Vulnerability detection device for casing preparation

A leak detection, casing technology, applied in the direction of detecting the appearance of fluid at the leak point, workpiece clamping device, liquid tightness measurement using liquid/vacuum degree, etc. It is difficult to identify whether the casing has loopholes, easy sagging and other problems, so as to prevent the casing from sagging, easy to clean, and easy to use later.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

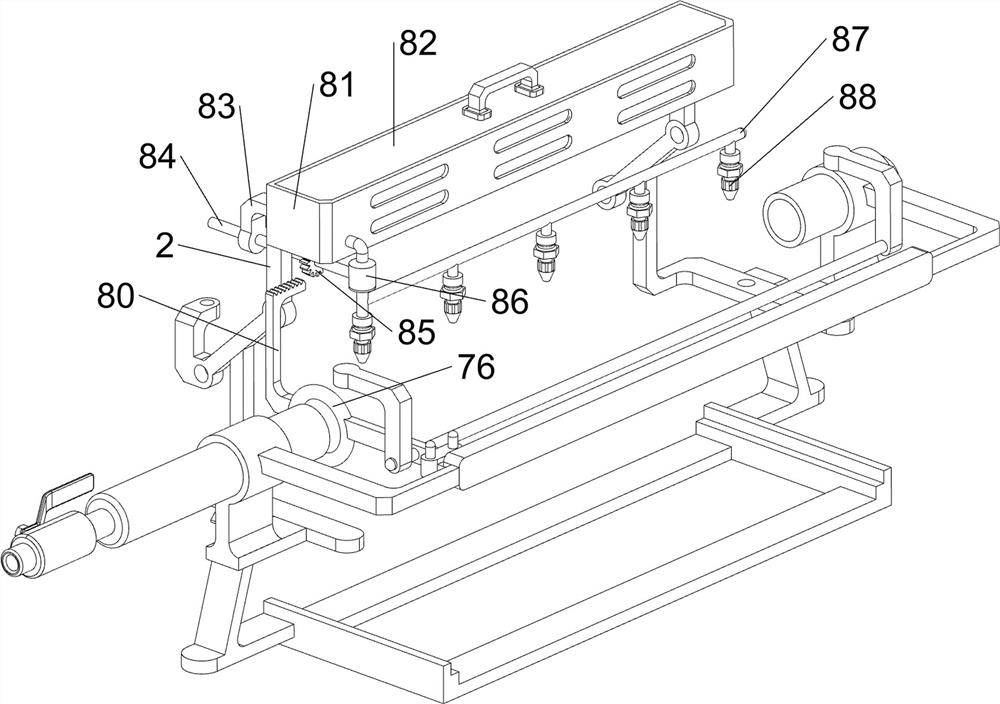

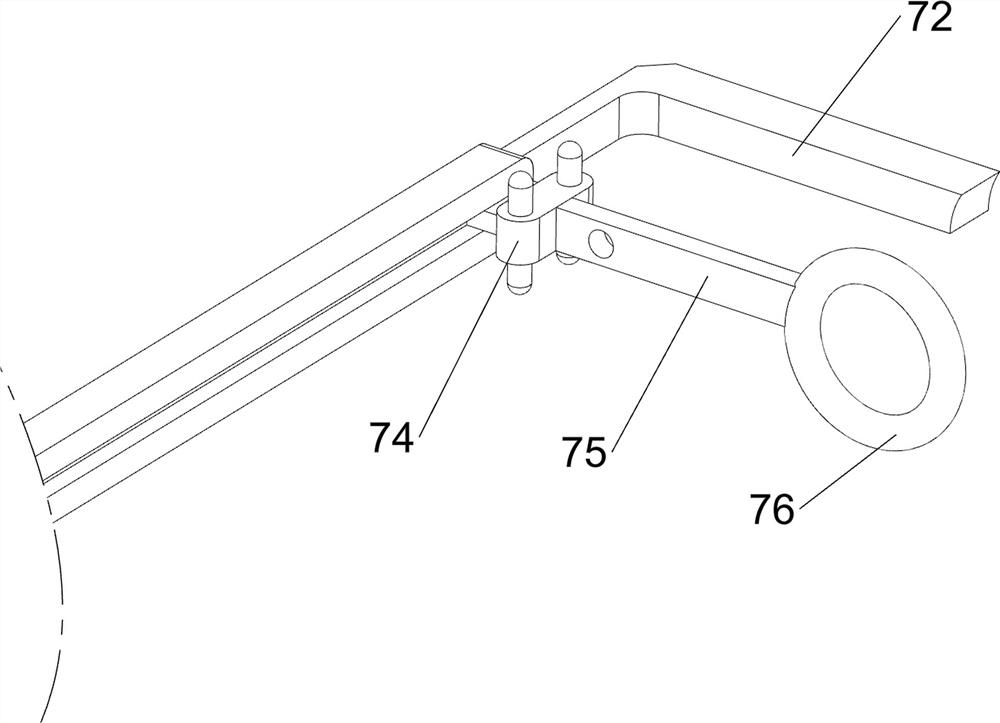

[0076] A leak detection device for casing preparation, such as Figure 1-Figure 8 As shown, it includes a bottom plate 1, a support frame 2, a water injection pipe 3, a ball valve 4, a fixed pipe 5, a clamping mechanism 6, a brushing mechanism 7 and a flushing mechanism 8. The bottom of the bottom plate 1 is provided with a non-slip pad, which can prevent slipping There are support frames 2 on the left and right sides of the rear end of the bottom plate 1, and a water injection pipe 3 is provided on the left support frame 2, which is used to inject clean water into the casing, so as to detect whether there are loopholes in the casing, and the left end of the water injection pipe 3 The rotary type is provided with a ball valve 4, the support frame 2 on the right side is provided with a fixed pipe 5, the water injection pipe 3 and the fixed pipe 5 are used to open the casing, and the top of the two support frames 2 is provided with a clamping mechanism 6 to clamp the casing. The...

Embodiment 2

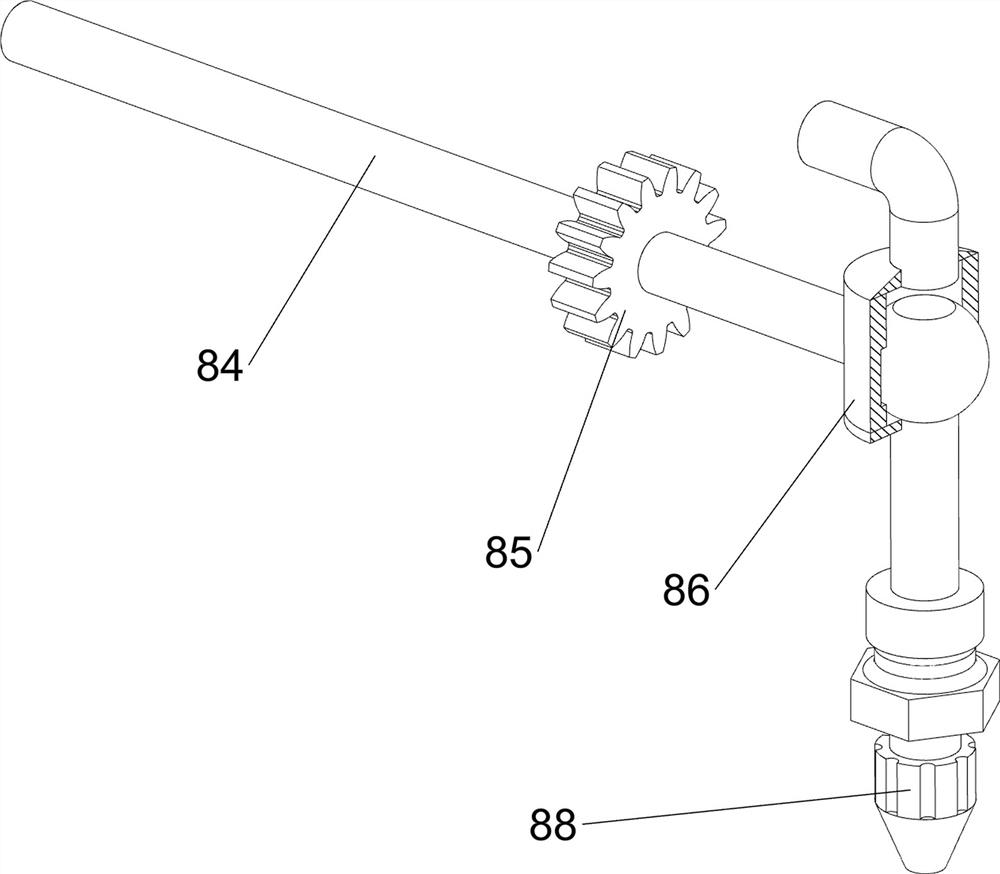

[0085] On the basis of Example 1, as figure 1 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it also includes a lifting mechanism 9. The lifting mechanism 9 includes a cam 90, a top rod 91, a first return spring 92, a rotating shaft 93, a lifting block 94 and a pressing block 95. The rear side of the rotating shaft 84 is provided with The cam 90, the support frame 2 on the left side is slidably provided with a push rod 91, the push rod 91 is in contact with the cam 90, and a first return spring 92 is arranged between the push rod 91 and the support frame 2. The rotating shaft 93 is provided with a rotating shaft 93 , a lifting block 94 is arranged on the rotating shaft 93 , and a pressing block 95 is arranged on the left side of the rotating shaft 93 , and the pressing block 95 is in contact with the ejector rod 91 .

[0086] When the casing is filled with water, the casing will sag under the gravity of the clean water, and the casing will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com