Pulling riveting fastener

A firmware and riveting technology, applied in the direction of rivets, etc., can solve the problems of inability to meet the needs of fastening processing, single function, and inability to effectively determine the completion status of fastening operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0032] In conjunction with the accompanying drawings.

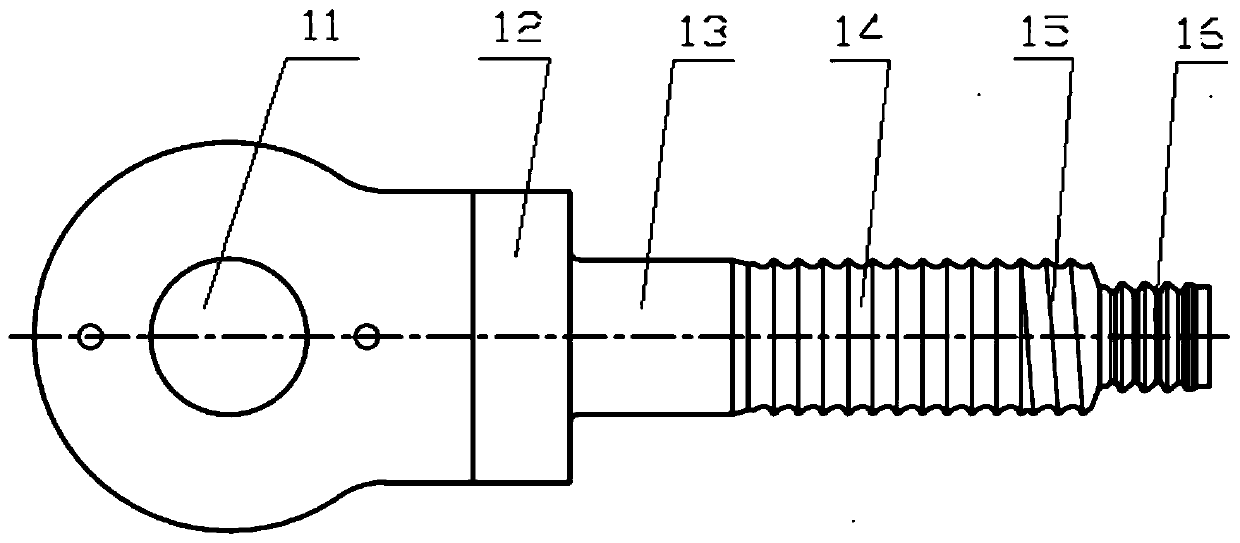

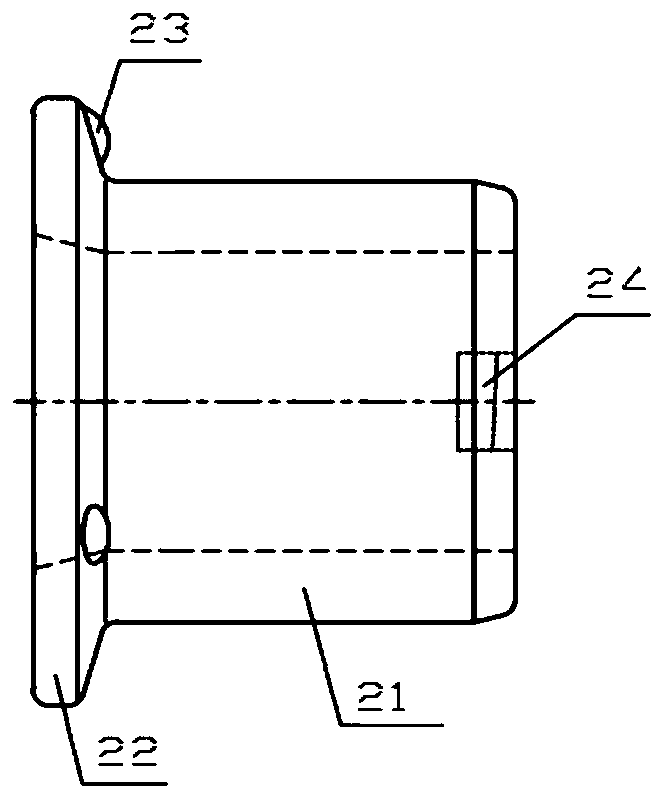

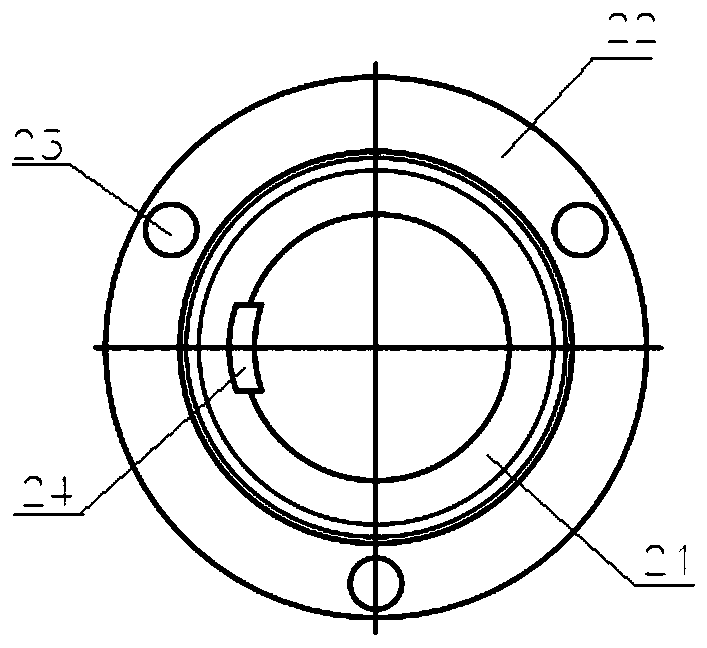

[0033] The blind rivet fastener is composed of a blind rivet 1 and a collar 2. The blind rivet 1 and the collar 2 adopt clearance fit. The blind rivet 1 includes an eye ring 11, a platform stage 12, a polished rod section 13, a locking Groove segment and grip groove segment 16 ; the collar 2 includes an integral flange segment 22 and a straight segment 21 .

[0034] The locking groove section consists of a ring groove section 14 and / or a threaded groove section 15 .

[0035] The eye ring is a through hole arranged on the head of the blind rivet 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com