Device for purifying heavy metal wastewater in biological fermentation mode

A bio-fermentation and heavy metal technology, which is applied in biological water/sewage treatment, special compound water treatment, water pollutants, etc., can solve problems such as non-existent and non-existent sludge containing heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

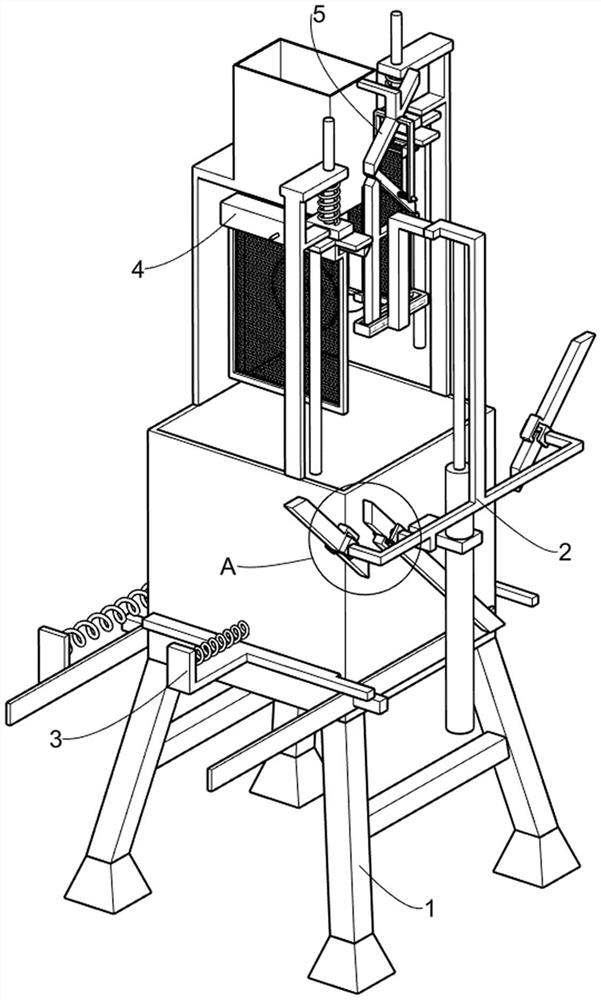

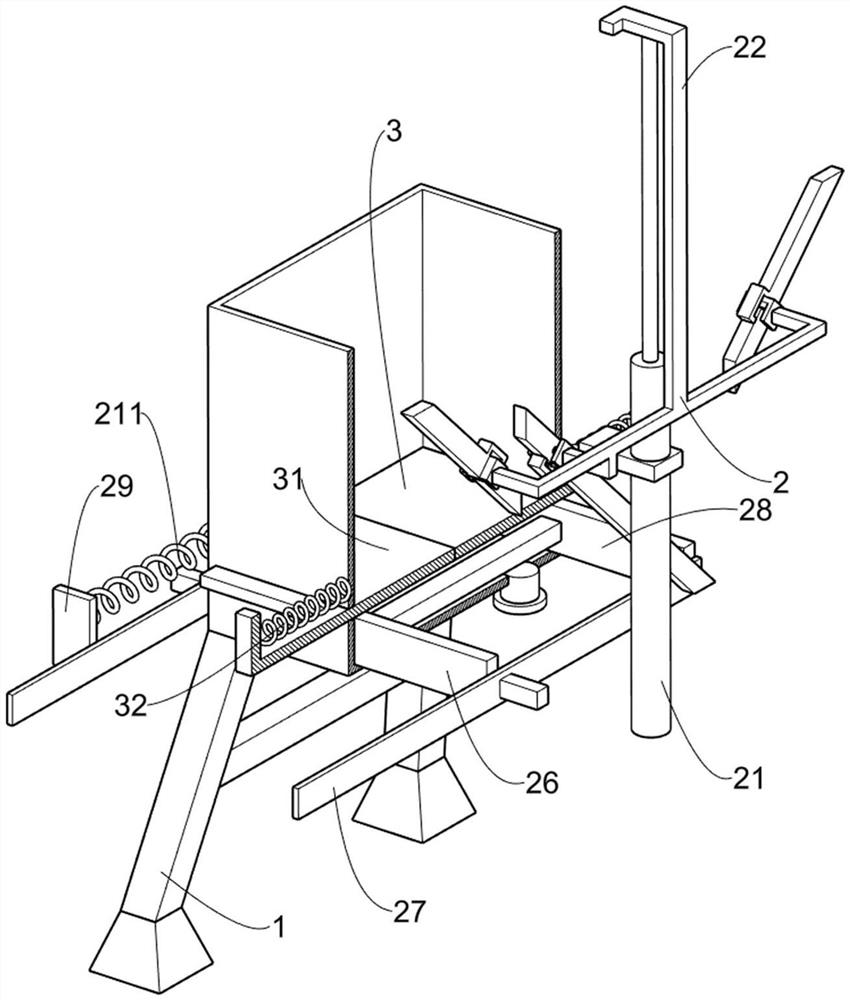

[0026] A device for purifying heavy metal wastewater by biological fermentation, such as Figure 1-9 As shown, it includes a first fixed frame 1, a pushing mechanism 2 and a blocking mechanism 3, a piston is arranged on one side of the first fixed frame 1, and a pushing mechanism 2 is arranged on the first fixed frame 1, and the pushing mechanism 2 is used to push the first fixed frame The heavy metal-containing sludge at the inner bottom of the fixed frame 1 is pushed out, and the blocking mechanism 3 is arranged on the first fixed frame 1 .

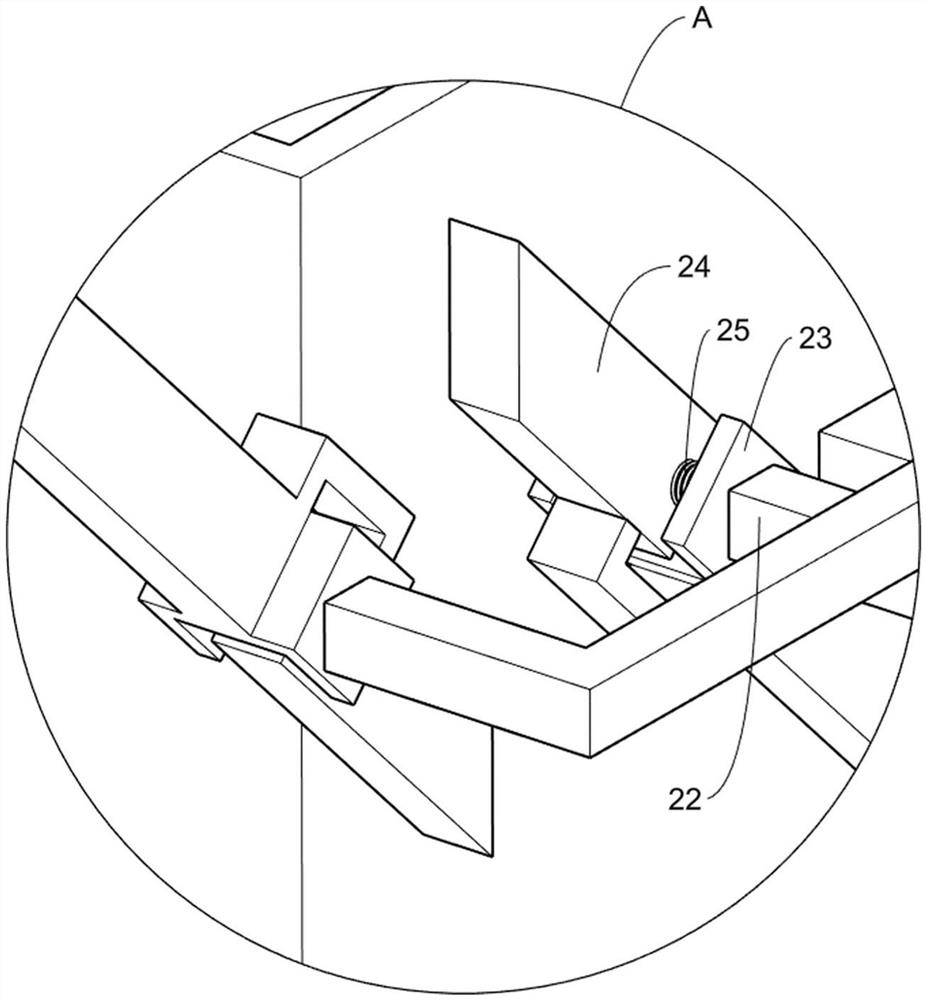

[0027] The pushing mechanism 2 includes an electric push rod 21, a second fixed frame 22, a third fixed frame 23, a first rotating plate 24, a first torsion spring 25, a first sliding plate 26, a blocking plate 27, a first fixed plate 28, The second fixed plate 29 and the first return spring 211, electric push rod 21 is installed on the first fixed mount 1, electric push rod 21 is used to drive the second fixed mount 22 and its upper de...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 5-9 As shown, a fermentation mechanism 4 is also included, and the fermentation mechanism 4 is located on the first fixed frame 1. The fermentation mechanism 4 includes a fifth fixed frame 41, a sixth fixed frame 401, a fixed rod 42, a fermentation filter screen 43, a first Slide bar 44, magnetic piece 45, the 3rd back-moving spring 46, rectangular block 47, sliding triangular block 48 and return spring 49, the 5th fixed mount 41 is connected on the first fixed mount 1, is connected with on the first fixed mount 1 The sixth fixed frame 401, the fifth fixed frame 41 is connected with the fixed rod 42, the sixth fixed frame 401 is also connected with the fixed rod 42, the fixed rod 42 is slidingly connected with the fermentation filter screen 43, the fermentation filter screen 43 is iron material, the fifth fixed frame 41 is slidably connected with a first slide bar 44, the sixth fixed frame 401 is also slidably connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com