Solid waste crushing and recycling device

A solid waste and recycling device technology, applied in grain processing and other directions, can solve problems such as hidden safety hazards, low work efficiency, and accidental injury to staff, and achieve the effects of improving work efficiency, facilitating collection, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

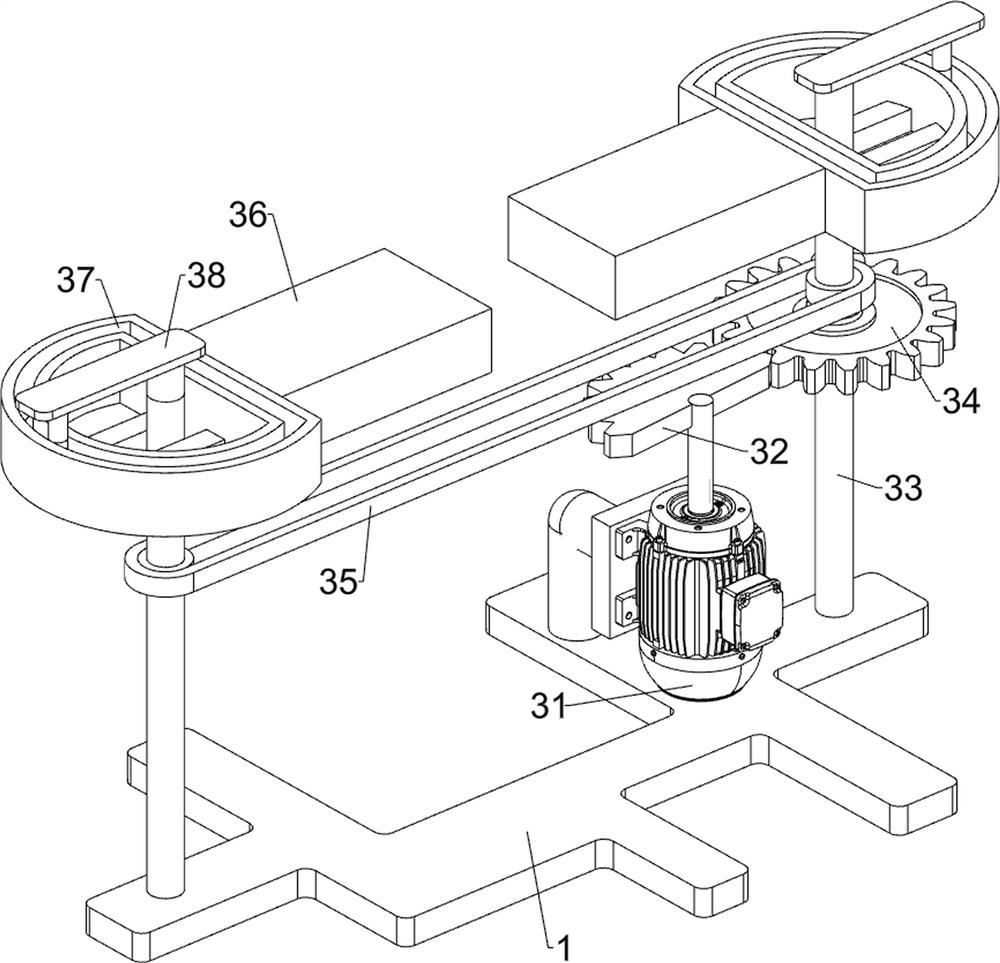

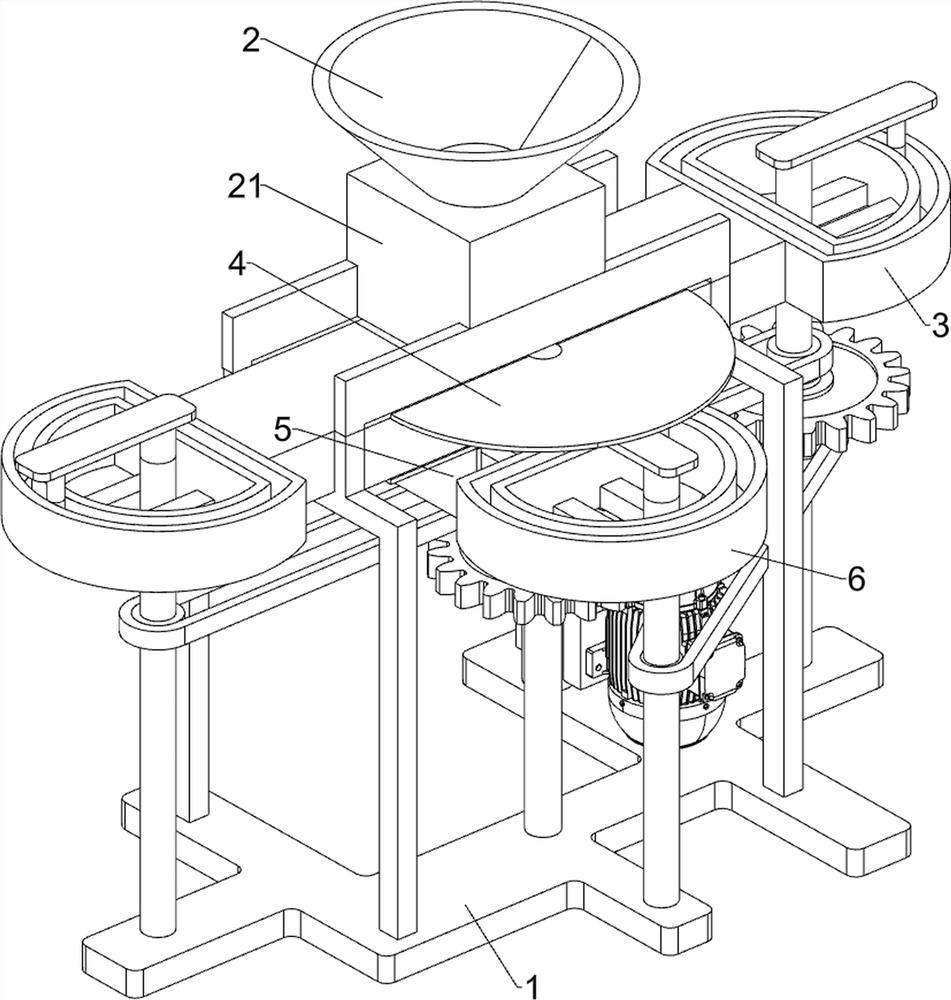

[0020] A solid waste crushing and recycling device, such as Figure 1-5 As shown, it includes a support 1, a lower hopper 2, a material storage frame 21, a crushing device 3 and a material blocking device 4, the support 1 is provided with a material storage frame 21, and the material storage frame 21 is provided with a lower hopper 2, and the support 1 There is a crushing device 3 for crushing by rotating, and the bracket 1 is provided with a blocking device 4 for blocking by rotating.

[0021] When using this device, the staff will pour the solid waste that needs to be crushed and recycled into the storage frame 21 through the lower hopper 2, and then discharge through the blocking device 4. At the same time, the solid waste is crushed by the crushing device 3. After the crushing is completed, the staff will collect the crushed waste.

[0022] Such as figure 1 , figure 2 and image 3 As shown, the crushing device 3 includes a reduction motor 31, a sector gear 32, a first...

Embodiment 2

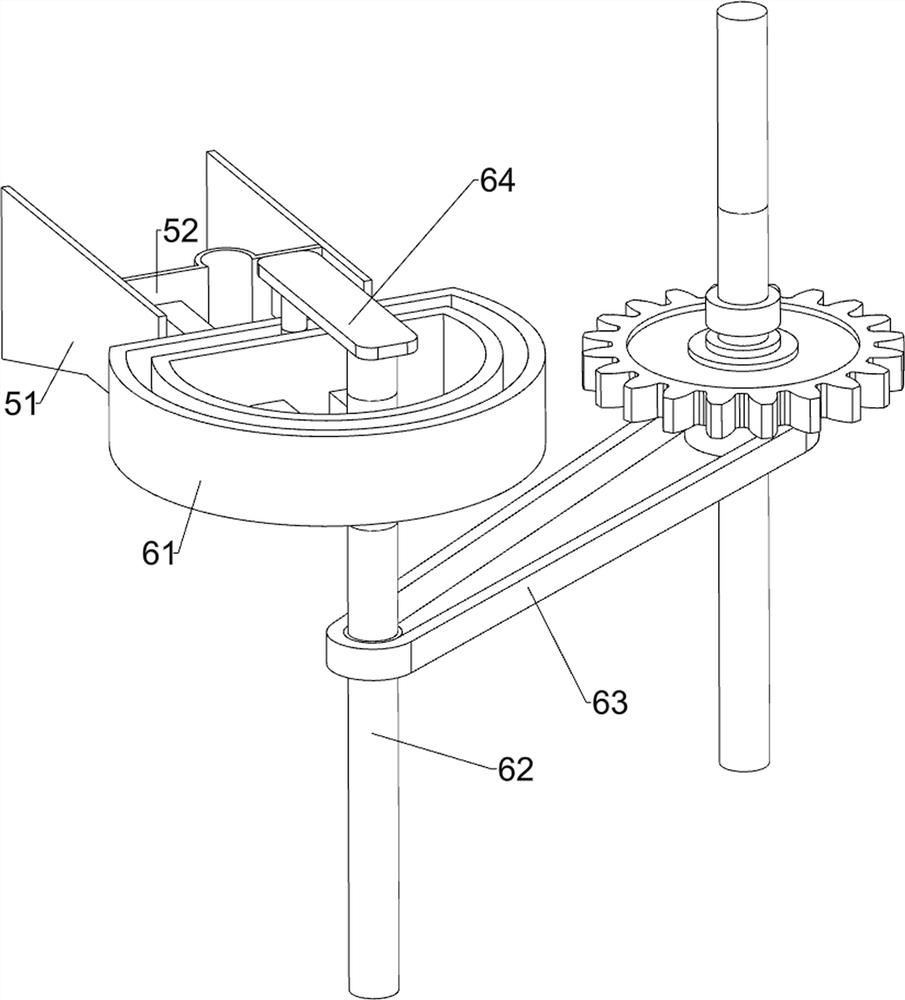

[0027] On the basis of Example 1, such as figure 1 , Figure 4 and Figure 5 As shown, a push-out device 5 is also included. The push-out device 5 includes a discharge frame 51 and a push plate 52. The support 1 is provided with a discharge frame 51, and the discharge frame 51 is provided with a slide push plate 52.

[0028] When crushing and recycling solid waste, the crushed waste falls into the discharge frame 51, and then the staff pushes the push plate 52 to slide backwards in the discharge frame 51, and the crushed solid waste follows Flow out through the discharge frame 51, so that the broken solid waste can be pushed out, which is convenient for people to collect.

[0029] On the basis of Example 1, such as figure 1 and Figure 5 As shown, an automatic pusher 6 is also included, and the automatic pusher 6 includes a second special-shaped track 61, a third rotating shaft 62, an acceleration rotation pulley set 63 and a push plate 64, and the push plate 52 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com