Paper product rotary printing mechanism for finished product packaging

A printing mechanism and packaging technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of long time consumption, low work efficiency, blurred fonts, etc., to improve the gas circulation effect, improve the heating effect, increase The effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

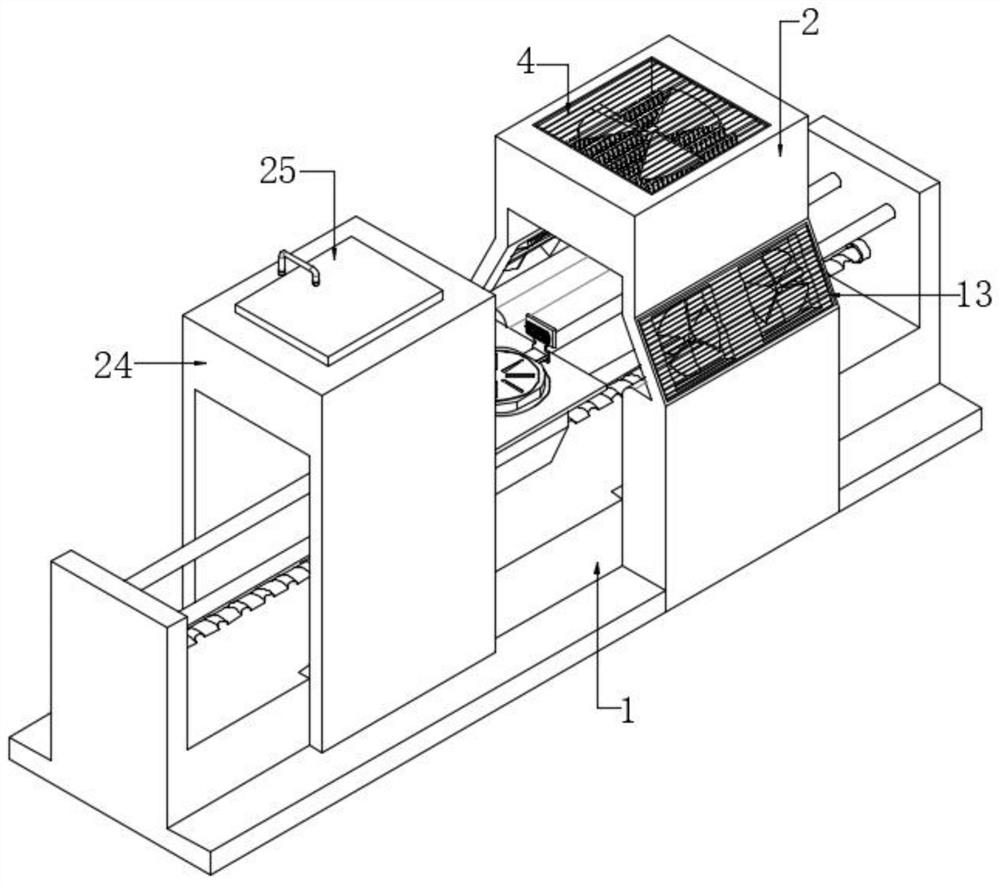

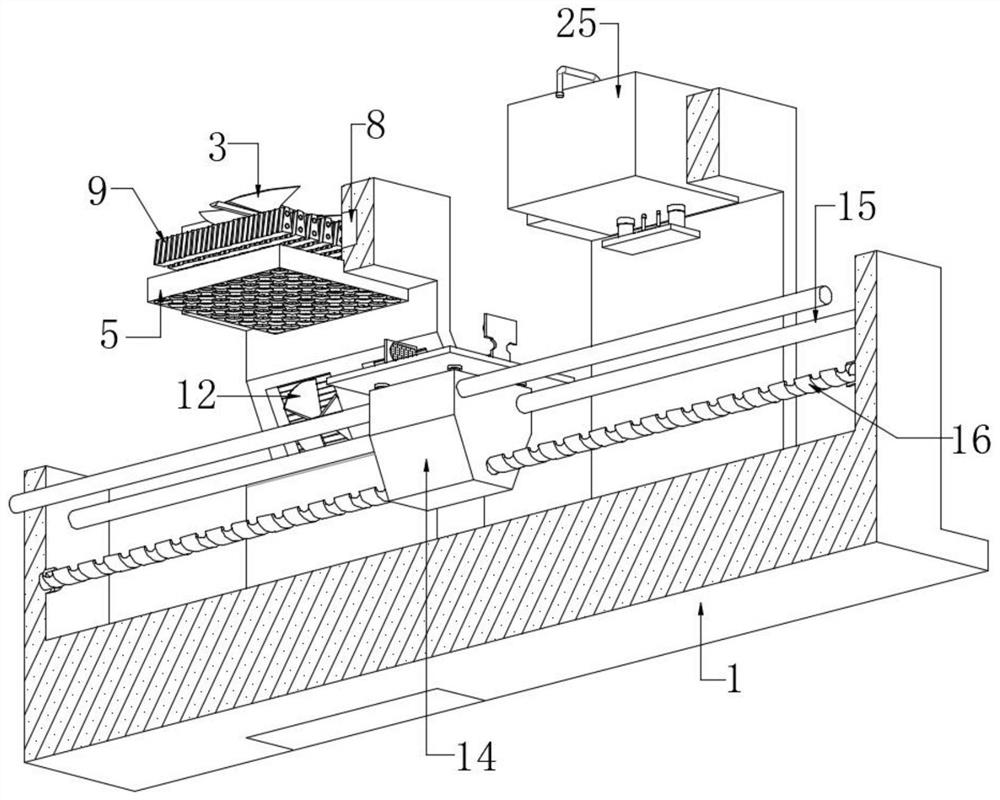

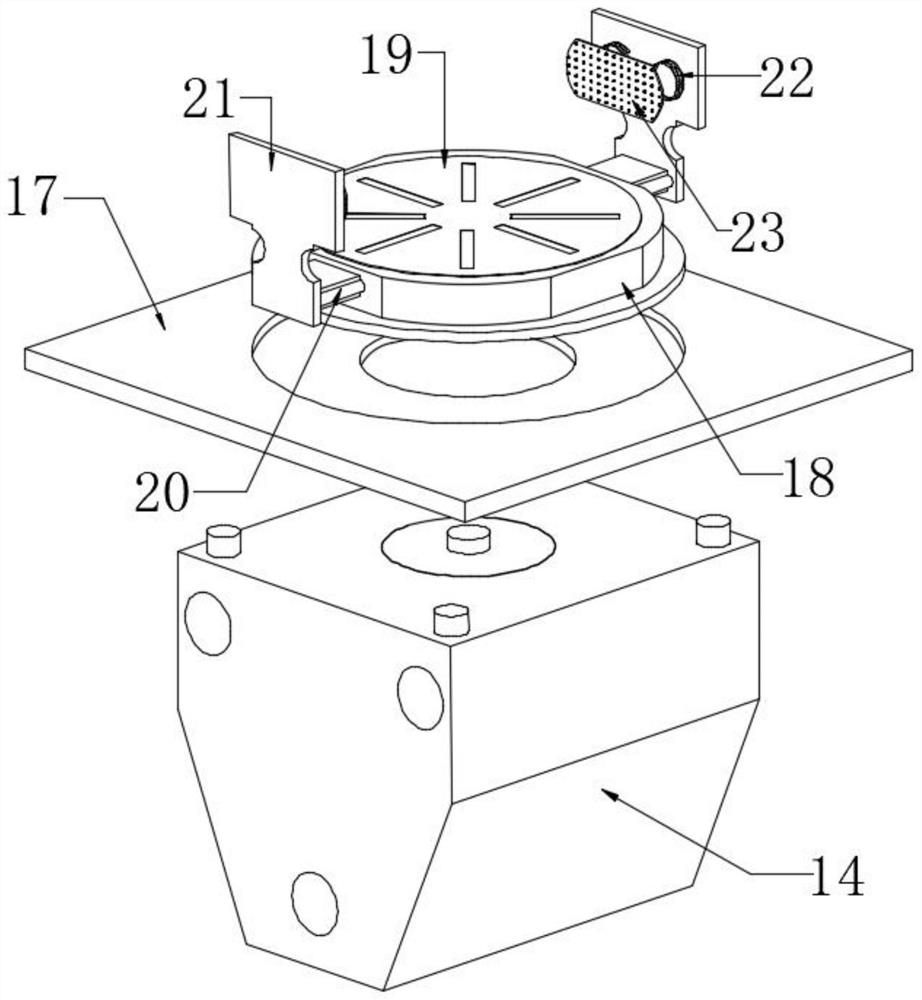

[0027] refer to Figure 1-5 , a paper product rotary printing mechanism for finished product packaging, comprising a base 1, the upper outer wall of the base 1 is connected with a drying box 2 by bolts, and a support rod is connected between the inner walls of the two sides of the drying box 2 by bolts, and the support rod One side of the outer wall is connected with a suction fan 3 by bolts, the upper outer wall of the drying box 2 is provided with a square groove, and the inner wall of the square groove is connected with a dust-proof net 4 by bolts, and a wind resistance box 5 is arranged below the suction fan 3, and the wind resistance The outer wall of the box 5 and the inner wall of the drying box 2 are connected by bolts, and the wind resistance box 5 is provided with a plurality of circular holes, and the inner walls of the plurality of circular holes are all rotatably connected with a drum 6, and the inner wall of the drum 6 is connected by bolts. A windshield 7, the w...

Embodiment 2

[0036] refer to Figure 6 , a paper product rotary printing mechanism for finished product packaging. Compared with Embodiment 1, this embodiment also includes a bottom plate 26 under the base 1, and the upper outer wall of the bottom plate 26 and the lower outer wall of the base 1 are provided with four a square slot, and a damper 27 is connected by bolts between the upper and lower square slots.

[0037] During use, the device will vibrate due to the rotation of the lead screw 16 and the work of the internal motor during use, and the damper 27 can slow down the vibration of the device, avoiding noise and excessive vibration that affect the normal operation of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com