A kind of method for ethylbenzene continuous oxidation separation coupling strengthening synthesis acetophenone and α-phenethyl alcohol

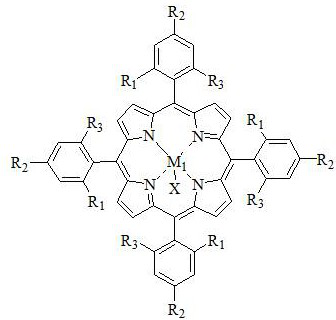

A technology of acetophenone and phenylethanol, which is applied in the field of preparation of acetophenone and α-phenylethanol by oxidation of ethylbenzene, biomimetic metalloporphyrin catalyst catalyzed air oxidation of ethylbenzene to prepare acetophenone and α-phenylethanol, which can solve the problem of improving Problems such as cost and difficulty of product separation, unfavorable production of α-phenylethanol, increased difficulty of product separation, etc., to achieve the effects of being beneficial to industrial production, avoiding side reactions, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

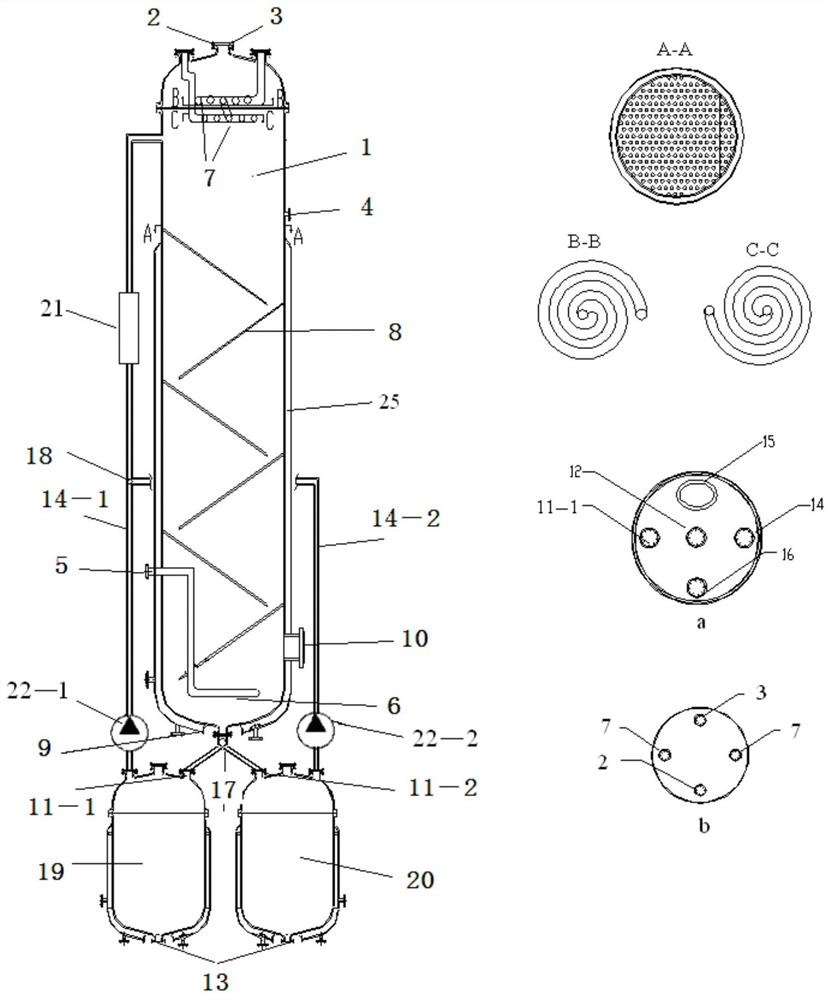

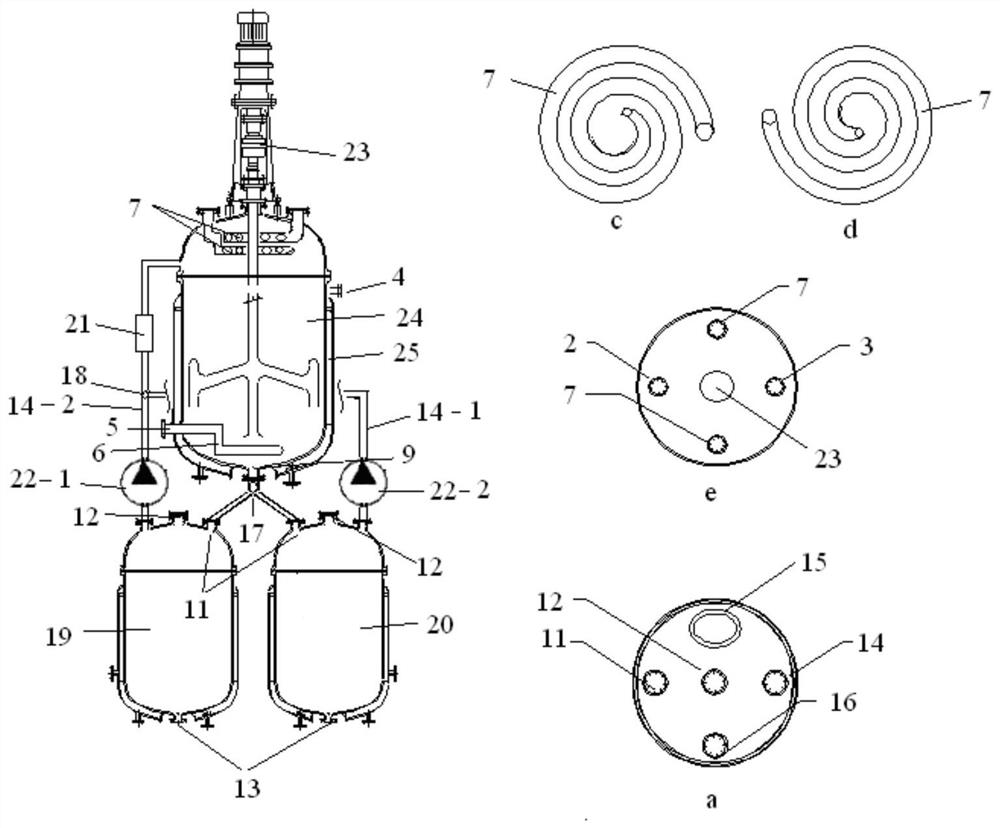

[0058] The ethylbenzene raw material whose water content is 1wt% and tetra-methoxyphenyl porphyrin manganese concentration is 5ppm enters the constant temperature settling tower I and the bubbling gravity reaction tower from the reaction material inlet on the upper part of the constant temperature settling tower I, and is full of the constant temperature settling tower I and the oxidation zone of the bubbling gravity reaction tower, the tee on the circulation pipe and the tee pipe at the bottom of the bubbling gravity reaction tower are connected to the constant temperature settling tower I, and the gas raw material from the bubbling gravity reaction tower Air is introduced into the inlet port, and the volume content of oxygen in the reaction gas exported from the outlet port of the reaction gas is controlled to be 5%. The ethylbenzene in the bubble gravity reaction tower is circulated through the external circulation system, and the circulation speed ensures that the average r...

Embodiment 2

[0064]Water content is 0.5wt%, tetra-p-butylphenyl porphyrin ferric chloride concentration is that the ethylbenzene raw material of 8ppm enters constant temperature settling tower I and bubbling gravity reaction tower from constant temperature settling tower I upper reaction material inlet, is full of constant temperature settling In the oxidation zone of tower I and the bubbling gravity reaction tower, the tee on the circulation pipe and the tee pipe at the bottom of the bubbling gravity reaction tower are connected to the constant temperature settling tower I, from the bubbling gravity reaction tower The gas raw material inlet is fed with air, and the volume content of oxygen in the reaction gas exported from the reaction gas outlet is controlled to be 8%, the temperature of the bubbling gravity reaction tower is adjusted to 75°C, the pressure inside the tower is kept at 2.5atm for oxidation reaction, and constant temperature sedimentation The ethylbenzene in the tower and th...

Embodiment 3

[0066] Water content is 1.5wt%, tetra-p-propylphenylporphyrin iron μ-dimer concentration is that the ethylbenzene raw material of 3ppm enters constant temperature settling tower 1 and bubbling gravity reaction tower from constant temperature settling tower 1 top reaction material import port, Fill the oxidation zone of the constant temperature settling tower I and the bubbling gravity reaction tower, connect the tee on the circulating pipe and the tee pipe at the bottom of the bubbling gravity reaction tower to communicate with the constant temperature settling tower I, from the bubbling gravity The gas raw material inlet of the reaction tower is fed with air, and the volume content of oxygen in the reaction gas exported from the reaction gas outlet is controlled to be 3%, the temperature of the bubbling gravity reaction tower is adjusted to 95°C, and the internal pressure of the tower is kept at 1.5atm for oxidation reaction , the ethylbenzene in the constant temperature settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com