Spray cooling device of solid waste incineration system

A spray cooling, solid waste technology, applied in gaseous discharge wastewater treatment, water/sludge/sewage treatment, steam condensation, etc., can solve the problems of environmental pollution, high cost, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

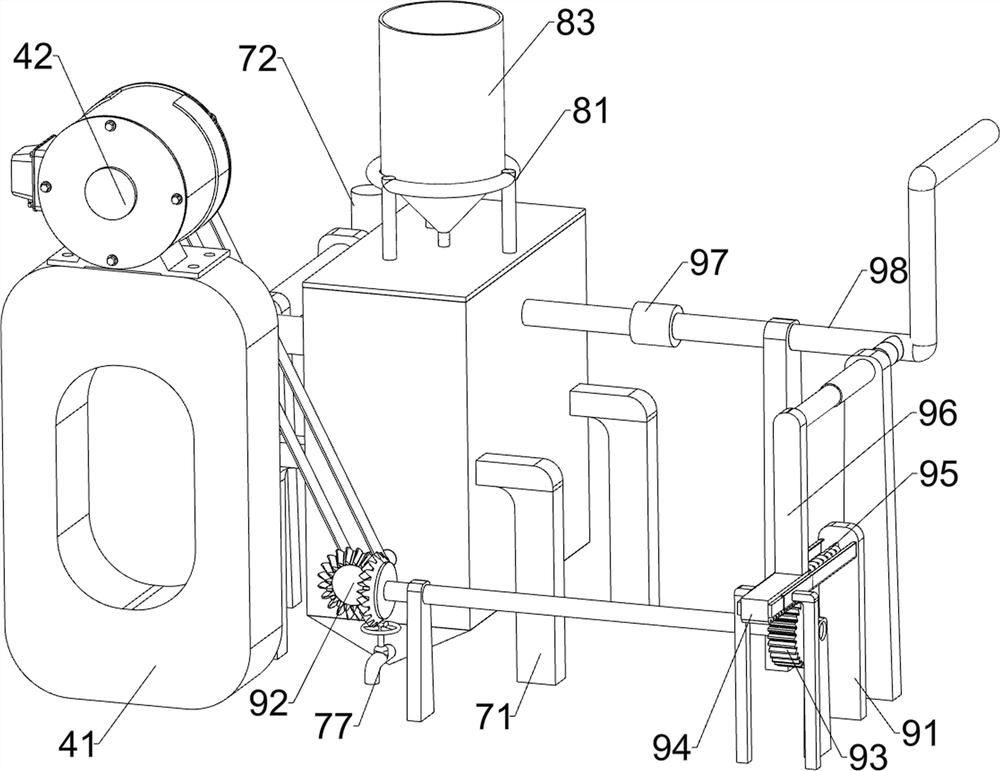

[0053] A spray cooling device for solid waste incineration system, such as figure 1 As shown, it includes a base 1, a water storage tank 2, a spray cooling mechanism 3 and an air extraction mechanism 4. The water storage tank 2 is arranged on the right rear side of the top of the base 1, and the spray cooling mechanism 3 is connected to the left rear side of the top of the base 1. 1. An air extraction mechanism 4 is connected to the left front side of the top.

[0054] The staff can connect the exhaust gas discharge pipe to the spray cooling mechanism 3, and then start the spray cooling mechanism 3, the exhaust gas is liquefied through the spray cooling mechanism 3, and the spray cooling mechanism 3 works to drive the exhaust mechanism 4 to work, and the remaining gas It can be discharged through the exhaust mechanism 4, so that the waste gas can be processed. After the treatment is completed, stop the work of the spray cooling mechanism 3 and get final product.

Embodiment 2

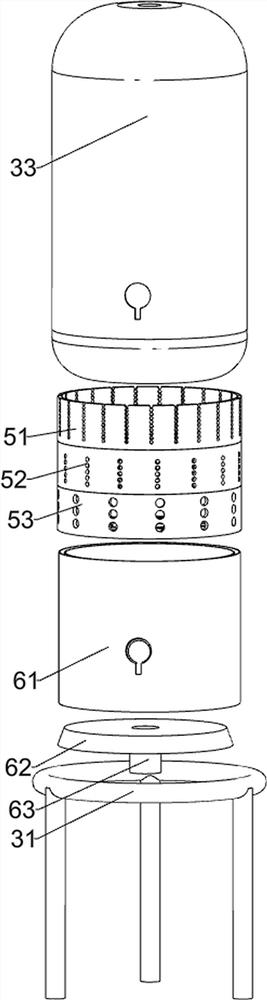

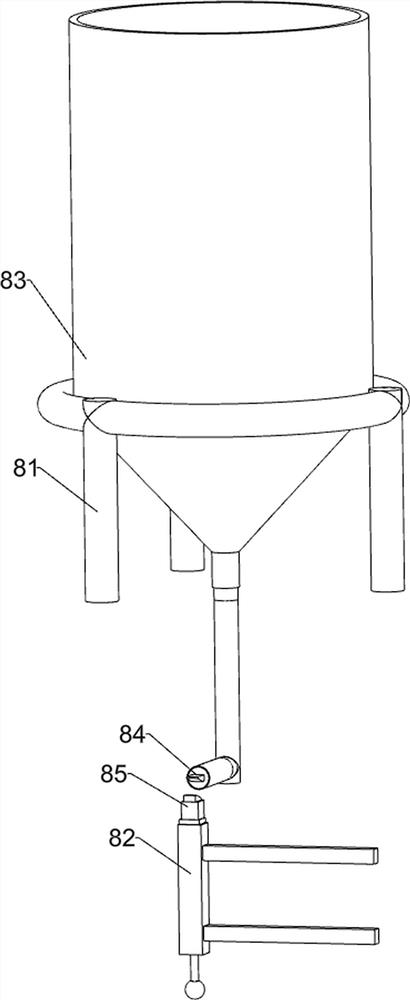

[0056] On the basis of Example 1, such as figure 2 As shown, the spray cooling mechanism 3 includes a support seat 31, an air intake pipe 32, a cooling tank 33, a water pump 34, a water inlet pipe 35 and an atomized water nozzle 36, and the left rear side of the base 1 is connected with a support seat 31, and the support seat The upper part of 31 is provided with a cooling tank 33, the top of the cooling tank 33 is connected with an air intake pipe 32, the top of the base 1 is provided with a water pump 34, the water pump 34 is connected with the water storage tank 2, the water pump 34 is located on the right side of the cooling tank 33, and the water pump 34 Both front and rear sides of the upper part are connected with water inlet pipes 35, and the upper parts of the water inlet pipes 35 are connected with atomized water nozzles 36, and the atomized water nozzles 36 are connected with the cooling tank 33 tops.

[0057] The exhaust mechanism 4 includes a mounting seat 41, a ...

Embodiment 3

[0060] On the basis of Example 2, such as Figure 3 to Figure 7 As shown, it also includes an exhaust gas pretreatment mechanism 5. The exhaust gas pretreatment mechanism 5 includes a first filter box 51, a second filter box 52 and a third filter box 53. The upper part of the inner wall of the cooling tank 33 is connected with the first A filter box 51 , a second filter box 52 and a third filter box 53 .

[0061] Also includes a gas-liquid separation mechanism 6, the gas-liquid separation mechanism 6 includes a diversion pipe 61, a diverter plate 62 and a water outlet pipe 63, the lower part of the inner wall of the cooling tank 33 is connected with a diversion pipe 61, and the bottom of the inner wall of the cooling tank 33 is connected with a water outlet pipe 63 , the top of the outlet pipe 63 is connected with a diverter plate 62 , and the diverter plate 62 is located below the flow guide pipe 61 .

[0062] Also include sewage filter mechanism 7, sewage filter mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com