Rust removal anticorrosion platform and method for flat bottom storage tank inner wall

A storage tank and platform technology, which is applied to the field of rust and anti-corrosion platforms for the inner wall of flat-bottomed storage tanks, achieves the effects of simple and efficient rust and anti-corrosion construction, simple and safe installation and disassembly, and convenient and quick adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

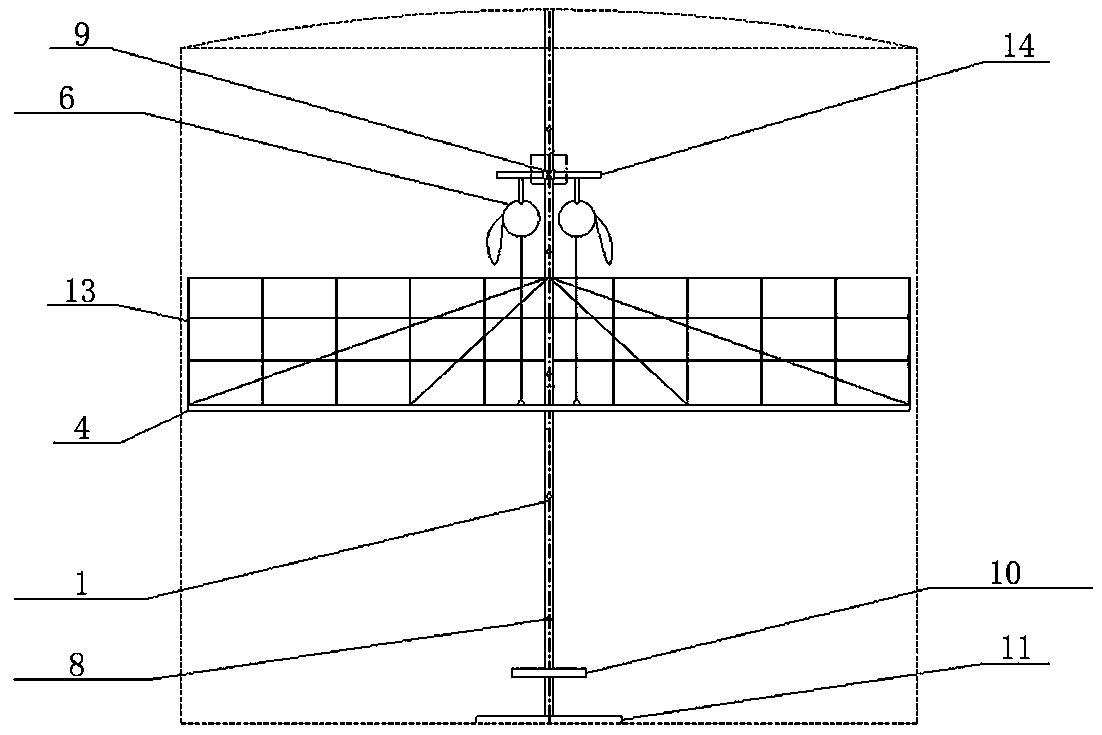

[0049] The non-standard equipment fire water tank involved in this embodiment has an inner diameter of 20m, a height of 22m, and an effective volume of V=5662m. The specific construction process is as follows:

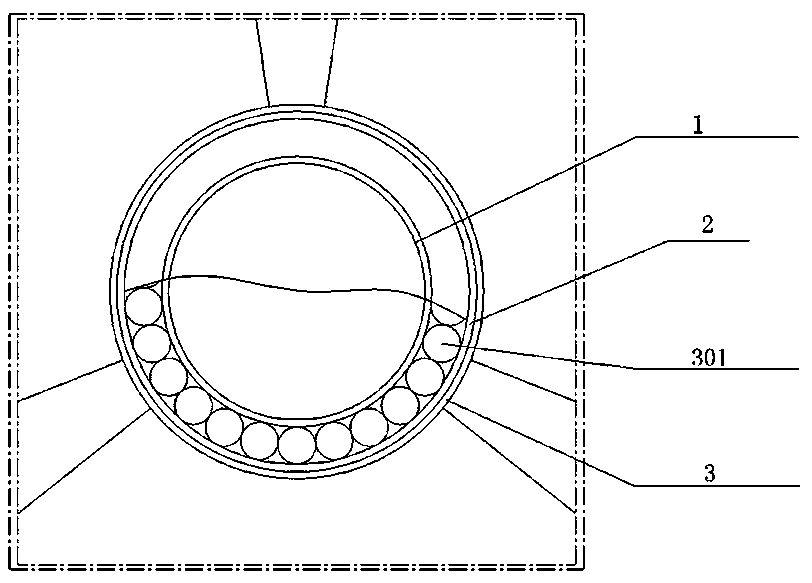

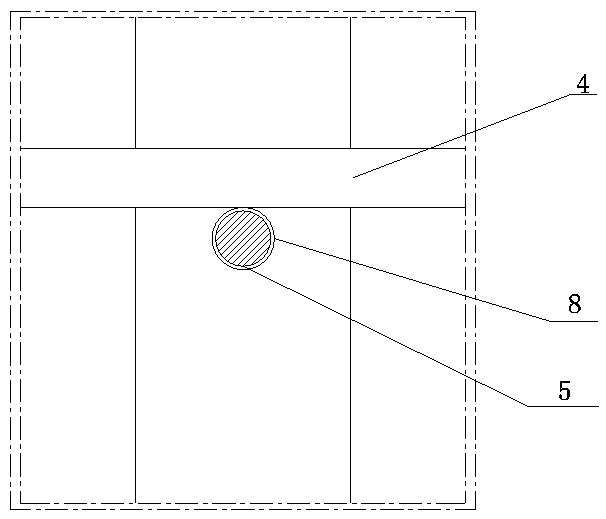

[0050] S1. Steel pipe 1 and casing 3 of the machining center. The central steel pipe 1 uses a φ219*6.3mm steel pipe, and a φ27 pair of limit holes 8 are opened every 1800mm on the central steel pipe 1 (the limit pin shaft 5 uses a φ25mm round steel), and the bearing 2 is inserted from one end and φ273 is welded outside the bearing 2. *12.5 Sleeve 3 is used to weld the external platform, and the supporting plate 15 (20mm thick) is welded under the sleeve 3.

[0051] S2. Fixing the central steel pipe 1 and the casing 3. Weld a circular guard plate (20mm thick) in the center of the bottom plate and top plate of the storage tank respectively, weld the processed central steel pipe 1 at the center position, and use theodolite to detect the verticality of the central steel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap