Aluminum alloy plate flatness detection device capable of marking unqualified parts

A technology for aluminum alloy plate and flatness detection, which is applied in the direction of mechanical roughness/irregularity measurement, and can solve problems such as inability to detect aluminum alloy plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

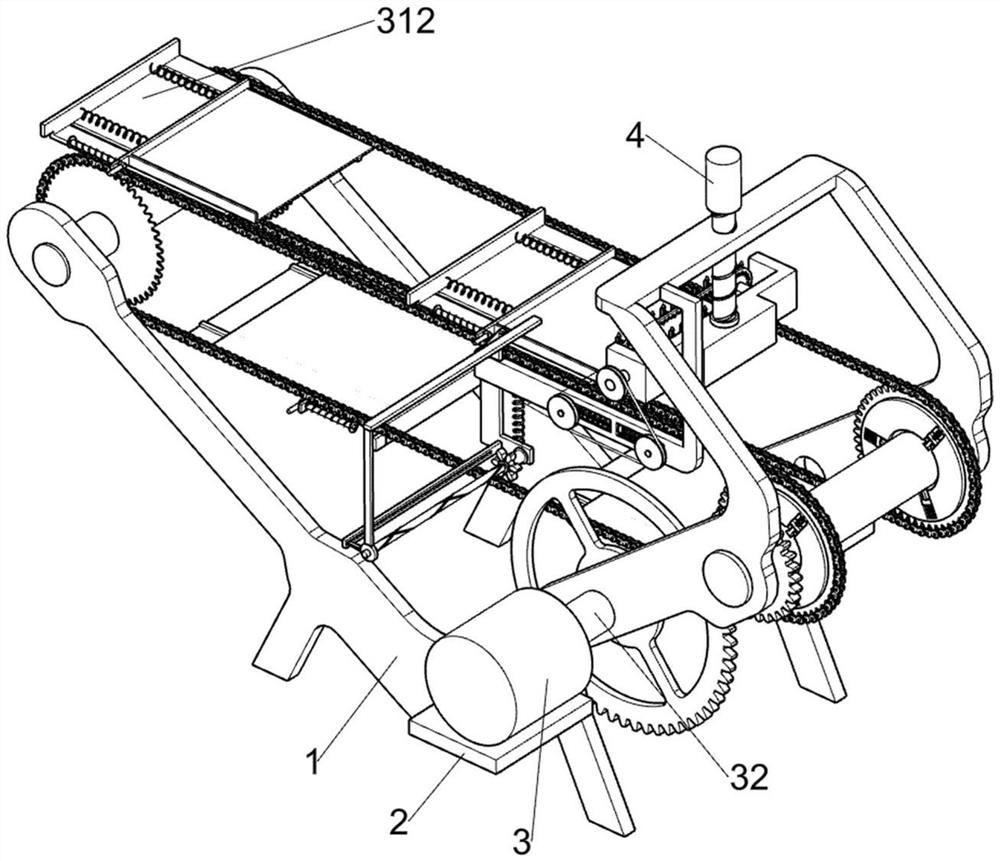

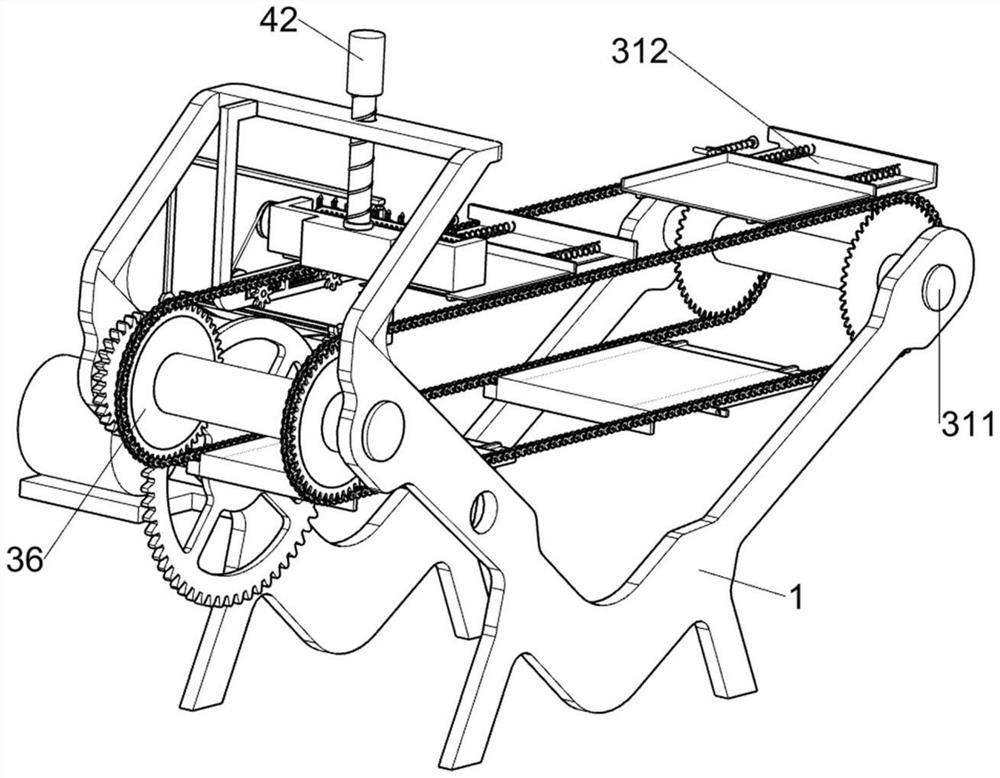

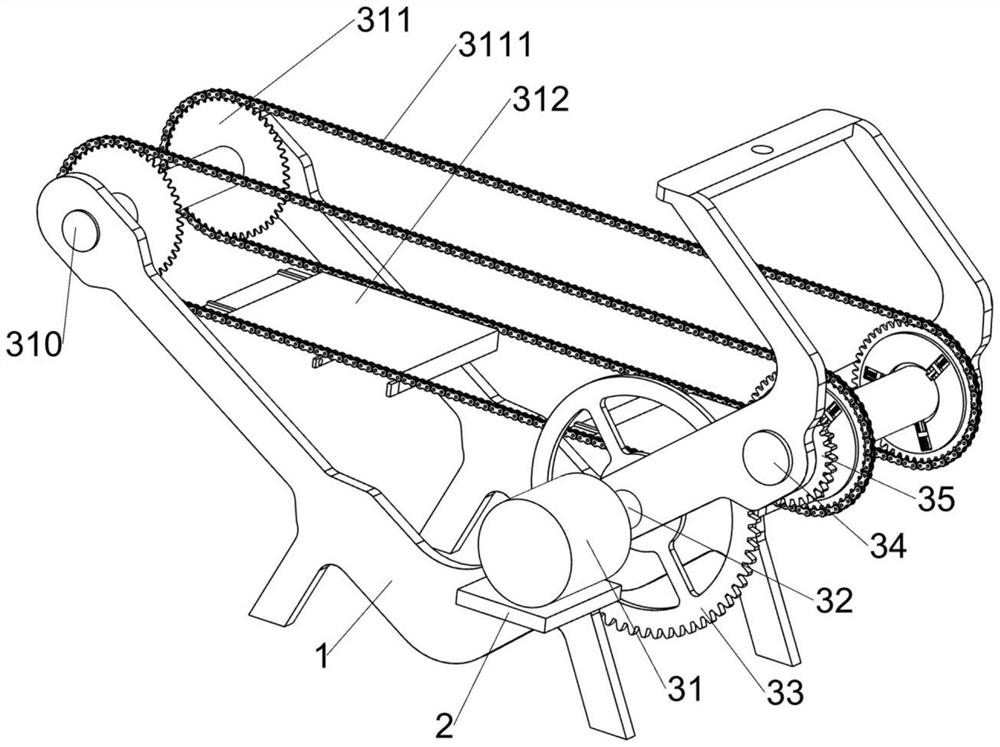

[0026] An aluminum alloy plate flatness detection device that can mark unqualified parts, such as Figure 1-9 As shown, it includes a bracket 1, a support plate 2, a clamping transmission assembly 3, an adjustment assembly 4 and a detection and recording assembly 5. The supporting plate 2 is fixedly installed on one side of the bracket 1, and the clamping transmission assembly 3 is rotatably connected to the bracket 1. , the adjustment component 4 is connected to the bracket 1 by means of screw connection, the adjustment component 4 is used to adjust the position of the detection plate 43 and the device on it, the detection and recording component 5 is arranged on the bracket 1, and the detection and recording component 5 is used for the aluminum alloy. board for inspection records.

[0027] The clamping transmission assembly 3 includes a motor 31, a power shaft 32, a sector gear 33, a clamping rod 1 34, a transmission gear 35, a sprocket 1 36, a sliding block 1 37, a clamping...

Embodiment 2

[0034] On the basis of Example 1, as Figure 8-9 As shown, it includes a toggle assembly 6, the detection and recording assembly 5 is slidably connected with a toggle assembly 6, and the toggle assembly 6 includes a push rod 61, a compression spring 62, a descending plate 63, a tension spring 64, and a fixed guide plate 65 , rotating ring 66 and pinion 67, a push rod 61 is slidably connected to the sliding placing plate 313, the pushing rod 61 is used to push the descending plate 63, and a compression spring 62 is connected between the pushing rod 61 and the sliding placing plate 313, and the descending The plate 63 is slidably connected to the fixed groove plate 51 away from the bracket 1, a tension spring 64 is connected between the fixed groove plate 51 and the descending plate 63, and the fixed guide plate 65 is fixed to the lower part of the descending plate 63 away from the fixed groove plate 51, close to the lower part of the descending plate 63. A rotating ring 66 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com