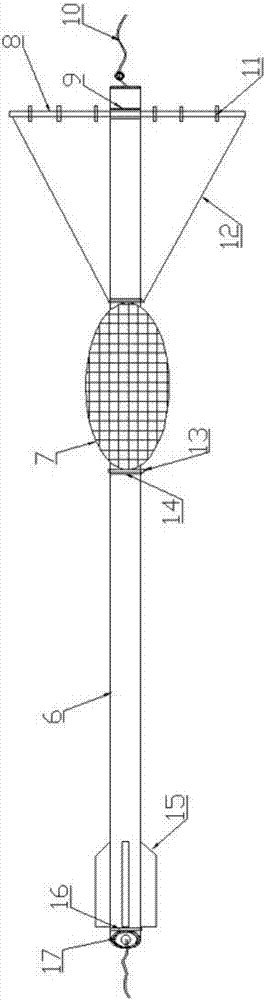

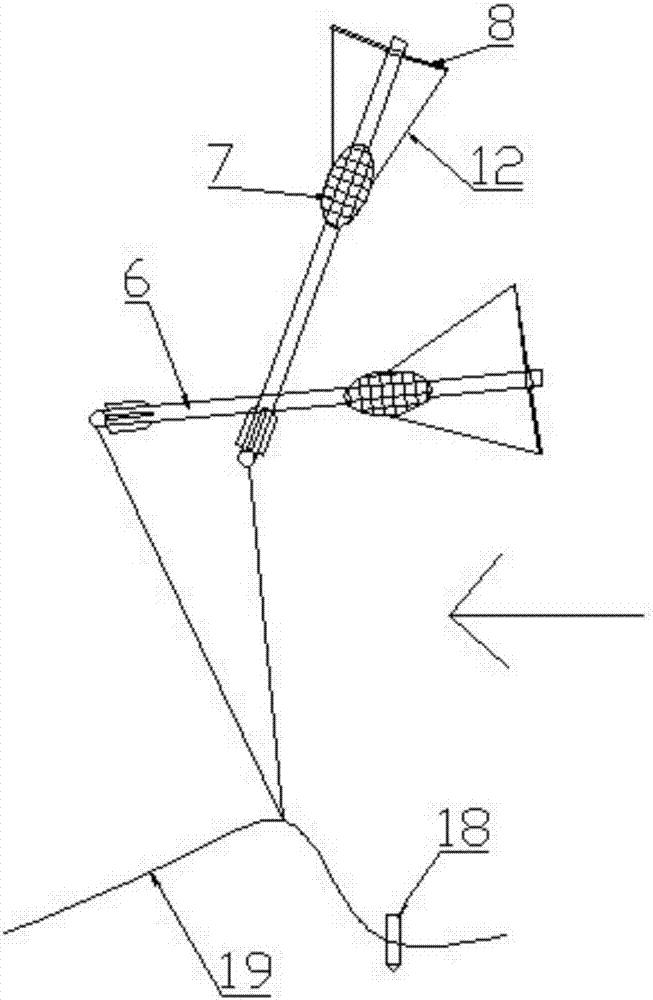

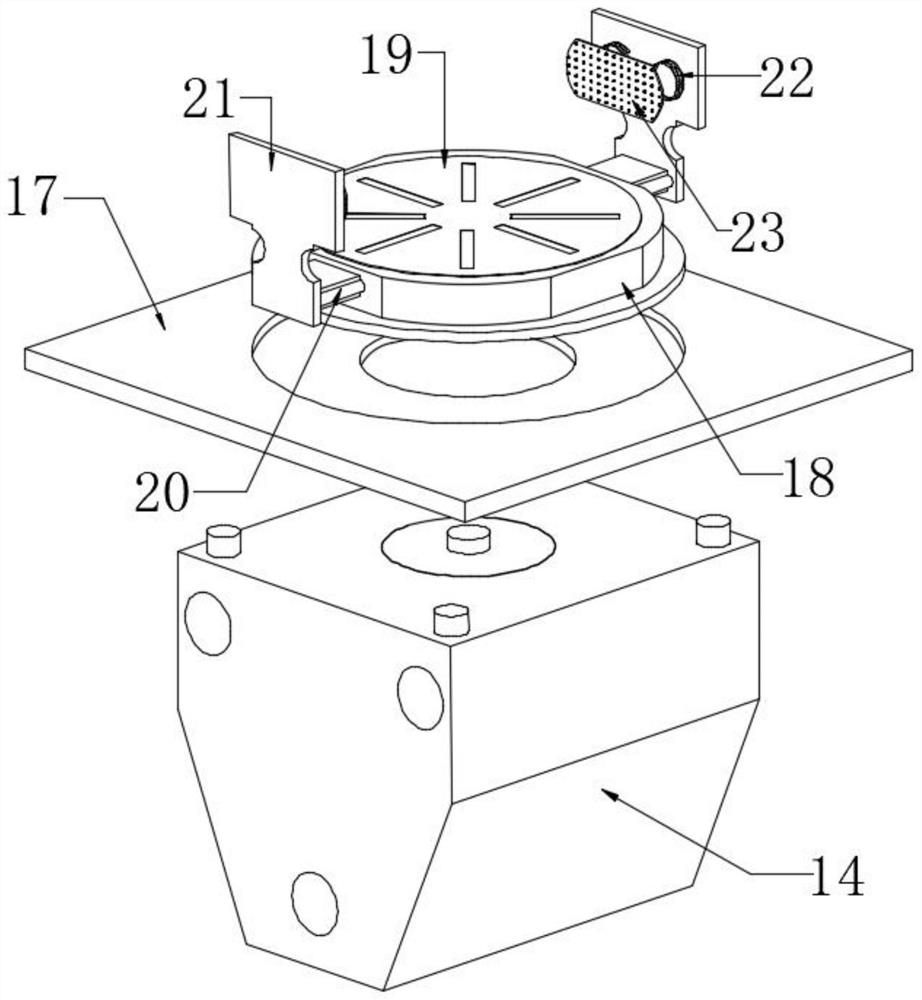

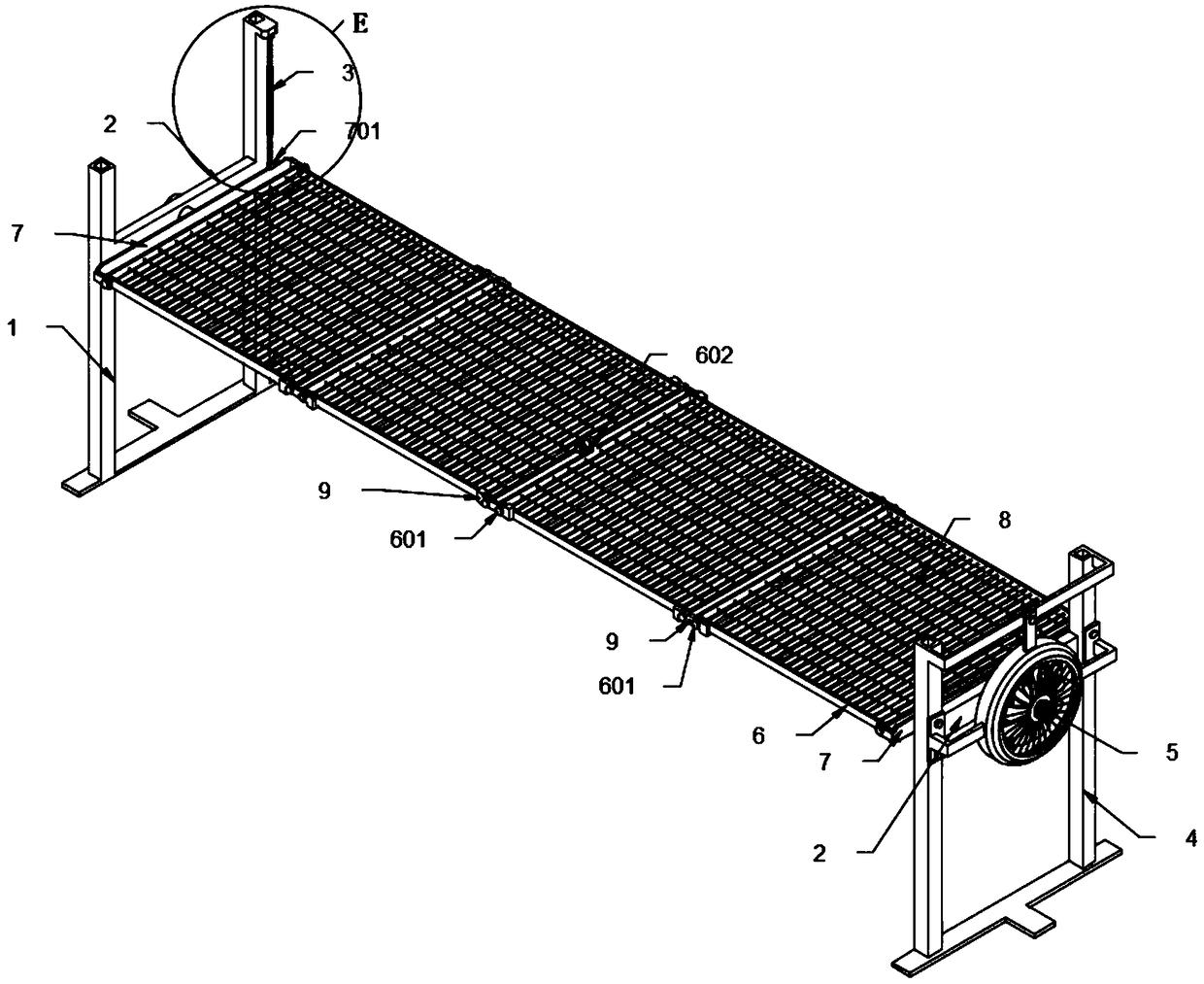

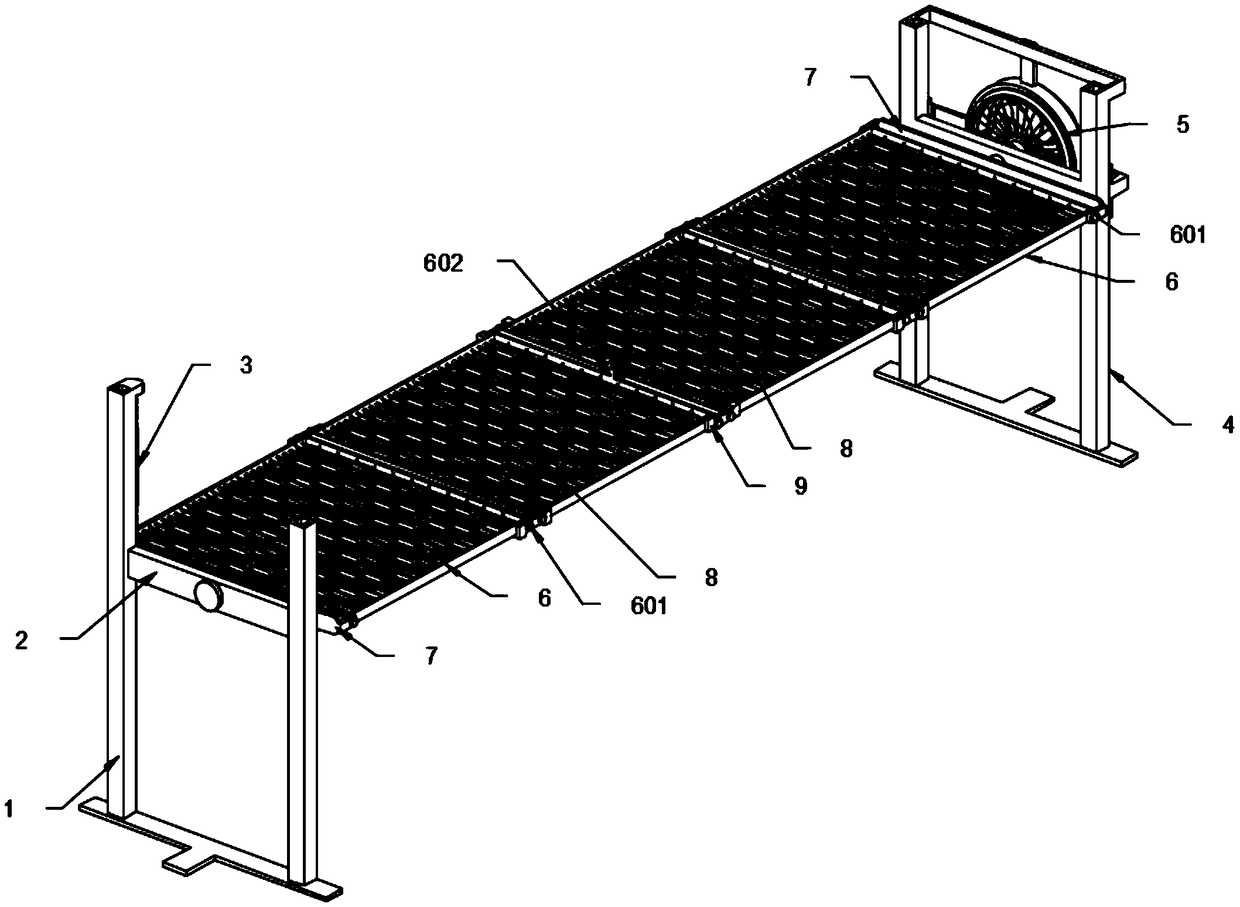

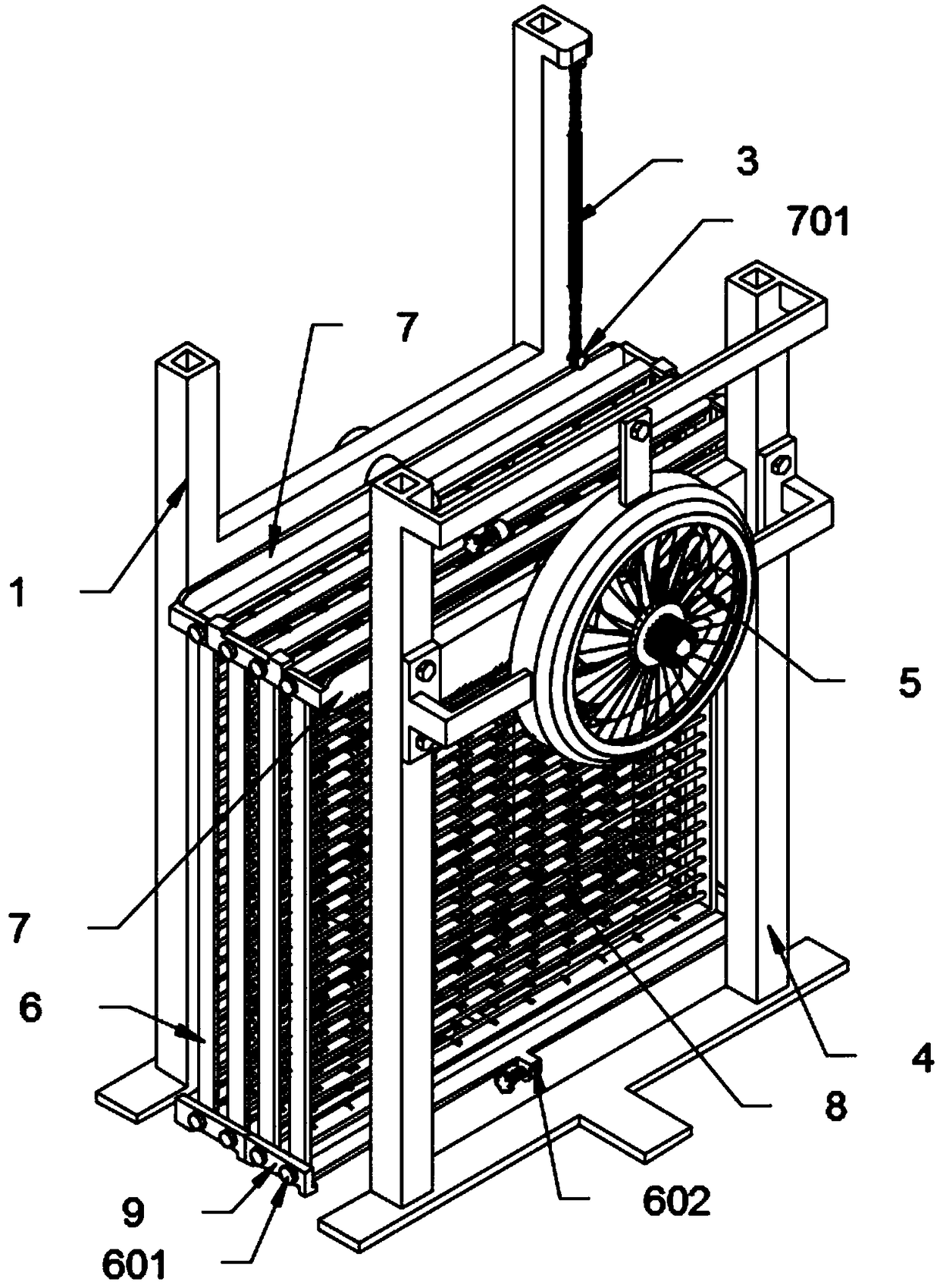

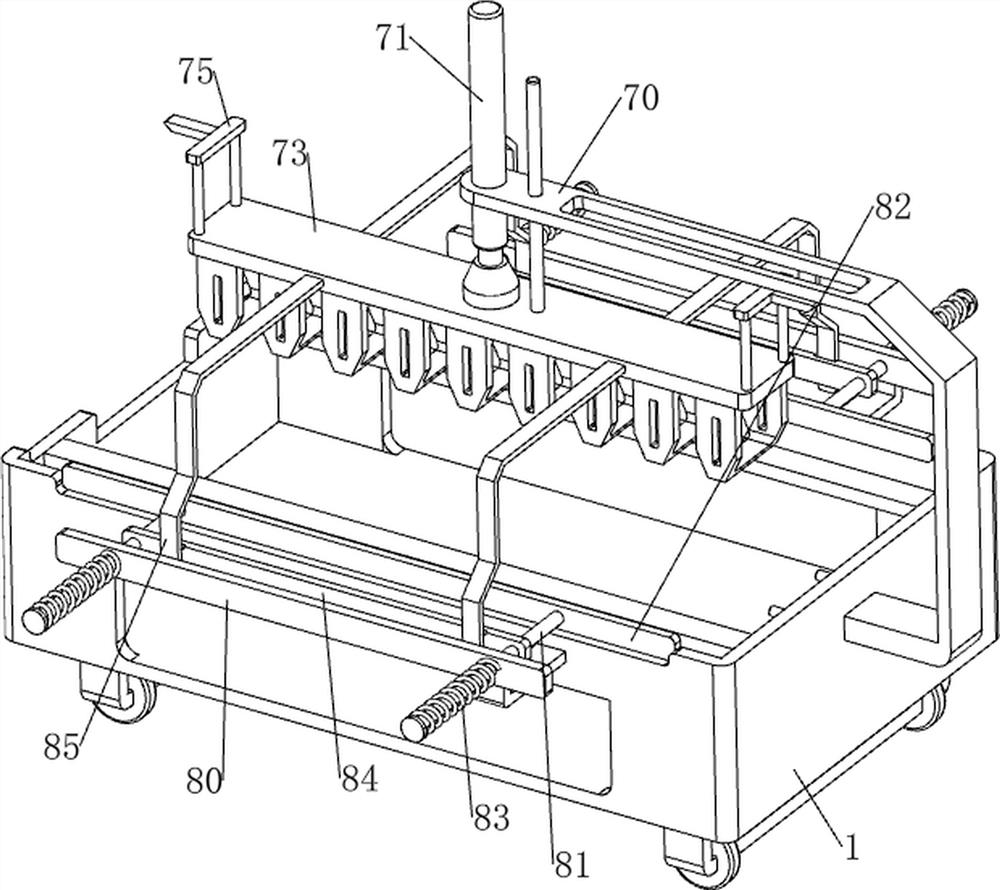

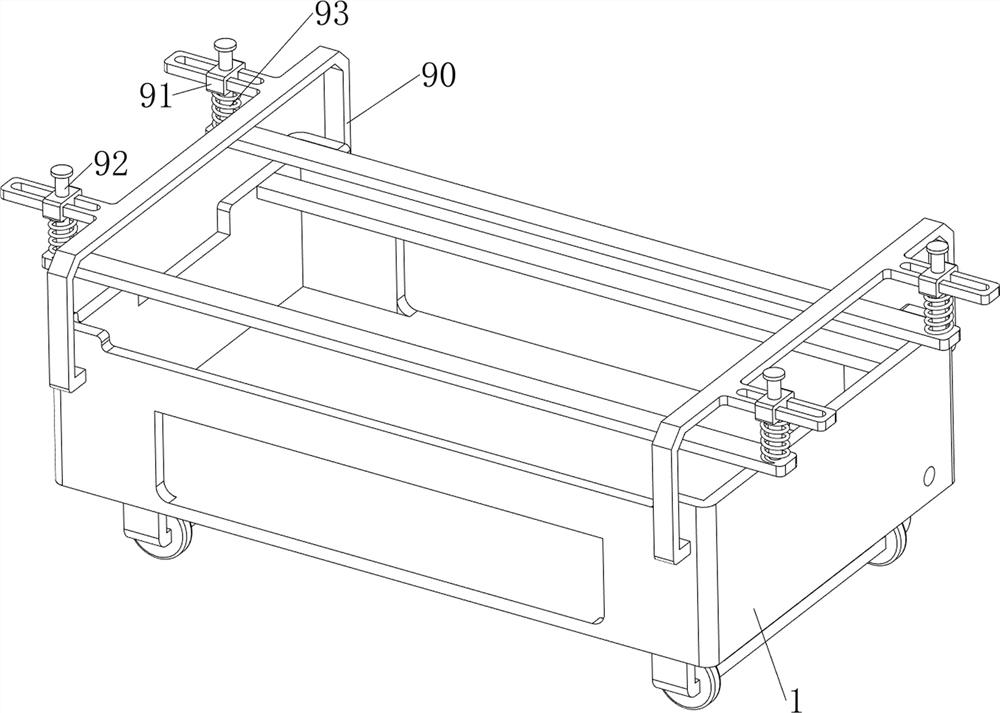

Crop sun-drying apparatus with adjustable irradiation angle

The invention provides crop sun-drying apparatus with adjustable irradiation angle. The crop sun-drying apparatus with adjustable irradiation angle comprises a left support frame, twin-head screw tighteners, a lock-up positioning table, a rotating frame, positioning rings, sun-drying nets and rotating-connecting flakes; T-shaped support plates are welded to bottoms of both the left support frame and the right support frame; connecting traverse rods are welded between upper sections of both the two support frames; each of the rotating-connecting flakes is arranged as a rectangle as a whole; tworotating holes are symmetrically formed on each of the rotating-connecting flakes in a penetrating way; and two bent bearing plates are supported by vertically bent symmetrical bulges on top sides ofthe rotating-connecting flakes. By arranging the twin-head screw tighteners, the crop sun-drying apparatus is capable of driving sun-drying net frames around to rotate via tightening of the twin-headscrew tighteners caused by rotation of the twin-head screw tighteners, so that adjustment on sun-drying angle of the crop sun-drying apparatus is realized; moreover, the twin-head screw tighteners are also capable of performing real-time hanging-tightening positioning on arbitrary rotation angle of the driving sun-drying net frames around so as to maintain the driving sun-drying net frames at adjusted posture.

Owner:吴志强

Dryer for producing mineral processing xanthate

ActiveCN114526589AEasily brokenAffect the drying effectDrying gas arrangementsDrying chambers/containersProcess engineeringXanthate

The invention discloses a dryer for mineral processing xanthate production, and belongs to the technical field of xanthate drying equipment.The dryer comprises a drying box, a xanthate feeding mechanism, a throwing mechanism, a first drying mechanism and a discharging pipe, the xanthate feeding mechanism is arranged over the drying box, the throwing mechanism is arranged in the drying box, and the first drying mechanism is arranged in the drying box; the xanthate feeding mechanism is arranged on the drying box, the throwing mechanism is arranged on the xanthate feeding mechanism and located under the xanthate feeding mechanism, the first drying mechanism is arranged at the side end of the drying box and located between the xanthate feeding mechanism and the throwing mechanism, and the discharging pipe is arranged on the drying box and located on the opposite side of the first drying mechanism. According to the xanthate drying device, xanthate can be prevented from being in a clustering state in the drying process, the xanthate is scattered through the xanthate feeding mechanism, and then the xanthate is dried through the first drying mechanism, so that the xanthate drying efficiency is improved, and the quality of the discharged xanthate is improved.

Owner:YANTAI HUMON CHEM AUX CO LTD

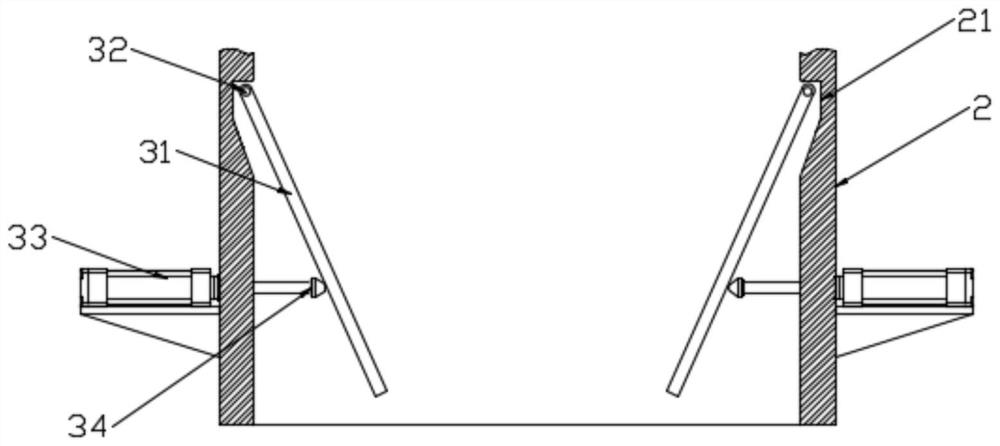

Biological medicine traditional Chinese herbal medicine drying device

InactiveCN113776294AImprove drying efficiencyAffect the drying effectDrying chambers/containersDrying solid materialsHerb medicineBiology

The invention relates to a drying device, and particularly relates to a biological medicine traditional Chinese herbal medicine drying device. The invention aims to provide the biological medicine traditional Chinese herbal medicine drying device which can dry herbal medicines at any time and can ensure that all positions of the herbal medicines are dried. The biological medicine traditional Chinese herbal medicine drying device comprises a frame body, supporting plates, rolling wheels, heating wires, a door frame mechanism and a feeding mechanism, the supporting plates are symmetrically connected to the two sides of the frame body, the rolling wheels are rotationally connected to the supporting plates, the heating wires are arranged on the frame body, the door frame mechanism is arranged on the frame body, and the feeding mechanism is arranged on the frame body. The biological medicine traditional Chinese herbal medicine drying device is provided with a descending mechanism, traditional Chinese herbal medicine can be evenly divided into equal parts, and therefore the traditional Chinese herbal medicine drying efficiency is higher.

Owner:黄红娟

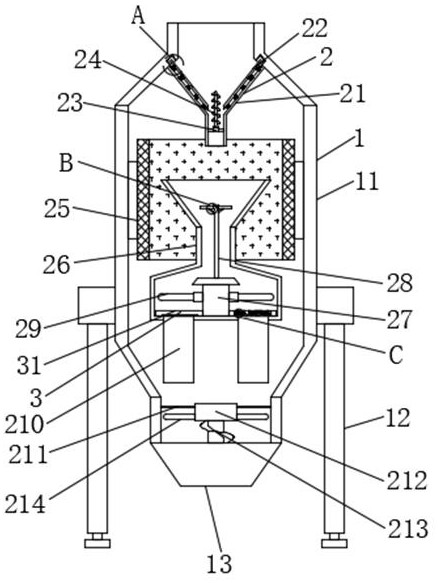

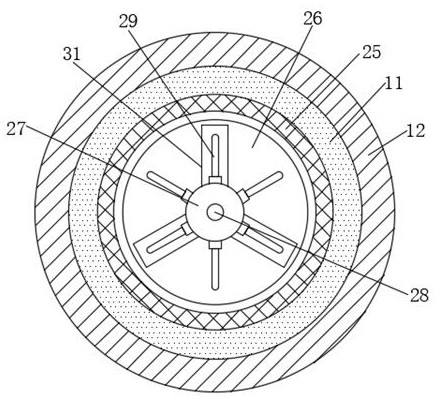

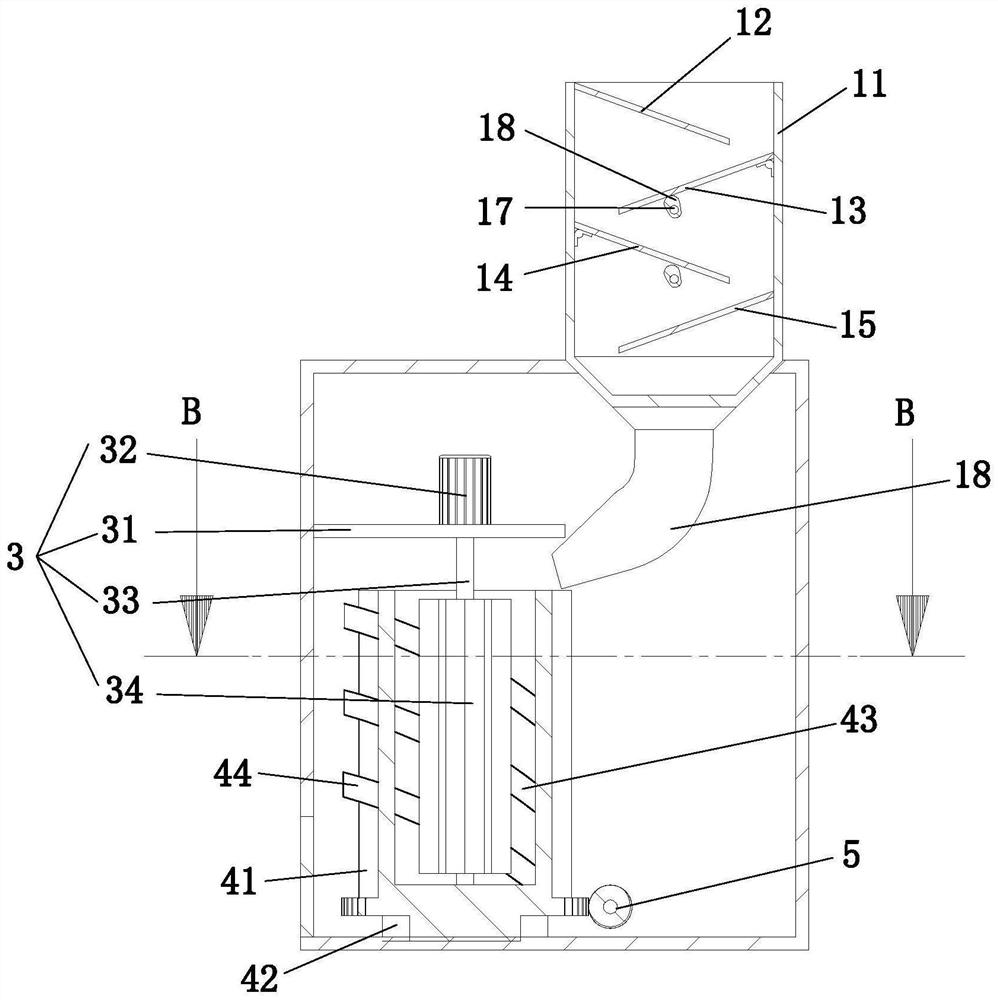

A tower dryer for Angelica dahurica

ActiveCN107062869BExtended drying timeAffect the drying effectDrying gas arrangementsDrying chambers/containersWater vaporWater source

The invention relates to a tower type dryer for radix angelicae. The tower type dryer comprises a base, a material storage box, a drying tower, a condensing chamber and a single chip microcomputer. One side of the top end of the base is provided with a supporting frame, the other side of the top end of the base is provided with a condensing box, the two sides inside the drying tower are both provided with heating plates, and one end inside the drying tower is provided with a motor chamber; the end, away from a warm air machine, of the bottom end inside the material storage box is provided with a pressure sensor, the end, close to the hot air machine, of the bottom end inside the material storage box is provided with a humidity sensor, and the output end of the humidity sensor is electrically connected with the input end of the single chip microcomputer through a wire. Through the installation of a condensing pipe and a sucking pump, when the radix angelicae is dried, hot steam in the drying tower can be condensed through the condensing pipe, condensed water is stored in a water tank, and the situation that the drying effect is influenced due to condensation of water steam inside the drying tower is avoided; and meanwhile, a water source is recycled, and the tower type dryer is more environmentally friendly.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com