Automatic graphite cutting machine

A material cutting machine and automatic technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of waste of space resources, space occupation, and unreasonable space layout, so as to save space resources and improve the cutting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

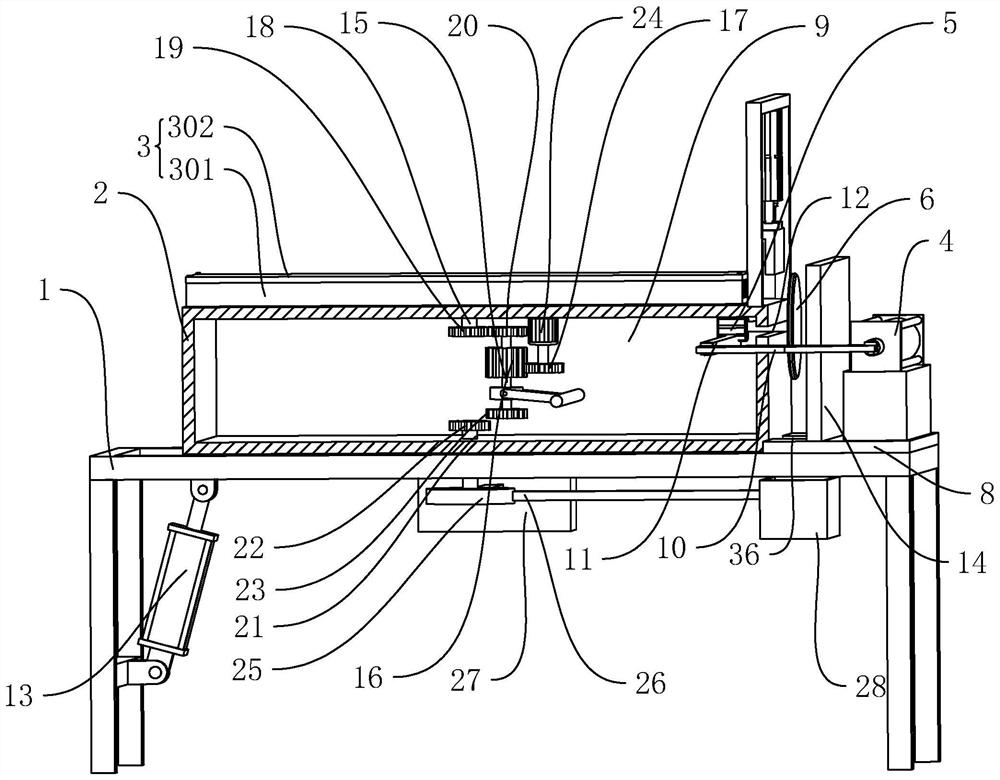

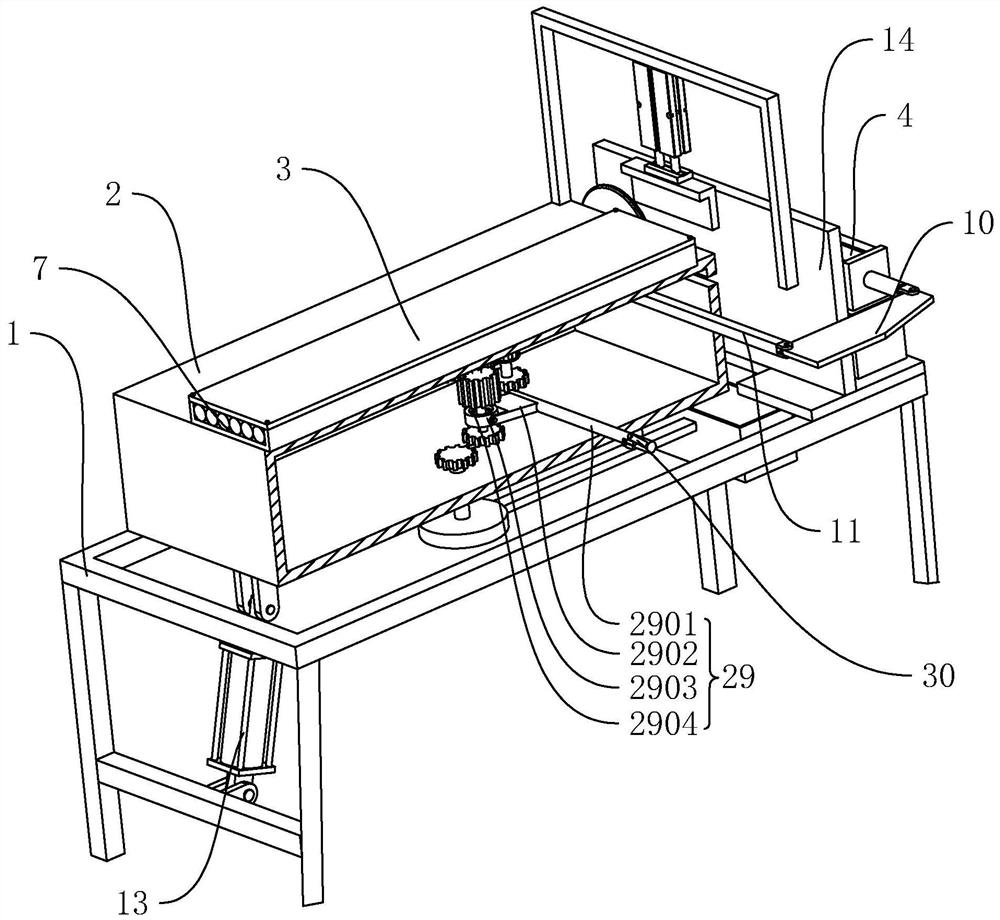

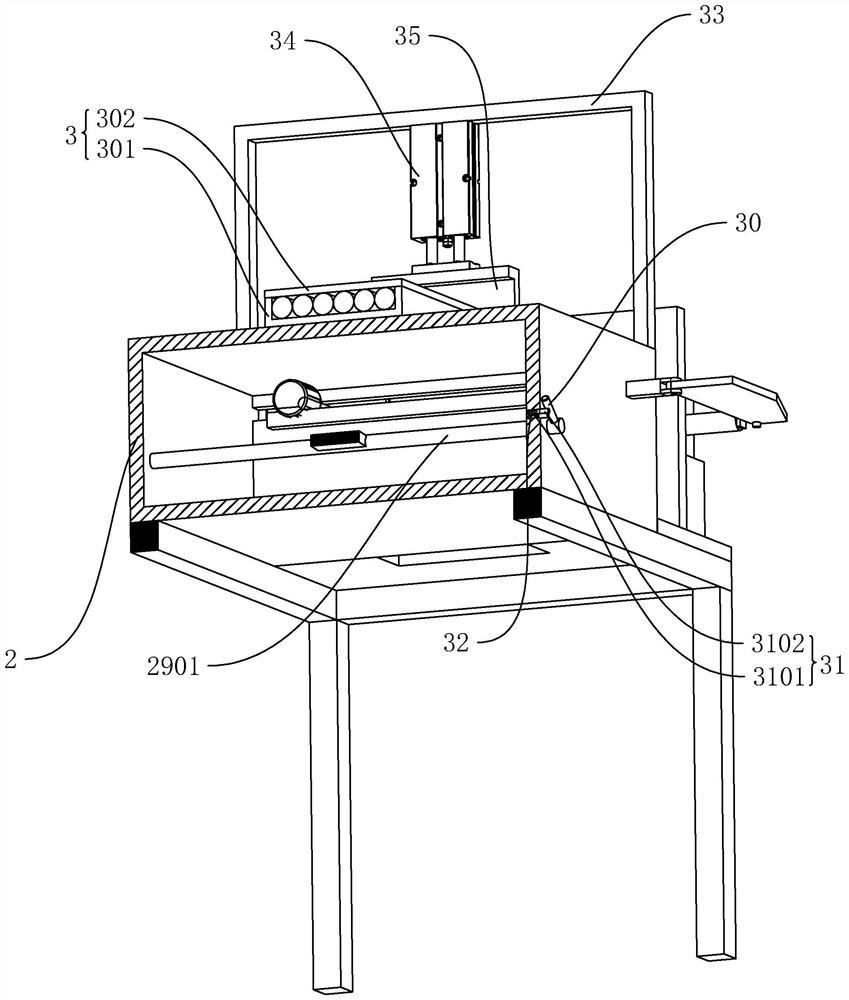

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses a graphite automatic cutting machine.

[0033] A kind of graphite automatic cutting machine, refer to figure 1 and figure 2, including a frame 1, a machine 2 arranged on the frame 1, a loading plate 3 arranged along the length direction of the machine 2, a driving cylinder 4 arranged on the machine 2, and a loading plate arranged along the length of the machine 2. The material plate 3, the cutting motor 5 arranged on the machine platform 2 and the blade 6 fixed on the rotating shaft of the cutting motor 5, a plurality of graphites are placed on the material carrier plate 3 along the length direction of the material carrier plate 3 and along the width direction of the material carrier plate 3 Arranged, the carrier plate 3 includes a bottom plate 301 arranged on the machine platform 2 and a cover plate 302 covered on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com