Patents

Literature

41results about How to "Easy to handle separately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

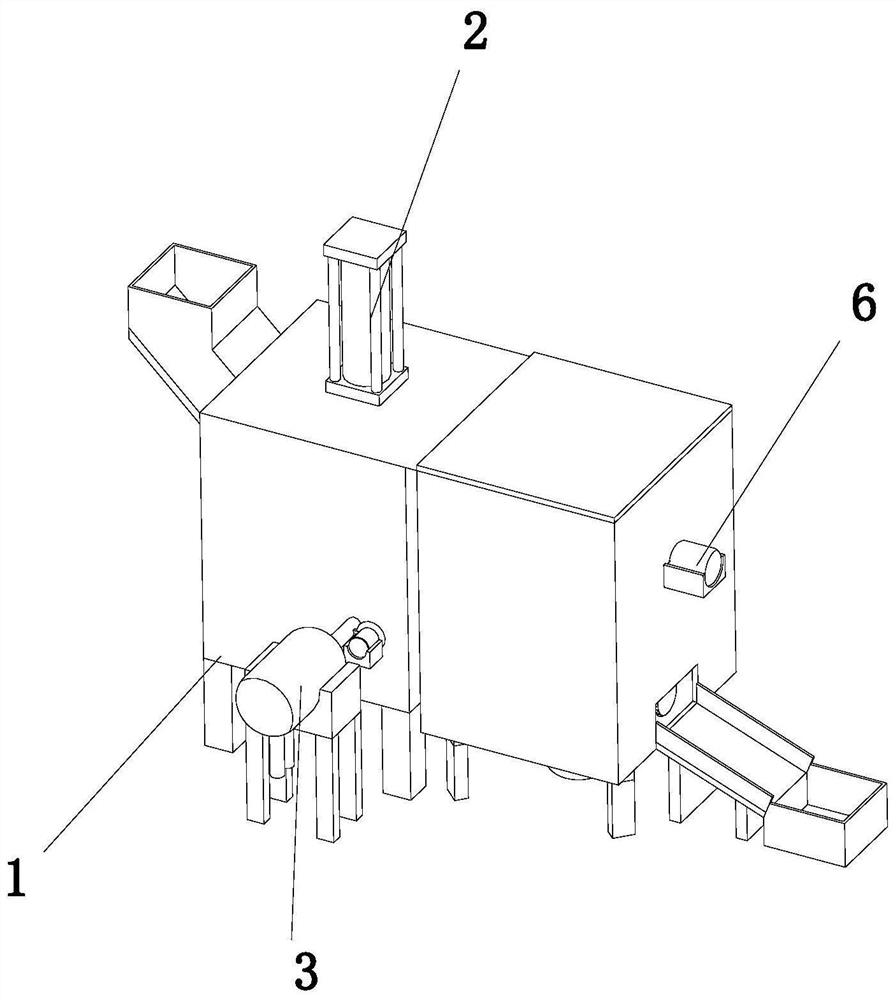

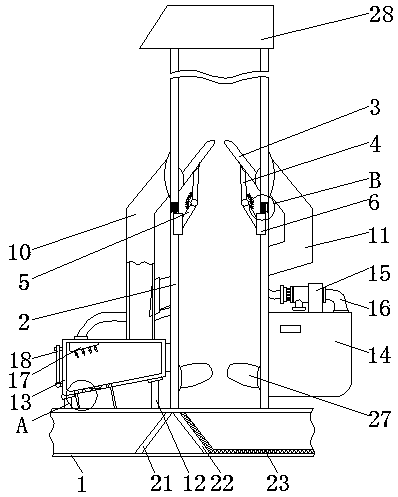

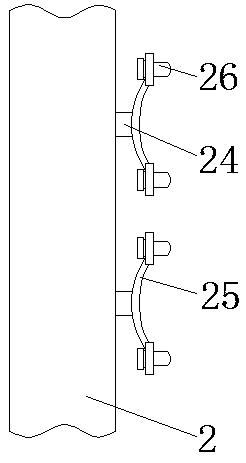

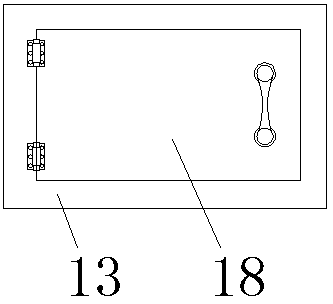

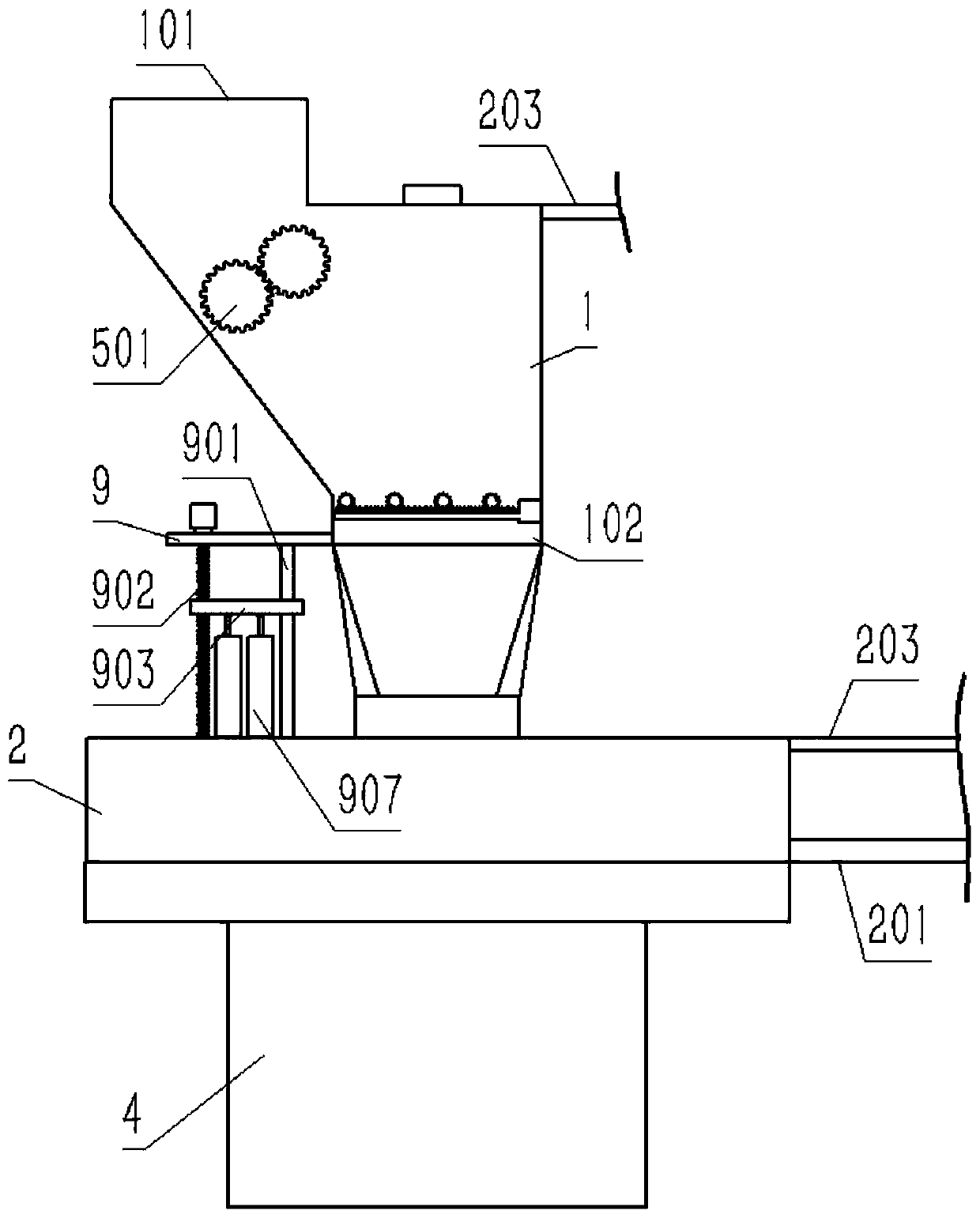

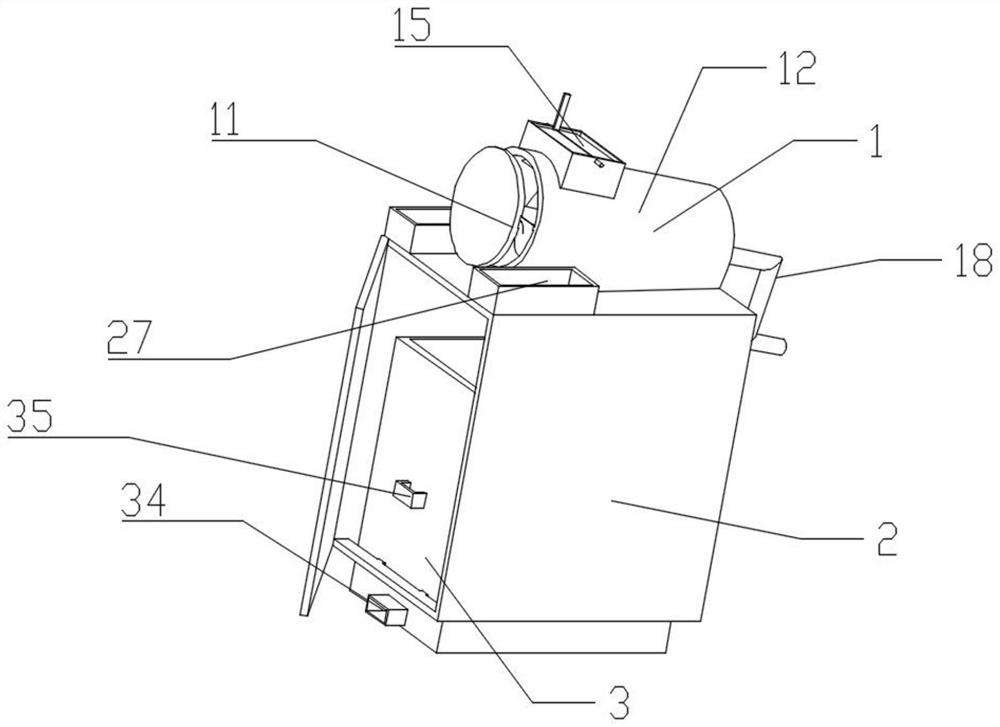

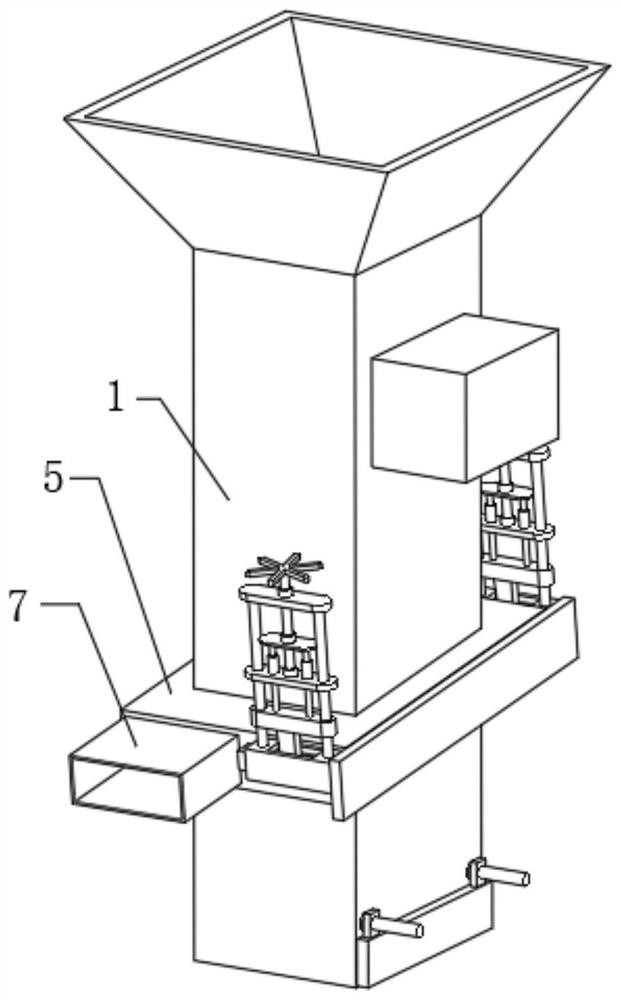

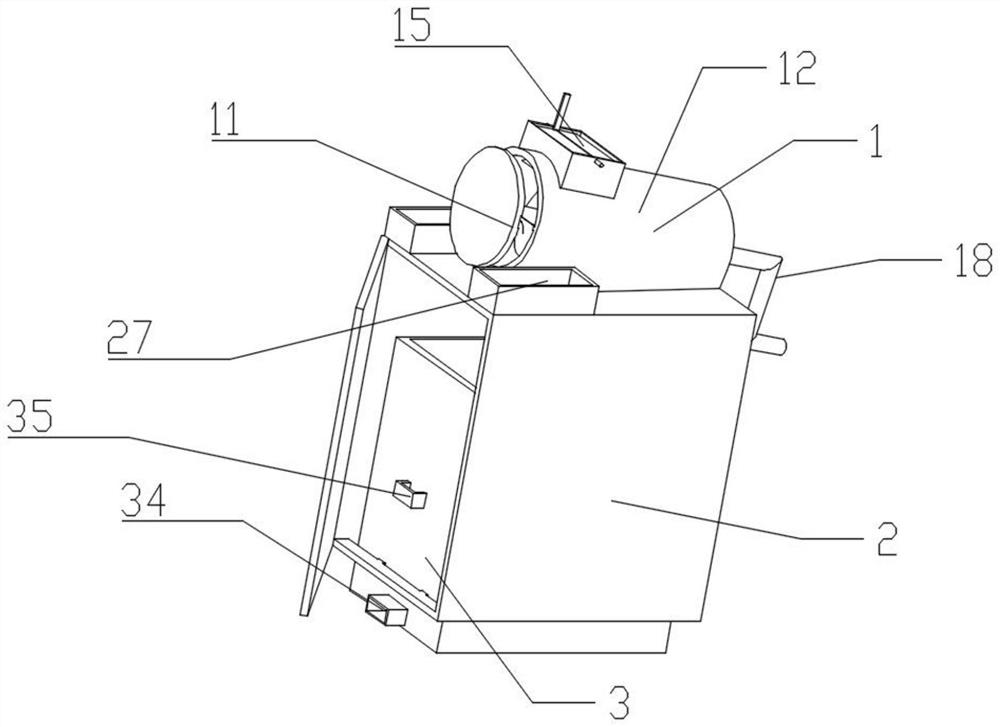

Automatic chip removal device for machine tool

ActiveCN112453994AAchieve up and down swingEasy to deal withMaintainance and safety accessoriesComputer hardwareElectric machinery

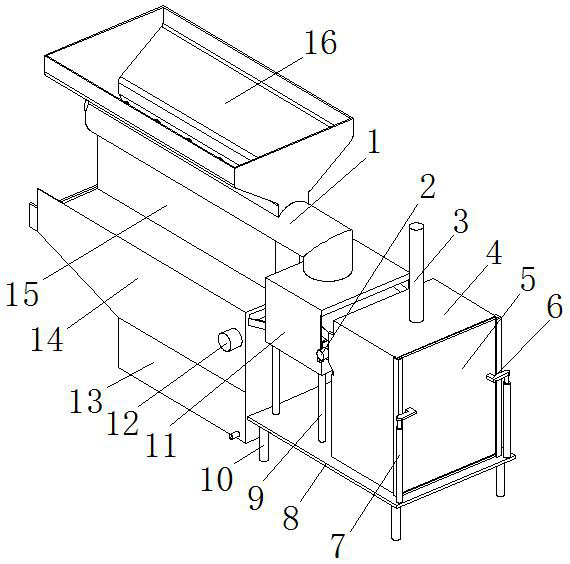

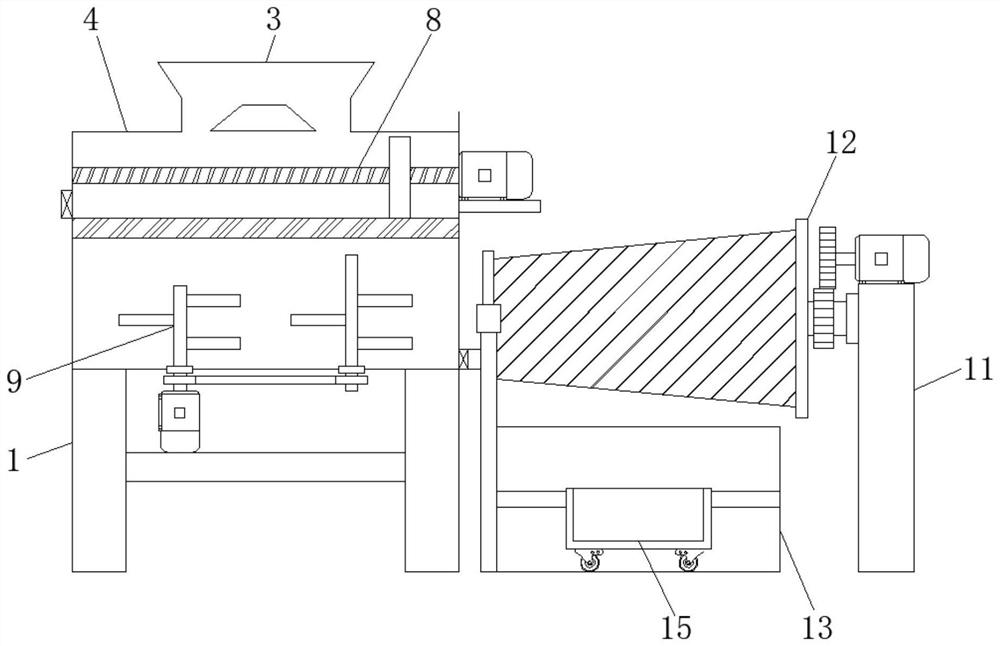

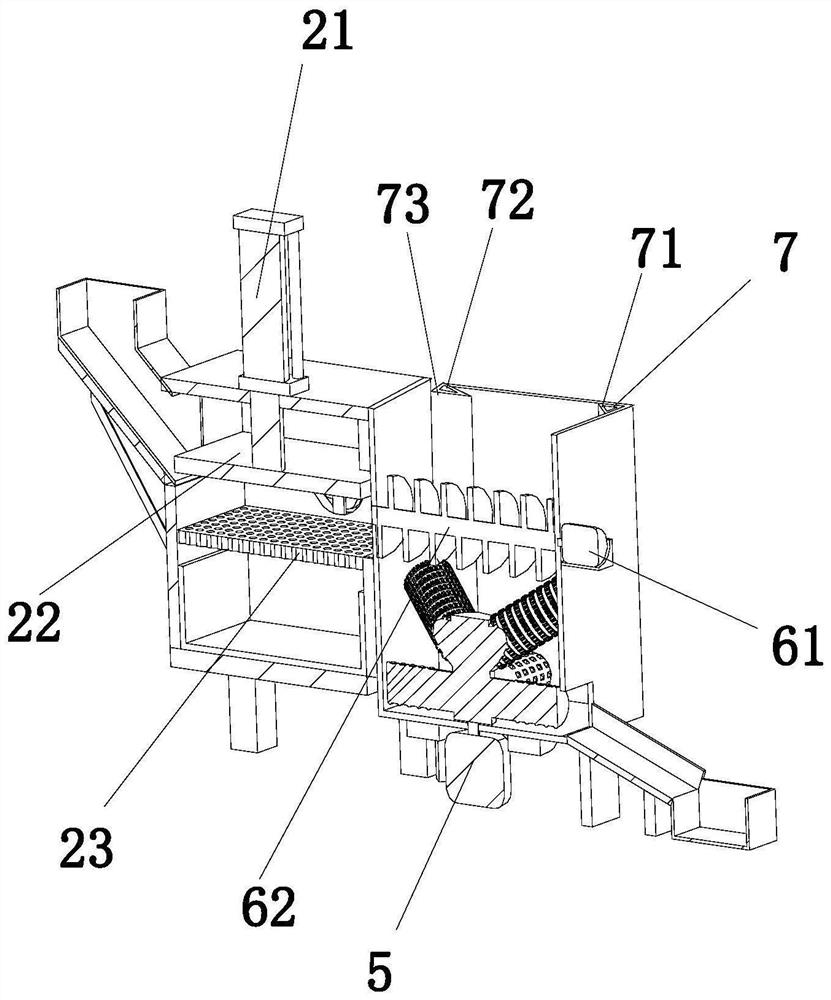

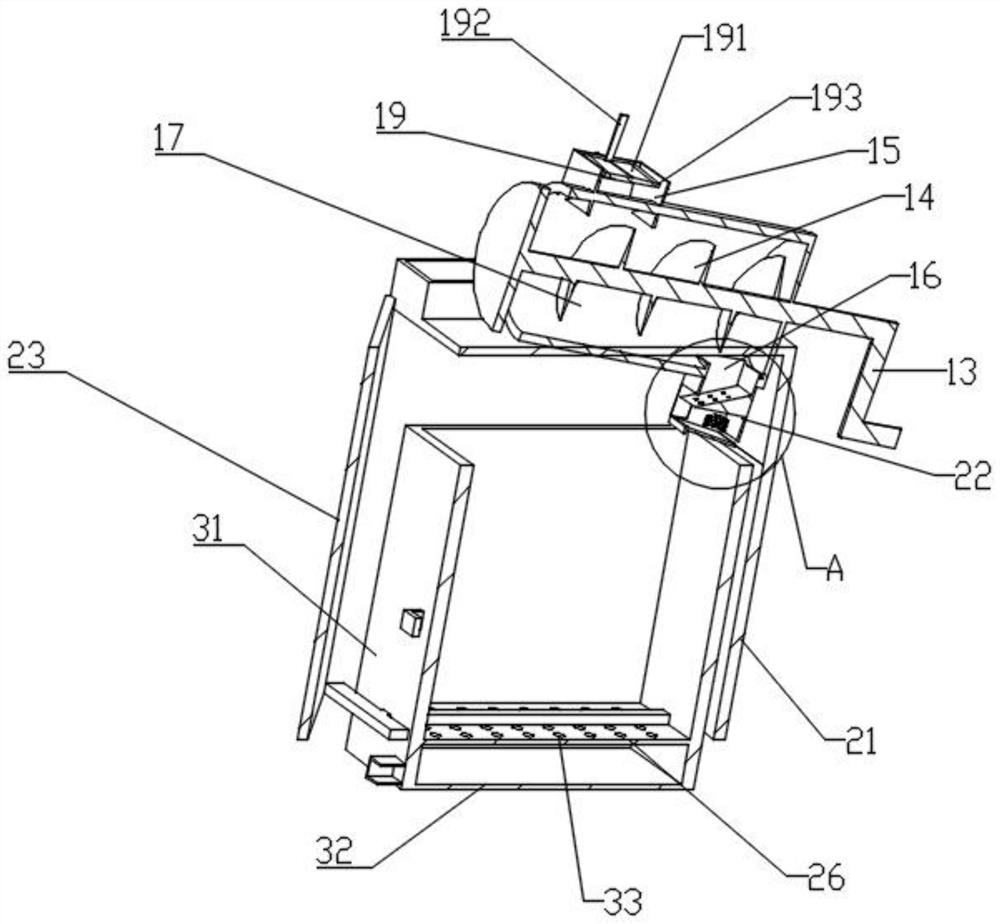

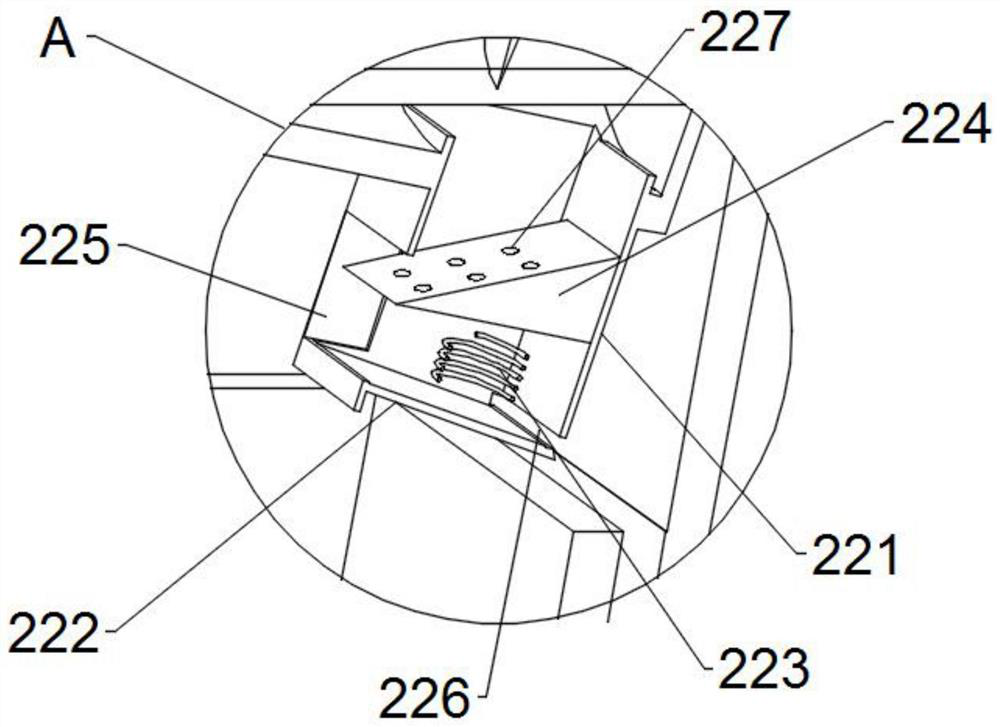

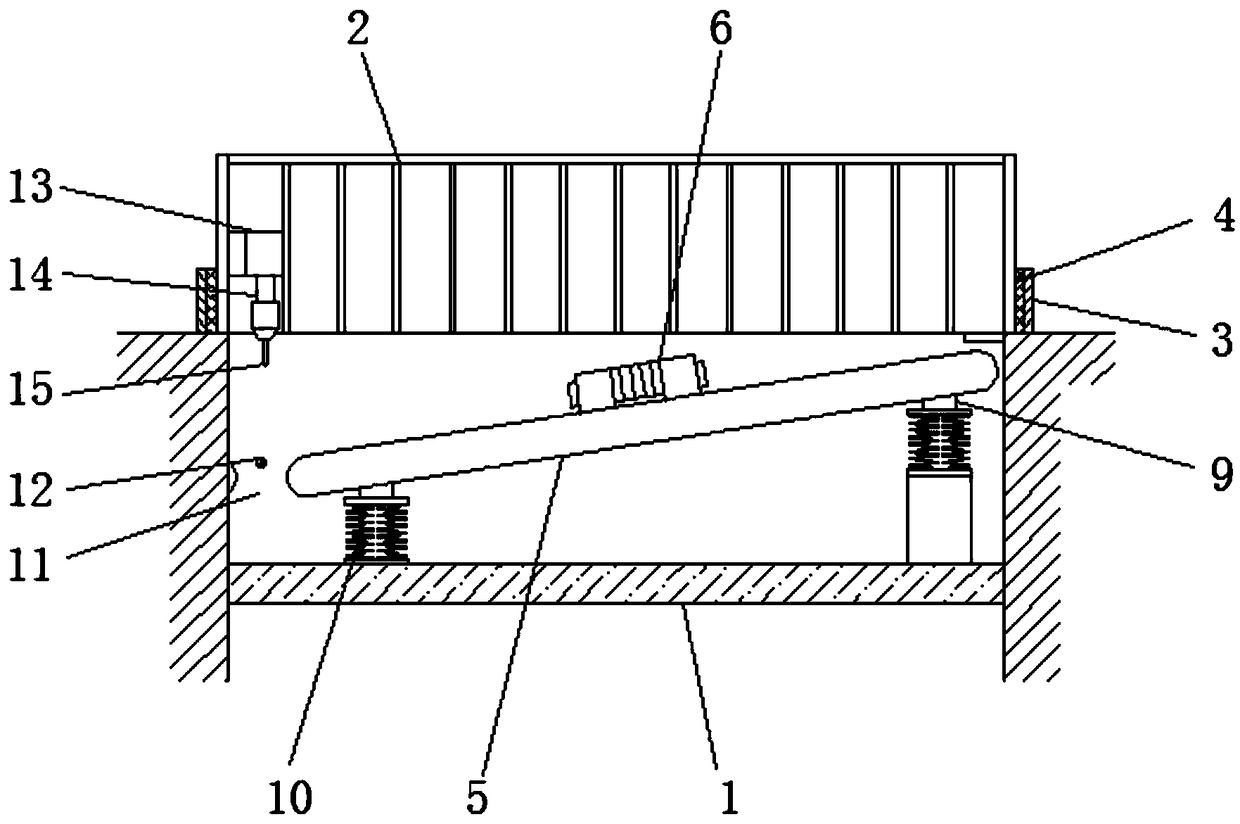

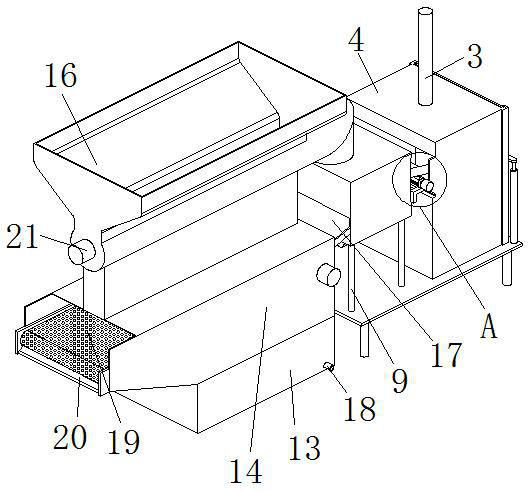

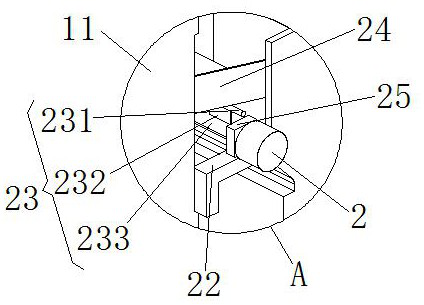

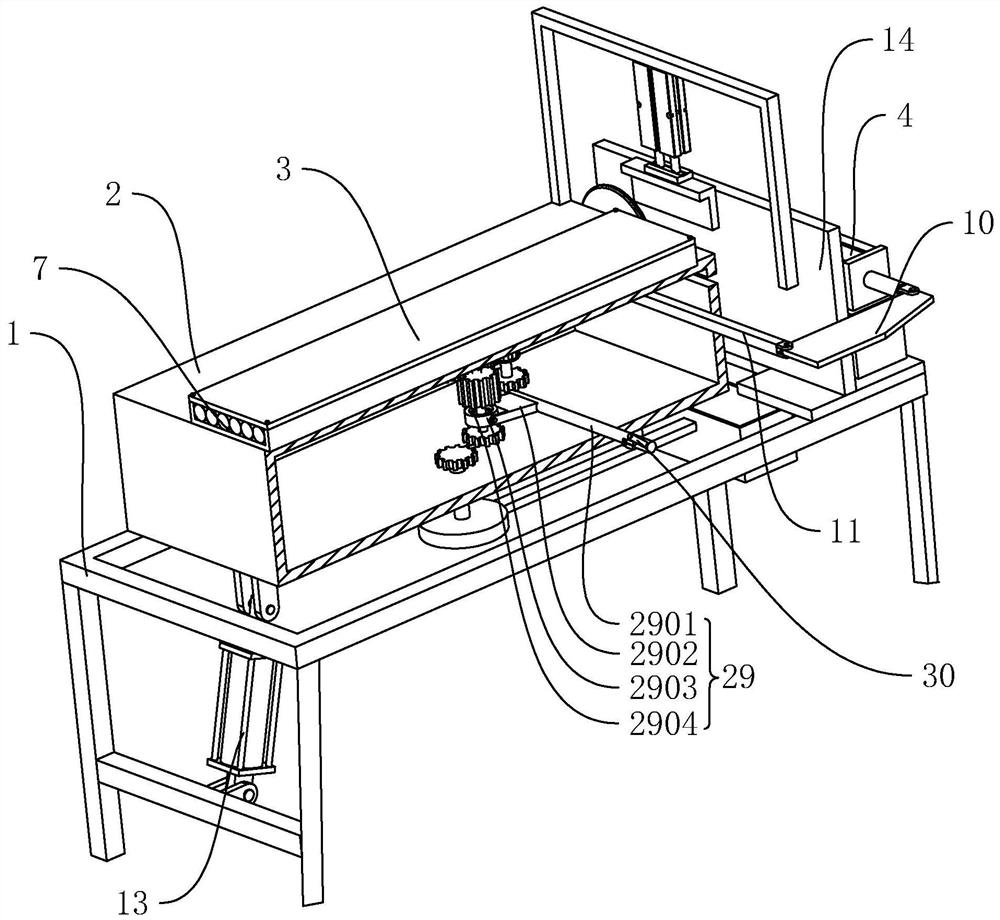

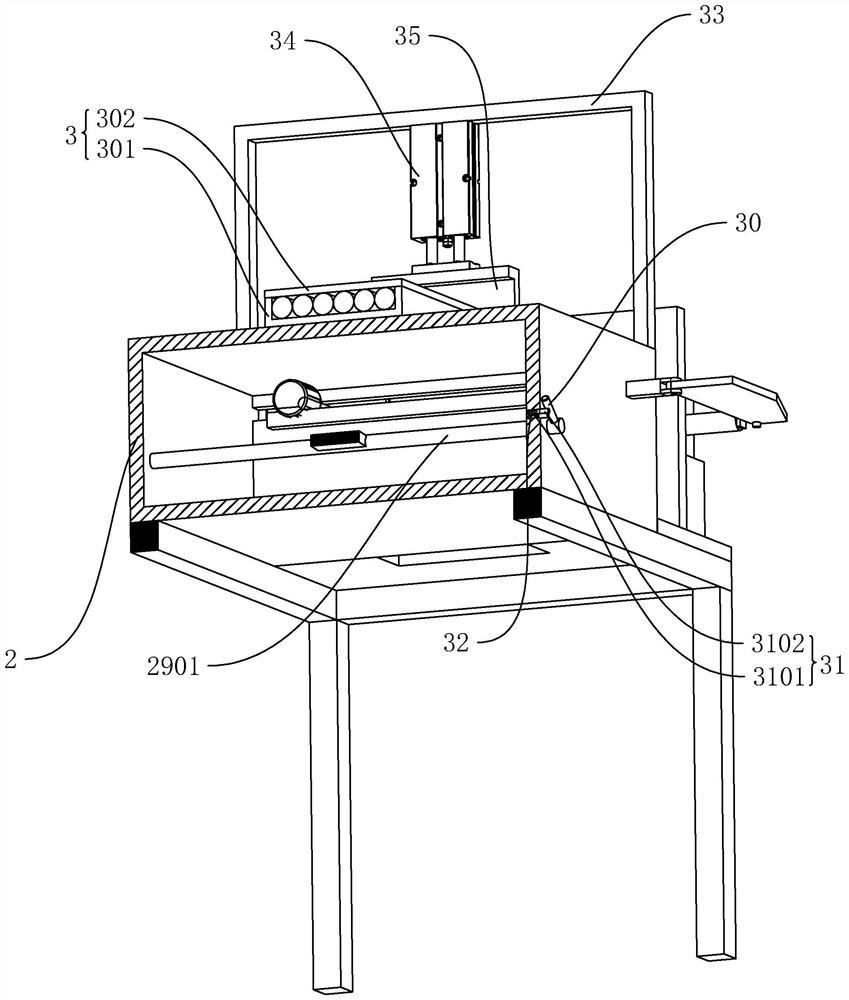

The invention discloses an automatic chip removal device for a machine tool. The device comprises a chip removal pipe, a chip compression box, a bottom plate, a slag-liquid separation box, a liquid storage box, a reciprocating swing mechanism and a conveying frame. A spiral discharging paddle is arranged in the chip removal pipe, a third motor is arranged at the left end of the chip removal pipe,and an output shaft of the third motor penetrates into the chip removal pipe and is connected with the spiral discharging paddle. A chip collecting groove is formed in the chip removal pipe, and the discharging end of the chip removal pipe is connected with the slag-liquid separation box. The conveying frame is arranged below the chip removal pipe, a roller is arranged on the conveying frame, a filtering conveying belt is arranged on the roller, cooling liquid and small-particle chips are separated through the filtering conveying belt, and the small-particle chips are conveyed out. A scrapingplate is arranged at the left end of the conveying frame. The automatic chip removal device for the machine tool is novel in structural design and good in chip removal effect, chip particles can be classified, separated treatment is facilitated, large chips are compressed, space is saved, frequent chip treatment is avoided, and time is saved.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

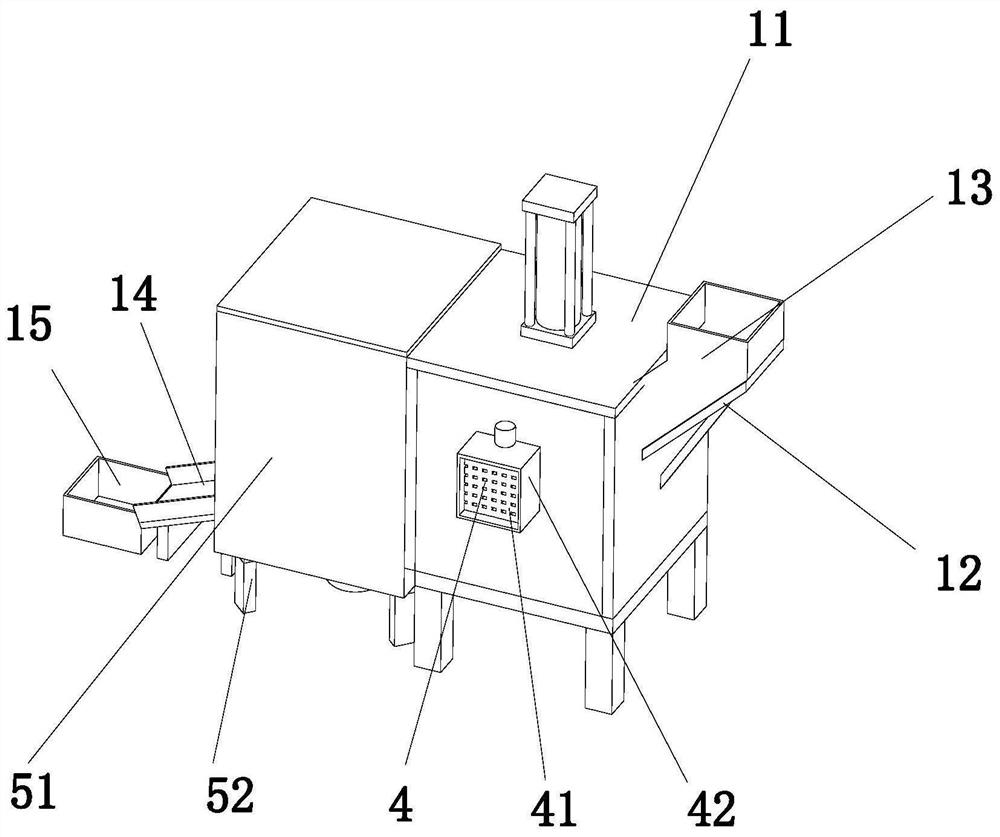

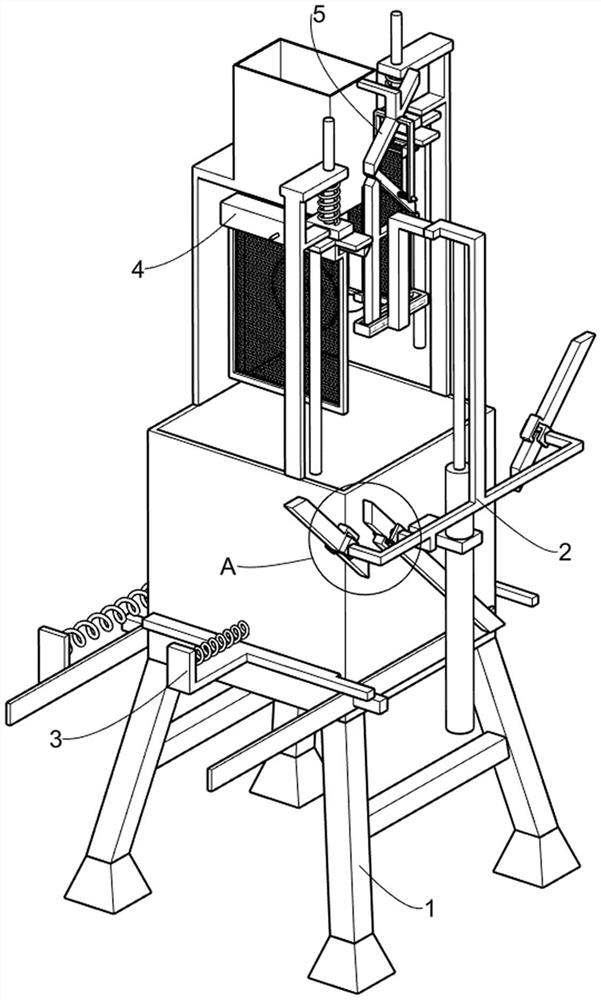

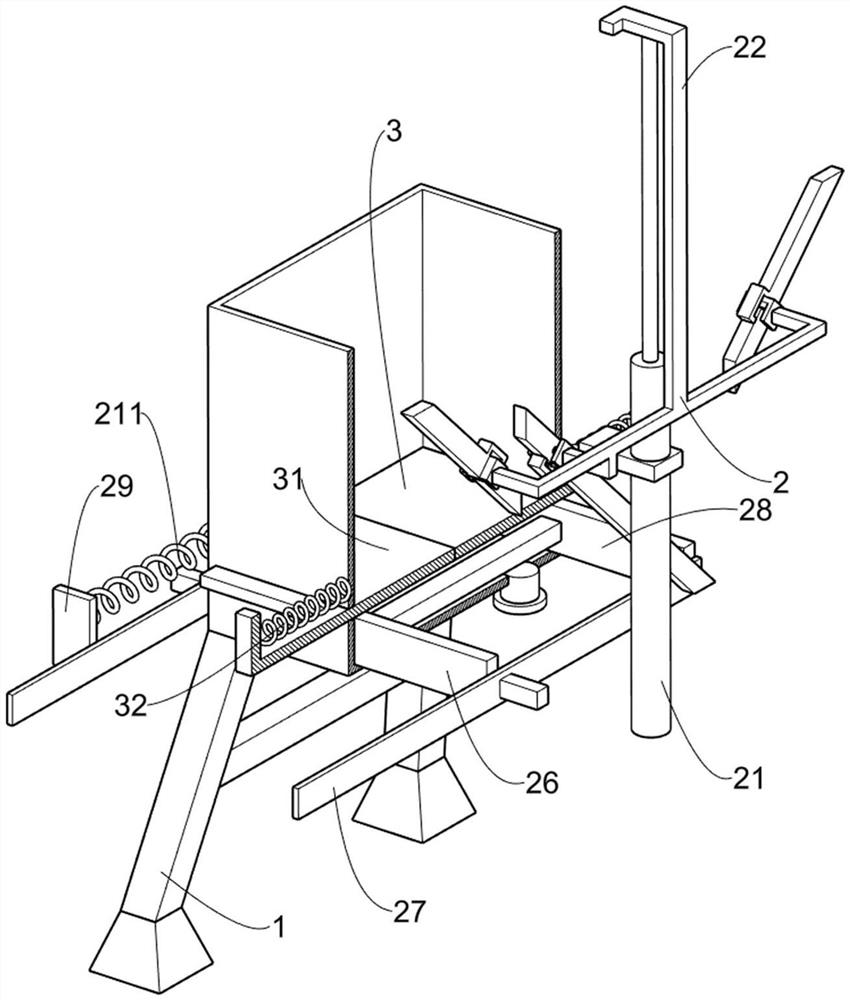

Silt separator with multilayer screening function for architectural engineering construction

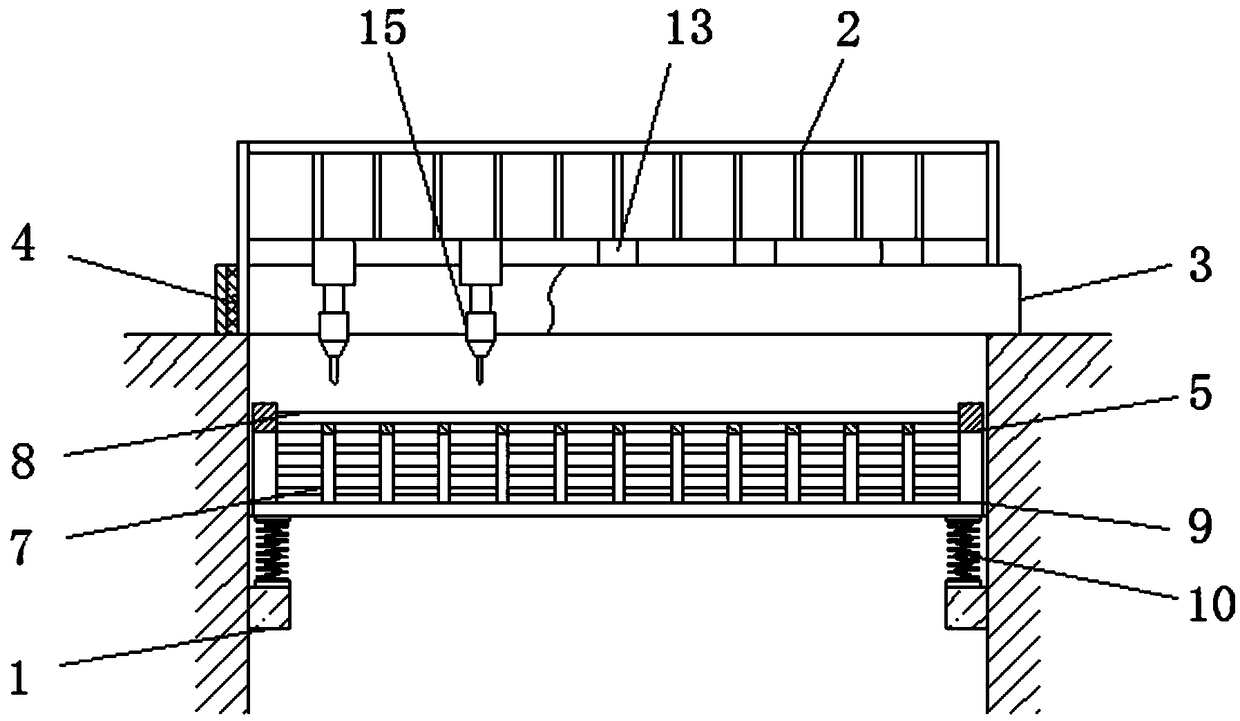

PendingCN112275621AAvoid cloggingSlow down the speed of entry into the subjectSievingGas current separationDrive wheelDrive shaft

The invention discloses a silt separator with a multilayer screening function for architectural engineering construction. The silt separator comprises a bracket, a rotating mechanism and a mud pool, and a main body is fixed to the upper side of the bracket; a vibration motor is fixed to the lower side of a filter plate; a waste opening is formed in the outer side of the filter plate, and a drivingshaft bearing is connected with the bottom of the main body; and a first motor is fixed to the right upper side of the main body, and a driven wheel is fixed to the right side of a rotating rod. Thesilt separator with the multilayer screening function for architectural engineering construction is provided with a second motor, first fan blades, a belt and second fan blades; silt is filtered through the filter plate, and then enters the lower side of the main body; a driving shaft is driven by the second motor to cooperate with a first belt wheel and the belt for driving a second belt wheel and the driven shaft to rotate at the same time, so that the silt is stirred through the first fan blades on the driving shaft and the second fan blades on the driven shaft; the mobility of the silt isimproved, and the separation speed of fine sand and mud in the silt is increased; and the working efficiency is improved.

Owner:徐州格雷安环保设备有限公司

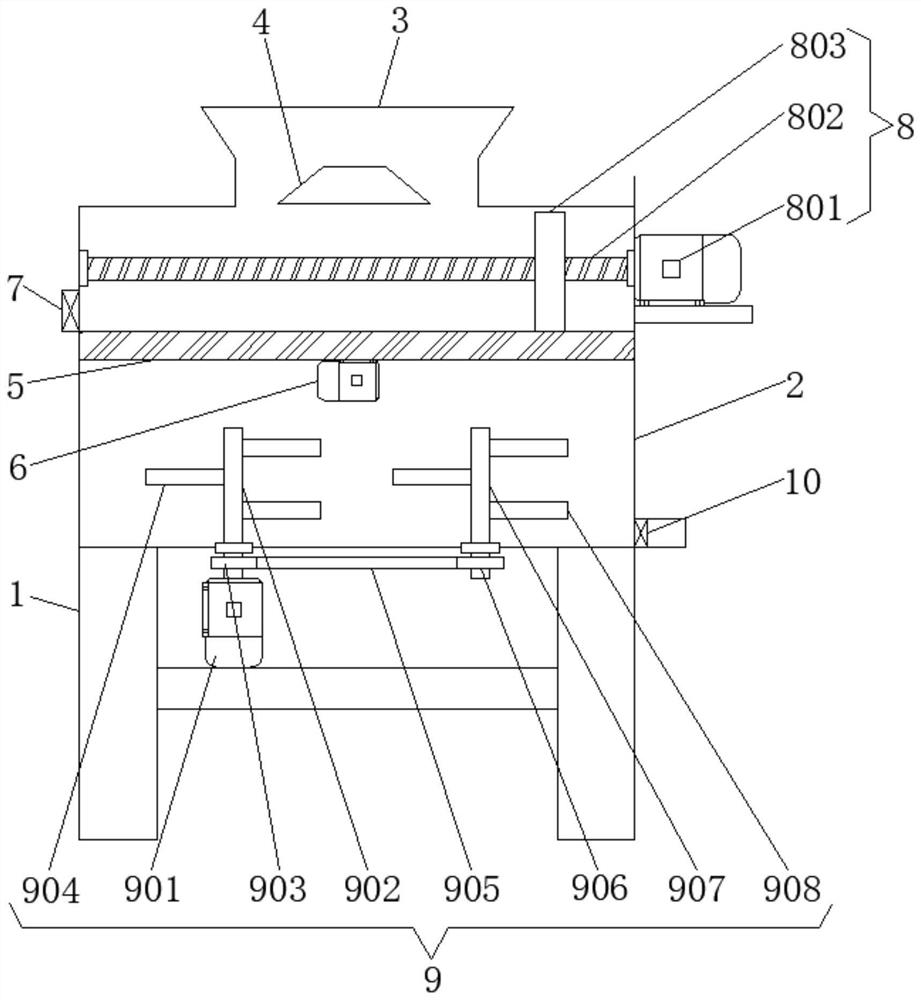

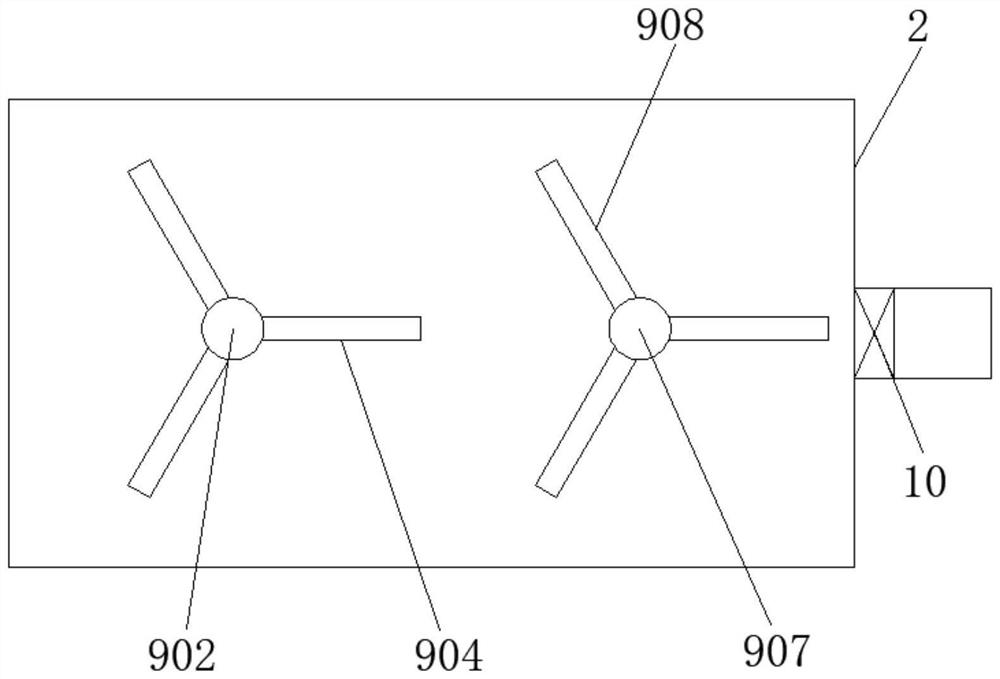

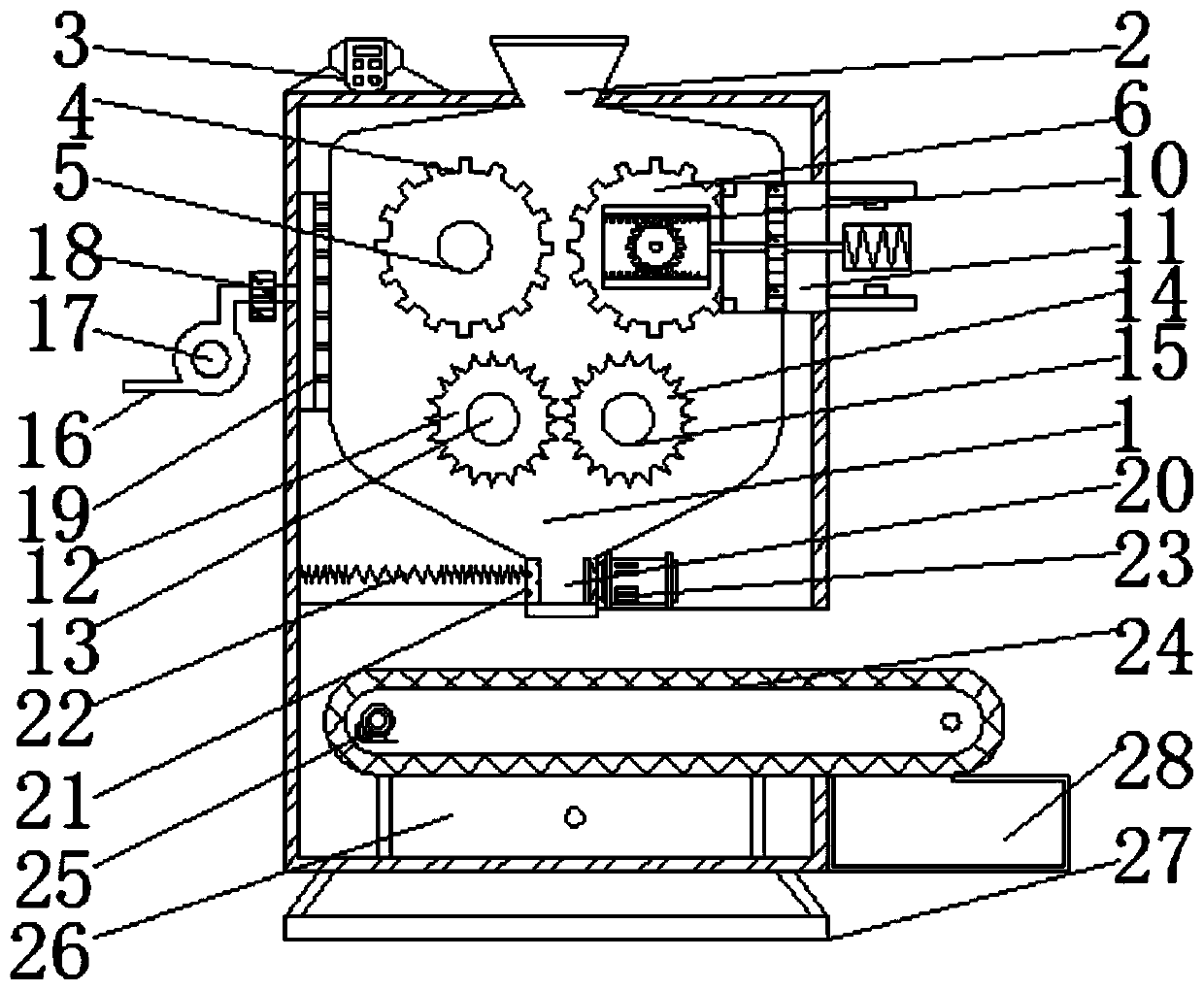

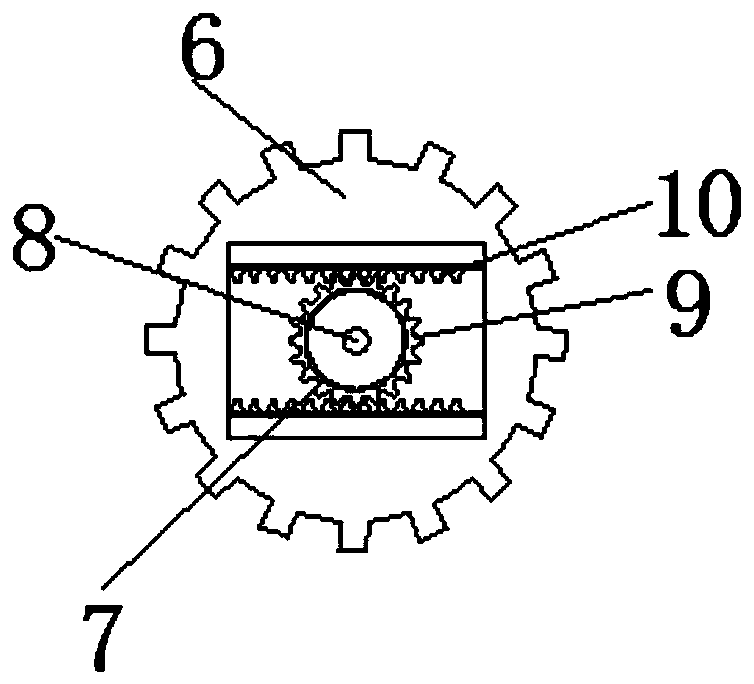

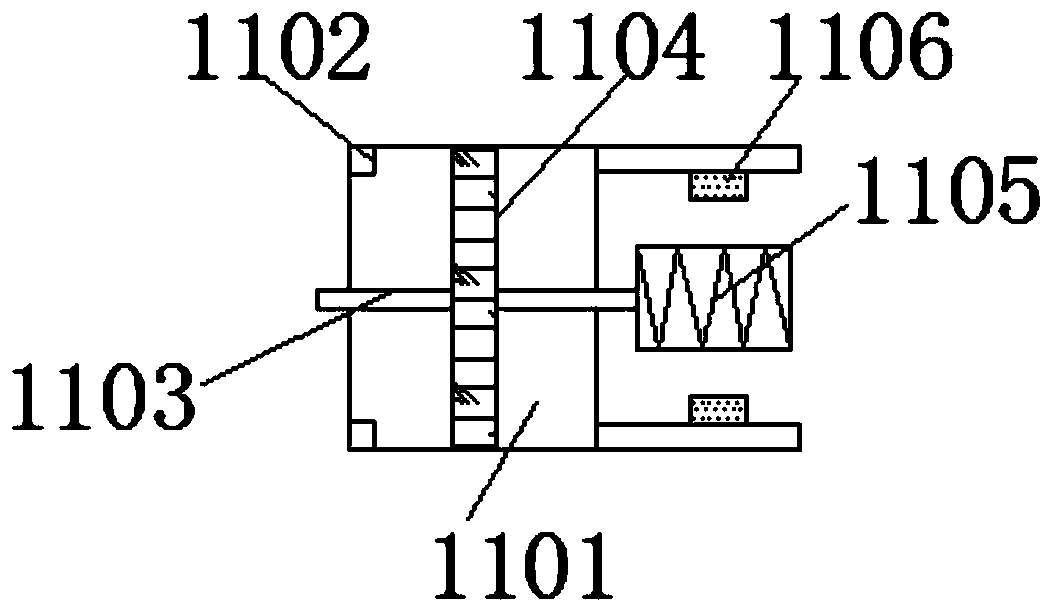

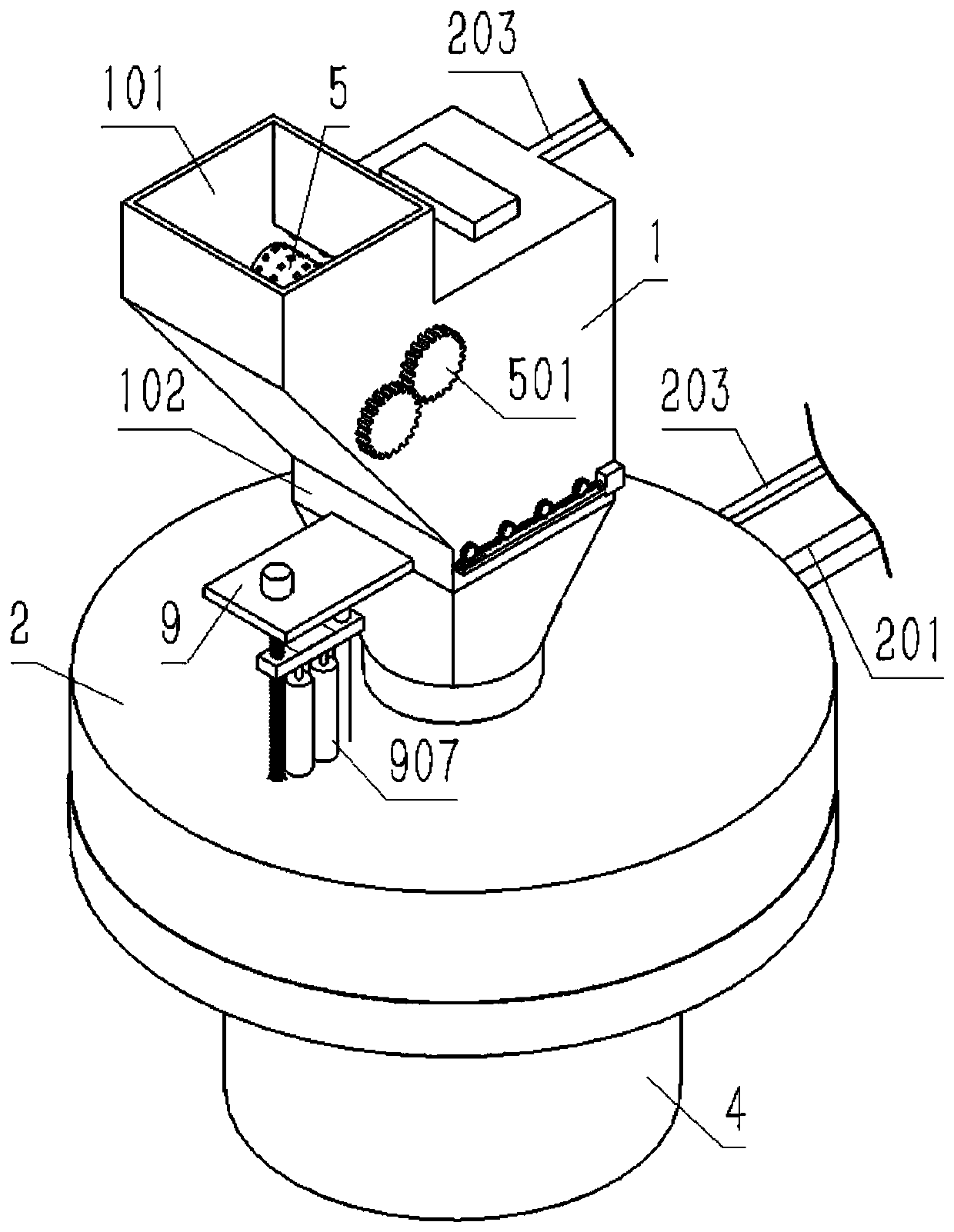

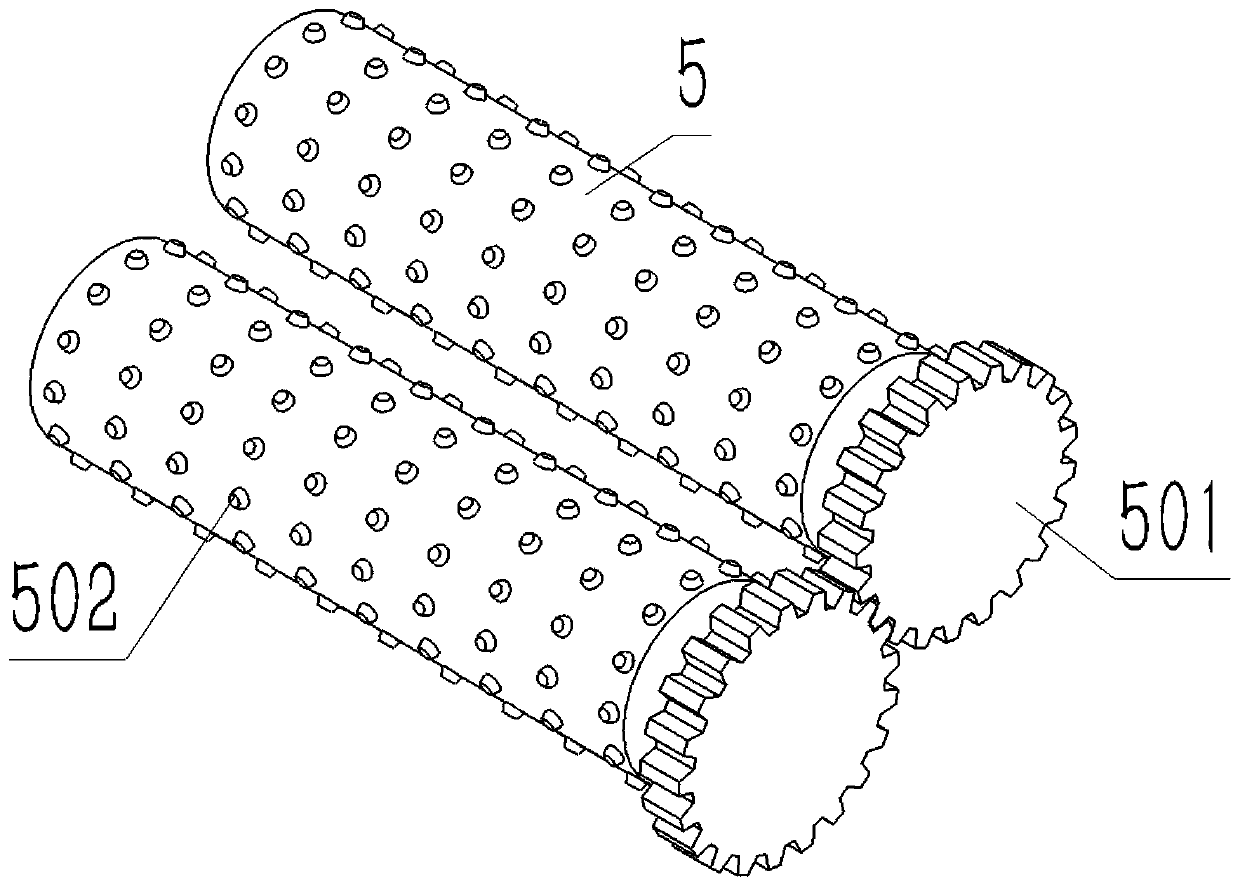

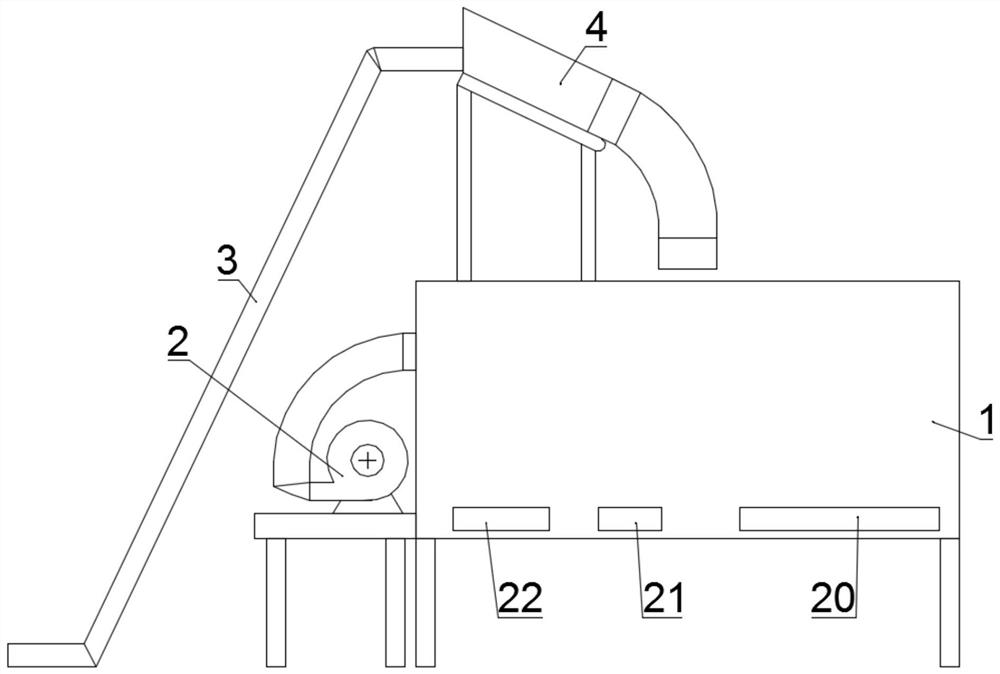

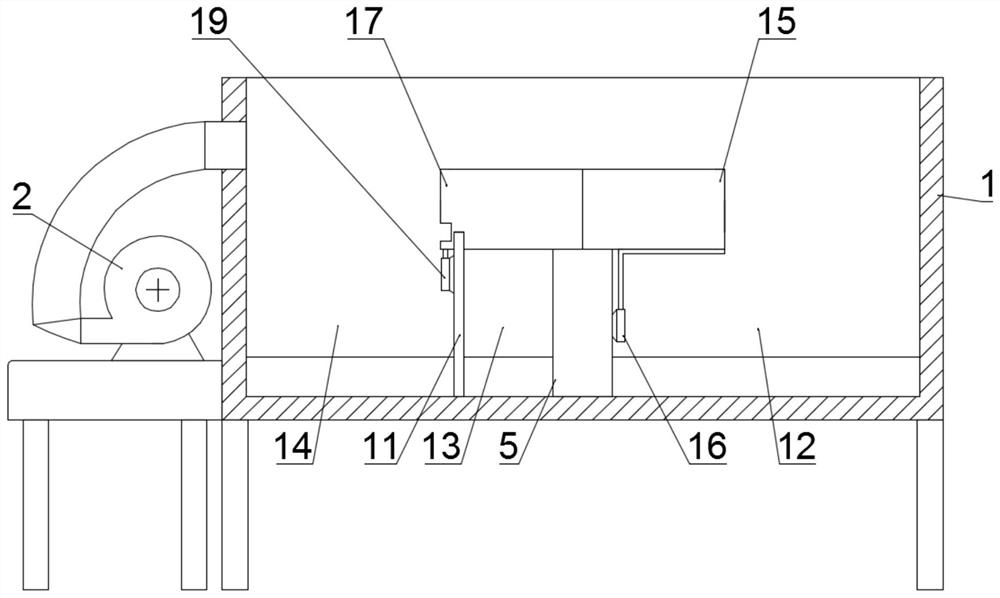

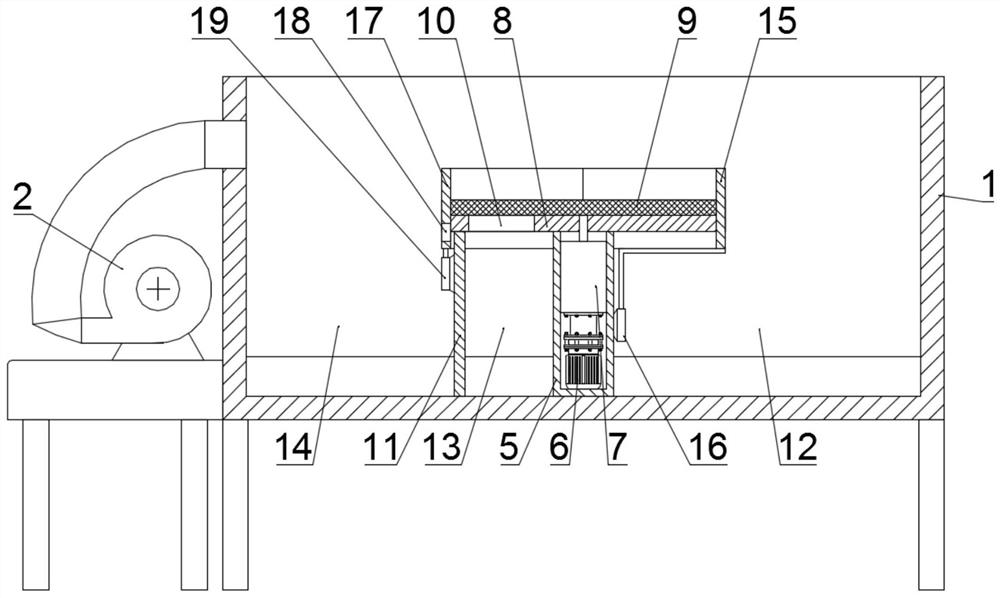

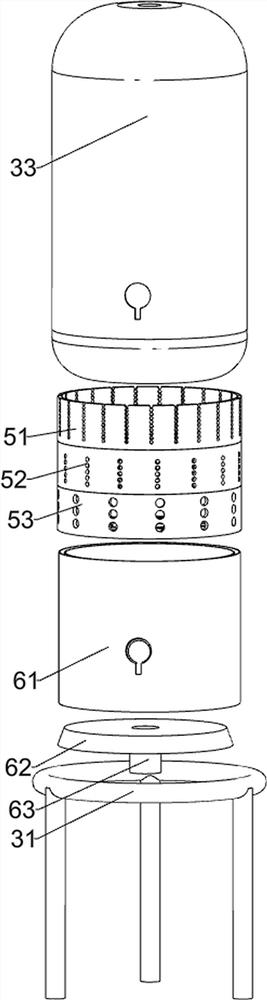

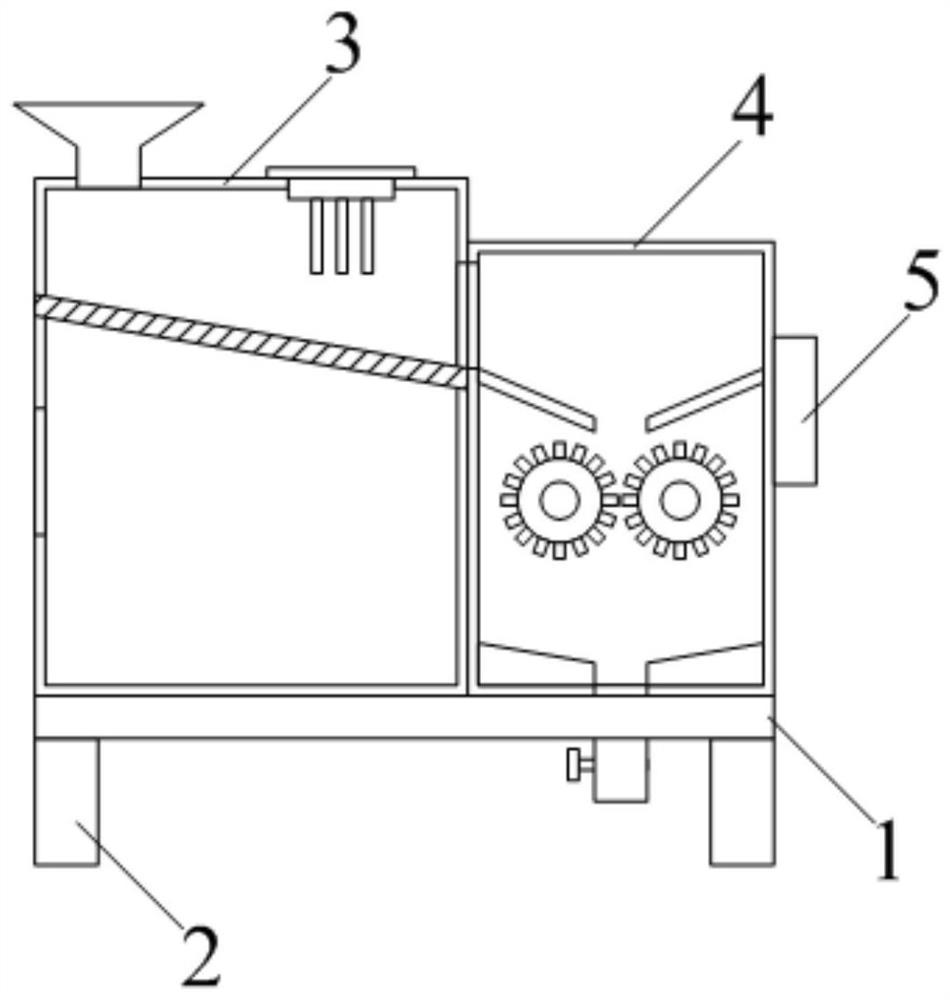

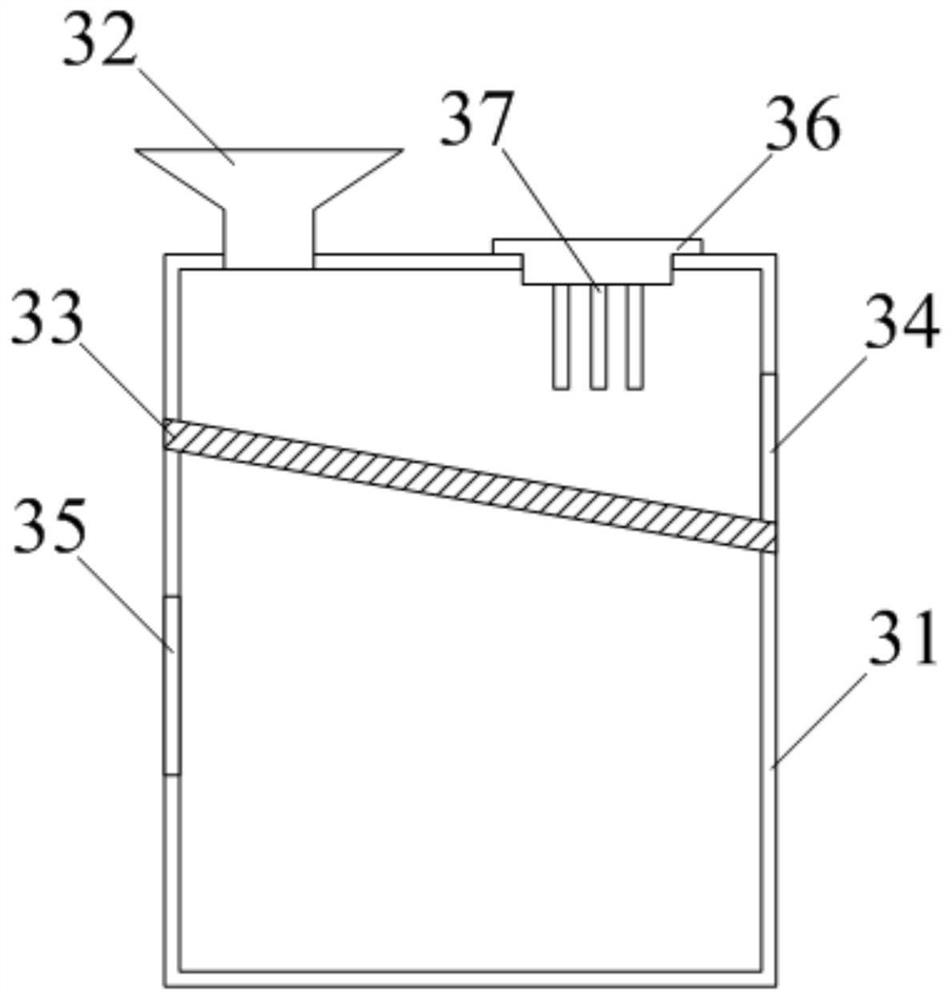

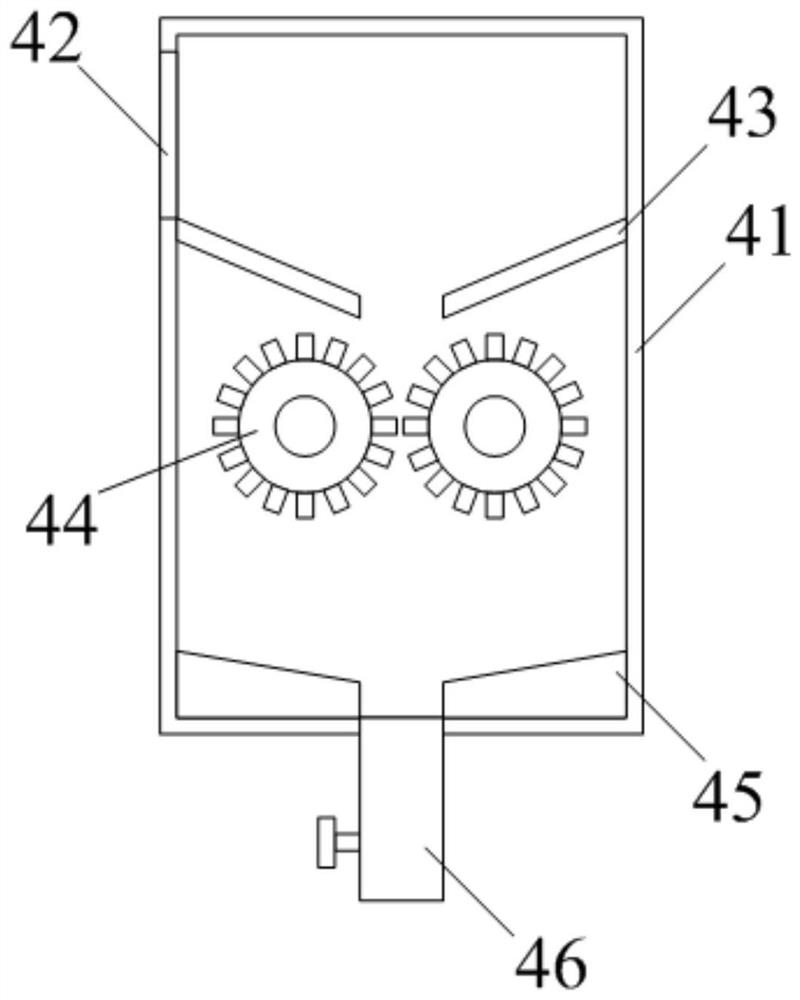

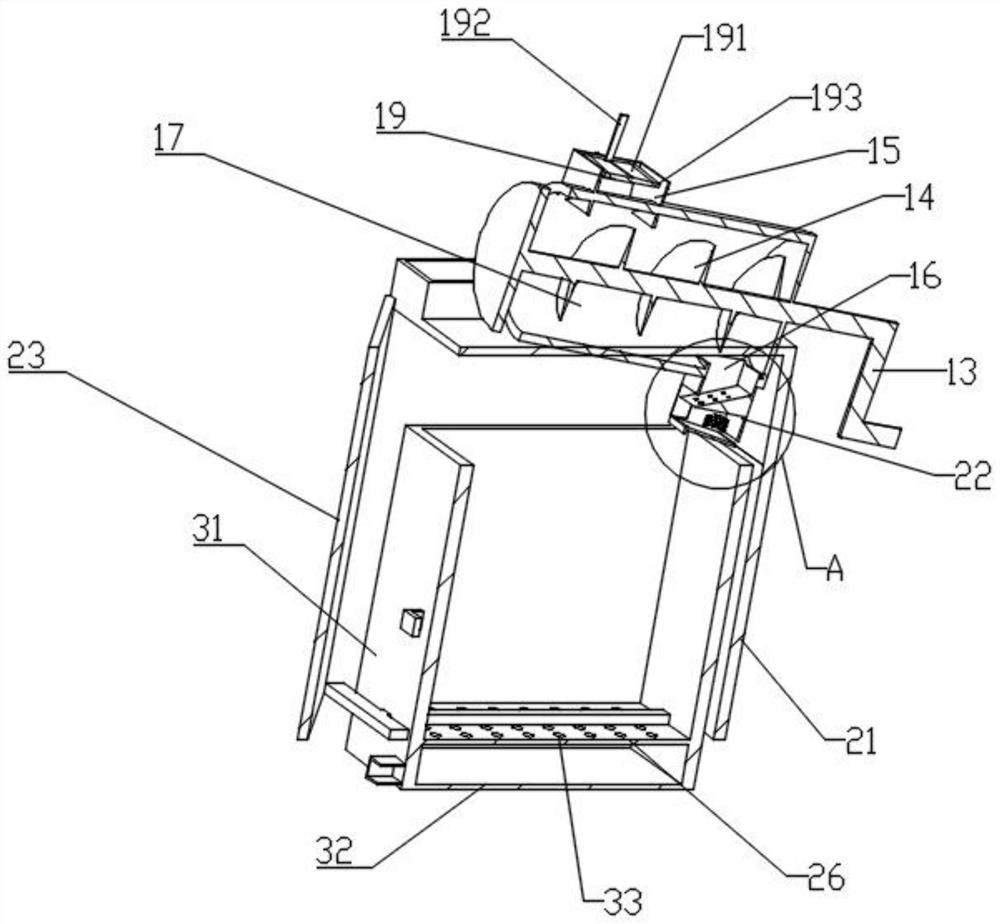

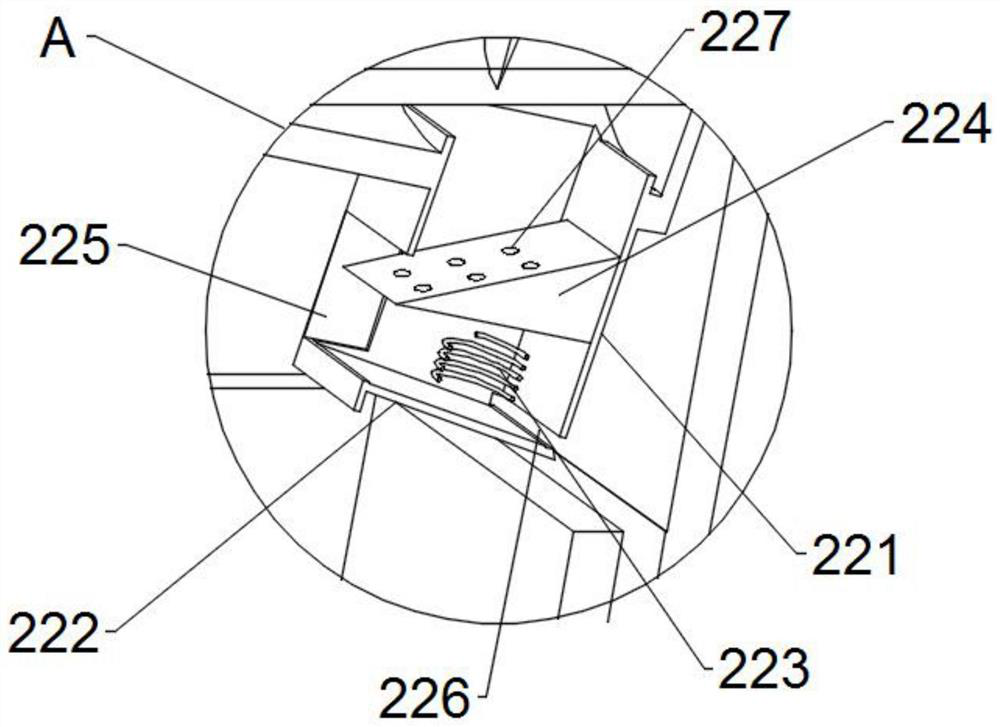

Kitchen garbage treatment device

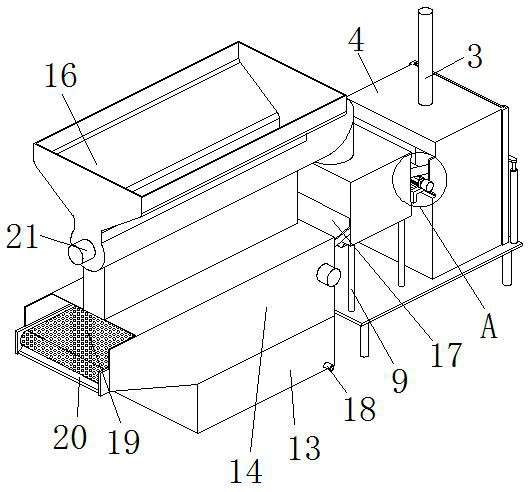

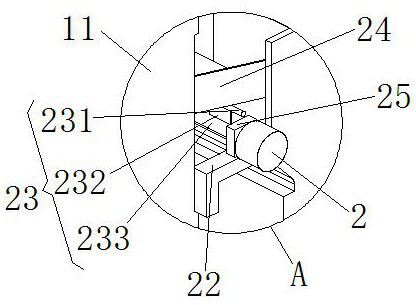

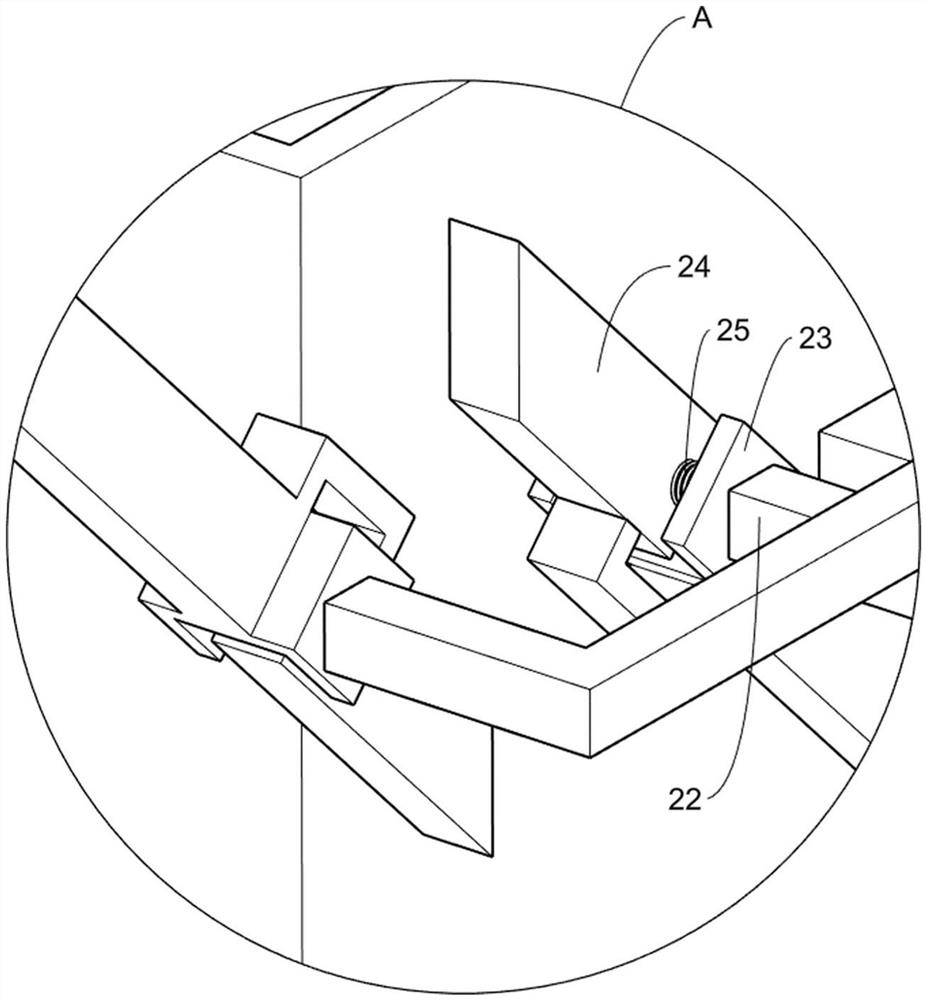

InactiveCN112547766AEasy to handle separatelyAvoid breedingFeeding-stuffTransportation and packagingOil separationProcess engineering

The invention discloses a kitchen garbage treatment device, and belongs to the technical field of garbage treatment. The kitchen garbage treatment device comprises a support table, a treatment box, afeeding frame, a feeding cylinder, a compaction device, an oil-water separation device, a drying device, a crushing device, a conveying device, an ultraviolet sterilization device, a discharging plateand a material collecting box, wherein the treatment box is arranged on the support table; the treatment box is provided with an opening and a material conveying opening; the feeding frame is arranged on the side wall of the treatment box; the feeding cylinder is arranged on the feeding frame; the compaction device is arranged on the treatment box; the oil-water separation device is arranged in the treatment box; the drying device is arranged on the side wall of the treatment box; the crushing device is arranged on the side wall of the treatment box; the conveying device is arranged on the crushing device; the ultraviolet sterilization device is arranged on the crushing device; and the discharging plate is arranged on the side wall of the crushing device. According to the kitchen garbagetreatment device provided by the invention, kitchen garbage is subjected to solid-liquid separation, meanwhile, water and oil in liquid are separated, and solid waste is completely crushed through a multi-directional crushing mechanism.

Owner:芜湖锋珉信息科技有限公司

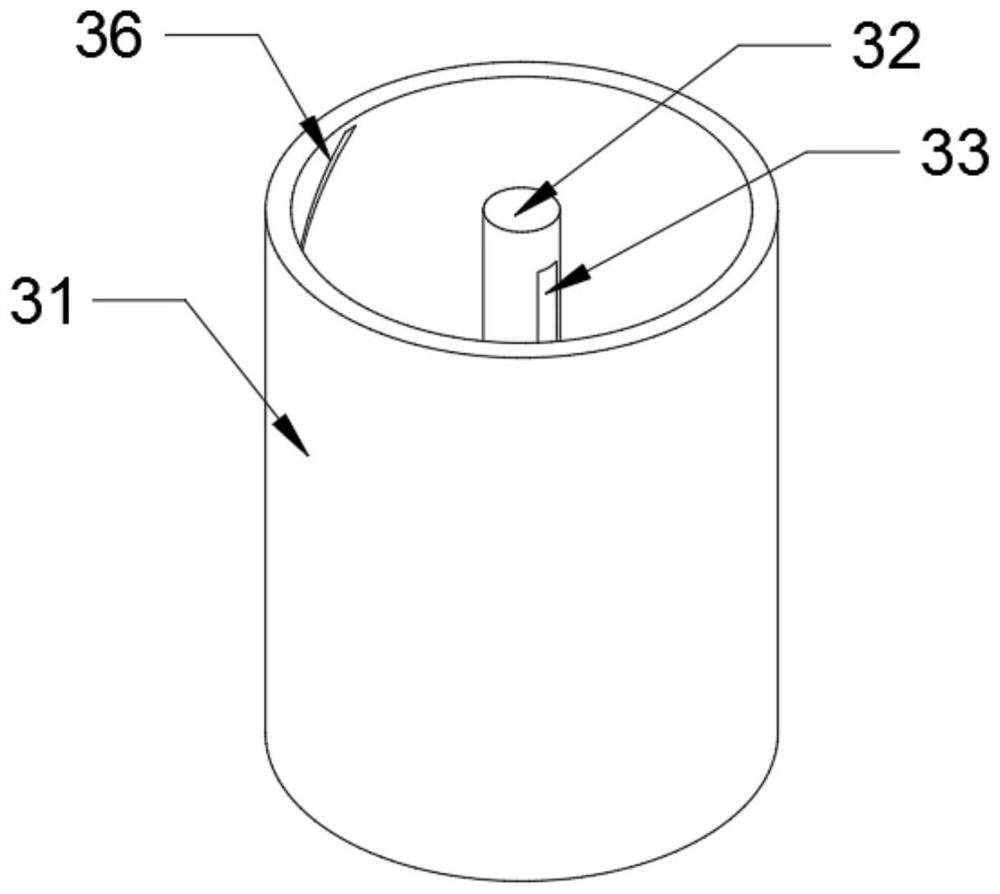

Waste liquid collection device for mass spectrometer

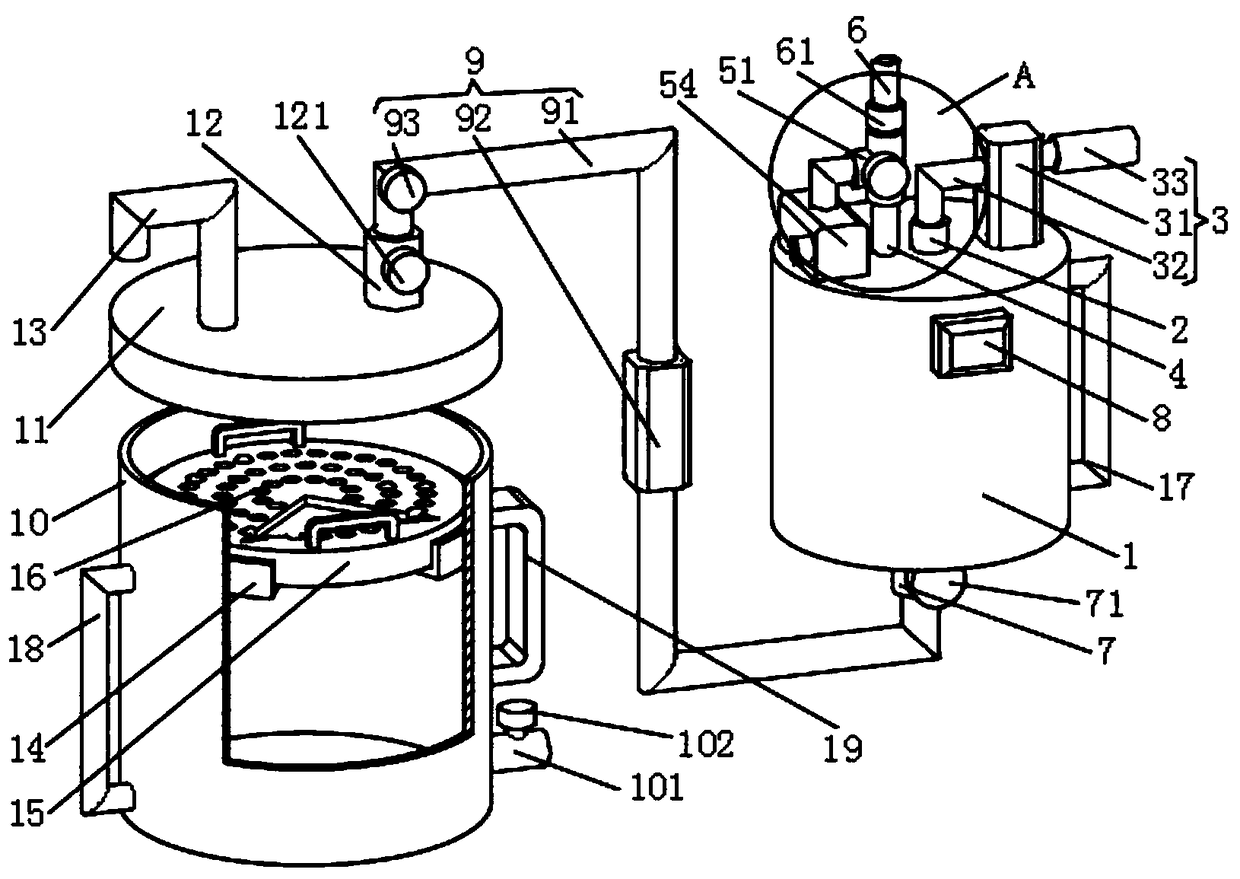

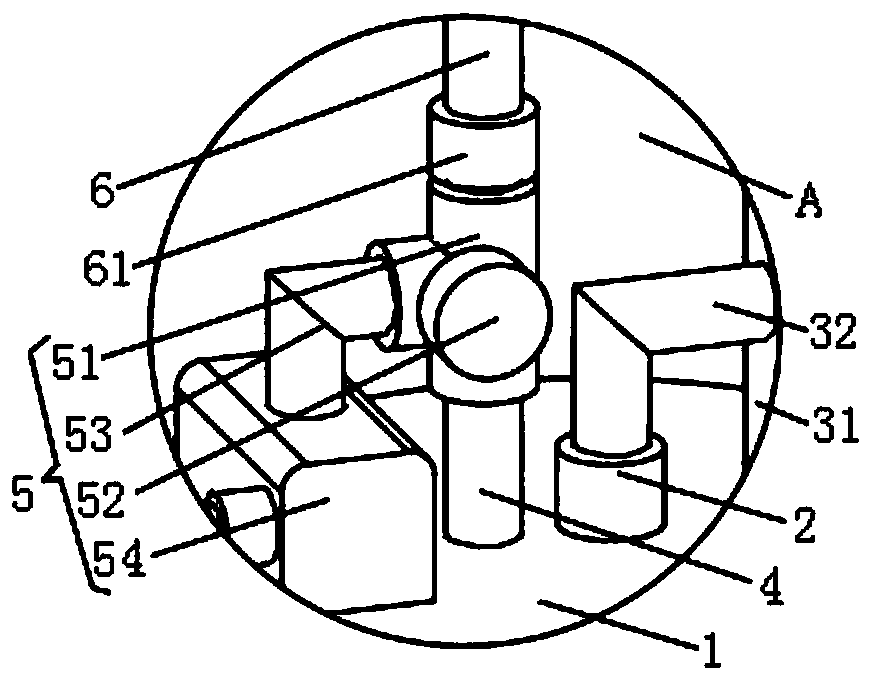

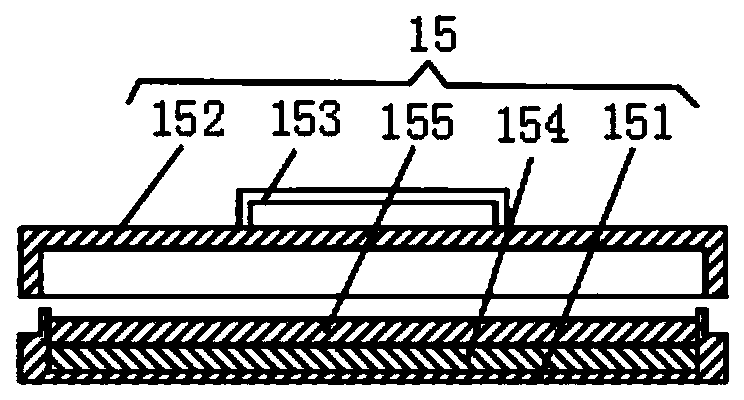

InactiveCN109142603AEasy dischargeClean up in timeComponent separationStationary filtering element filtersLiquid wasteAtmospheric pressure

The invention discloses a waste liquid collection device for a mass spectrometer. The device comprises a transfer barrel, a feeding device is arranged at the right end of the upper surface of the transfer barrel, and a single-way valve is arranged at the junction of a conveying pipe and the transfer barrel of the feeding device; a ventilation pipe is arranged in the middle of the upper surface ofthe transfer barrel, an air pressure adjustment device is arranged at the upper end of the ventilation pipe, and a pipe opening of the lower end of a tee pipe of the air pressure adjustment device isfixedly connected with the ventilation pipe; a switch unit is arranged on the side face of the transfer barrel, an input end of the switch unit is electrically connected with an output end of an external power supply, a discharging pipe is arranged on the lower surface of the transfer barrel, and a first manual valve is arranged on the side face of the discharging pipe. The waste liquid collectiondevice for the mass spectrometer can extract, convey and collect waste liquid, redundant waste liquid can be transferred and stored, gas in the transfer barrel and a storage barrel can be discharged,the storage amount of waste liquid in the storage barrel can be increased, and the device is easy to operate and convenient to use.

Owner:镇江市爱威尔电子有限公司

High-rise building garbage clearing and conveying passage

The invention discloses a high-rise building garbage clearing and conveying passage, and relates to the technical field of high-rise buildings. The high-rise building garbage clearing and conveying passage comprises a bottom pipe and a passage pipe, the bottom end of the passage pipe communicates with the top of the surface of the bottom pipe, and rotating plates are rotatably connected to the left and right sides of the inner surface of the passage pipe. First rotating rods are rotatably connected to one sides of the bottoms of the rotating plate, second rotating rods are rotatably connectedto the bottom ends of the first rotating rods, sliding blocks are rotatably connected to the bottom ends of the second rotating rods, one sides of the sliding blocks are slidably connected with one side of the inner surface of the passage pipe, and first springs are fixedly connected between one sides of the surfaces of the first rotating rods and the second rotating rods. The high-rise building garbage clearing and conveying passage can separate garbage with different size by using the cooperation of the rotating plates, the first rotating rods and the second rotating rods, facilitates the separation processing of the garbage with different size, facilitates the separation of large and small solid wastes, and prevents the condition that dust and large pieces of garbage are mixed togetherand difficult to process.

Owner:广东恒新建设集团有限公司

Treatment method for accelerating peeling of walnut green seedcases

PendingCN113892622AEasy to handle separatelyShort heating timeDrying gas arrangementsDrying solid materialsFood scienceJuglans

The invention discloses a treatment method for accelerating peeling of walnut green seedcases, and relates to the technical field of epidermis treatment. The treatment method comprises the steps that S1, sorting is conducted, and walnut fruits with cracked green seedcases and walnut fruits with uncracked green seedcases are sorted; S2, the walnut fruits with cracked green husks and the walnut fruits with uncracked green husks are heated and dried, and the heating time of the walnut fruits with cracked green husks is shorter than that of the walnut fruits with uncracked green husks; S3, the heated and dried green walnut fruits are naturally stacked; and S4, green seedcases are removedmanually or mechanically. According to the treatment method for accelerating peeling of the walnut green seedcases, peeling of the walnut green seedcases can be accelerated, the treatment efficiency is improved, and pollution to the fruit surface and the environment can be reduced or avoided.

Owner:云南省林业和草原科学院漾濞核桃研究院

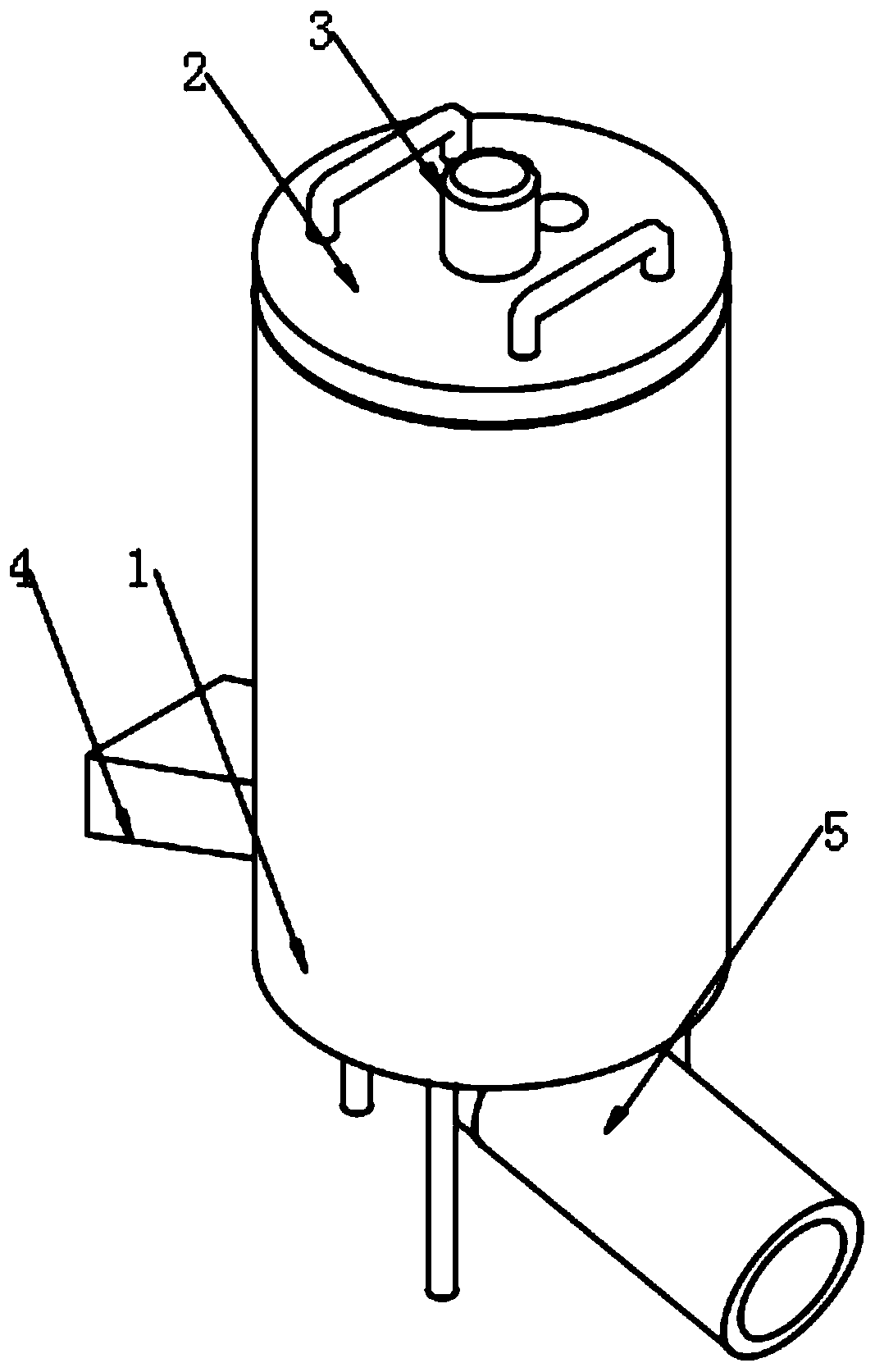

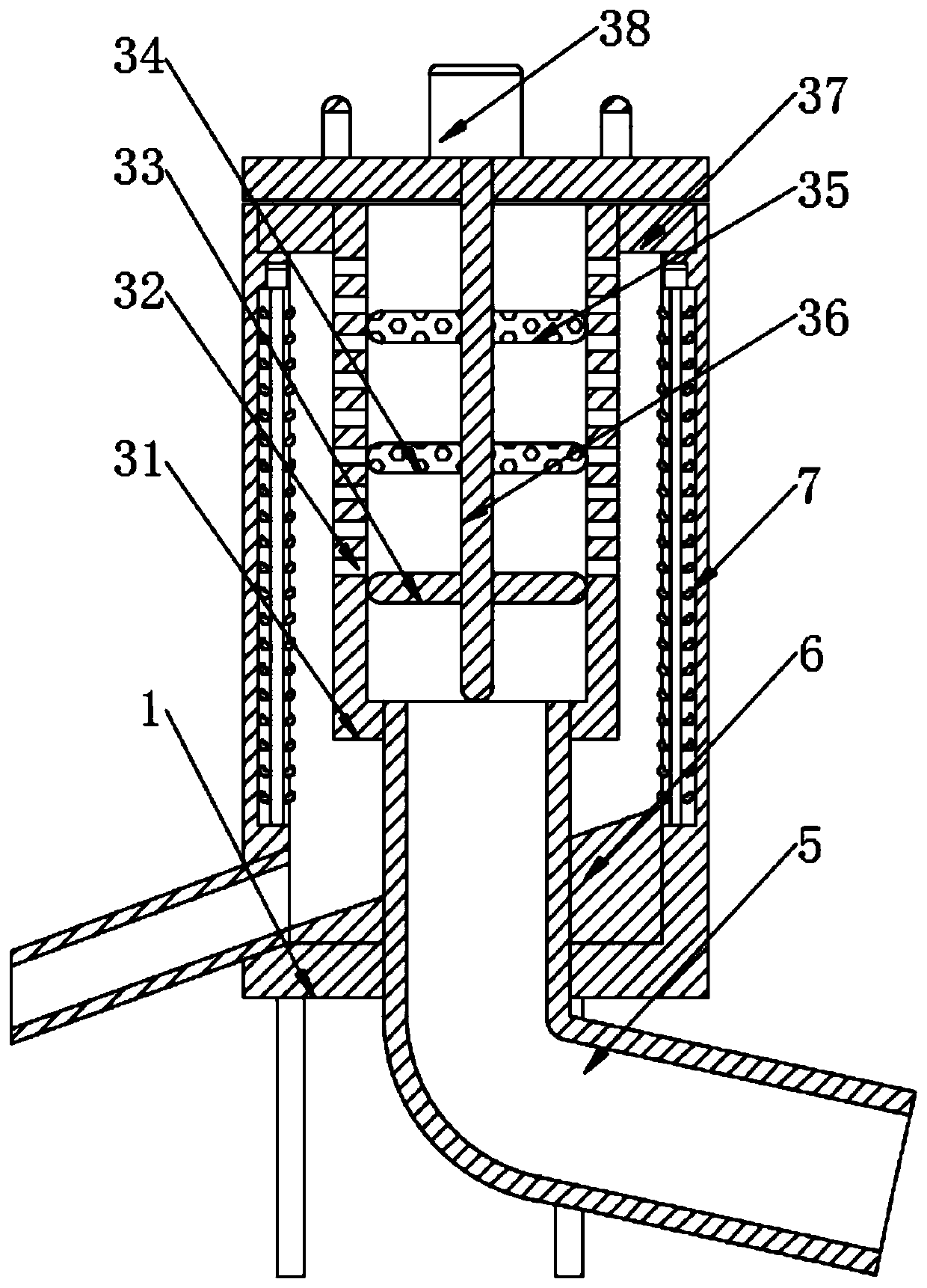

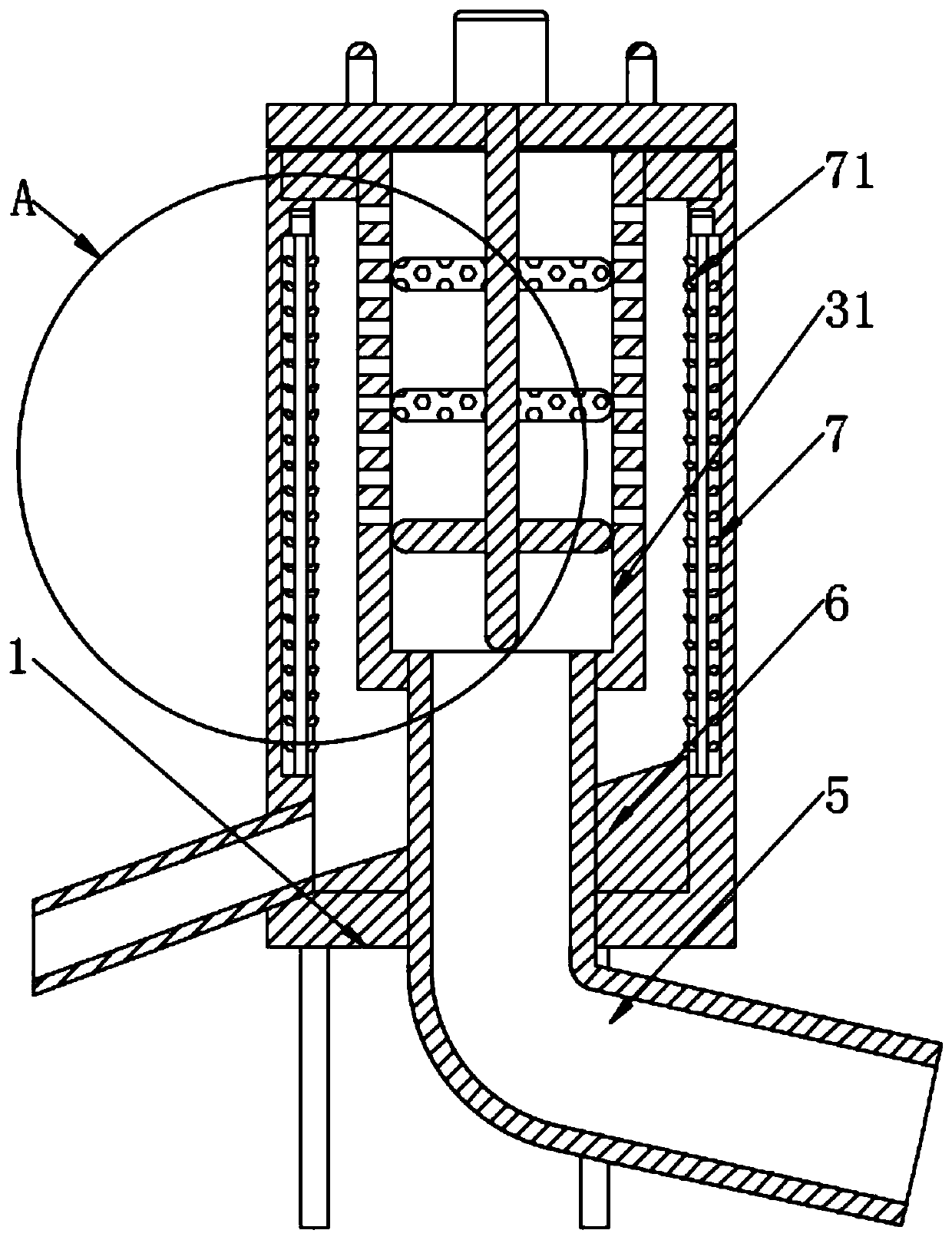

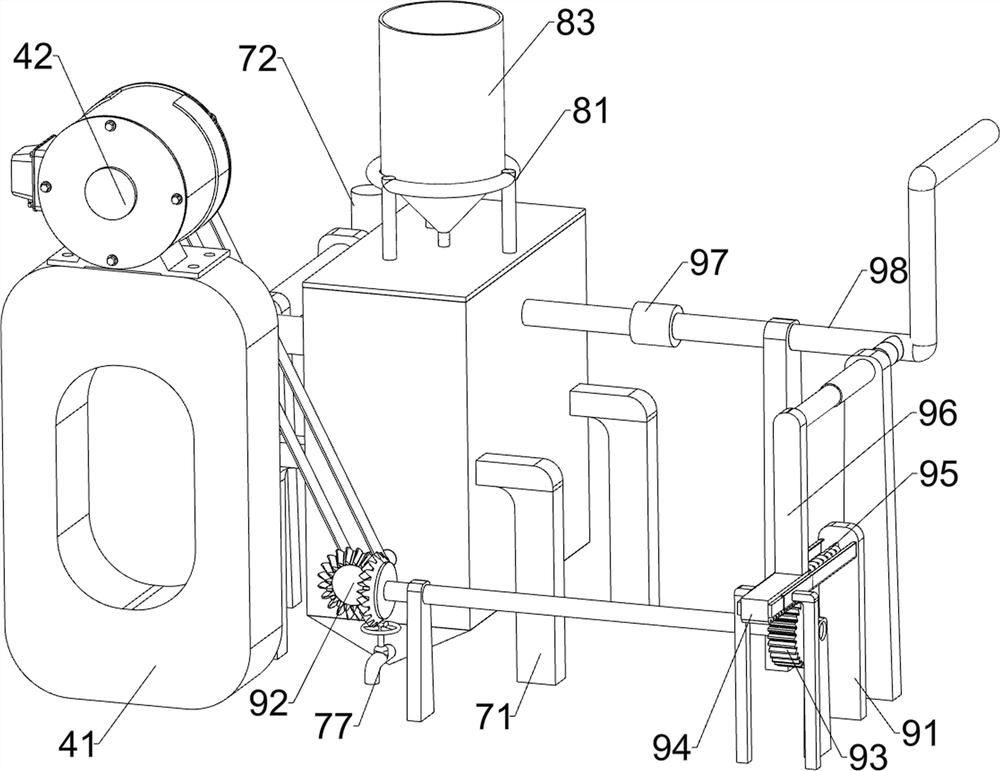

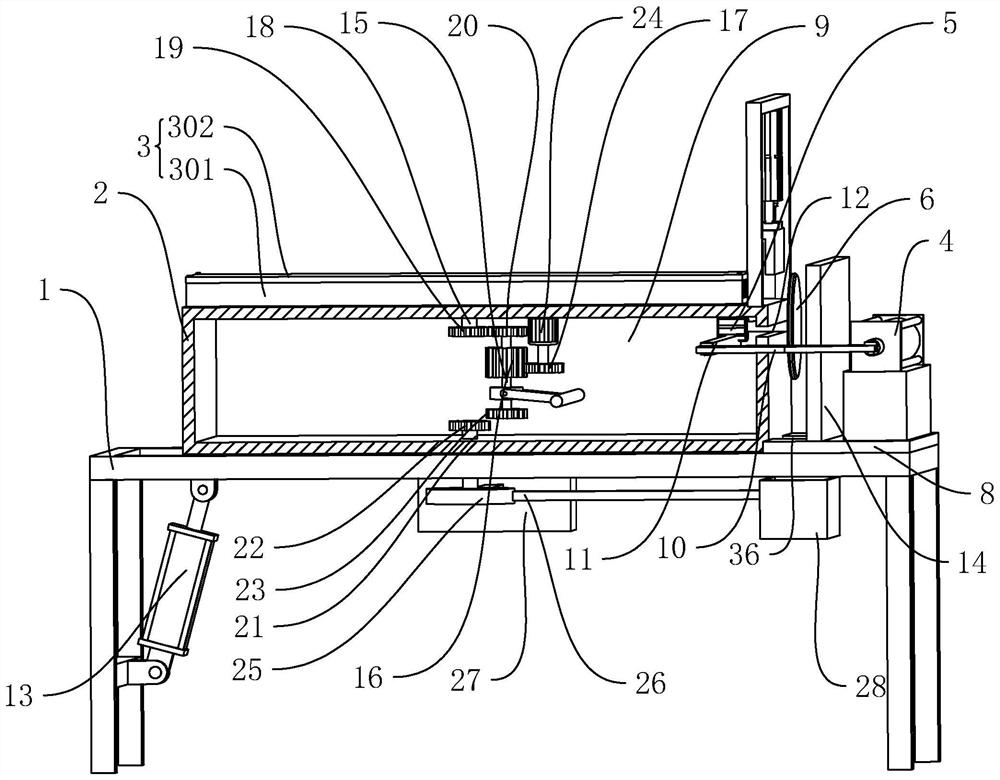

Raw material back flow processing mechanism for casting motor case production

InactiveCN110394216AEasy to handle separatelyImprove crushing effectRotary centrifugesGrain treatmentsCouplingControl theory

The invention discloses a raw material back flow processing mechanism for casting motor case production. The mechanism comprises a separating barrel, a barrel cover, a centrifuging assembly, a crude particle discharging pipe and a breaking assembly. The barrel cover is arranged at the top of the separating barrel, and the centrifuging assembly is arranged on the separating barrel; the centrifugingassembly comprises an inner barrel, a rotating alpha and a servo motor, a clamping ring is arranged at the edge ring of the top of the inner barrel, the inner barrel is clamped to an annular groove formed in the top of the separating barrel through the clamping ring, the inner barrel is located in an inner cavity of the separating barrel, a plurality of filter holes are evenly formed in the outerwall of the inner barrel, the servo motor is fixed to the center of the top of the barrel cover through a screw, the output shaft of the servo motor is in transmission connection with the rotating shaft alpha through a coupler, and the rotating shaft alpha perpendicularly penetrates through the barrel cover to be communicated with the inner cavity of the inner barrel; granular raw materials can be distinguished through the sizes of granules, and separated treatment is facilitated; raw material granules are broken, and the raw material smashing effect is improved.

Owner:徐州全盛电机有限公司

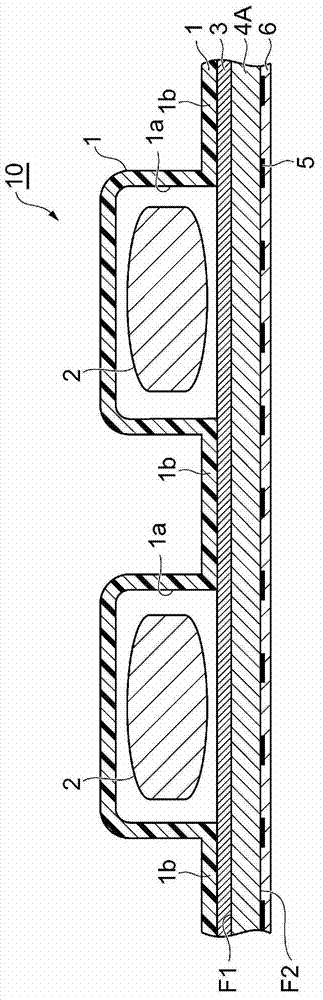

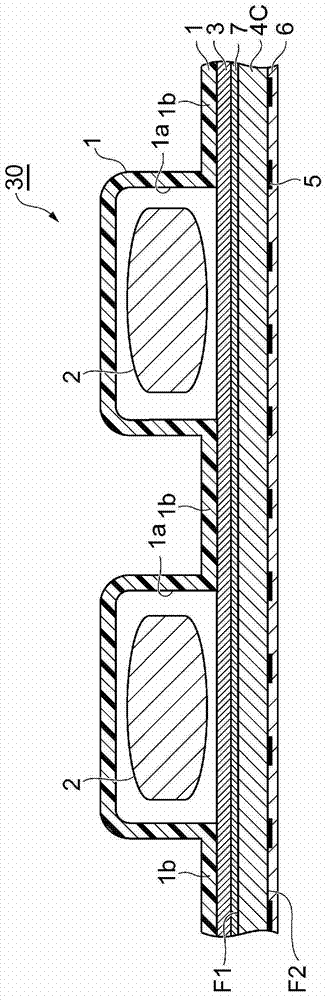

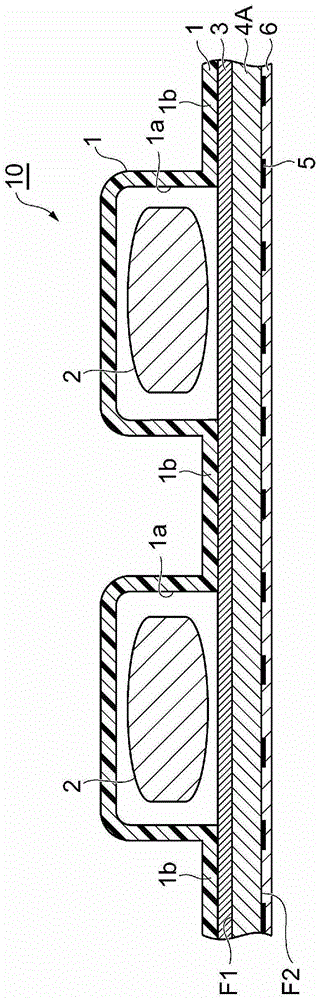

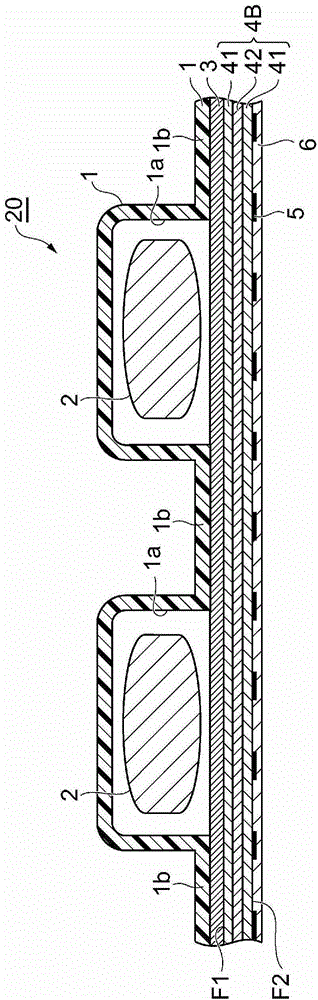

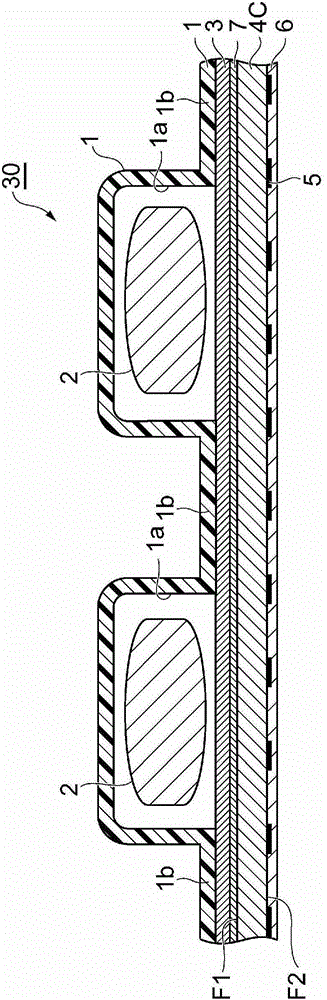

Push-through pack packaging

ActiveCN103201189ALess incineration residueGood environmentSmall article dispensingFlexible coversMethacrylic acid copolymerPolymer chemistry

The disclosed push-through pack packaging has a cover material comprising a stretched film having at least one layer which includes a thermoplastic resin, and an inorganic filler making up less than 5 parts by mass per 100 parts by mass of said thermoplastic resin. Said thermoplastic resin contains at least one species selected from a group consisting of styrene-acrylic acid copolymer resin, styrene-methacrylic acid copolymer resin, styrene-maleic anhydride copolymer resin, and terpolymer resins containing an ester component in addition to any one of the aforementioned three copolymer resins.

Owner:ASAHI KASEI KK

Crusher clearing blockage device

The invention discloses a crusher clearing blockage device. The crusher clearing blockage device comprises a base, a first high-speed rotating rod, a first connecting rod, a second high-speed crushingroller, a second low-speed crushing roller, a water collecting box, a crushing outlet, a buffer spring, a conveying belt and supporting legs, wherein a crushing inlet is arranged in the upper end ofan equipment main body, a control device is arranged at the upper end of the equipment main body close to the crushing inlet, and the first high-speed crushing roller is arranged inside the equipmentmain body. A pushing device and an anti-blocking layer are arranged in the crusher clearing blockage device, the anti-blocking layer is of an elastic structure, and when the outlet is blocked, a firstmotor drives a rotating shaft on the pushing device to work, so that an electric stretchable rod is driven to move forwards, a pressing plate at the tail end of the electric stretchable rod applies aforward pushing force to a blockage block, the blockage block extrudes the anti-blocking layer, the anti-blocking layer vibrates, the electric stretchable rod retracts backwards, and the purpose of clearing the blockage block is achieved.

Owner:界首市宏佳塑业有限公司

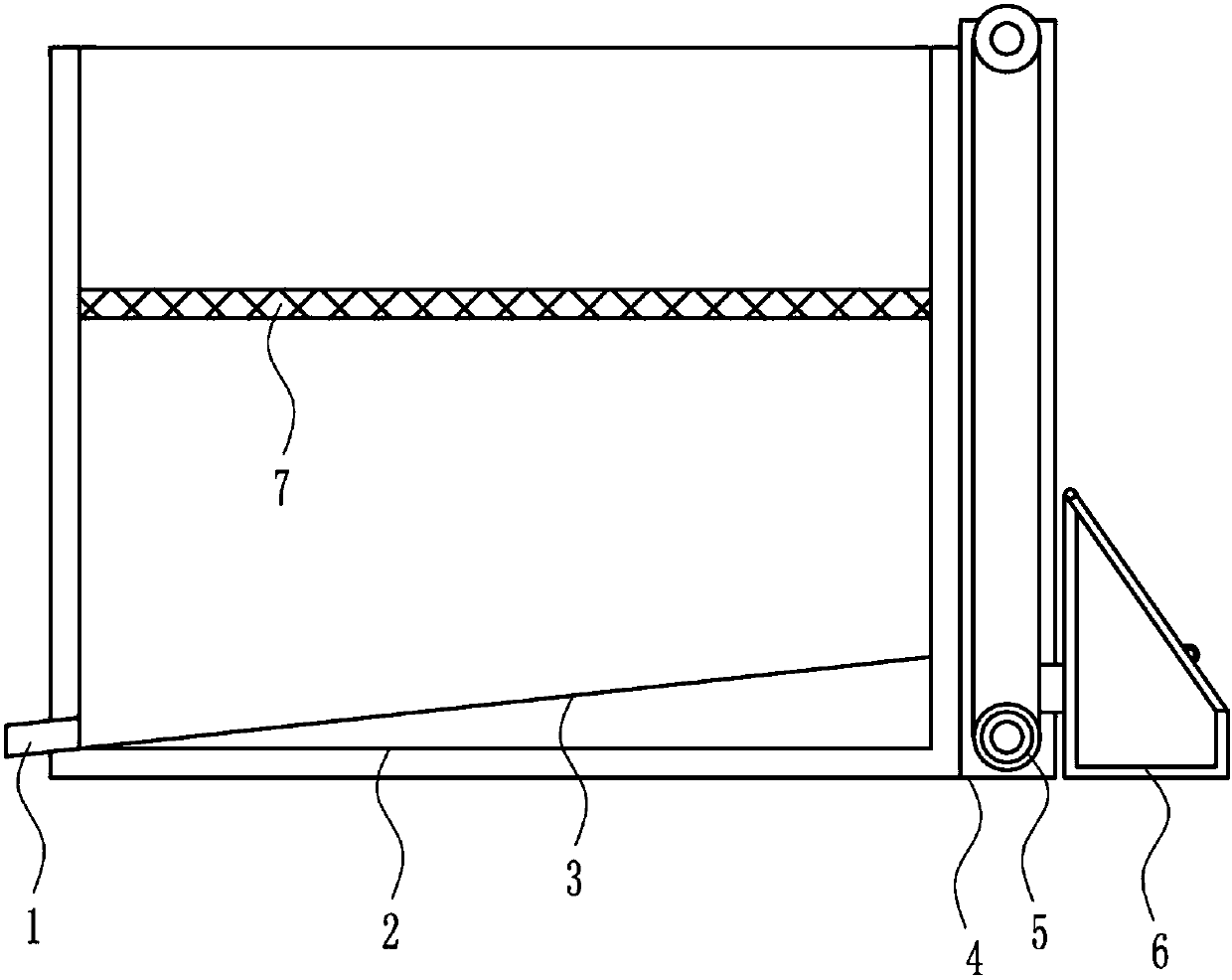

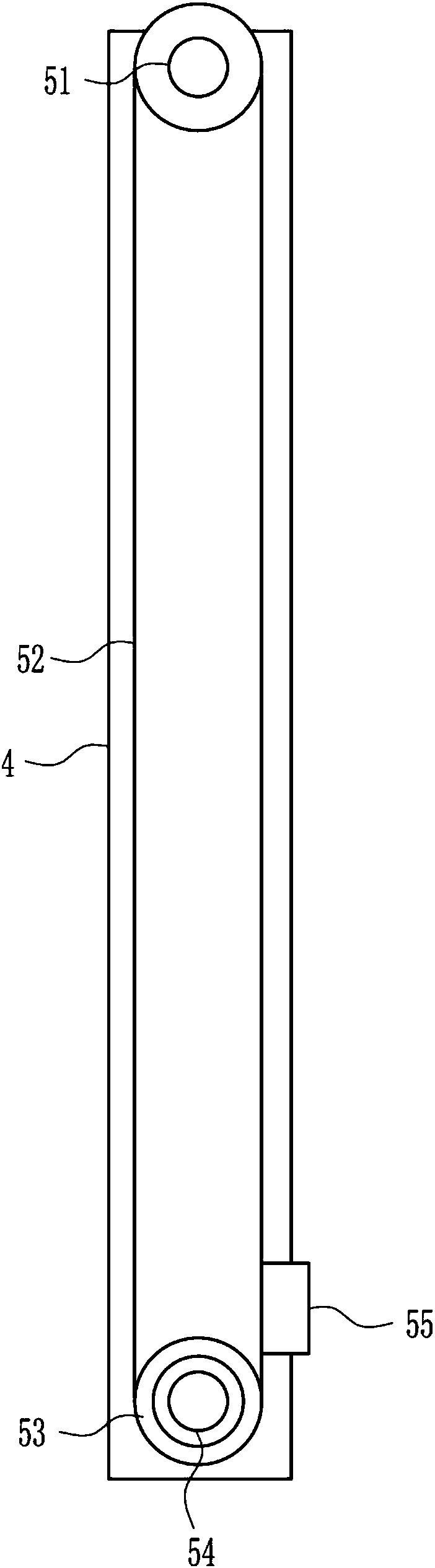

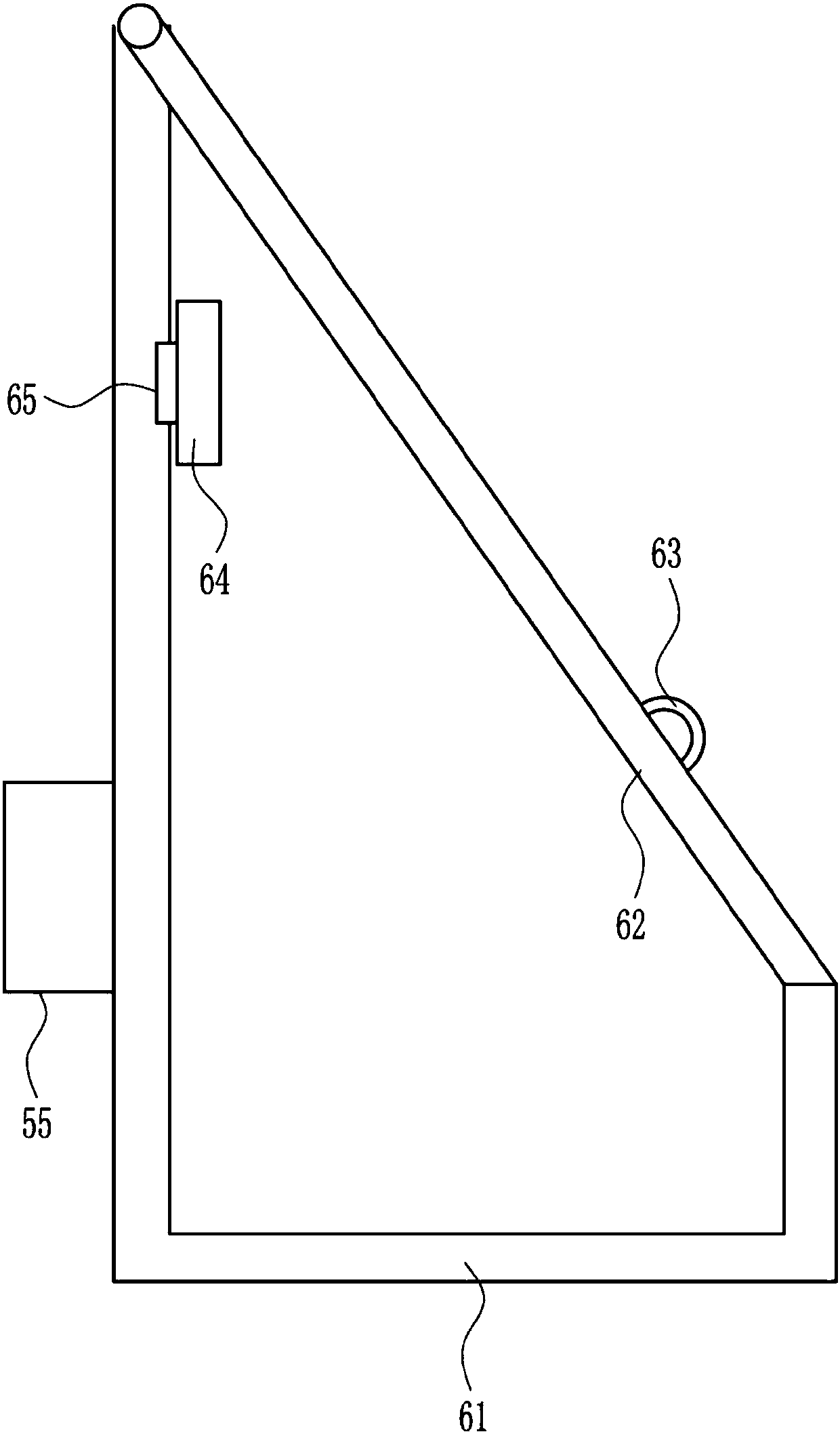

Rough sorting equipment for household garbage

InactiveCN107684761ARealize moving up and downAvoid pollutionWater/sewage treatmentStationary filtering element filtersLeachateDomestic waste

The invention relates to sorting equipment, in particular to rough sorting equipment for domestic garbage. The technical problem to be solved by the present invention is to provide a rough sorting device for domestic garbage. In order to solve the above-mentioned technical problems, the present invention provides such a rough sorting device for household garbage, which includes a liquid outlet pipe, etc.; The middle and upper part of the processing box is connected with a screen plate, the rear end of the right side wall outside the processing box is connected with a fixed plate, the front side of the fixed plate is provided with a lifting mechanism, and the lifting mechanism is provided with a collecting device. The invention can accelerate the discharge of waste liquid, prevent the waste liquid from remaining in the bottom of the treatment box and cause foul smell, dry and wet separation can facilitate people's rough sorting of recyclable household garbage, and facilitate the separate treatment of recyclable garbage and non-recyclable garbage , the wet domestic waste leachate is purified and then discharged, which can reduce the wear of the collection frame and prolong the service life of the collection frame.

Owner:万慧龙

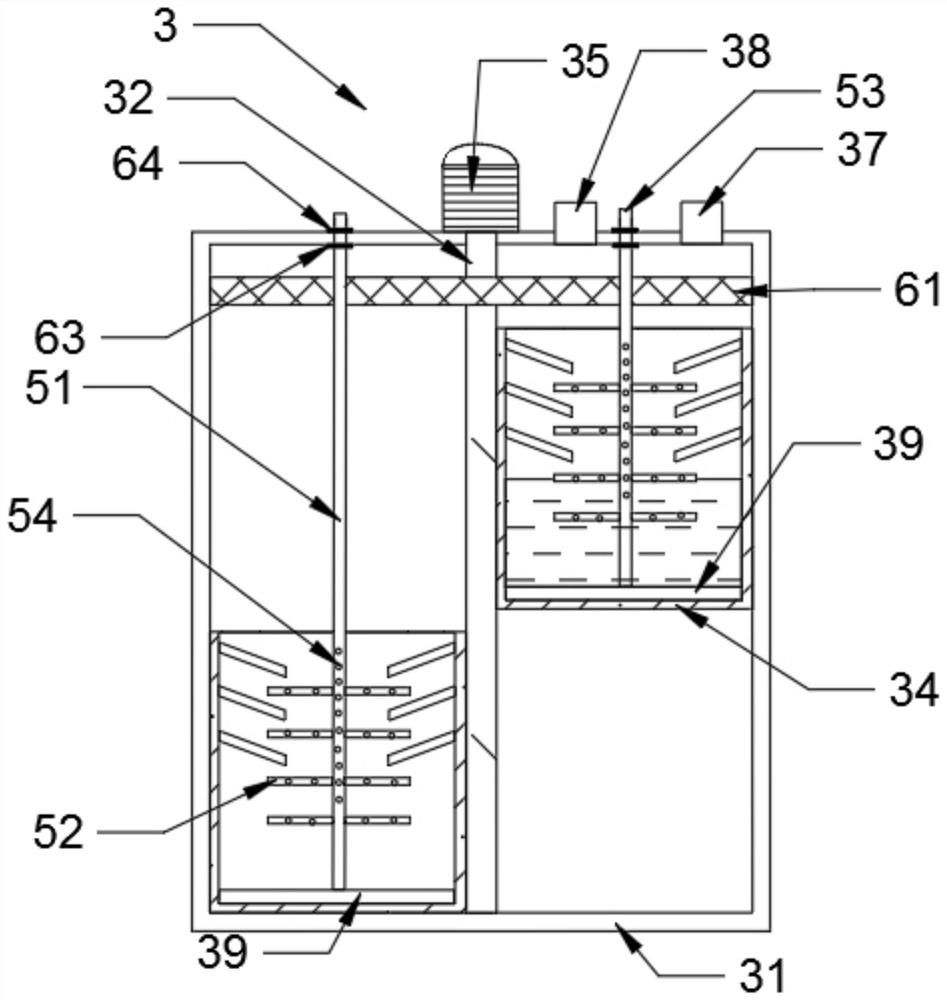

Processing device for kitchen waste

InactiveCN111437919AAchieve cleaningEasy to shredHollow article cleaningGrain treatmentsWater filterEnvironmental engineering

The invention provides a processing device for kitchen waste. The processing device comprises a crushing box and a water filtering box which are connected fixedly from top to bottom; a feeding openingis formed in the top of the crushing box; a grinding mechanism is arranged in the position, located below the feeding opening, inside the crushing box; a cutting mechanism is further arranged insidethe crushing box; a connection channel is arranged at the bottom of the crushing box and communicates with the inside of the water filtering box; a moving door mechanism is arranged inside the connection channel; a rotating drum is rotationally connected inside the water filtering box, is driven by a rotating mechanism to rotate and adopts the hollow structure; a plurality of filtering holes are formed in the side wall; a discharging opening is formed in the bottom of the rotating drum; a door opening mechanism is arranged at the discharging opening; the discharging opening communicates with adischarging channel located at the bottom through the door opening mechanism; and cleaning mechanisms are arranged inside a box body of the crushing box and a box body of the water filtering box. Theprocessing device has the beneficial effects that the processing device is reasonable in design, simple in structure, safe and reliable, cutting processing and solid-liquid separation processing canbe effectively performed on the kitchen waste, and the device can be cleaned.

Owner:闫兰兰

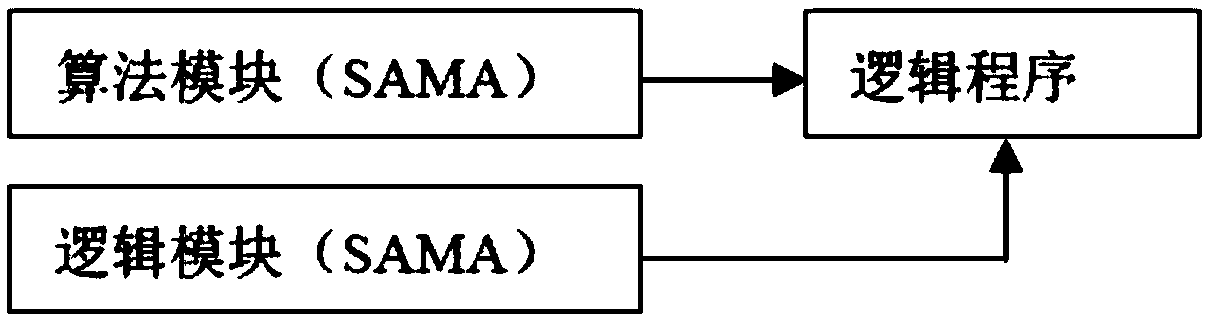

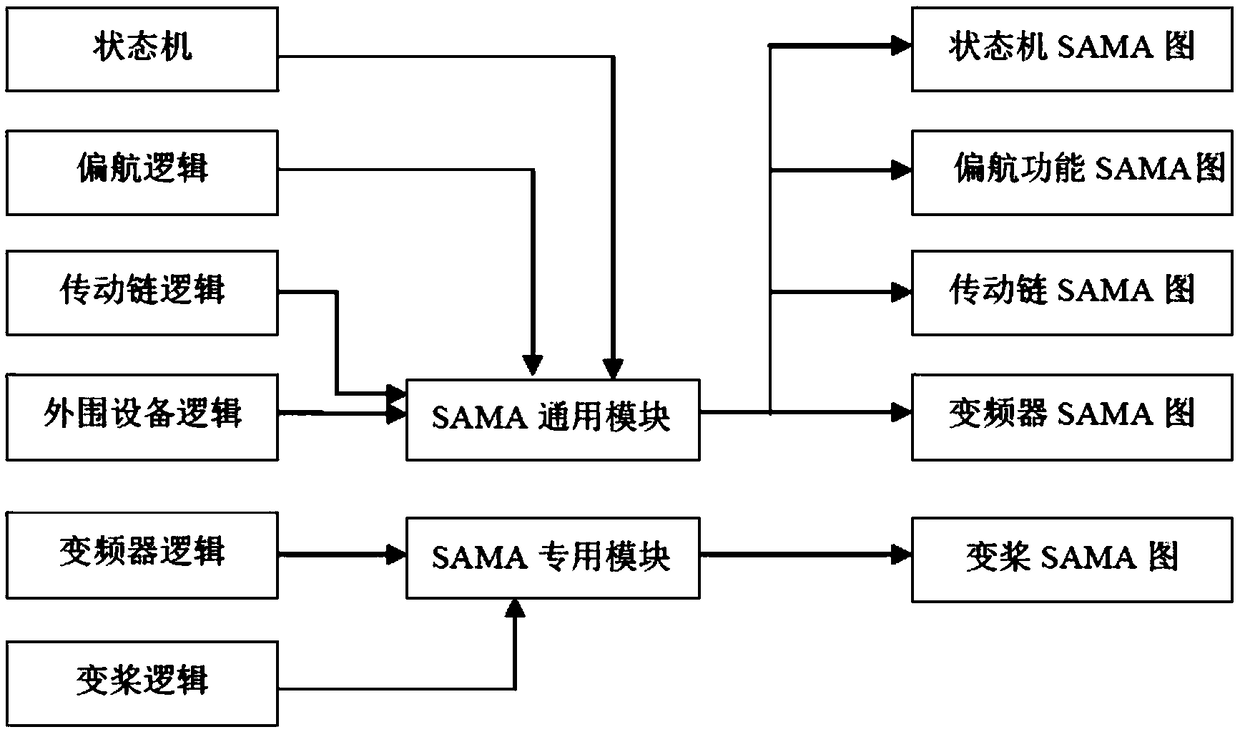

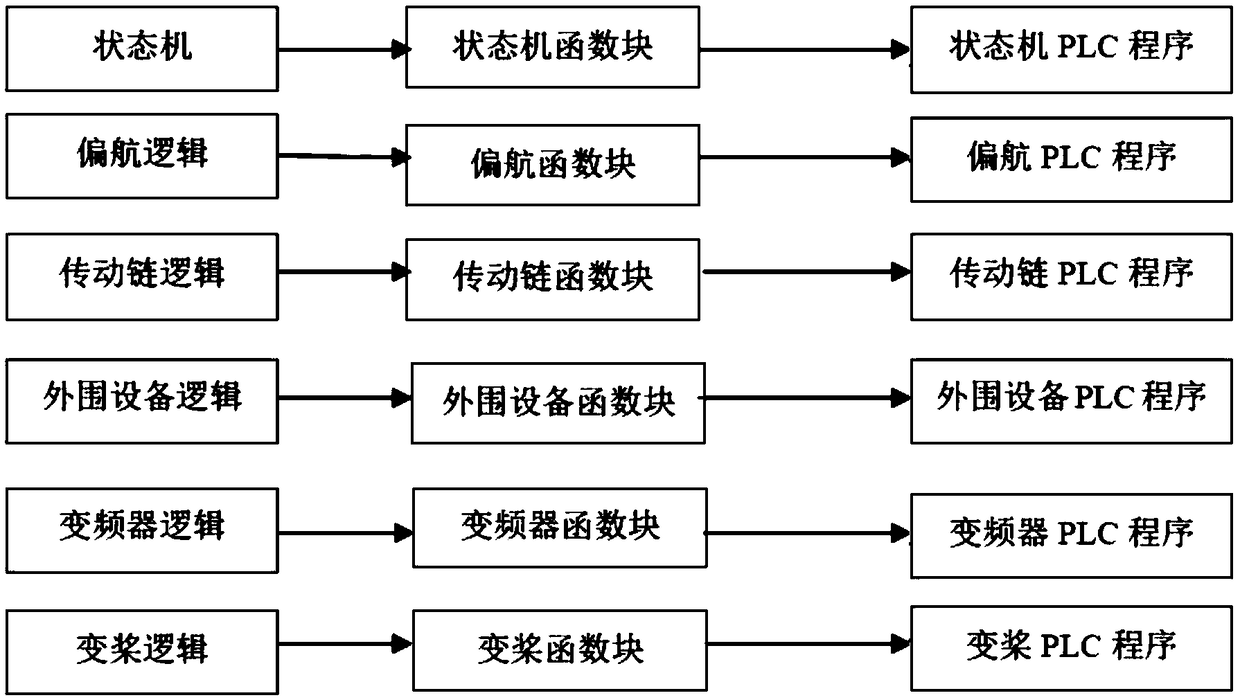

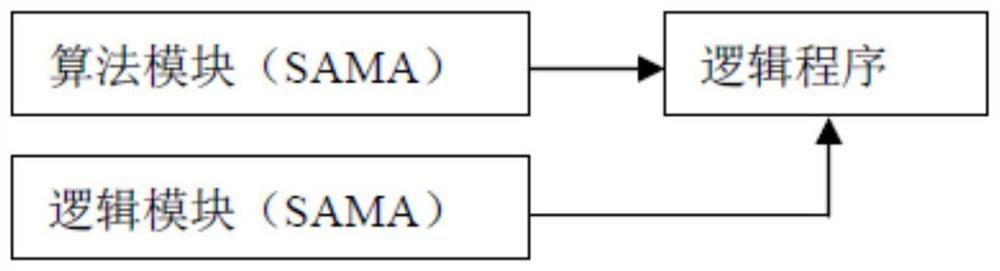

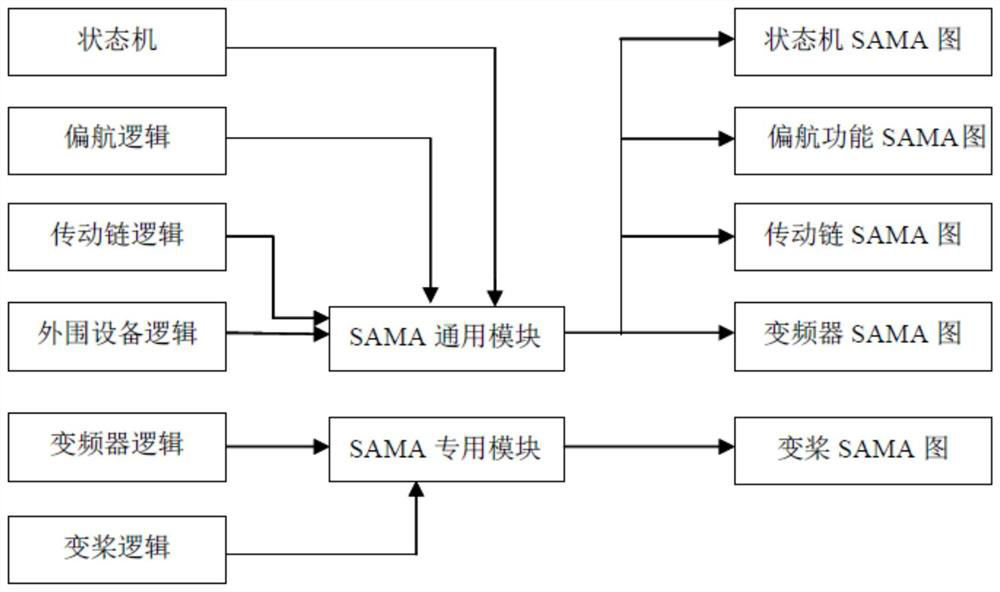

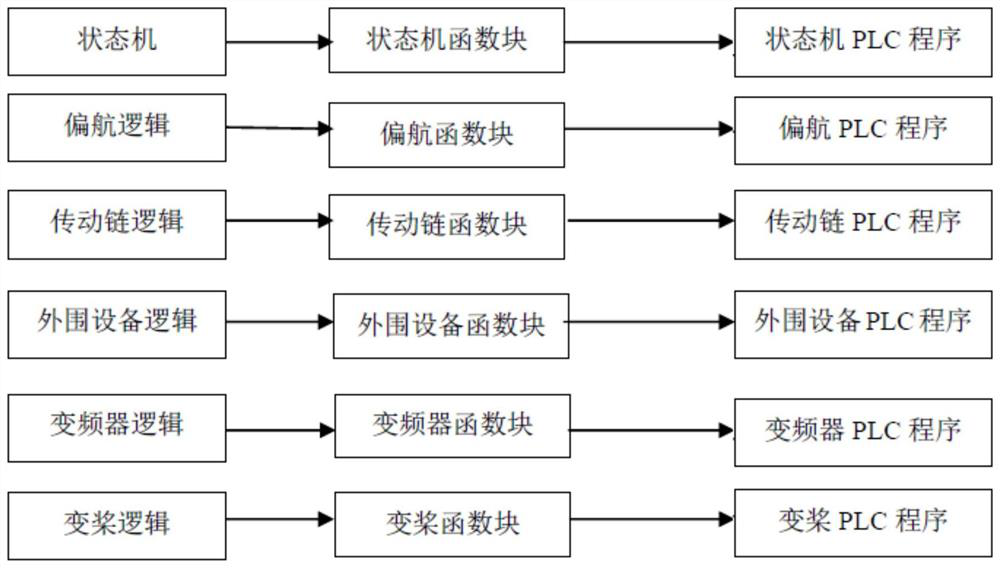

Programming system and method for integrated fan control system

ActiveCN109343448ALower the thresholdShorten the development cyclePump controlPIc programmingProcess logicControl system

The invention discloses a programming system for an integrated fan control system and a programming method; it belongs to the field of fan control. The programming system comprises an algorithm module, a logic module, a SAMA universal module and a SAMA special module. The SAMA universal module includes a corresponding general SAMA diagram; the algorithm module includes the corresponding general logic program; the general SAMA diagram is linked with the corresponding general logic program through the call of the logic module; the SAMA special module includes a corresponding special SAMA diagram; the algorithm module includes the corresponding special logic program; the special SAMA diagram is linked to the corresponding special logic program by the call of the logic module. The invention applies the SAMA diagrams to the PLC programming, which lowers the threshold of programming, greatly shortens the development period, accelerates the development, and frees skilled engineers from the tedious work; at the same time, it makes it convenient to keep the process logic secret and to carry out debugging.

Owner:GUODIAN UNITED POWER TECH

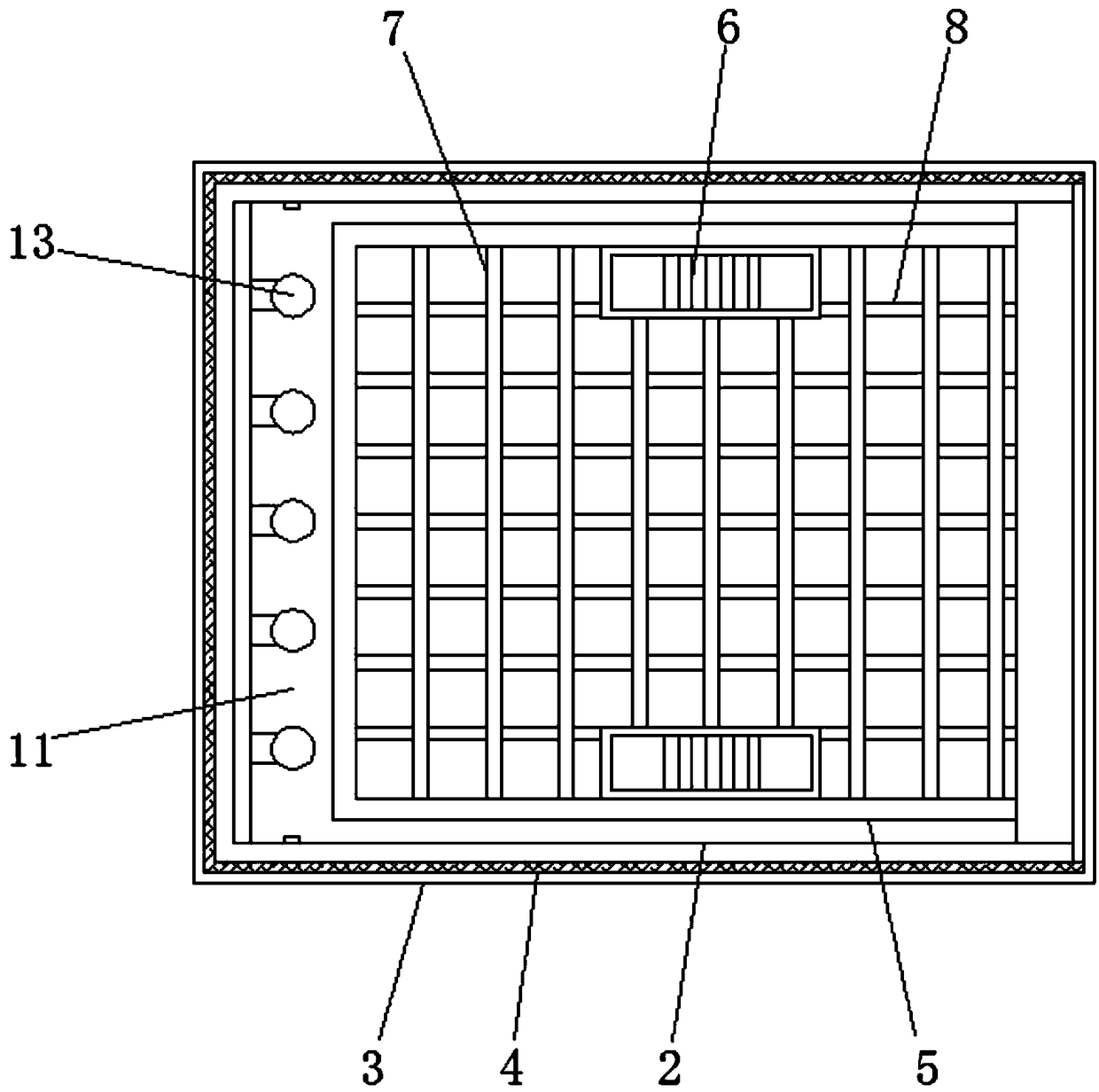

Material receiving mechanism in landscaping waste sorting system

ActiveCN112916148AWide variety of sortingEasy to handleSievingGas current separationWaste treatmentLandscaping

The invention provides a material receiving mechanism in a landscaping waste sorting system, and relates to the technical field of waste treatment. The material receiving mechanism in the landscaping waste sorting system comprises an installation box installed in a sorting box, and the upper part of the installation box is fixedly connected with a fixed disc. A screen which is the same as the fixed disc in shape and is coaxially arranged together with the fixed disc is arranged at the upper part of the fixed disc, and a rotation driving device is installed in the installation box. By means of the material receiving mechanism, small-particle metal blocks, stones or soil blocks and the like and large-particle metal blocks, stones or soil blocks and the like can be sorted out, leaves, hay, branches and the like for recycling can also be sorted out, the sorting variety is wide, and various types of waste can be conveniently treated in a separated mode. Through structural cooperation of the screen, a discharging port, a first semicircular cover body, a second semicircular cover body and the like, the materials which are sorted out can not be mixed, and various materials can be further conveniently treated.

Owner:高逸平

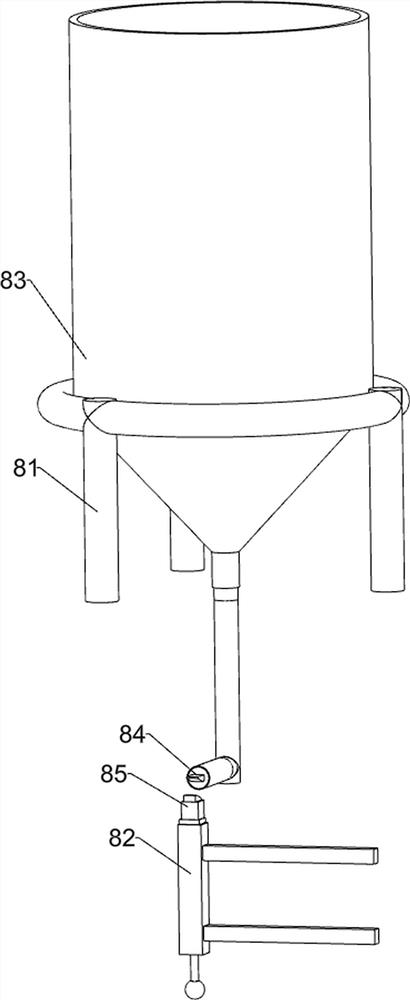

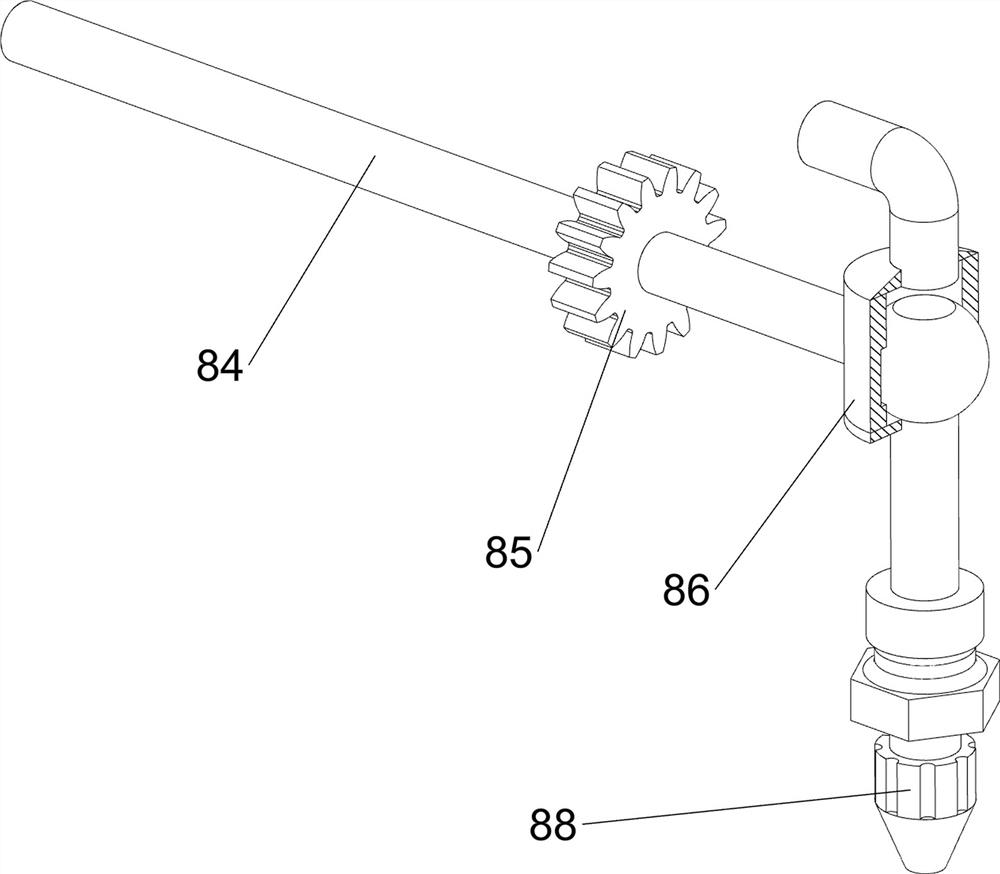

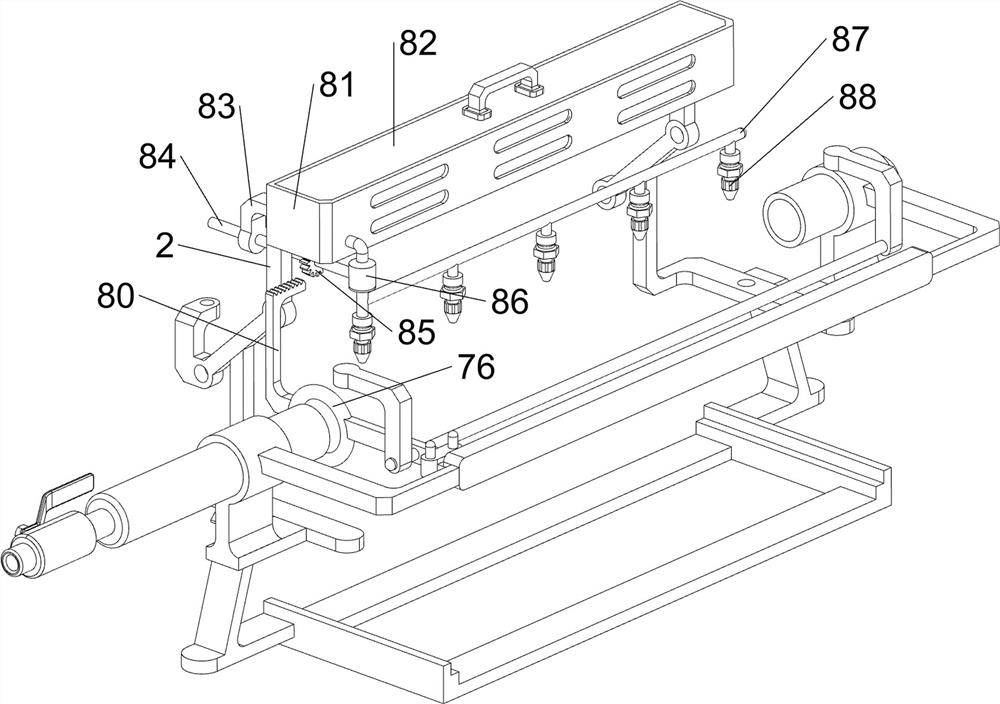

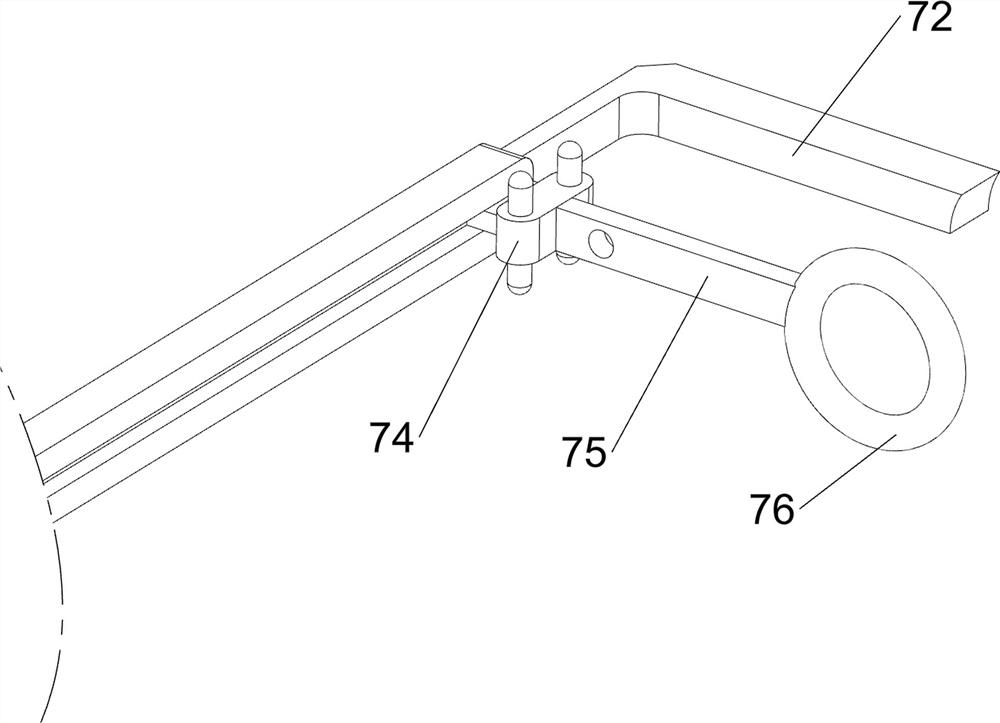

Spray cooling device of solid waste incineration system

PendingCN112387058AEasy to handle separatelyAchieve recyclingDispersed particle separationTreatment involving filtrationThermodynamicsWater storage tank

The invention relates to a spray cooling device, in particular to a spray cooling device of a solid waste incineration system. The spray cooling device of the solid waste incineration system is capable of recycling water and liquid, low in cost and capable of treating and purifying waste gas. The spray cooling device of the solid waste incineration system comprises a base, a spraying cooling mechanism and an air extracting mechanism, and a water storage tank is arranged on one side of the top of the base; one side of the top of the base is connected with the spraying cooling mechanism; and oneside of the top of the base is connected with the air extracting mechanism. Through cooperation of the spraying cooling mechanism and the air extracting mechanism, the waste gas is cooled and liquefied, then an air exhaust fan is driven to rotate, and residual gas is exhausted; and by arranging a waste gas pretreatment mechanism, the liquefied waste gas is primarily filtered.

Owner:徐新会

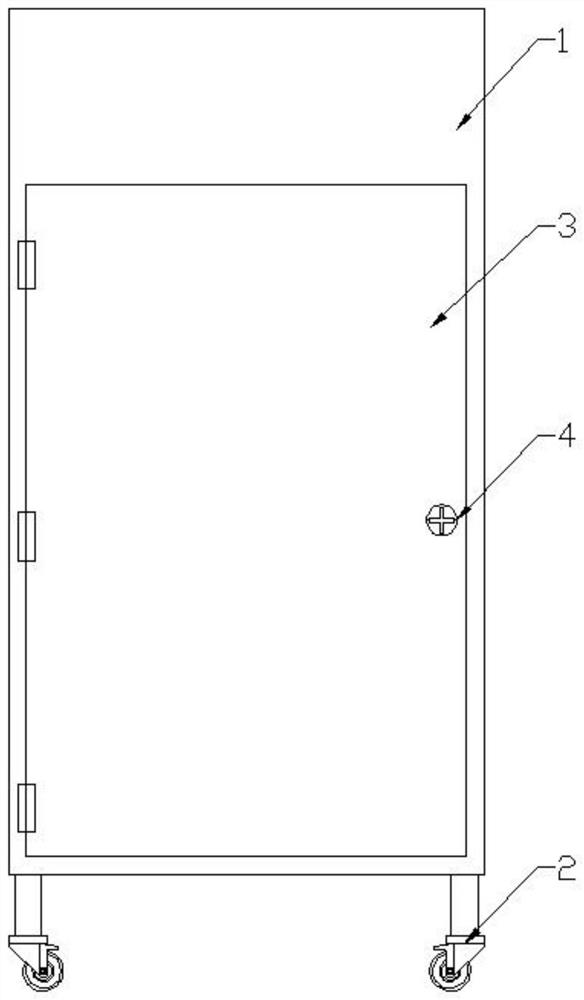

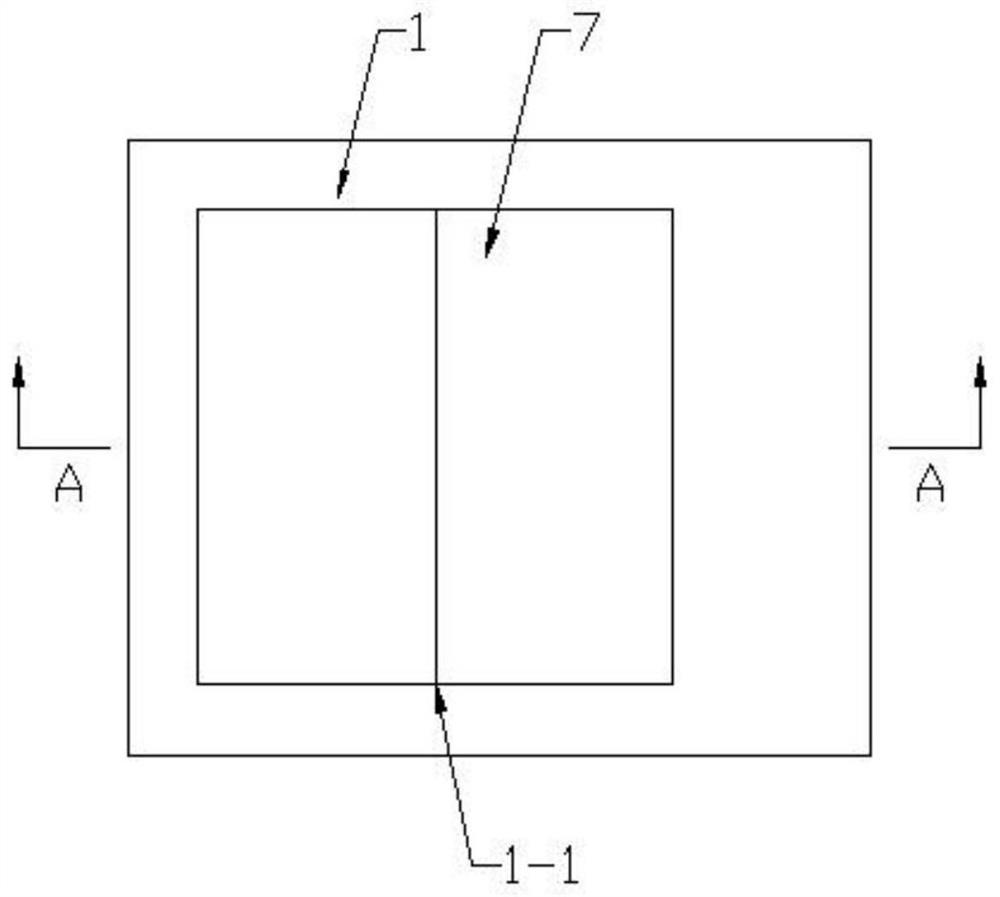

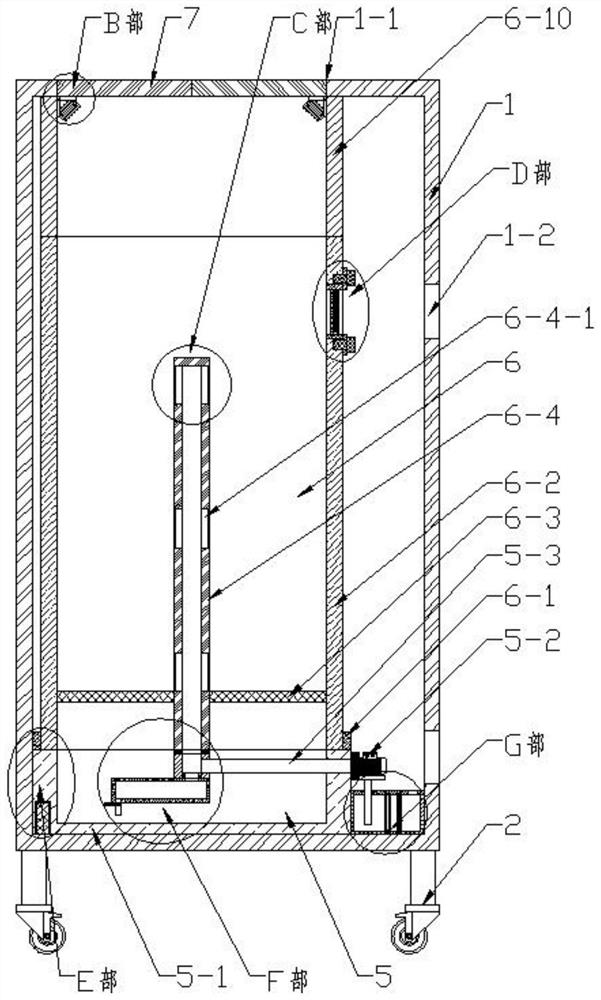

Collecting device for medical waste

ActiveCN111746980AEasy to handle separatelyAvoid smallWaste collection and transferRefuse receptaclesRefuse collectionSpiral blade

The invention discloses a collecting device for a medical waste. The collecting device comprises a compression bucket, a storage bucket and a filter bucket, wherein the compression bucket comprises anend cover, a shell, a rotating shaft and spiral blades; a plurality of spiral blades are fixedly connected with the rotating shaft, the rotating shaft and the shell are rotationally connected and located in the shell, and the end cover seals the shell, so that the wastes can enter the compression bucket and rotate the rotating shaft to compress the wastes through the spiral blades; the storage bucket comprises a storage bucket main body, a waste pipe and a baffle; the waste pipe communicates with the waste outlet of the compression bucket and is located in the storage bucket main body, the baffle and the storage bucket main body are rotationally connected, so that the storage bucket main body can be opened to take out the waste; the filter bucket comprises an inner bucket and a liquid storage bucket; and the waste enters the inner bucket of the storage bucket main body through the bucket pipe, liquid enters the liquid storage bucket by mesh holes on the inner bucket so as to separatethe solid from the liquid, the actual amount of the waste stored in a trash can is increased, and the solid and liquid are easier to be disposed respectively in the later stage.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

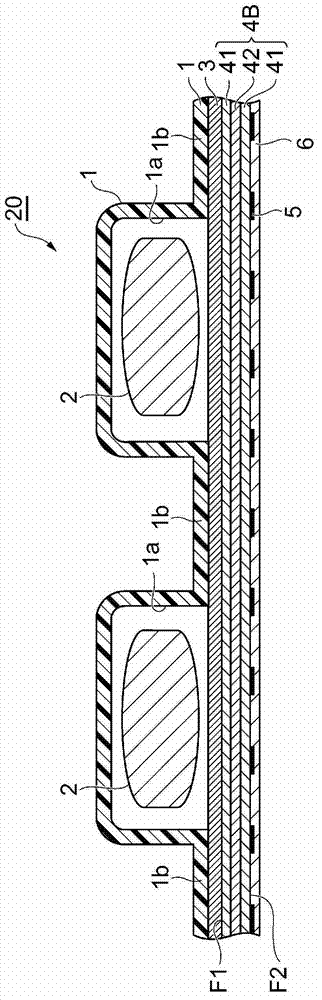

Push-through pack packaging

ActiveCN103201189BExcellent pressure penetrationDon't worry about damageSmall article dispensingFlexible coversStyrene-maleic anhydride copolymerPolymer chemistry

The press-through package of the invention has a covering material composed of a stretched film including at least one layer, the layer comprising a thermoplastic resin including at least one selected from the group consisting of styrene-acrylic acid copolymer resins, styrene-methacrylic acid copolymer resins, styrene-maleic anhydride copolymer resins and terpolymer resins comprising one of these three copolymer resins and an ester component, and an inorganic filler at less than 5 parts by weight with respect to 100 parts by weight of the thermoplastic resin.

Owner:ASAHI KASEI KK

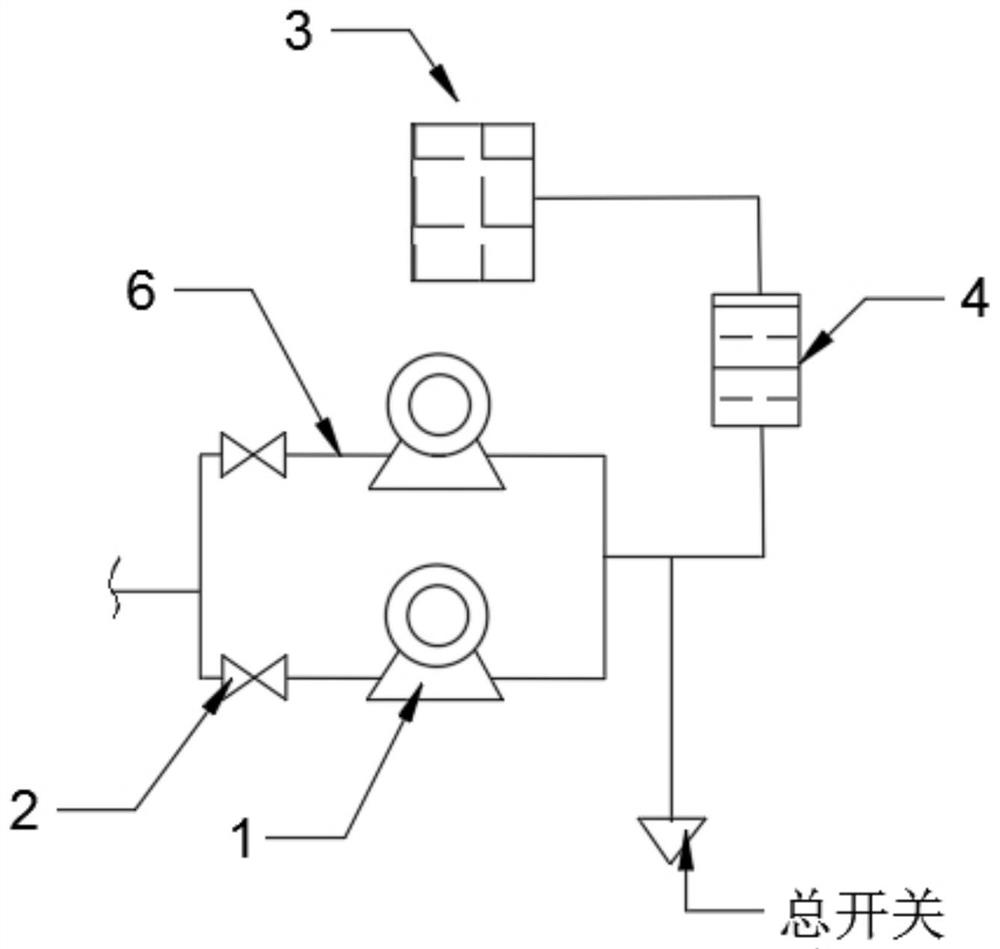

Unattended oil-gas mixed transportation process device

PendingCN113188042AReduce investmentReduce pollutionSludge treatment by de-watering/drying/thickeningLiquid hydrocarbon mixture productionAutomatic controlControl system

The invention discloses an unattended oil-gas mixed transportation process device which comprises a mixed transportation assembly and an intelligent sensing control system. The mixed transportation assembly is used for realizing oil-gas mixed transportation, the mixed transportation assembly comprises a plurality of oil-gas mixed transportation pumps and dirty oil recovery assemblies, the plurality of oil-gas mixed transportation pumps are communicated in series through pipelines, and the multiple oil-gas mixed transportation pumps are all provided with control valves; and the intelligent sensing control system is used for controlling the control valves to enable the oil-gas mixed transportation pumps to operate, the pipelines are further provided with the dirty oil recovery assemblies and buffer tanks, and the buffer tanks are used for oil-gas separation. The unattended oil-gas mixed transportation process device is scientific and reasonable in structure and safe and convenient to use, large-displacement and high-oil-gas-ratio oil-gas mixed transportation can be achieved through the oil-gas mixed transportation pumps 1, the oil and gas directly enter the oil-gas mixed transportation pumps to be transported outwards, technological processes and capital investment are reduced, automatic control is achieved, stations are unattended, labor cost is reduced, oil-gas mixed transportation is achieved, and emission pollution of associated gas can be effectively reduced.

Owner:JIANGSU HONGSHENG PUMP TECH

Self-vibration blanking mechanism for drop shaft

InactiveCN108775257APlay a blocking rolePrevent accidental falling into the wellSievingMining devicesEngineeringMechanical engineering

The invention discloses a self-vibration blanking mechanism for a drop shaft. The self-vibration blanking mechanism comprises a mounting base and a grate bar outer frame, wherein safety guard rails are arranged on the side surface of the mounting base; a baffle plate is arranged in front of the safety guard rails; the grate bar outer frame is located behind a rubber washer; an exciting motor is arranged above the grate bar outer frame; longitudinal grate bars are arranged on the inner side of the grate bar outer frame; transverse grate bars are arranged on the side surfaces of the longitudinalgrate bars; support shafts are arranged below the grate bar outer frame; exciting springs are arranged below the support shafts; a crushing tank is arranged behind the grate bar outer frame; a material sensor is arranged on the side surface of the crushing tank; an air cylinder is arranged above the crushing tank; a connecting rod is arranged below the air cylinder. The self-vibration blanking mechanism for the drop shaft is provided with the crushing tank, larger material blocks can fall into the crushing tank automatically with vibration in a using process of the mechanism, so that separated treatment of large materials is facilitated, and blockage of the mechanism due to the large material blocks is prevented.

Owner:贵州政立矿业有限公司

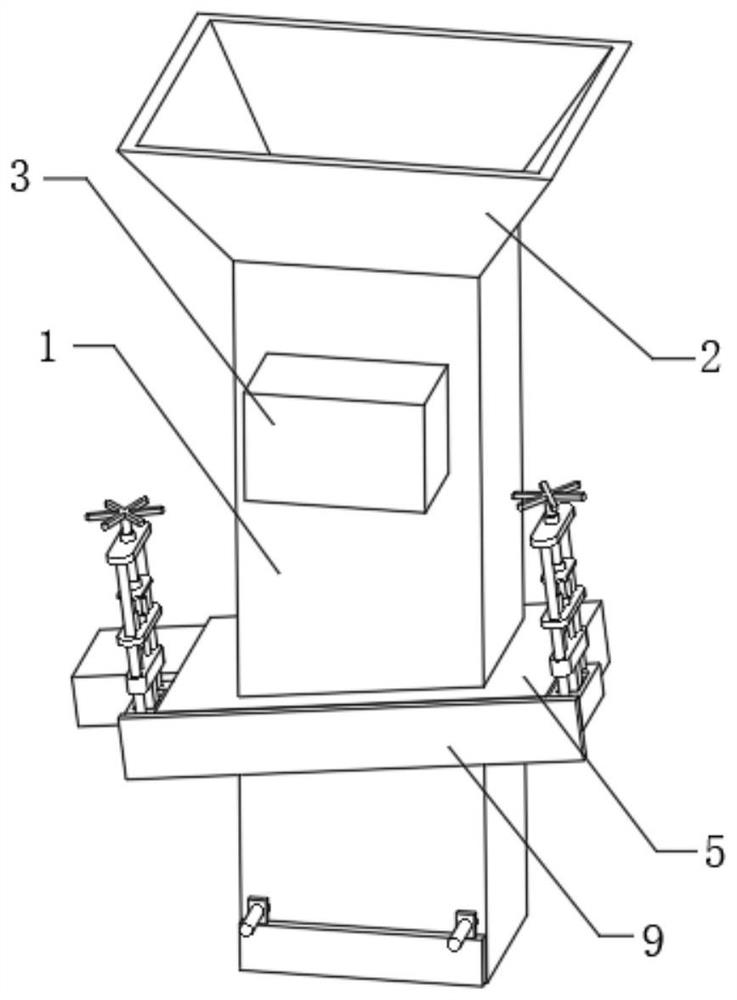

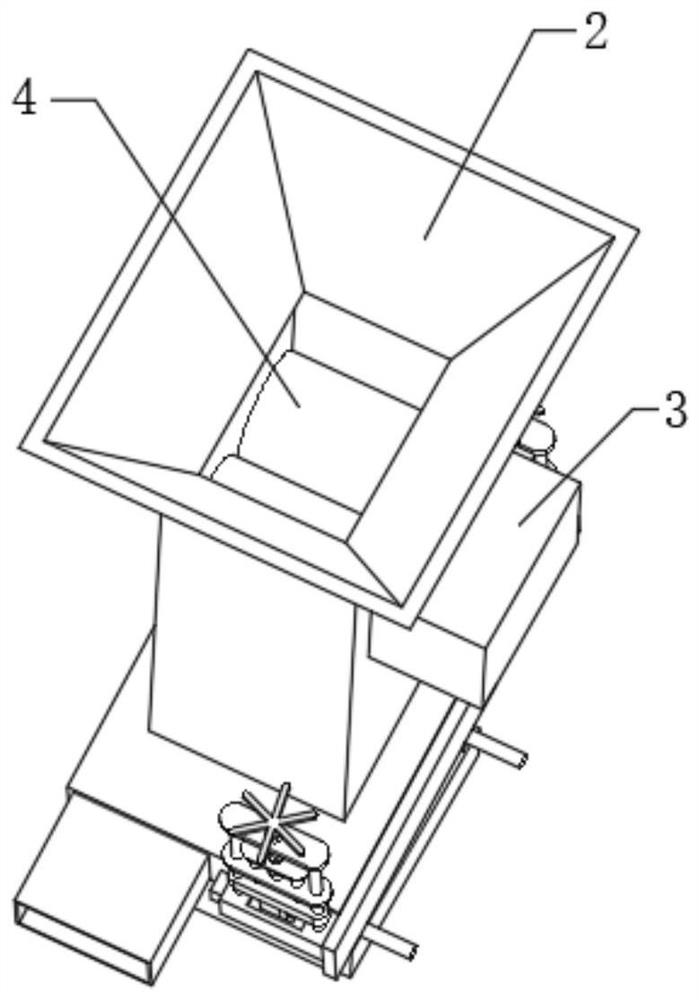

Smart city garbage environment-friendly treatment system

InactiveCN113042150ATo achieve the purpose of solid-liquid separationAvoid damageMagnetic separationGrain treatmentsElectric machineEngineering

The invention discloses a smart city garbage environment-friendly treatment system. The system comprises a bottom plate, supporting legs, an impurity removal assembly, a crushing assembly and an electric control cabinet. According to the system, through arrangement of the impurity removal assembly, garbage enters an impurity removal box through a feeding pipe, solid garbage enters the crushing assembly through a discharging opening and a through hole along a filter screen, liquid falls to the lower side of the interior of the impurity removal box through the filter screen, the purpose of solid-liquid separation of the garbage is achieved, and solid and liquid separation treatment is facilitated; strong magnetic strips attract magnetic metal in the solid waste, and the situation that the magnetic metal enters the crushing assembly and damages the crushing assembly is avoided; through arrangement of the crushing assembly, the solid waste enters the space between crushing rollers through a material guide plate, a driving motor connected with the crushing rollers is powered on to run, the driving motor drives the crushing rollers to rotate, the crushing rollers crush the solid waste, the crushed solid waste can be recycled subsequently, and the environment-friendly requirement for resource recycling is met.

Owner:中山市满鑫科技有限公司

Hematology department nursing waste recovery device and using method thereof

PendingCN113333435AEasy to handle separatelyAvoid pollutionSievingScreeningNursing careElectric machinery

The invention discloses a hematology department nursing waste recovery device and a using method thereof, and relates to the field of hematology department nursing. The hematology department nursing waste recovery device comprises a recovery device shell; the top of the recovery device shell is fixedly connected with a feeding hopper; the upper end of the front face of the recovery device shell is fixedly connected with a motor main body; the output end of the motor main body is fixedly connected with a crushing roller; the crushing roller is located in an inner cavity of the recovery device shell; the middle of the recovery device shell is fixedly connected with a filter screen plate mounting box; and the top wall of an inner cavity of the filter screen plate mounting box is fixedly connected with a bending limiting baffle. When the hematology department nursing waste recovery device is in use, a user can utilize the device to crush and recover hematology department nursing waste, and then separate the crushed solid and liquid.

Owner:JILIN UNIV FIRST HOSPITAL

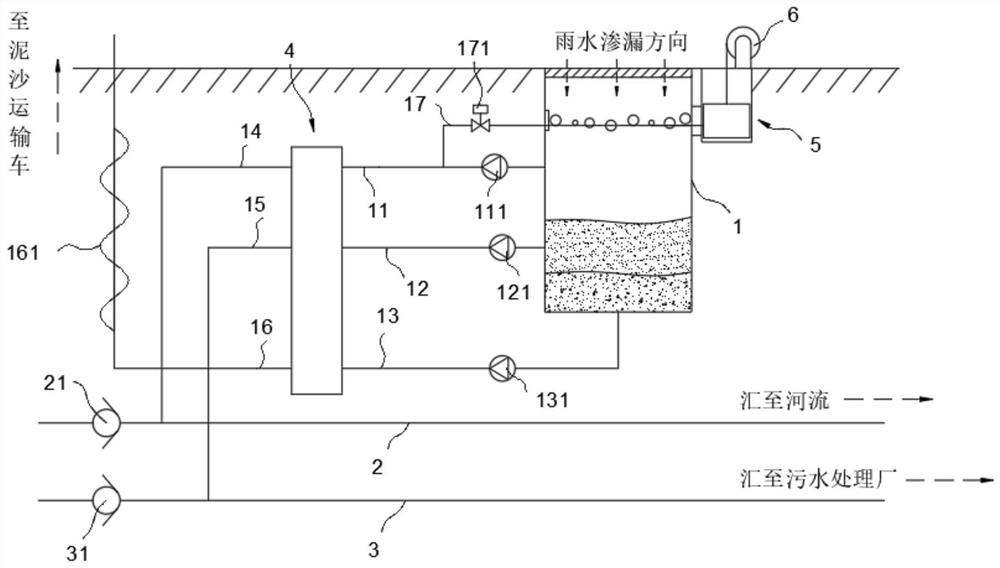

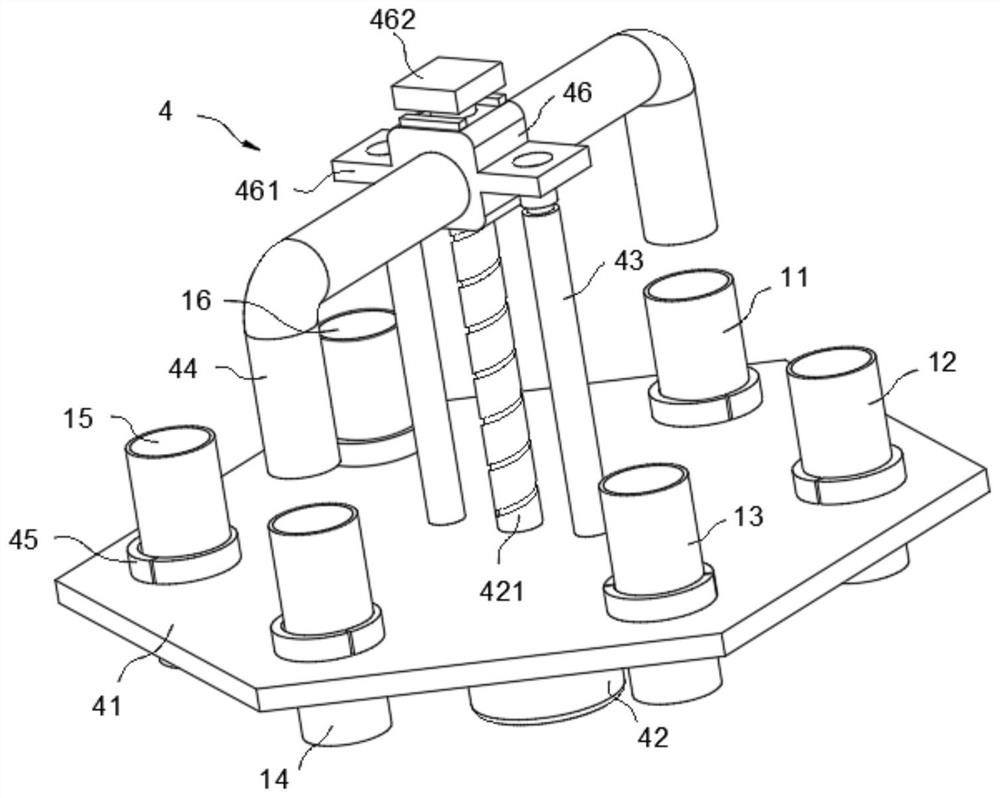

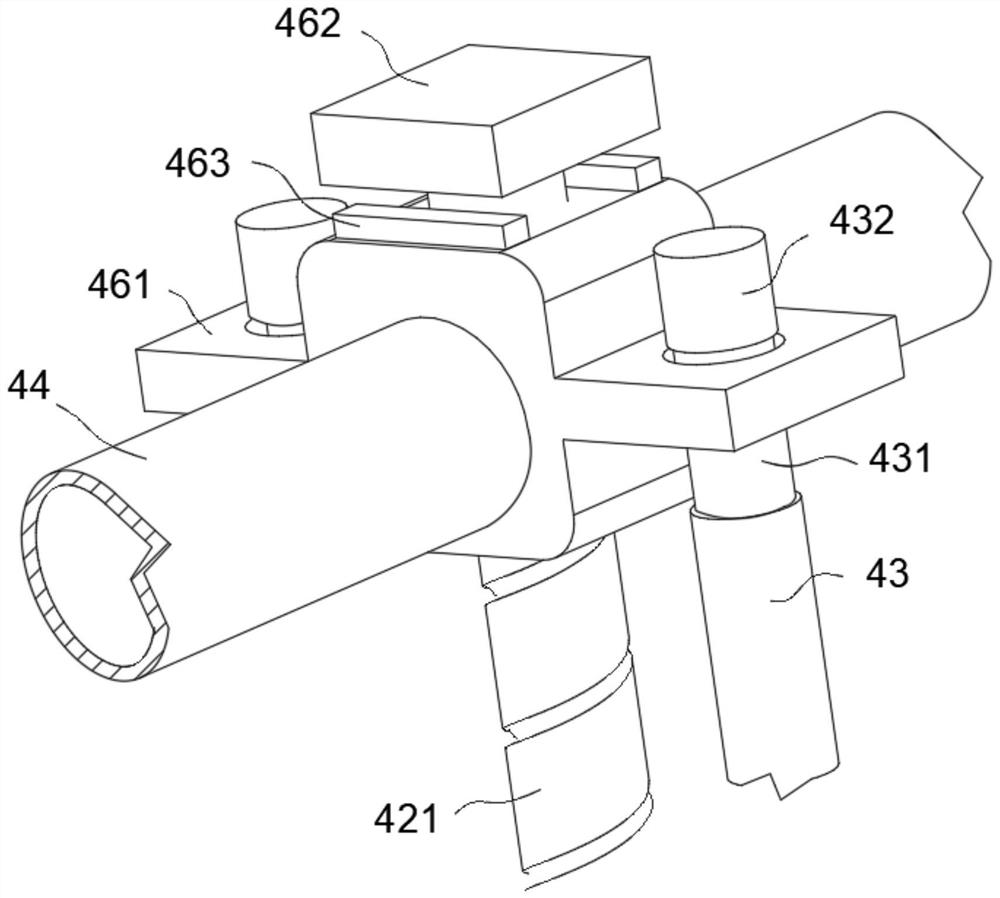

Diversion treatment and conveying equipment for municipal sewage pipe network

ActiveCN111252926BReduce processingEasy to handle separatelyFatty/oily/floating substances removal devicesSewerage structuresMunicipal sewageDrainage tubes

The invention discloses diversion treatment and conveying equipment for a municipal sewage pipe network, which includes a river drainage pipe and a sewage pipe. An underground rainwater well is arranged on the top of the river drainage pipe, and one side of the underground rainwater well is sequentially connected from top to bottom. There are clean water pipes, sewage pipes and sediment pipes. One end of the clean water pipes, sewage pipes and sediment pipes is connected with a pipeline connection device, and one side of the pipeline connection device is sequentially connected from top to bottom. There are river confluence pipes, sewage confluence pipes and mud discharge pipes, the river confluence pipes are connected to river drainage pipes, the sewage confluence pipes are connected to sewage pipes, and a screw conveyor is arranged on the mud discharge pipes. One end of the mud discharge pipe extends to the ground, the river drainage pipe is provided with a first one-way valve, the sewage pipe is provided with a second one-way valve, and the clean water pipe is provided with a clean water pump. The present invention has It has the characteristics of strong practicability and saving water treatment volume.

Owner:SUZHOU XIQUAN SOFTWARE TECH CO LTD

Garbage classification and recovery device for ecological tourism

ActiveCN113978957ATimely processingReduce adverse effectsDispersed particle separationWaste collection and transferAir pumpSewage

The invention discloses a garbage classification and recovery device for ecological tourism, and relates to the technical field of garbage recovery devices. A treatment mechanism is arranged at bottom of a box. A sewage box is arranged at the bottom of the box. An air pump is fixed on the right side wall of the sewage box, and a battery is arranged in the air pump. A first air guide pipe is connected with the air inlet end of the air pump and fixed to the right side wall of the sewage box in a penetrating mode. A connecting pipe is in through connection with the left end of the first gas-guide pipe. A first sealing ring is fixed to the upper end of the connecting pipe. A sewage pipe is arranged at the lower end of the connecting pipe. A threaded ring is fixed on the right side of the upper end of the annular wall of the sewage pipe and penetrates through the sewage pipe. The threaded ring is screwed to the bottom of the connecting pipe through threads. Peculiar smell generated by the garbage can be conveniently treated in time, and adverse effects on the tourist industry are reduced; garbage and water can be separated, separate treatment is facilitated, and the garbage is prevented from generating larger peculiar smell under the action of water and high temperature.

Owner:HULUNBUIR UNIV

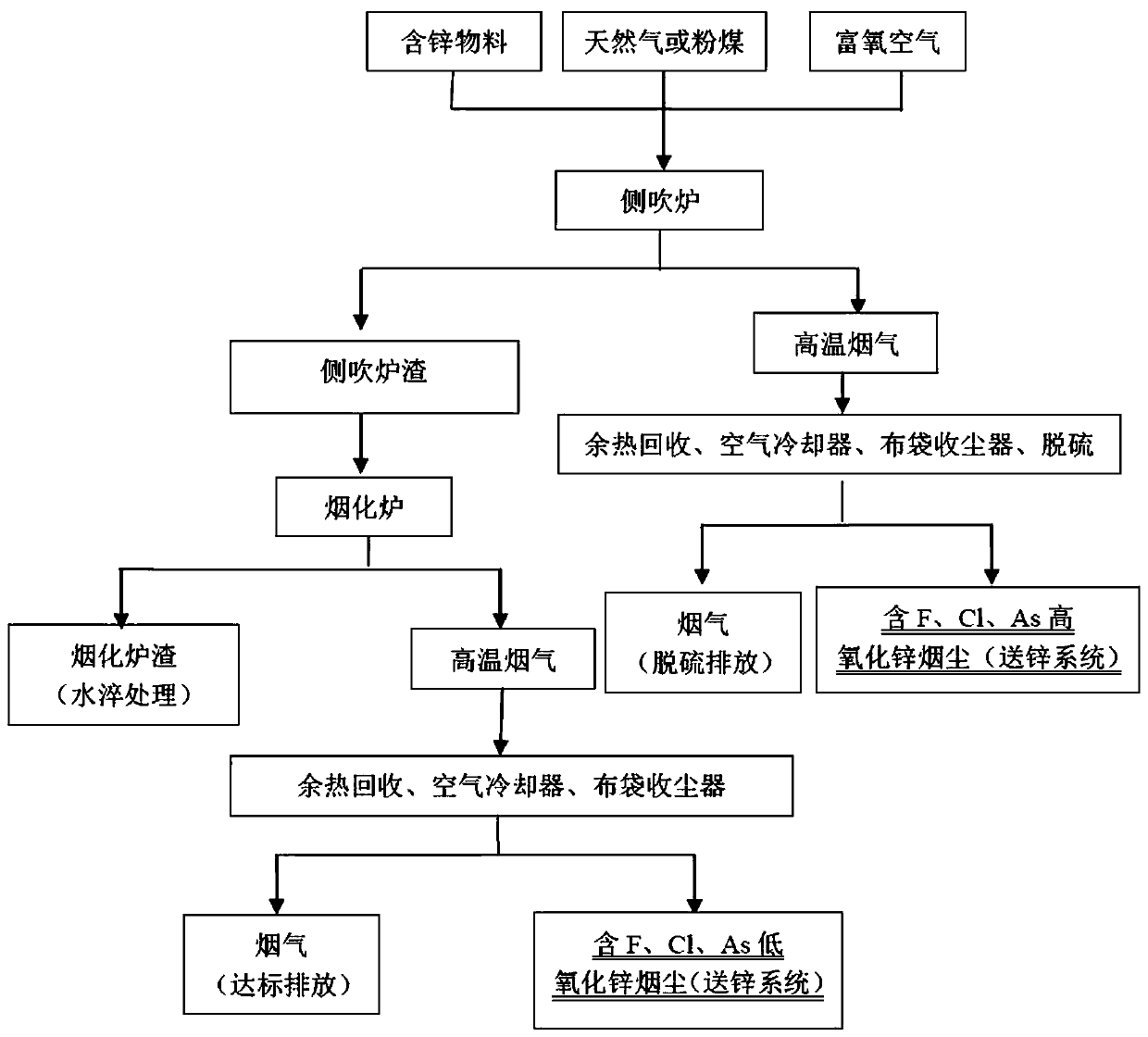

A method for combined treatment of zinc-containing materials by side-blowing material-fume blowing

The invention discloses a method for treating zinc-containing materials by combining side blowing material melting-fuming blowing. The method comprises the following steps: preparing the zinc-containing materials including lead-zinc paragenous minerals, zinc leaching residues and the like into a mixed material according to any ratio; adding the mixed material into a side blowing furnace and carrying out material melting; treating flue gas of the side blowing furnace to obtain zinc oxide smoke dust and flue gas, which have high F, Cl and As content; after desulfurizing the flue gas to reach standards, discharging the flue gas; directly putting furnace slag into a fuming furnace and carrying out blowing to obtain the furnace slag, wherein the obtained furnace slag can be directly sold afterbeing subjected to water quenching treatment; treating the flue gas of the fuming furnace to obtain zinc oxide smoke dust and flue gas, which have high F, Cl and As content, and directly discharging the flue gas after the flue gas reaches the standards. According to the method disclosed by the invention, continuous oxidization of the zinc-containing materials is realized; the bed capacity is highand low-concentration SO2 in the flue gas is stable; meanwhile, the zinc oxide smoke dust which has the high F, Cl and As content and the zinc oxide smoke dust which has the low F, Cl and As content are separated, so that zinc oxide is easy to treat separately in the next step and the cost can be reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

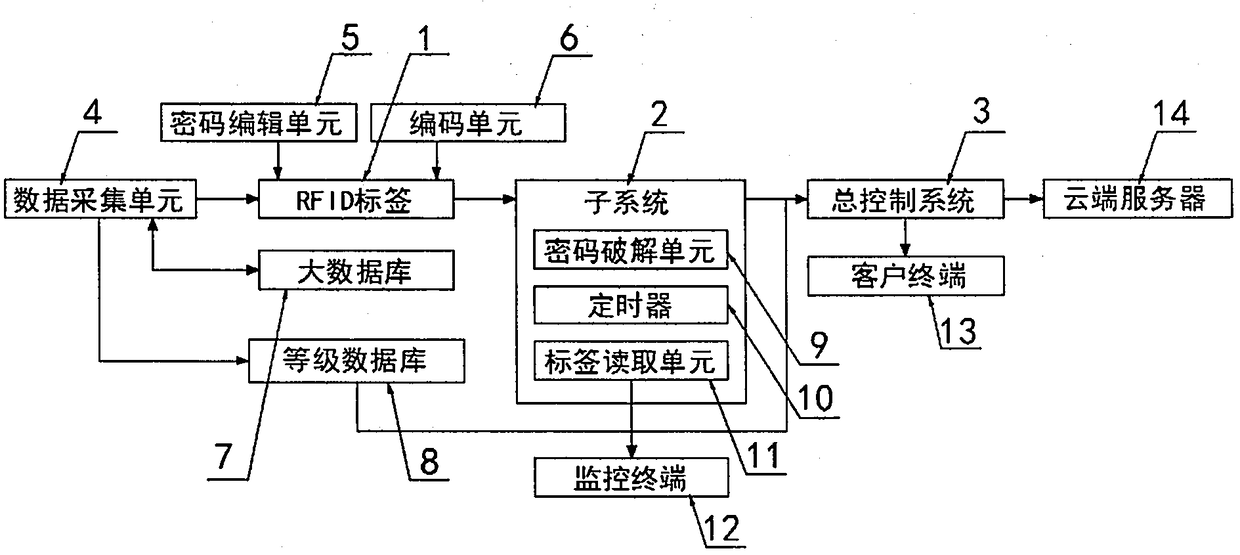

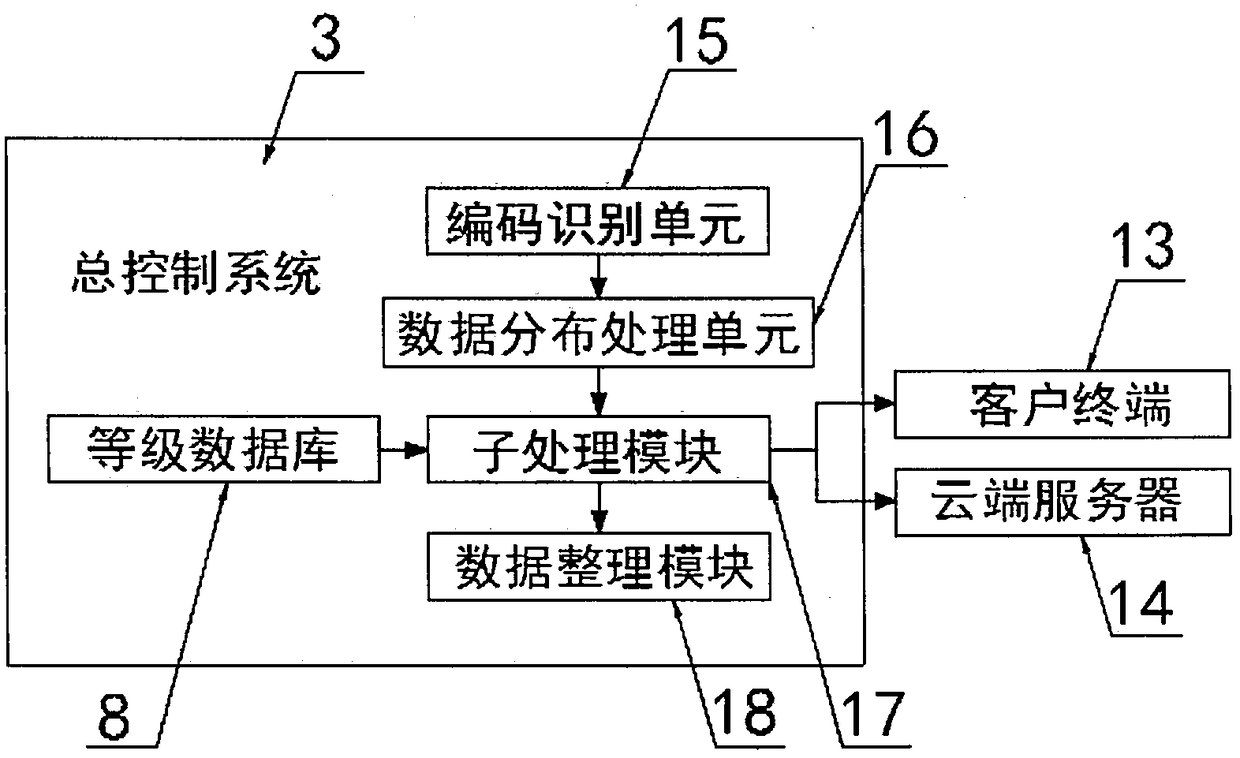

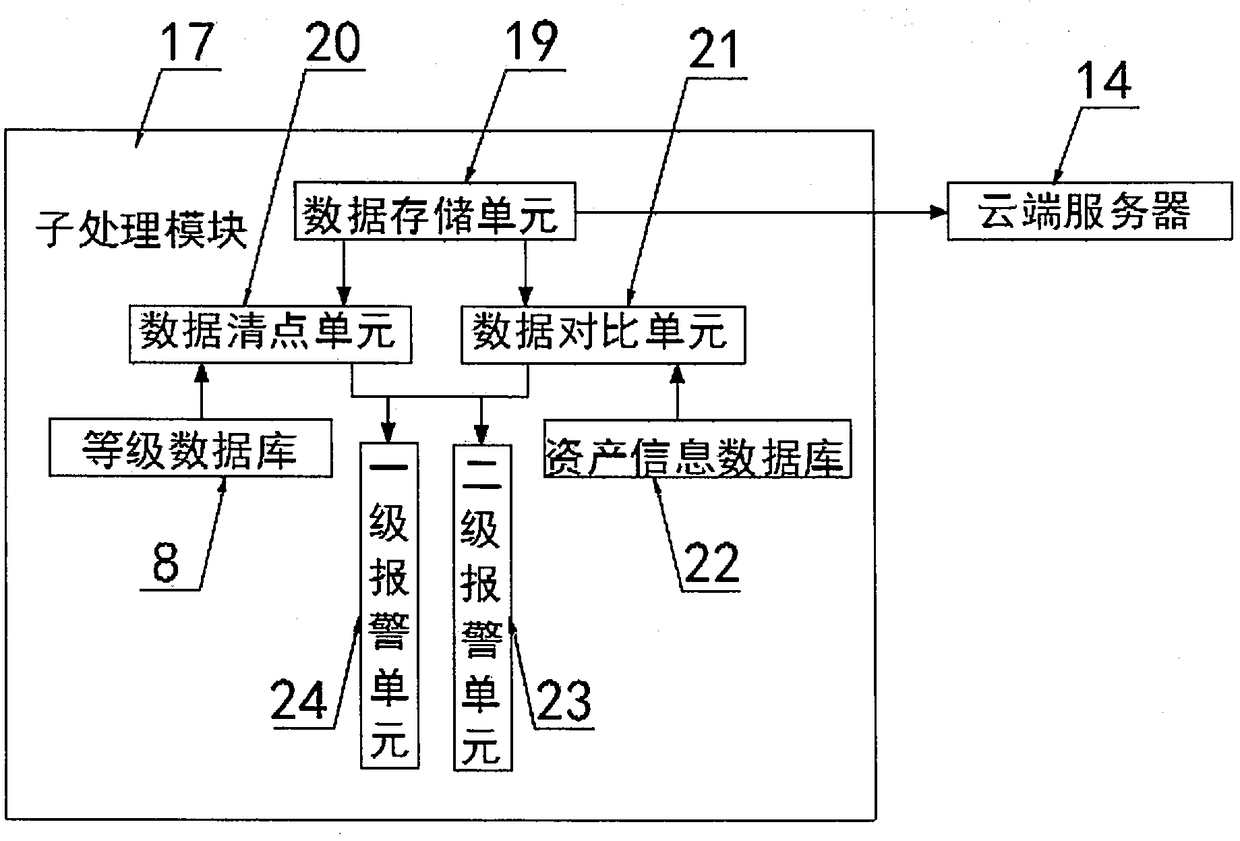

Asset management system

PendingCN109034685AAvoid confusionEasy to handle separatelyCo-operative working arrangementsLogisticsRadio frequencyData acquisition unit

An asset management system includes RFID tags, a subsystem and a general control system, wherein that output end of each RFID tag is connected with the input end of the subsystem, the output end of the subsystem is connected with the input end of the general control system, the input end of the RFID tag is provided with a data acquisition unit, a cipher editing unit and a coding unit, and the connection end of the RFID tag is provided with a large database. By encoding the RFID tag and the data sent by the RFID tag in each region, a plurality of sub-processing modules process the encoded dataseparately, avoid data confusion in each area, send its own positioning information in real time through RFID tags to avoid the loss of physical assets, encrypt RFID tags to prevent irrelated personnel from scanning RFID tags randomly by a radio frequency scanning device, and keep the data of physical assets confidential and good confidentiality.

Owner:SHANGHAI ZIYUE NETWORK TECH

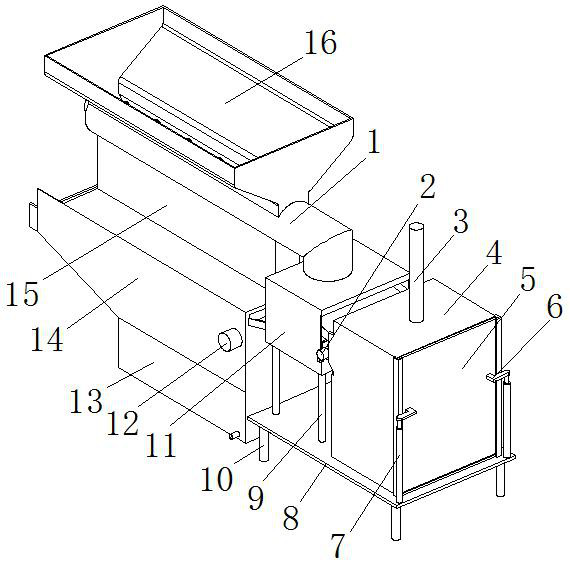

A machine tool automatic chip removal device

ActiveCN112453994BAchieve up and down swingEasy to deal withMaintainance and safety accessoriesLiquid storage tankElectric machinery

The invention discloses an automatic chip removal device for a machine tool, comprising a chip removal pipe, a chip compression box, a bottom plate, a slag-liquid separation box, a liquid storage tank, a reciprocating swing mechanism and a conveying frame. The inside of the chip removal pipe is provided with a spiral The discharge paddle, the left end of the chip discharge pipe is provided with a third motor, the output shaft of the third motor penetrates into the inside of the chip discharge pipe and is connected with the screw discharge paddle, the chip discharge pipe is provided with a chip collection groove, and the The discharge end is connected with the slag-liquid separation box, the conveying frame is arranged below the chip discharge pipe, the conveying frame is provided with a roller, and the roller is provided with a filter conveyor belt, through which the cooling liquid and small particle debris are removed. The left end of the conveying frame is provided with a scraper; the invention has novel structure design, good chip removal effect, can classify the chip particles, is convenient for separate processing, and compresses large chips , saves space, avoids frequent handling of debris and saves time.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

Device for purifying heavy metal wastewater in biological fermentation mode

InactiveCN113428988ARoll out automaticallyEasy to handle separatelyWater treatment compoundsWater contaminantsXanthomonas campestrisXanthomonas sp.

The invention relates to the field of biological fermentation, in particular to a device for purifying heavy metal wastewater in a biological fermentation mode, which comprises a first fixing frame, a pushing mechanism, a blocking mechanism, a fermentation mechanism and the like, a piston is arranged on one side of the first fixing frame, the pushing mechanism is arranged on the first fixing frame, the blocking mechanism is arranged on the first fixing frame, and the fermentation mechanism is arranged on the first fixing frame. Through cooperation of internal parts of the equipment, the two nozzles alternately spray mixed powder of the xanthomonas sp. Strain and the D-glucose to the two corresponding fermentation filter screens, so that the mixed powder of the xanthomonas sp. Strain and the D-glucose can be supplemented to the fermentation filter screens in time; and the L-ascorbic acid on the two fermentation filter screens can be alternately and fully contacted with the heavy metal wastewater in the first fixing frame, so that convenience is provided for purifying the heavy metal wastewater in the first fixing frame, and the effect of timely supplementing the mixed powder of the xanthomonas sp. Strain and the D-glucose for the fermentation filter screens is achieved.

Owner:黄文强

Vulnerability detection device for casing preparation

PendingCN114544090APrevent disengagementConvenience for subsequent useDetection of fluid at leakage pointAnimal intestines working-upEngineeringVulnerability detection

The invention relates to a detection device, in particular to a loophole detection device for casing preparation. The loophole detection device for sausage casing preparation can clamp sausage casings, prevent the sausage casings from falling off and facilitate detection of the sausage casings by people. According to the loophole detection device for casing preparation, supporting frames are arranged on the left side and the right side of the rear end of a bottom plate; the water injection pipe is arranged on the supporting frame on the left side; the ball valve is rotationally arranged at the left end of the water injection pipe; the supporting frame fixing pipe is arranged on the right side; and the clamping mechanisms are arranged at the tops of the two supporting frames, and the clamping mechanisms are located at the inner ends of the water injection pipe and the fixing pipe. The worm is rotated to drive the worm wheel to rotate, and the worm wheel drives the bidirectional screw rod to rotate, so that the clamping blocks move towards the inner side to be in contact with the casing, and the casing is clamped by the clamping blocks, and the casing is prevented from being separated from the water injection pipe and the fixed pipe under the gravity of clear water.

Owner:罗志秋

A medical waste collection device

ActiveCN111746980BEasy to handle separatelyAvoid smallWaste collection and transferRefuse receptaclesRefuse collectionHelical blade

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Automatic graphite cutting machine

PendingCN114407208ASave space resourcesEasy to handle separatelyWorking accessoriesStone-like material working toolsElectric machineryEngineering

The invention relates to an automatic graphite cutting machine which comprises a machine table, a material carrying plate arranged on the machine table, a driving air cylinder arranged on the machine table, a cutting motor arranged on the machine table and a blade arranged on a rotating shaft of the cutting motor, graphite is placed in the material carrying plate, a placing plate is arranged at one end of the machine table in the length direction, and the driving air cylinder is arranged on the placing plate. A cavity is formed in the machine table, the cutting motor is arranged in the cavity, a rotating shaft of the cutting motor penetrates through and extends out of the machine table, the rotating shaft of the cutting motor faces the driving air cylinder, the blade is located outside the cavity, and a piston rod of the driving air cylinder is provided with a connecting plate. The other end of the connecting plate in the length direction is rotationally connected with a connecting rod, the connecting rod is away from the first connecting plate and connected to the cutting motor, and the driving cylinder drives the cutting motor to slide in the width direction of the machine table. The device has the function of saving space.

Owner:嘉善屹凯轴承配件有限公司

A programming system and programming method for an integrated control system of a fan

ActiveCN109343448BLower the thresholdShorten the development cyclePump controlPIc programmingControl systemSoftware engineering

Owner:GUODIAN UNITED POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com