A method for combined treatment of zinc-containing materials by side-blowing material-fume blowing

A technology of joint processing and mixing materials, which is applied in the field of metallurgy to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

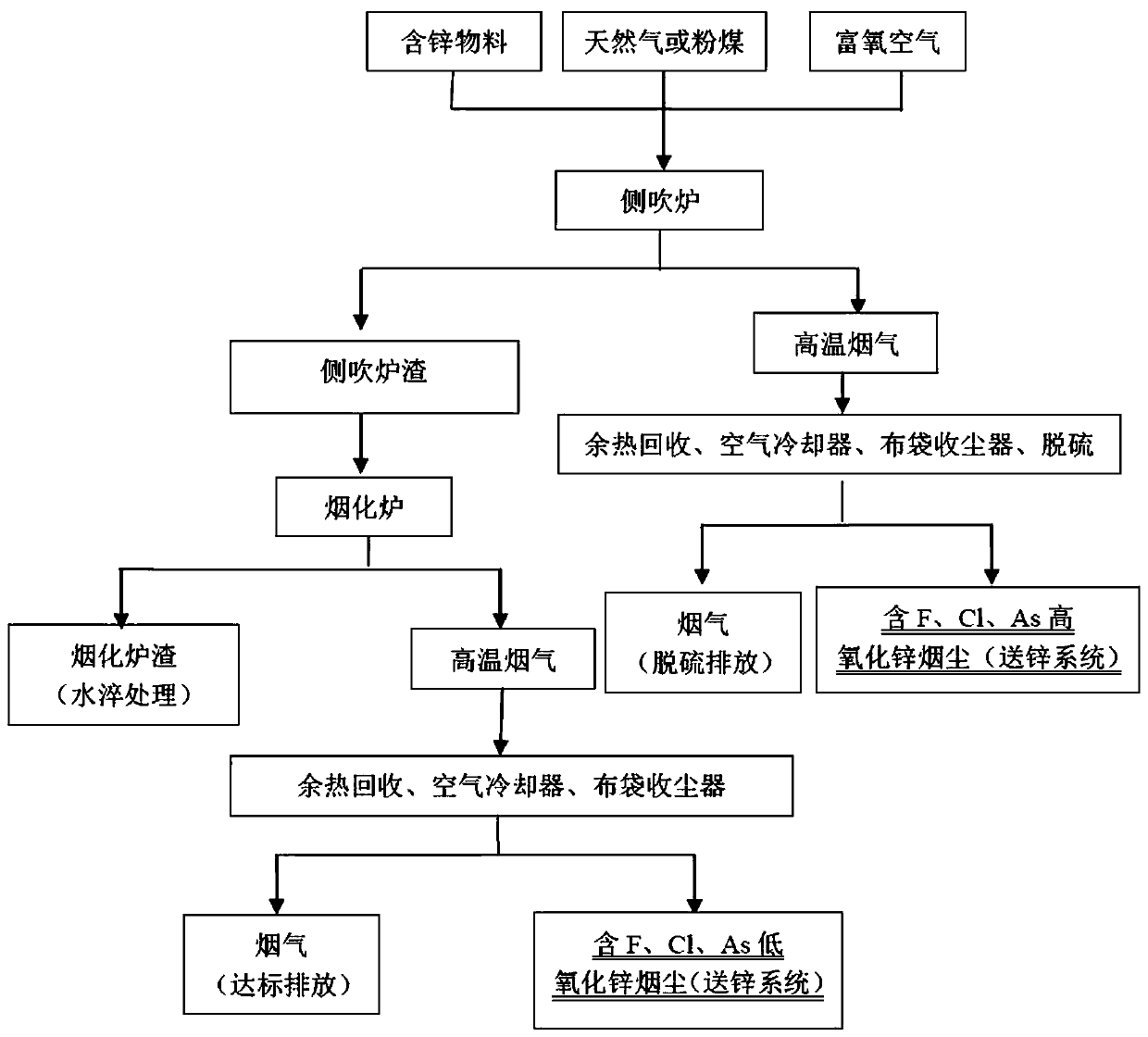

Method used

Image

Examples

Embodiment 1

[0024] The bed area is 15m 2 side-blown furnace, first lead-zinc symbiotic ore (Pb: 3%, Zn: 15%, S: 3%, F: 0.06%, Cl: 0.01%, As: 0.1%) and zinc leaching slag (Pb: 5 %, Zn: 16%, S: 6%, F: 0.03%, Cl: 0.03%, As: 0.2%), according to the ratio of 1:5 to form the mixed material, according to 400t / d into the side blowing furnace, evenly added within 1h Mixed ingredients. Inject oxygen-enriched air, natural gas or pulverized coal from the side-blowing lance, the volume ratio of oxygen-enriched air is 40%, the temperature is 1250°C, the excess air coefficient is 0.9, and the side-blown slag (Pb: 1%, Zn: 15%, S: 0.7%, F: 0.02%, Cl: 0.01%, As: 0.05%), the slagging time is 15min, and it is directly put into the fuming furnace through the chute;

[0025] After the flue gas is cooled by the waste heat boiler, air cooler, and bag filter, it produces zinc oxide dust with high F, Cl, and As (Pb: 30%, Zn: 25%, S: 2%, F: 0.08% , Cl: 0.03%, As: 0.4%), after the flue gas with 1% sulfur content ...

Embodiment 2

[0029] The bed area is 15m 2 side-blown furnace, first lead-zinc symbiotic ore (Pb: 4.5%, Zn: 17%, S: 4%, F: 0.09%, Cl: 0.03%, As: 0.3%) and zinc leaching slag (Pb: 7 %, Zn: 18%, S: 8%, F: 0.06%, Cl: 0.06%, As: 0.4%), according to the ratio of 1:1 to form the mixed material, according to 600t / d into the side blowing furnace, evenly added within 2h Mixed ingredients. Inject oxygen-enriched air, natural gas or pulverized coal from the side-blowing lance, the volume ratio of oxygen-enriched air to oxygen is 50%, the temperature is 1300°C, the excess air coefficient is 1.0, and the side-blown slag (Pb:3%, Zn: 17%, S: 0.9%, F: 0.03%, Cl: 0.02%, As: 0.07%), the slag discharge time is 20 minutes, and it is directly put into the fuming furnace through the chute;

[0030] After the flue gas is cooled by the waste heat boiler, air cooler, and bag filter, it produces zinc oxide dust with high F, Cl, and As (Pb: 35%, Zn: 30%, S: 3%, F: 0.11% , Cl: 0.05%, As: 0.6%), after desulfurizatio...

Embodiment 3

[0034] The bed area is 15m 2side-blown furnace, first lead-zinc symbiotic ore (Pb: 6%, Zn: 19%, S: 6%, F: 0.12%, Cl: 0.05%, As: 0.5%) and zinc leaching slag (Pb: 9 %, Zn: 20%, S: 10%, F: 0.09%, Cl: 0.09%, As: 0.6%), according to the ratio of 5:1 to form the mixed material, according to 800t / d into the side blowing furnace, evenly added within 3h Mixed ingredients. Inject oxygen-enriched air, natural gas or pulverized coal from the side-blowing lance, the volume ratio of oxygen-enriched air to oxygen is 60%, the temperature is 1350°C, the excess air coefficient is 1.1, and the side-blown slag (Pb:5%, Zn: 19%, S: 1.1%, F: 0.04%, Cl: 0.03%, As: 0.09%), the slag discharge time is 30 minutes, and it is directly put into the fuming furnace through the chute;

[0035] After the flue gas is cooled by the waste heat boiler, air cooler, and bag filter, it produces zinc oxide dust with high F, Cl, and As (Pb: 40%, Zn: 35%, S: 4%, F: 0.14% , Cl: 0.07%, As: 0.8%), after the flue gas wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com