Paint drying device for computer production

A drying device, computer technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of harmful substances emission, physical impact of staff, and speed up the drying rate of paint, so as to avoid direct Emission, accelerated drying rate, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

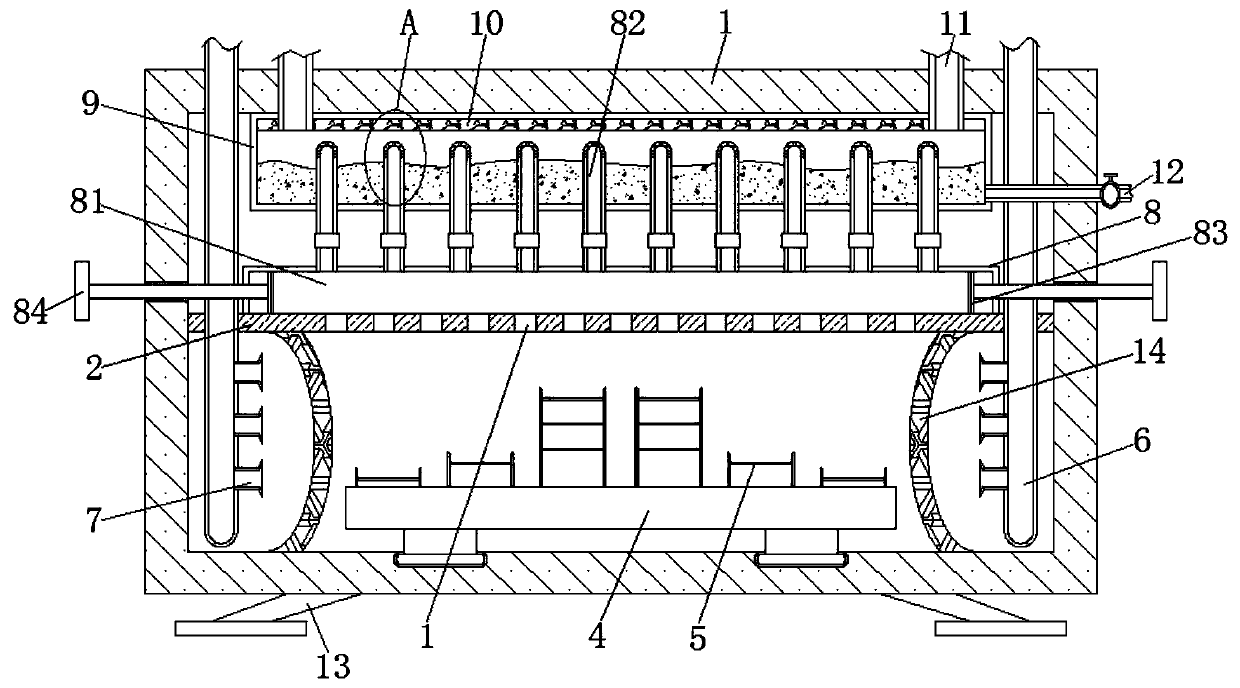

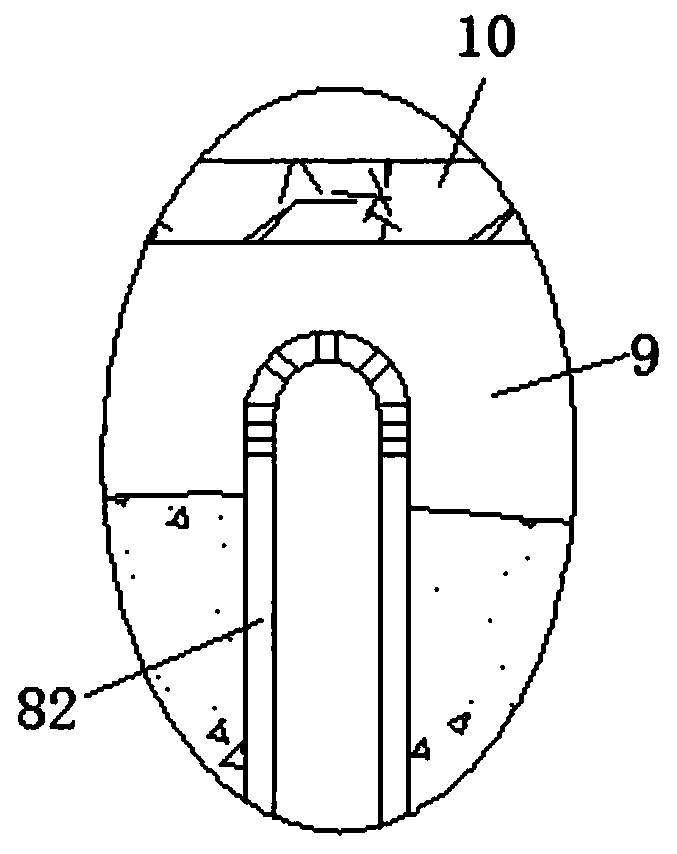

[0030] see Figure 1-2 , a paint drying device for computer production, comprising a drying box 1, the interior of the drying box 1 is fixedly connected with a partition 2, and the top of the partition 2 is provided with evenly distributed air holes 3, and the inside of the drying box 1 And be positioned at the bottom of dividing plate 2 and be provided with support plate 4, the bottom of support plate 4 is fixedly connected with the inner bottom wall of drying box 1, the top of support plate 4 is placed with the drying platform 5 that equidistant arrangement is arranged, and drying box 1 The left and right sides of the top are provided with an air delivery pipe 6, and the top of the air delivery pipe 6 is fixedly connected with a blower mechanism (not shown in the figure), and the bottoms of the two air delivery pipes 6 run through the drying box 1 and the partition in turn 2 and extend to the bottom of the partition 2, the opposite sides of the two air ducts 6 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com