Puffed feed drying device

A drying device and technology for extruding feed, applied in drying, drying machine, drying gas arrangement and other directions, can solve problems such as affecting drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

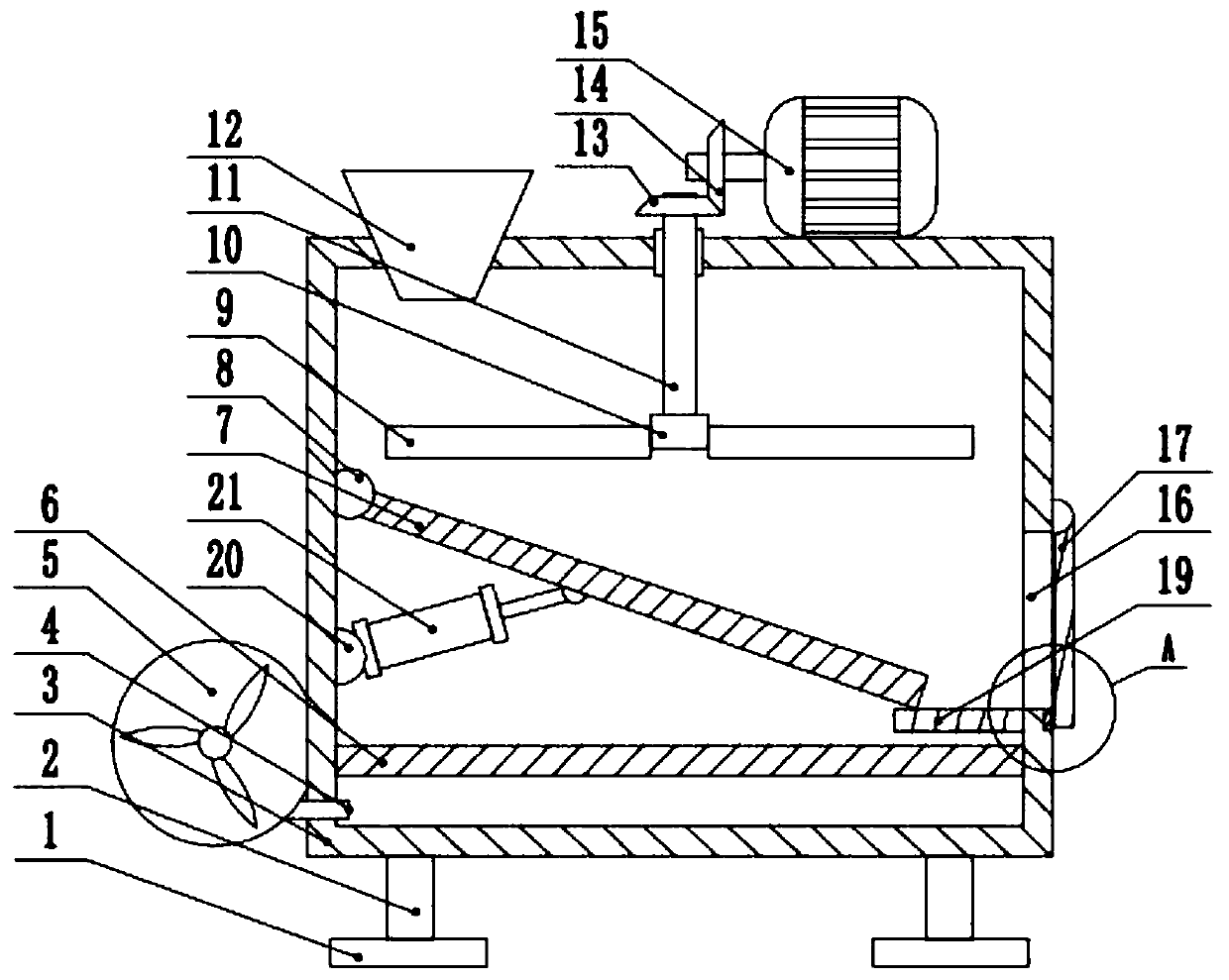

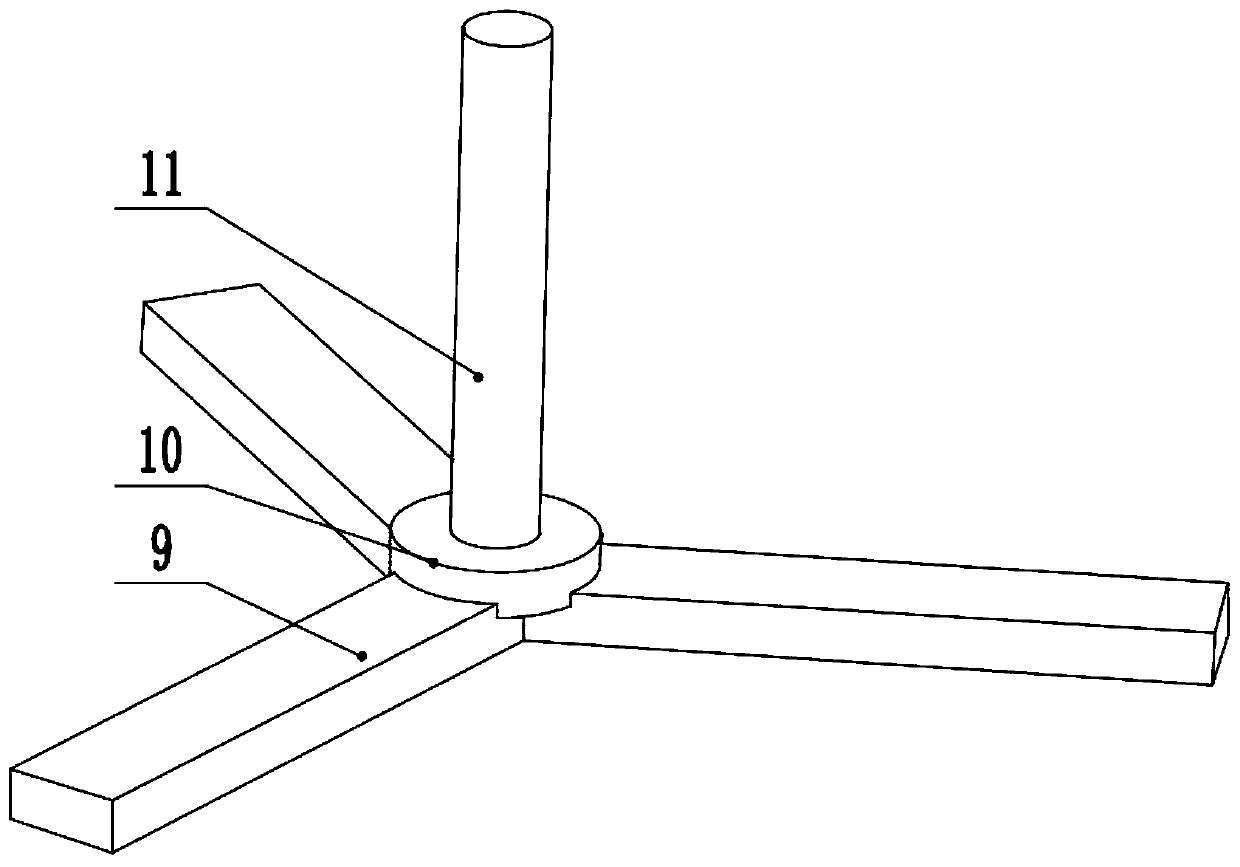

[0022] see Figure 1-3 , an extruded feed drying device, comprising a drying box 3, the left and right sides of the lower surface of the drying box 3 are provided with support columns 2, the lower end of the support column 2 is connected to the pad 1, and the left upper part of the drying box 3 is provided with There is a feed port 12, the middle part of the right side of the drying box 3 is provided with a discharge port 16, the left side wall of the drying box 3 is provided with an air pump 5, and the output end of the air pump 5 is connected to the drying box 3 through the air inlet 4 , the bottom of the drying box 3 is provided with a heating plate 6, the middle part of the left side wall of the drying box 3 is provided with a first rotating seat 8, and the first rotating seat 8 is connected to the air-permeable plate 7 in rotation, and the top of the drying box 3 Rotate and connect the rotating shaft 11, the top right side of the drying box 3 is provided with a drive moto...

Embodiment 2

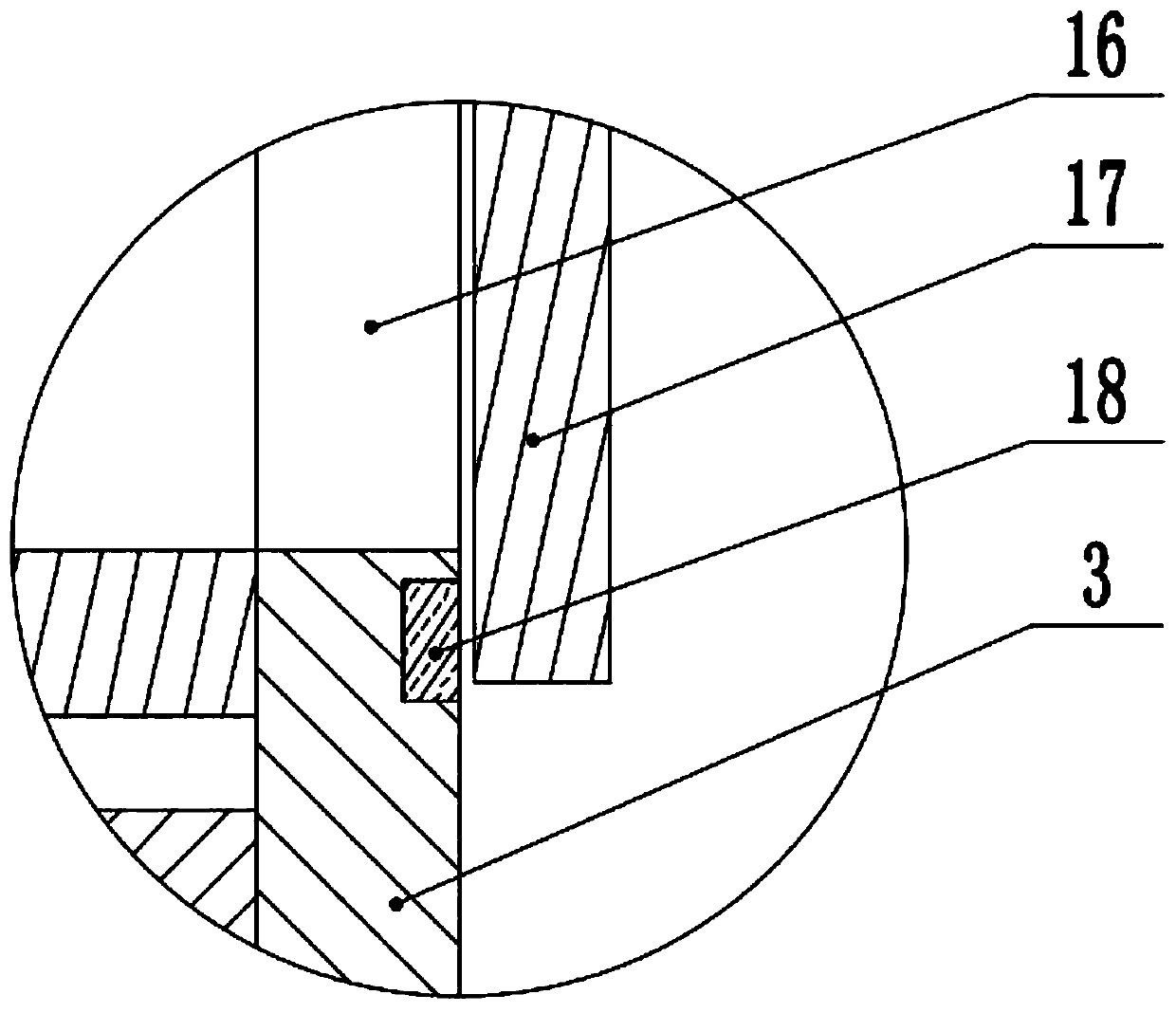

[0024] see figure 2 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the lower part of the discharge port 16 is provided with a magnet 18, and the baffle plate 17 is made of metal. In the unstressed state, the baffle plate 17 will maintain a vertical state under the influence of gravity. At this time, the baffle plate 17 will block the discharge port 16, but in order to ensure that the baffle plate 17 can stably block the discharge port 16, the A magnet 18 is arranged at the bottom of the feed port 16, and the baffle plate 17 is made of metal, so that the baffle plate 17 is adsorbed to the column by the magnet 18, and now the baffle plate 17 can stably block the discharge port 16.

[0025] In the implementation process of the present invention, the cylinder 21 is first started, and the piston rod of the cylinder 21 stretches out, thereby pushing the air-permeable plate 7 to rotate counterclockwise. When the piston rod is full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com