Glue feeding mechanism, glue sticking mechanism and cell winding device

A glue sticking mechanism and glue feeding technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as high cost and difficulty in improving production efficiency, achieve large glue feeding, improve production efficiency, and save tape replacement effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

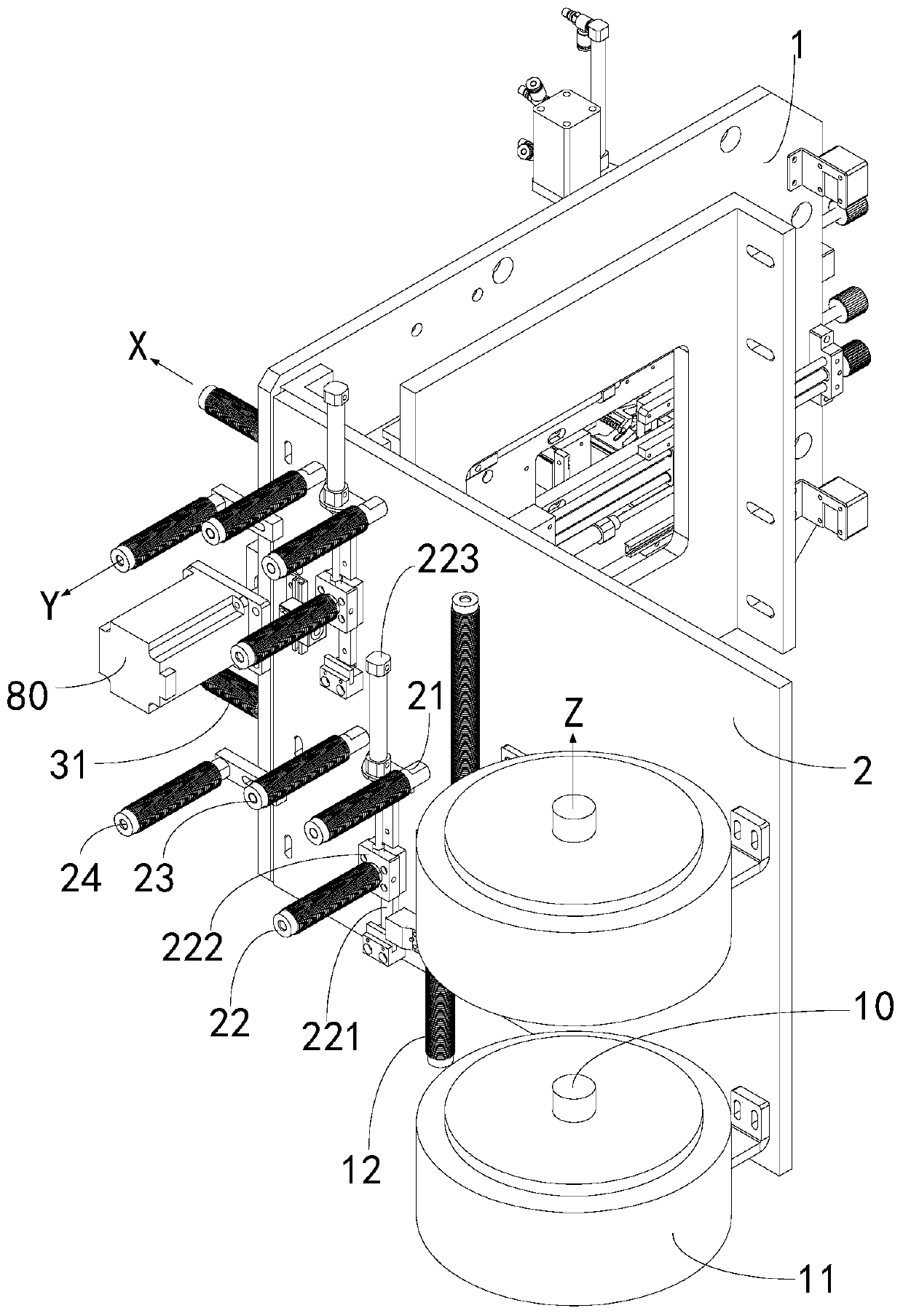

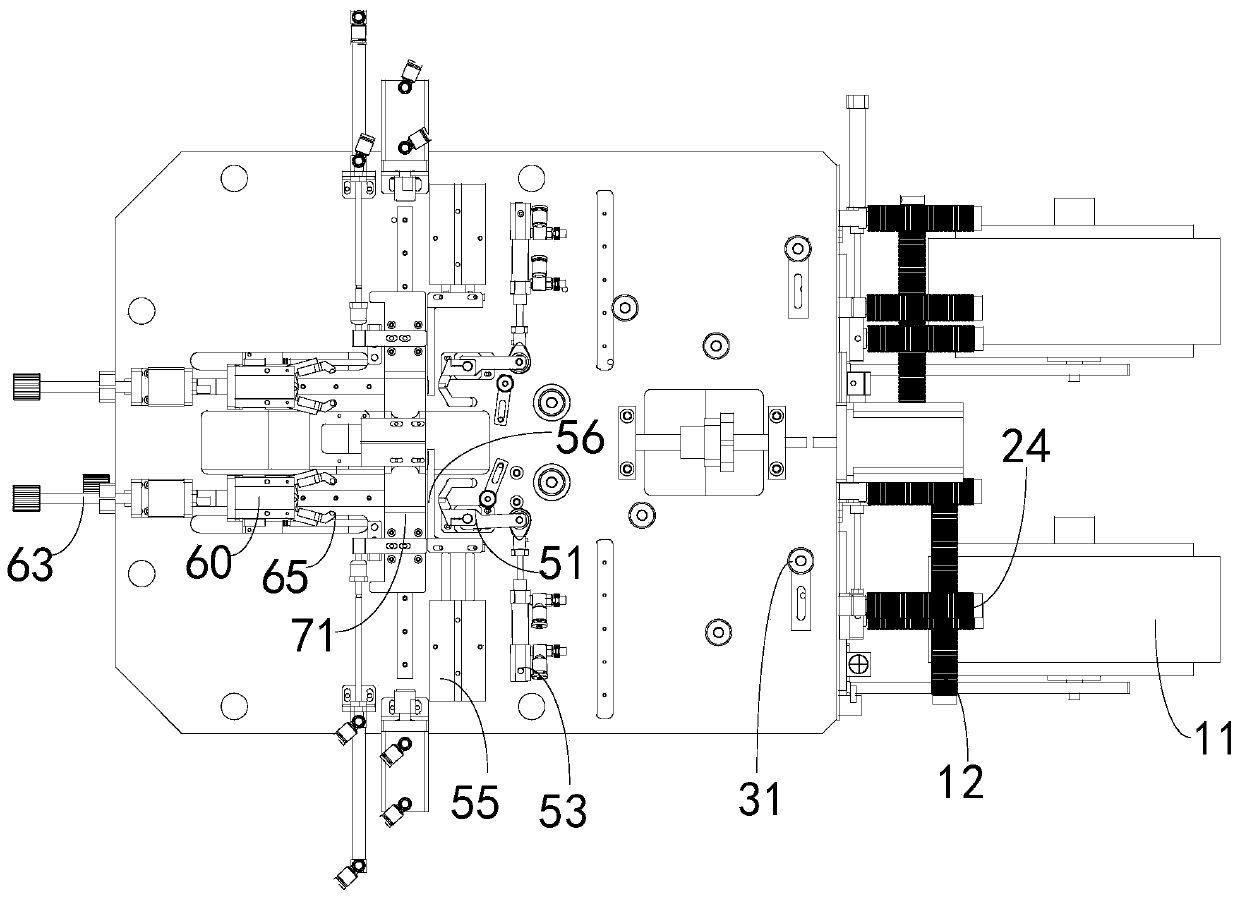

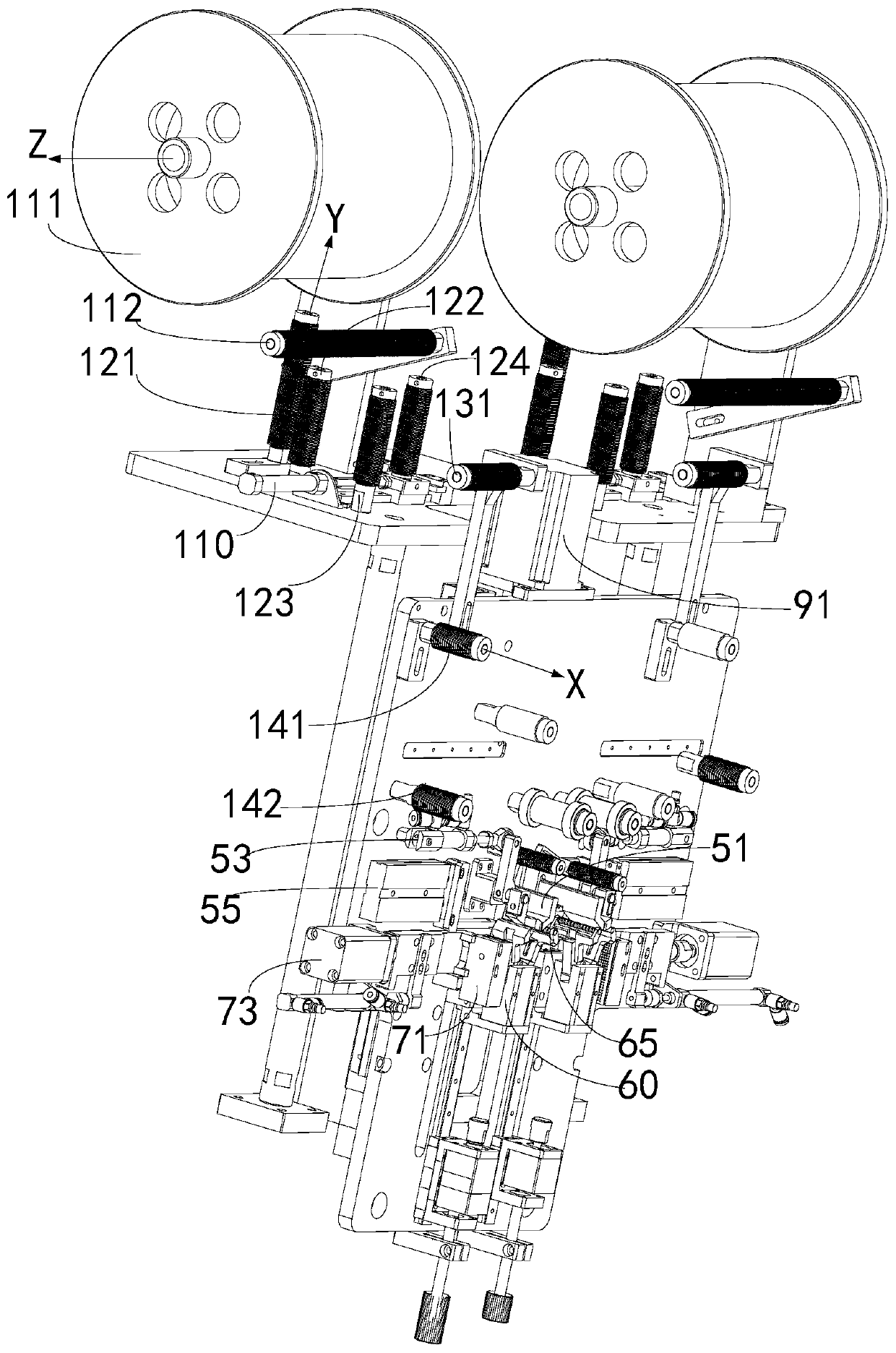

[0039] Please also refer to Figure 1 to Figure 4 , the gluing mechanism of this embodiment is used for conveying tapes for the gluing mechanism.

[0040] The glue feeding mechanism includes a large-sized tape reel assembly, a first glue feeding assembly, a second glue feeding assembly and a third glue feeding assembly. According to the length of the glue feeding path, the third glue feeding assembly can be provided in multiples, and the adhesive tape can be spirally rotated several times.

[0041] In order to extend the glue feeding path in order to form a spatial hierarchy, the first space angle formed between the central axis of the large-size tape reel assembly and the central axis of the first glue feeding assembly, the central axis of the first glue feeding assembly and the second A second space angle formed between the central axes of the glue feeding assembly, a third space angle formed between the central axis of the second glue feeding assembly and the central axis ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap