Drying equipment for biomass fuel

A technology for biomass fuel and drying equipment, which is applied in drying solid materials, drying chambers/containers, non-progressive dryers, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

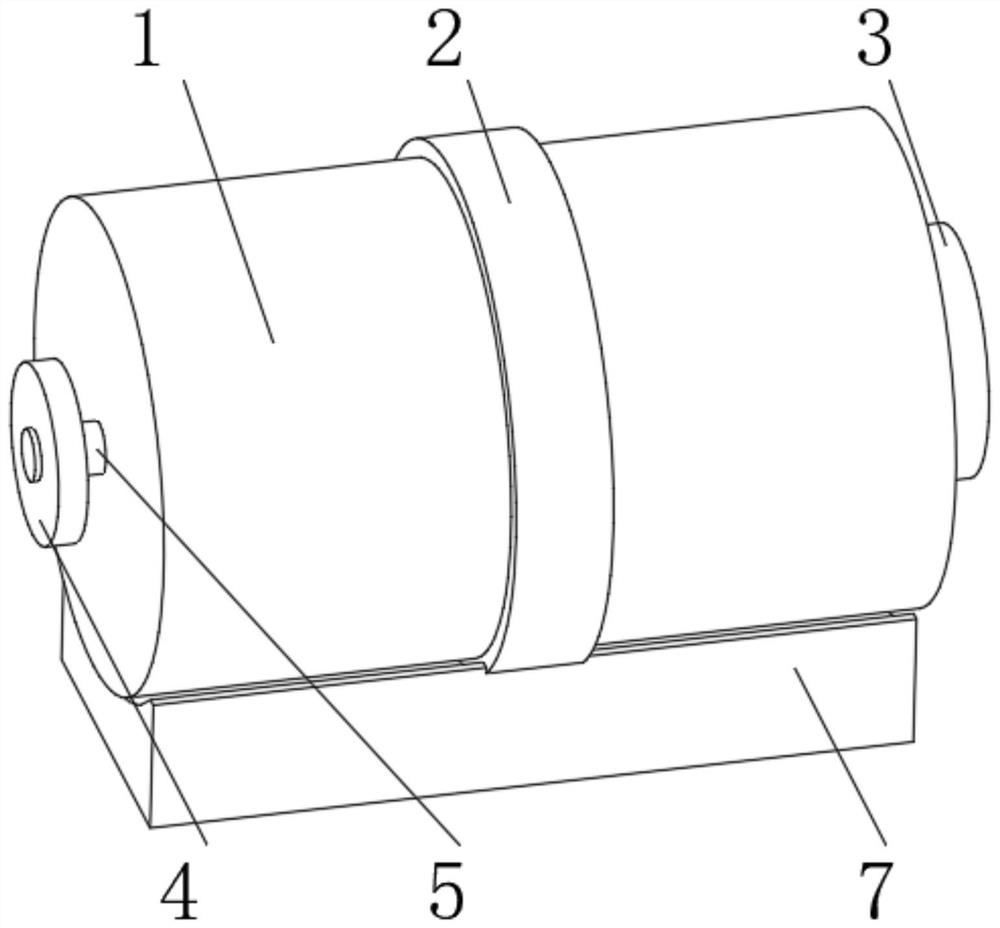

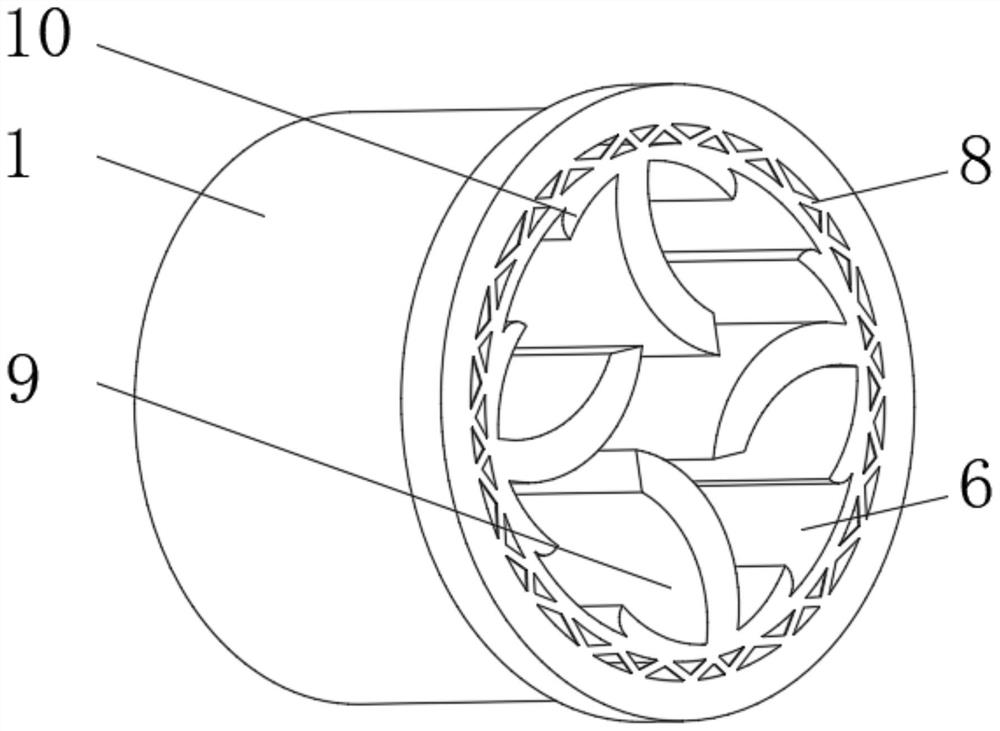

[0029] see Figure 1-4 , the present invention provides a technical solution: a drying equipment for biomass fuel, comprising an outer frame 1, a reinforcement frame 2 is installed on the outer side of the outer frame 1, a feed inlet 3 is opened on one side of the outer frame 1, and the outer frame 1 A drive motor 4 is installed on the side away from the feed port 3, the output shaft of the drive motor 4 is rotatably connected to a rotating shaft 5, and the end of the rotating shaft 5 away from the driving motor 4 is fixedly connected to a rotating frame 6, and the bottom of the outer frame 1 is fixedly connected to There is a base 7, a heating wire 8 is installed on the inner wall of the outer frame 1 close to the rotating frame 6, and a stirring device 9 is evenly installed on the inner wall of the rotating frame 6.

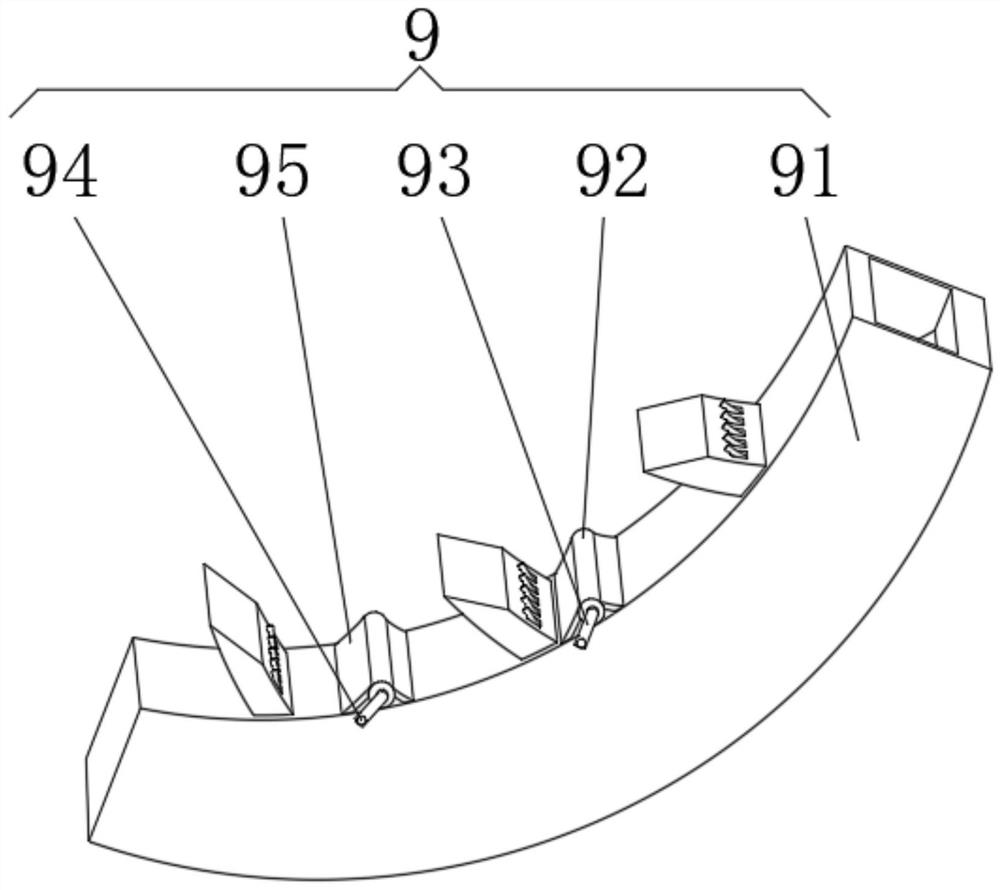

[0030] Stirring device 9 comprises arc-shaped stirring plate 91, and one side of arc-shaped stirring plate 91 is fixedly connected with rotating frame 6, and o...

Embodiment 2

[0036] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an ejection device 10 is evenly installed on the inner wall of the rotating frame 6 close to the position of the stirring device 9, and the ejection device 10 includes a semicircular frame 101, and one side of the semicircular frame 101 is connected to the The rotating frame 6 is fixedly connected, the inside of the semicircular frame 101 is fixedly connected with a spring 102 , and the end of the spring 102 away from the semicircular frame 101 is fixedly connected with an arc plate 103 .

[0037] An elastic rod 104 is fixedly connected to the inner wall of the semicircular frame 101 away from the spring 102 , and an elastic ball 105 is fixedly connected to the end of the elastic rod 104 away from the semicircular frame 101 .

[0038] When in use, the internal stalks are turned over with the rotating frame 6 and touch the extrusion arc plate 103, and the arc plate 103 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com