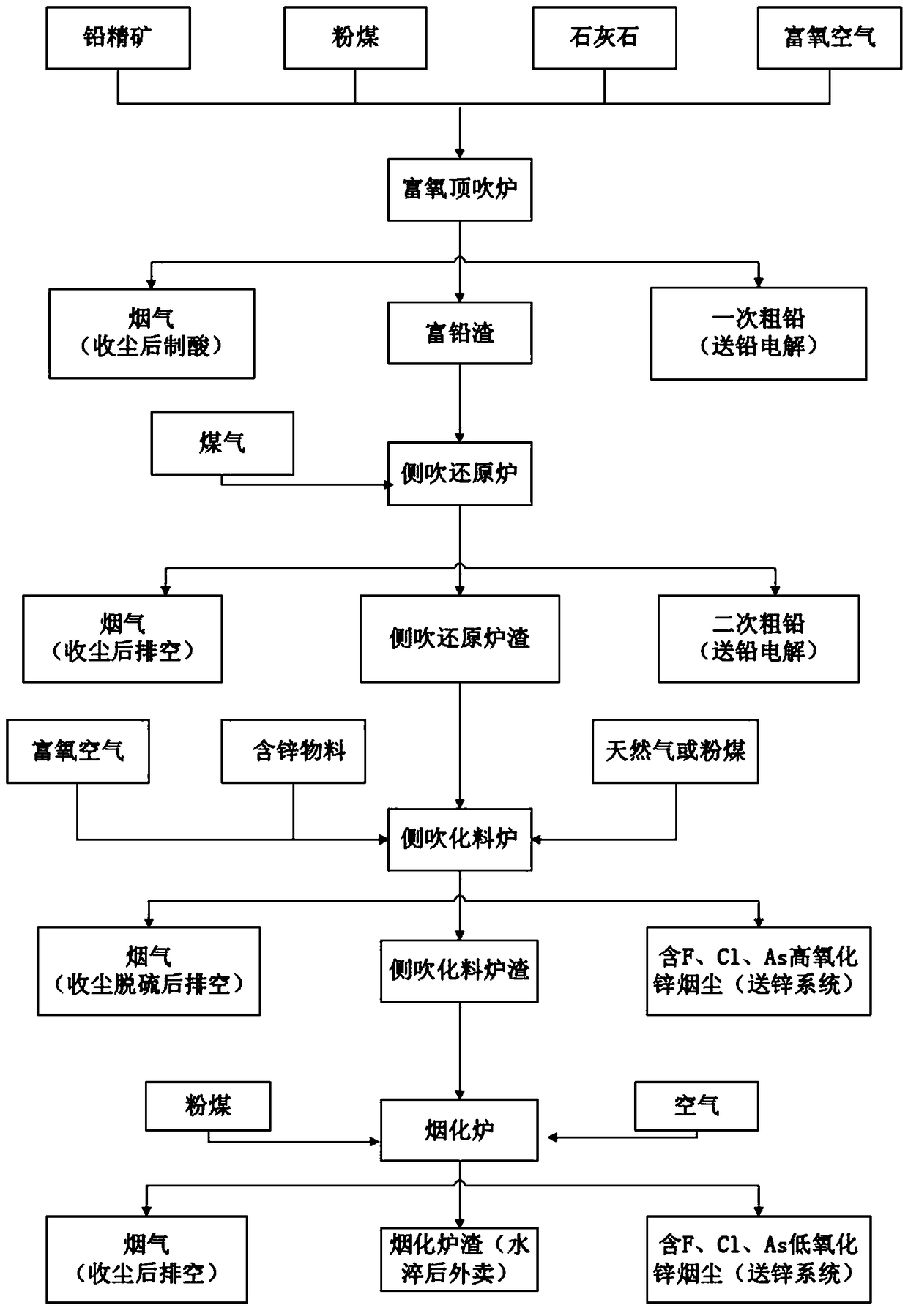

Method of treating lead-zinc material with four continuous furnaces

A lead-zinc and material technology, applied in the field of metallurgy, can solve the problems of small bed capacity, high cost, and non-compact structure, and achieve the effect of reducing cost, low energy consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Use a bed area of 10m 2 Oxygen-enriched top-blown furnace, the lead concentrate and limestone are batched according to the weight ratio of 100:1, and pelletized into pellets through a cylinder, with a particle size of 5mm and a moisture content of 6%; wherein limestone is added as a slagging agent, and the The main components of the lead concentrate are 55% lead, 3% zinc, and 15% sulfur, the iron powder contains Fe: 98%, and the limestone contains CaCO 3 :80%;

[0037] 2) Send the pellets obtained in step 1) continuously and evenly to the oxygen-enriched top-blown furnace with a belt conveyor. The top spray gun is sprayed in, and the furnace top spray gun is a liftable furnace top spray gun arranged perpendicular to the furnace roof. The pulverized coal addition is 3% of the pellet addition, and the pulverized coal particle size is -200 mesh 80% , which contains 53.5% carbon, 1.5% sulfur, 35% ash, and 20% volatile matter. The amount of oxygen-enriched air added i...

Embodiment 2

[0046] 1) Use a bed area of 10m 2 Oxygen-enriched top-blown furnace, the lead concentrate and limestone are batched according to the weight ratio of 100:3, and pelletized into pellets through a cylinder, with a particle size of 10mm and a moisture content of 9%; wherein limestone is added as a slagging agent, and the The main components of the lead concentrate are 60% lead, 5% zinc, and 20% sulfur, the iron powder contains Fe: 98%, and the limestone contains CaCO 3 :80%;

[0047] 2) Send the pellets obtained in step 1) continuously and evenly to the oxygen-enriched top-blown furnace with a belt conveyor. The top spray gun is sprayed into, and the top spray gun of the oxygen-enriched top-blown furnace is a liftable top spray gun arranged perpendicular to the furnace roof, and the pulverized coal addition is 9% of the pellet addition, and the pulverized coal particle size is -200 mesh 80%, which contains 52% carbon, 1% sulfur, 36% ash, 18% volatile matter, and the amount of ...

Embodiment 3

[0056] 1) Use a bed area of 10m 2 Oxygen-enriched top-blown furnace, the lead concentrate and limestone are batched according to the weight ratio of 100:5, and pelletized into pellets through a cylinder, with a particle size of 15mm and a moisture content of 12%; wherein limestone is added as a slagging agent, and the The main components of the lead concentrate are 65% lead, 7% zinc, and 25% sulfur, the iron powder contains Fe: 98%, and the limestone contains CaCO 3 :80%;

[0057] 2) Send the pellets obtained in step 1) continuously and evenly to the top-blown furnace with a belt conveyor, the pellets added is 40t / h, and then the pulverized coal and oxygen-enriched air are sprayed from the top-blown furnace of the oxygen-enriched top-blown furnace together Injection, the oxygen-enriched top-blown furnace roof lance is a liftable roof lance arranged perpendicular to the furnace roof, the pulverized coal addition is 15% of the pellet addition, and the pulverized coal particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com