Concrete stirring device convenient to clean

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixer accessories, etc., can solve the problems of low cleaning quality, impact on service life and product quality, power consumption, etc., and achieve the effect of saving power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

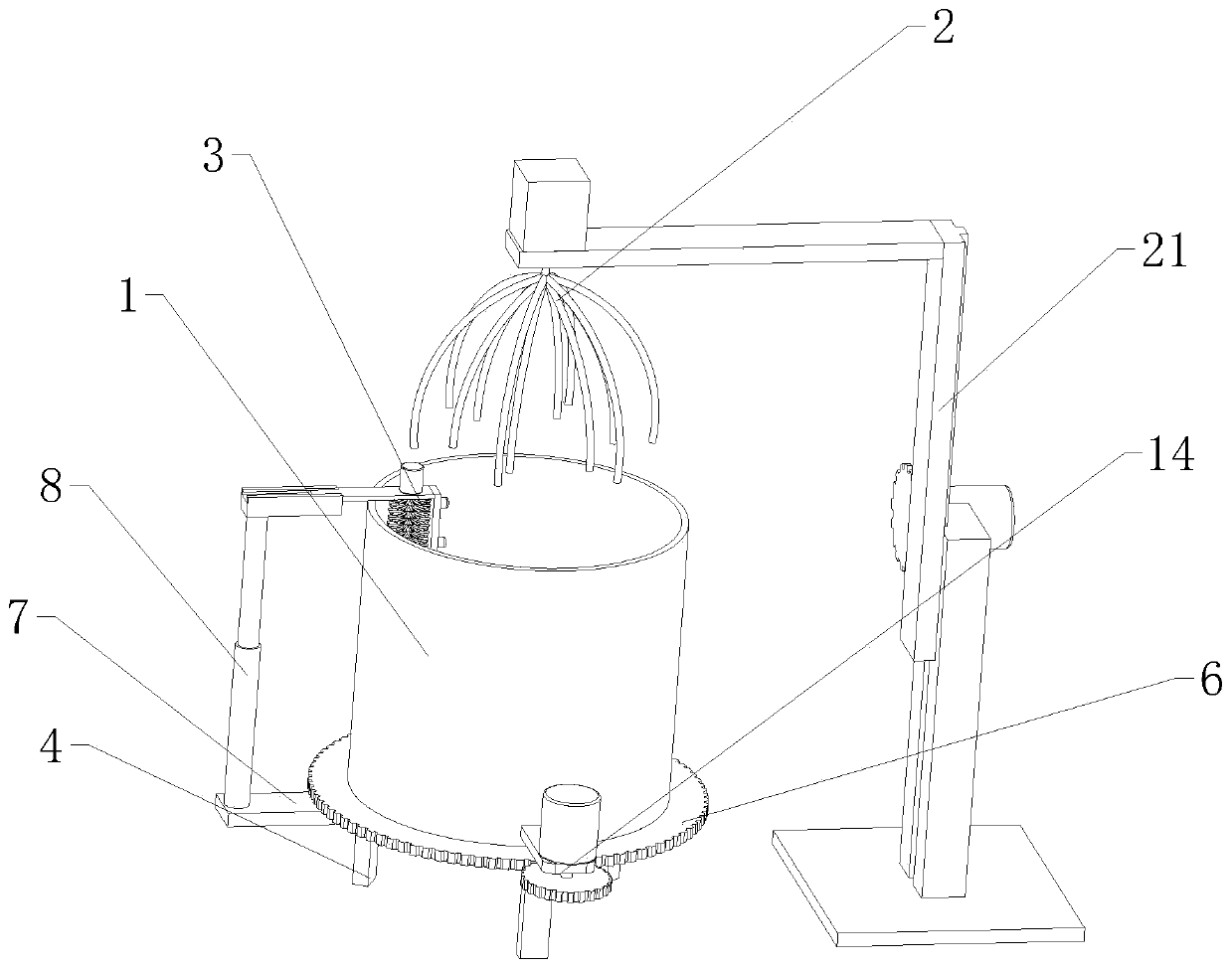

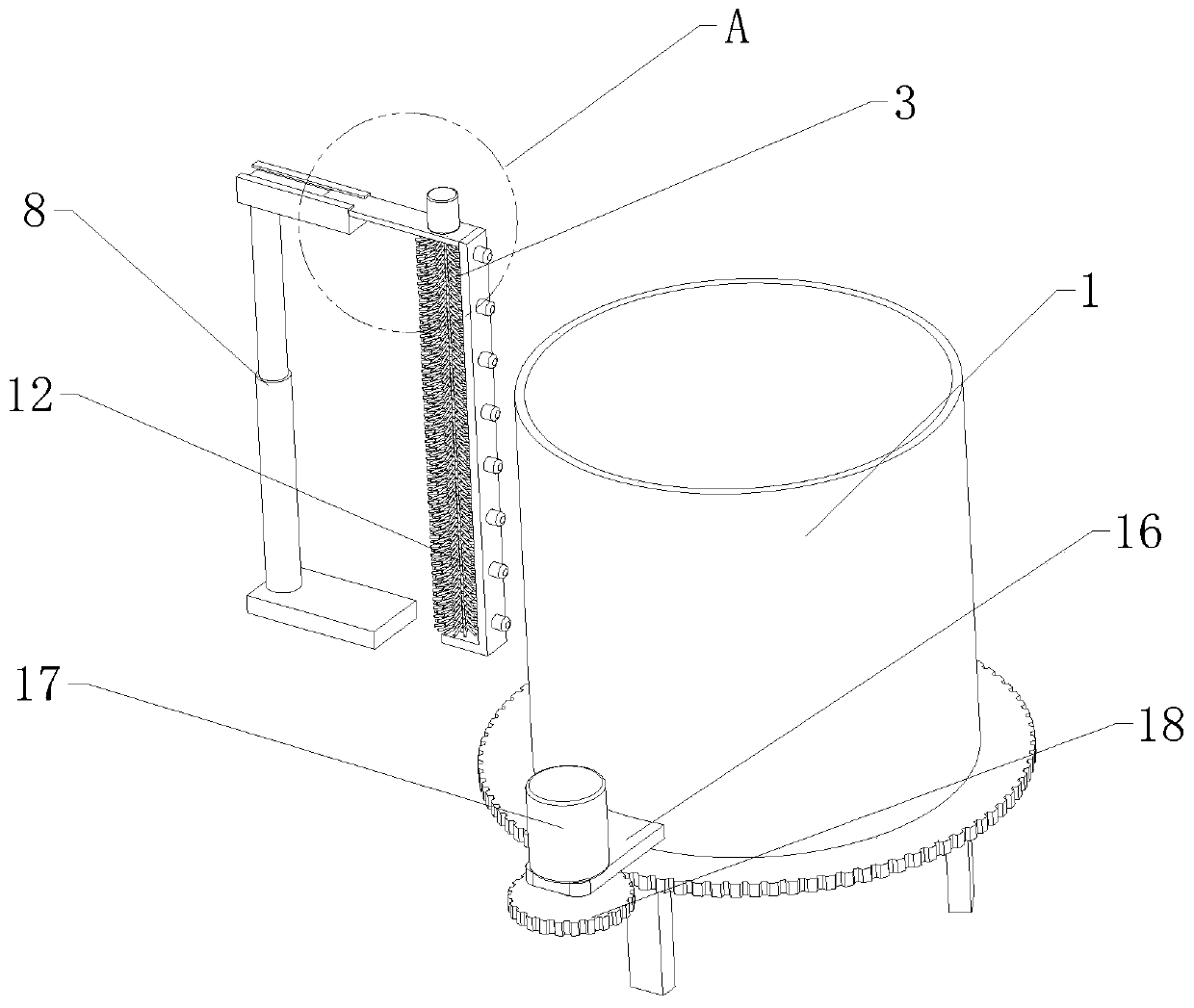

[0028] Embodiment 1: refer to Figure 1 to Figure 5 The shown concrete mixing device for easy cleaning includes a mixing tank 1, a mixing mechanism 2 and a cleaning mechanism 3, the mixing tank 1 is a cylindrical structure, and the bottom of the mixing tank 1 is provided with a plurality of support frames 4, And the lower side of the mixing tank 1 is provided with a feeding port, an electric switch door 5 is installed on the feeding port, the mixing mechanism 2 is arranged on the side of the mixing tank 1, and the outer wall of the mixing tank 1 is also axially connected with a first gear 6, The cleaning mechanism 3 is fixedly installed on the first gear 6. The cleaning mechanism 3 includes a mounting plate 7, an electric telescopic rod 8, a fixed plate 9, a cleaning brush 10 and an "L"-shaped first mounting base 11. The mounting The plate 7 is fixedly arranged on the first gear 6, the electric telescopic rod 8 is fixedly installed on the mounting plate 7, and the output end o...

Embodiment 2

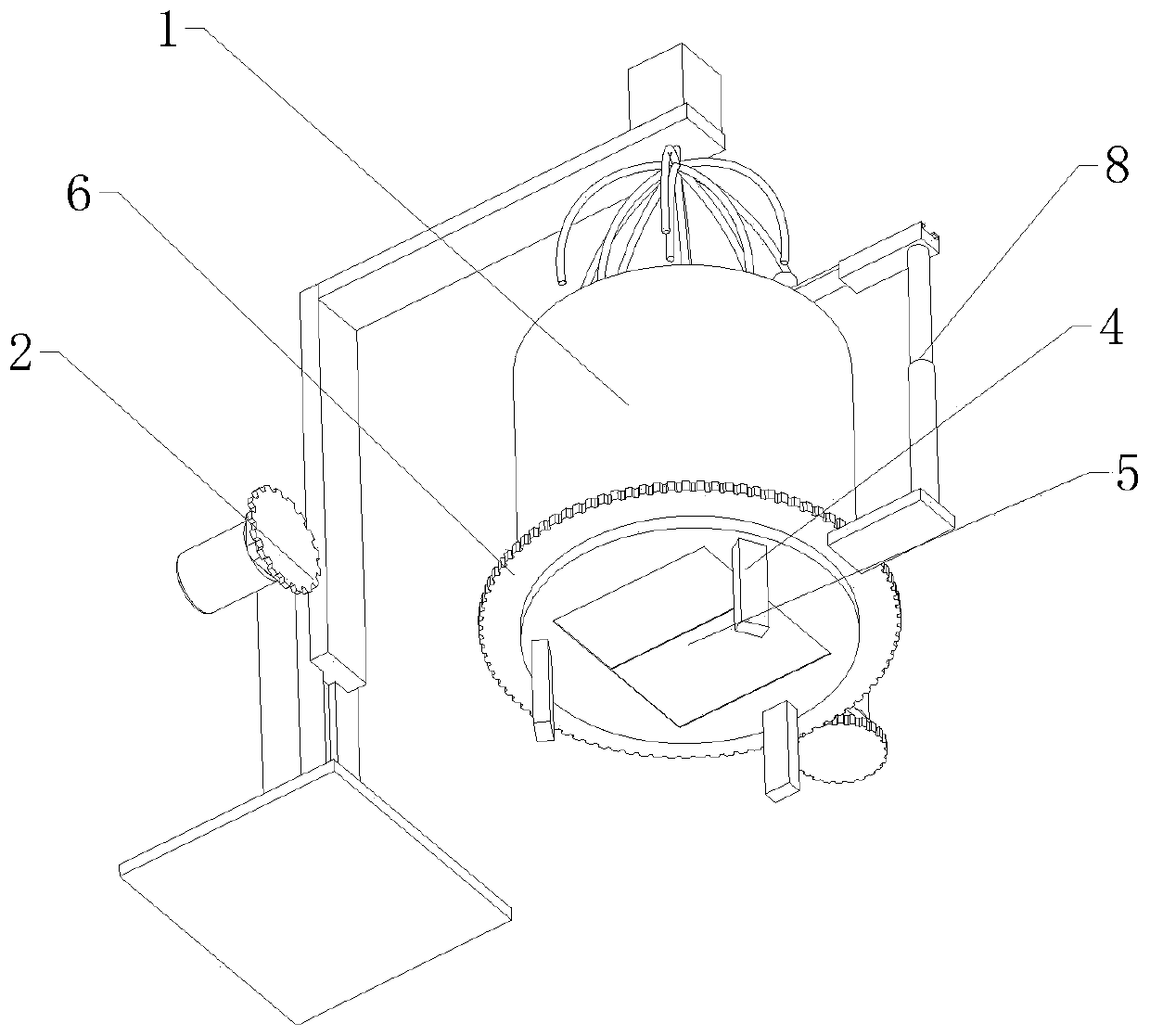

[0036] Embodiment 2: A kind of concrete mixing device that is easy to clean includes a mixing bucket 1, a mixing mechanism 2 and a cleaning mechanism 3, the mixing bucket 1 is a cylindrical structure, and a driving disc is arranged at the bottom of the mixing bucket 1, and the stirring The barrel 1 is slidingly supported in the circular groove on the upper surface of the driving disc, and a plurality of connecting pendants are arranged at equal angles on the upper surface of the driving disc, and a plurality of connecting parts are arranged at corresponding positions on the outer wall of the mixing barrel 1. The hook is used to complete the detachable connection between the mixing tank 1 and the driving disc. The bottom of the driving disc is provided with a plurality of support frames 4, and the lower side of the driving disc is provided with a feeding port, and an electric switch door 5 is installed on the feeding port. Stirring mechanism 2 is arranged on the side of mixing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com