Reciprocating type solid waste fermentation tank capable of balancing internal air pressure for bioengineering

An internal air pressure, bioengineering technology, applied in the field of bioengineering, can solve the problems of lack of balance and inability to push out organic solid waste, and achieve the effect of balanced air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

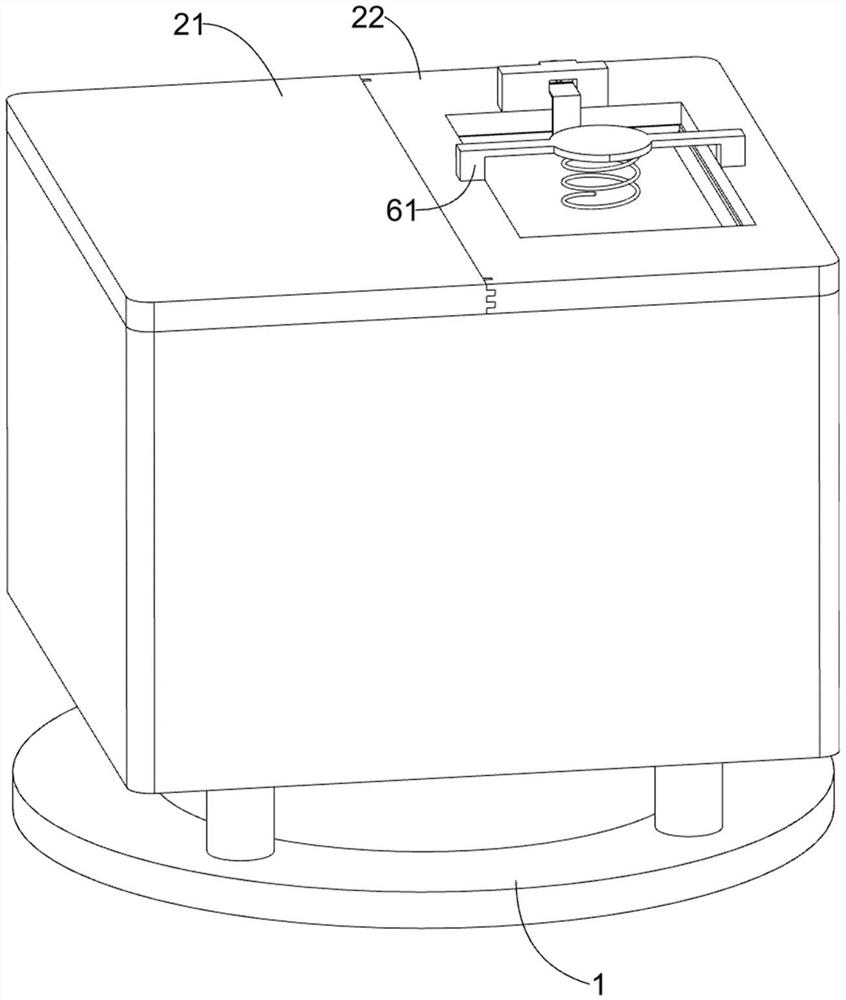

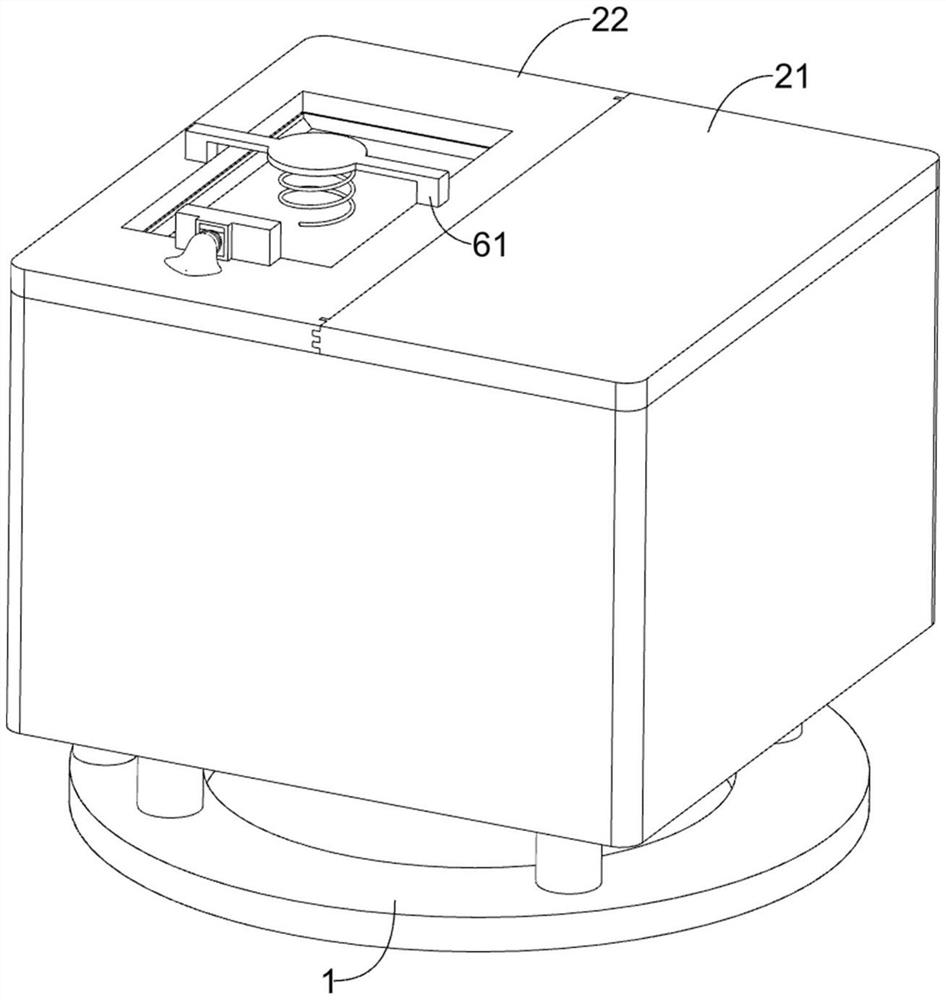

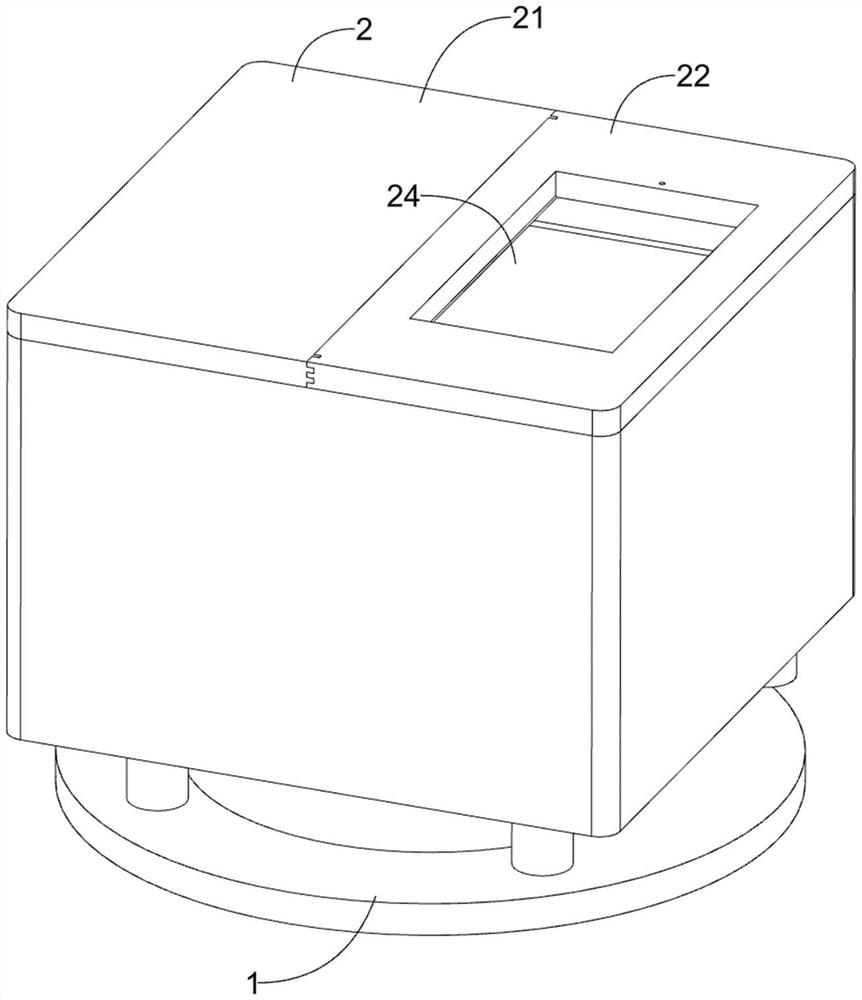

[0031] A biological engineering to balance the internal pressure of the fermentation tank reciprocating solid waste, such as Figure 1-13 , Includes a first support frame 1, 2 and closure assembly storage component 3, the support frame is provided with a first upper storage component 12, storage assembly 2 is provided with opening and closing assembly 3, to facilitate opening and closing the other feeding assembly 3 the organic solid waste into the device 24 within the second support frame.

[0032] Storage assembly 2 comprises a first plate 21, second plate 22, an electric push rod 23, the second support frame 24 and the swing shutter 25, the first supporting frame 1 connected with a first sliding plate 21, a support frame 1 is connected to a second sliding plate 22, a second cover plate 22 in contact with the first plate 21, the first support frame 1 is coupled with an electric push rod 23, push rod 23 is used to drive the second electric and means on the support frame 24 recipro...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 8-9 , The flip assembly 4 further comprises, inversion baffle assembly 4 provided on the pivot 25, the flip module 4 comprises a side flap 41, the push bar 42, a first support frame 43, second slot plate 44, the first a spring 45, struts 46 and the first card wedge frame 47, the swing shutter 25 is coupled with a side flap 41, the flap 25 is coupled with a rocking push rod 42, coupled to the second support frame 24 on the first support frame 43, a first support frame 43 slidably connected to a second slotted plate 44, by cooperating with the second side of the slotted plate 44 of the flap 41, can play a role in limiting the swing shutter 25, the second slotted plate 44 and the connection between the first support 43 and 45, a first spring 45 for 44 moves downward to drive the second slot of the first spring plate, the swing shutter 25 is coupled with a post card holder 46, a card column carrier 46 with the slotted plate 44 and the s...

Embodiment 3

[0040] Example 2 On the basis of the above, such as Figure 7 , The assembly further comprises a Release 5, Release assembly 5 is provided on the second support frame 24, for the introduction of assembly 5 inside of the second support frame 24 to complete the fermentation of organic solid wastes Release, Release 5 includes a turret assembly 51, the push plate 53, slide frame 54, a third grooved plate 55, second support 56, with a card holder 57 to promote the column, the second spring 571 and the second wedge frame 58, the second support frame 24 on a rotary connected to turret 51, the inner wall of the second support frame 24 is slidably connected to push plate 53, push plate 53 for supporting the inside of the second frame 24 to complete the fermentation of organic solid waste introduced, the push plate 53 rotates with turret 51 connection, coupled with a slide frame 54, sliding plate 55 is connected with a third groove 54 on the slide rail holder plate 31 a first slot, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com