Tidal range automatic drying cultivation method for laver culture

A breeding method and technology of tidal range, which is applied in the field of self-drying laver cultivation with tidal range, can solve the problems of limited length and strength of the pole, long operation time, and high labor intensity, so as to reduce the labor intensity of drying, The effect of improving quality and output and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

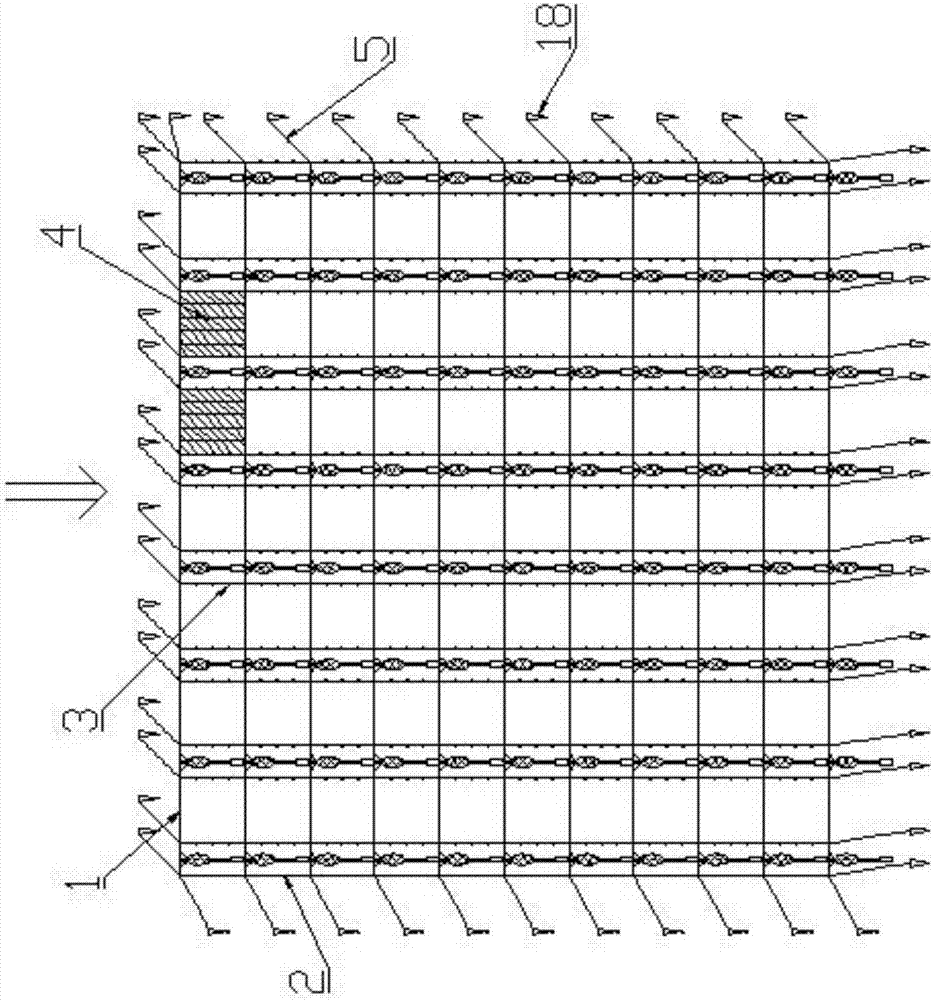

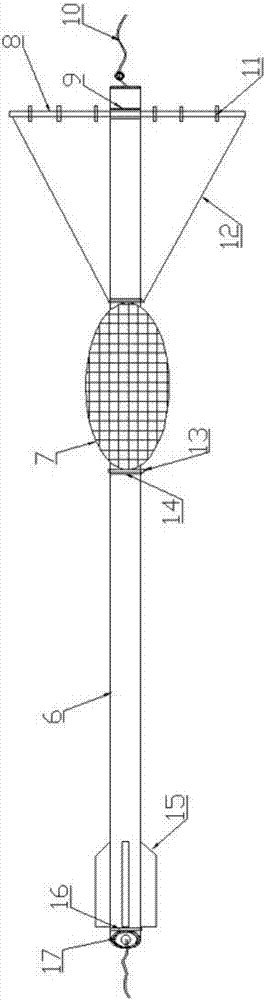

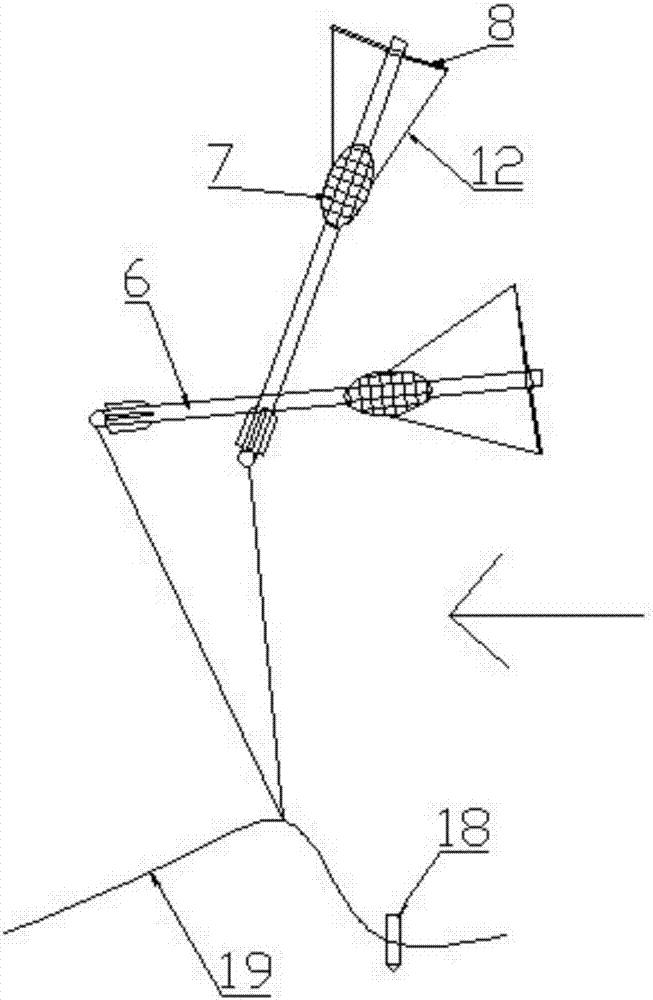

[0023] Embodiment 1, with reference to figure 1 and figure 2 , a kind of cultivation method of seaweed cultivation with tidal range self-drying type, the method adopts the cultivation device as described below, and the cultivation device is provided with a cultivation net field composed of several horizontal floating rods 1 and vertical floating rods 2. Several small floats 3 are arranged on each vertical floating rope 2, and a drying device group and a net curtain group are arranged at intervals between adjacent vertical floating ropes 2. 1 and the net curtain 4 on the vertical floating rope 2, each row of drying device group is composed of a number of self-drying devices, and the floating rod 8 on each self-drying device is fixed on the horizontal floating rope 1 by fasteners; Several culture net field root cables 5 are arranged on the horizontal float 1 and the vertical float 2 around the culture net field;

[0024] The self-drying device includes a hollow pick rod 6 and...

Embodiment 2

[0027]Embodiment 2, in the laver cultivation described in embodiment 1, in the tidal range self-drying type cultivation method: the rod body of the hollow pick rod 6 is composed of a plastic inner tube and a composite material outer tube compounded outside the plastic inner tube. A foam layer is arranged between the plastic inner pipe and the composite material outer pipe, and pipe plugs 17 with through holes are arranged at both ends of the hollow pole.

Embodiment 3

[0028] Embodiment 3, in the laver cultivation described in embodiment 1, in the tidal range self-drying type culture method: the hollow pick rod 6 at the outer end of the tail wing 15 is provided with the first clamping hollow pick rod 6 rod tail and tail wing 15. A fastening hoop 16, the second fastening hoop 9 for clamping the floating rod 8 and the head of the hollow pole 6 is provided on the hollow pole 6 on both sides of the floating pole 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com