Printed circuit board pad

A technology of printed circuit boards and pads, which is applied in the direction of printed circuit components, electrical connection printed components, etc., can solve problems such as difficulty in meeting the requirements for mounting electronic components of different specifications, and achieve the effect of saving space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

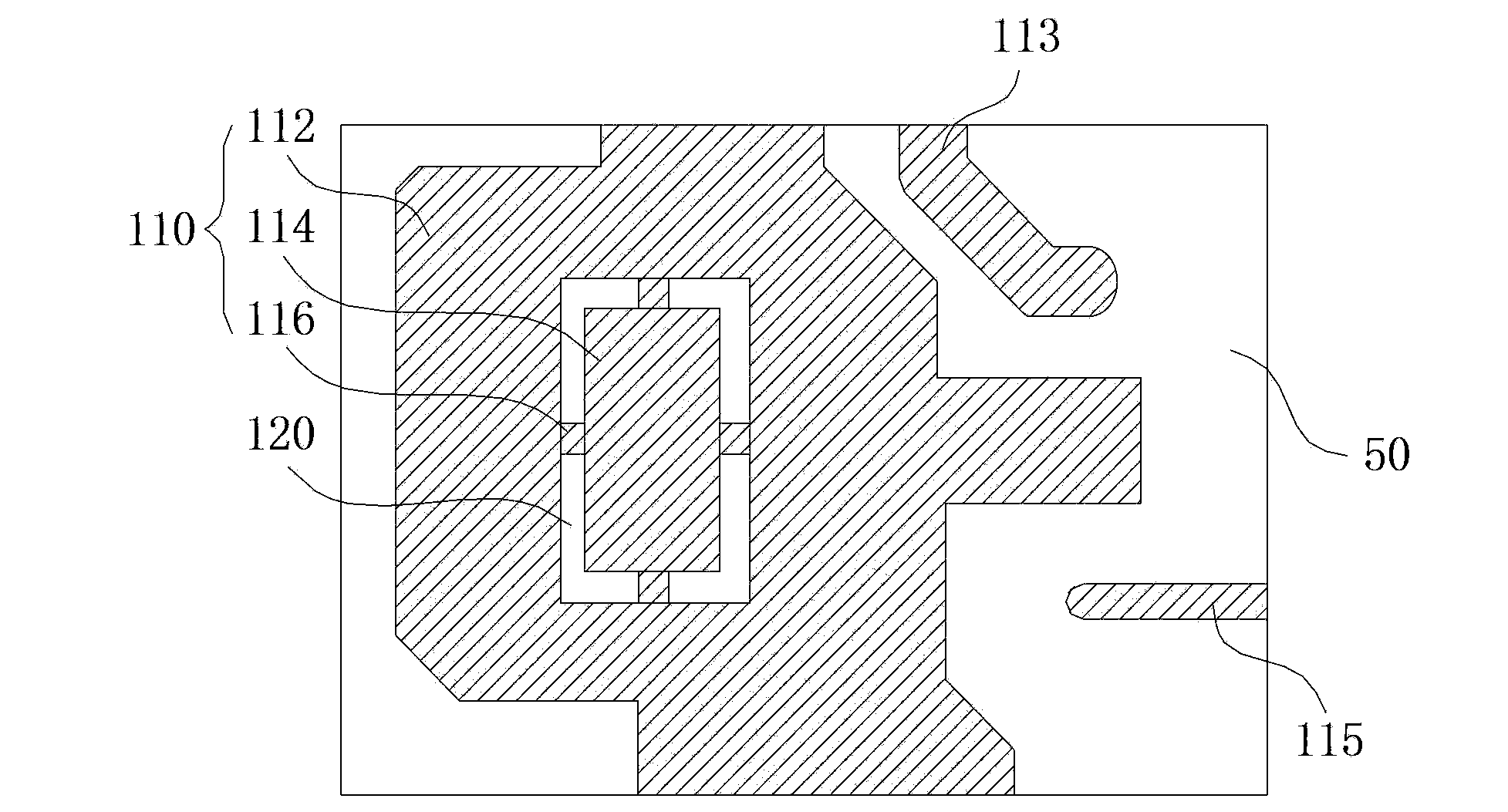

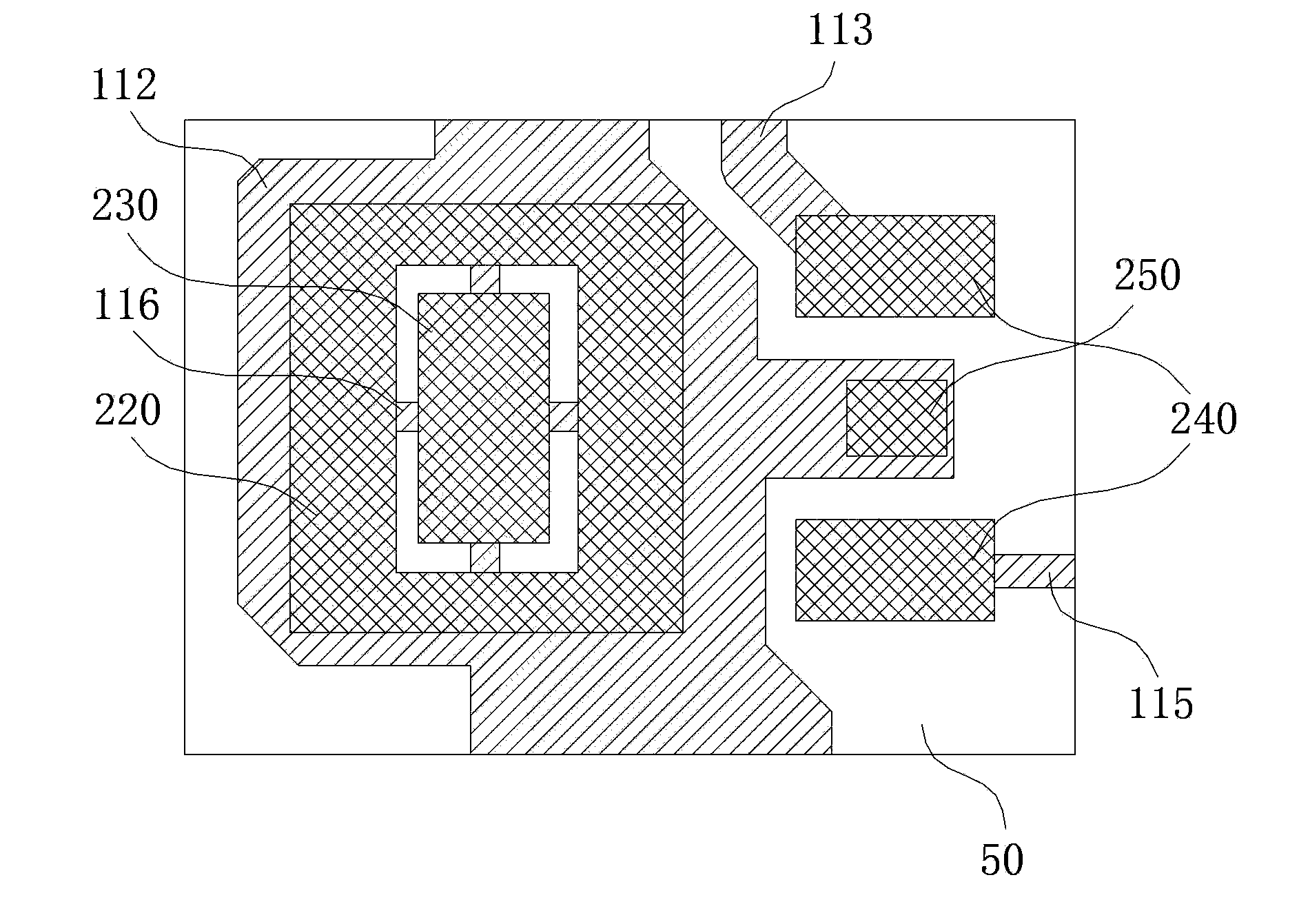

[0021] Such as figure 1 and figure 2 As shown, the pads of the printed circuit board according to the preferred embodiment of the present invention include a large pad and at least one small pad. Usually, the large pads and the small pads are disposed on the printed circuit board 50 . The large pad includes a copper skin layer 110, and the copper skin layer 110 includes an outer ring copper skin 112, an inner ring copper skin 114 surrounded by the outer ring copper skin 112, and a copper wire 116 connecting the inner ring copper skin 114 and the outer ring copper skin 112 . A gap 120 is provided between the inner ring copper skin 114 and the outer ring copper skin 112 . The outer copper skin 112 and the inner copper skin 114 are respectively provided with tin layers to form the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com