Device for adjustment of a printhead

A technology of printing heads and equipment, applied in printing, general parts of printing machinery, printing machines, etc., to avoid overshoot or undershoot, and achieve the effect of accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

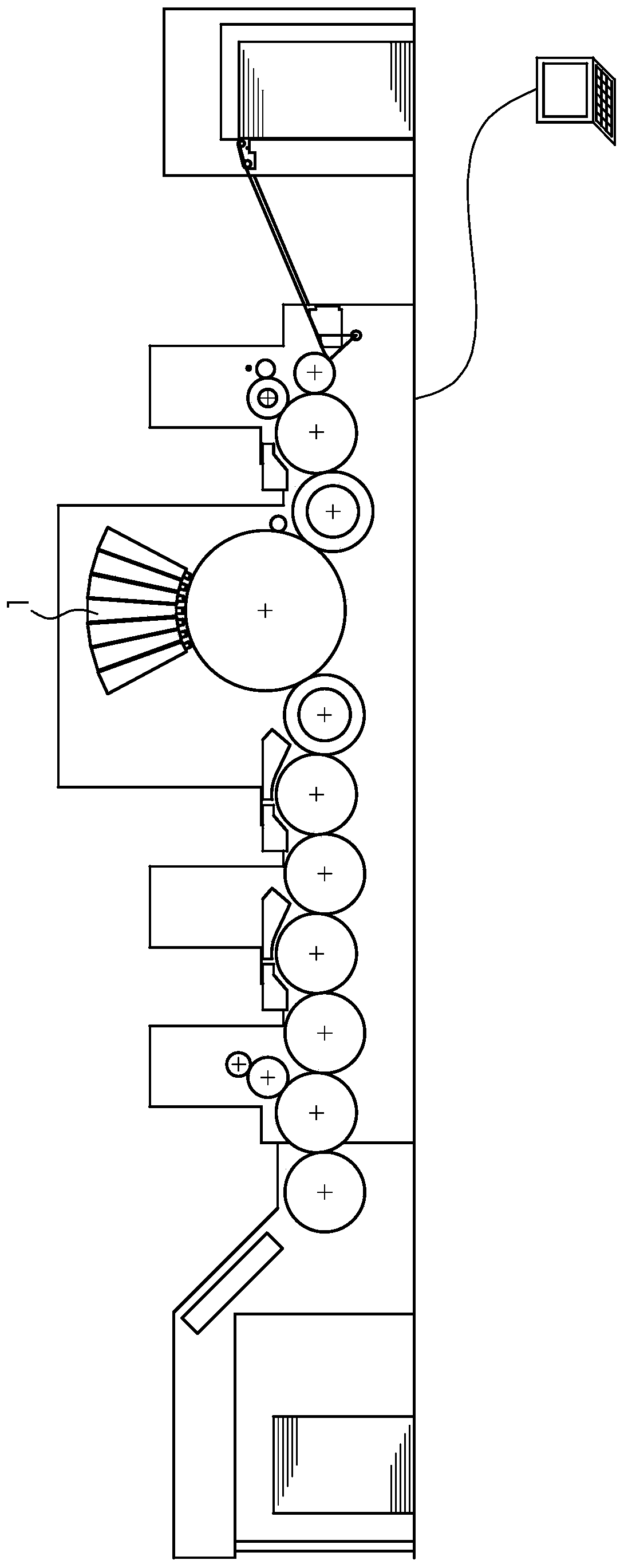

[0022] figure 1 A printing press with a plurality of printing beams 1 is shown for inkjet printing onto printing substrates made of paper or thick paper. The printing material is in the form of a sheet, but can also be in the form of a web. These printing beams 1 are identical in structure, so that only one printing beam 1 needs to be described. The printing beam 1 has printing heads 2 in an arrangement perpendicular to the figure 1 The graph plane extension of . The printing heads 2 are arranged to extend over the formatted width of the printing material, and the printing beam 1 is used for page-width printing.

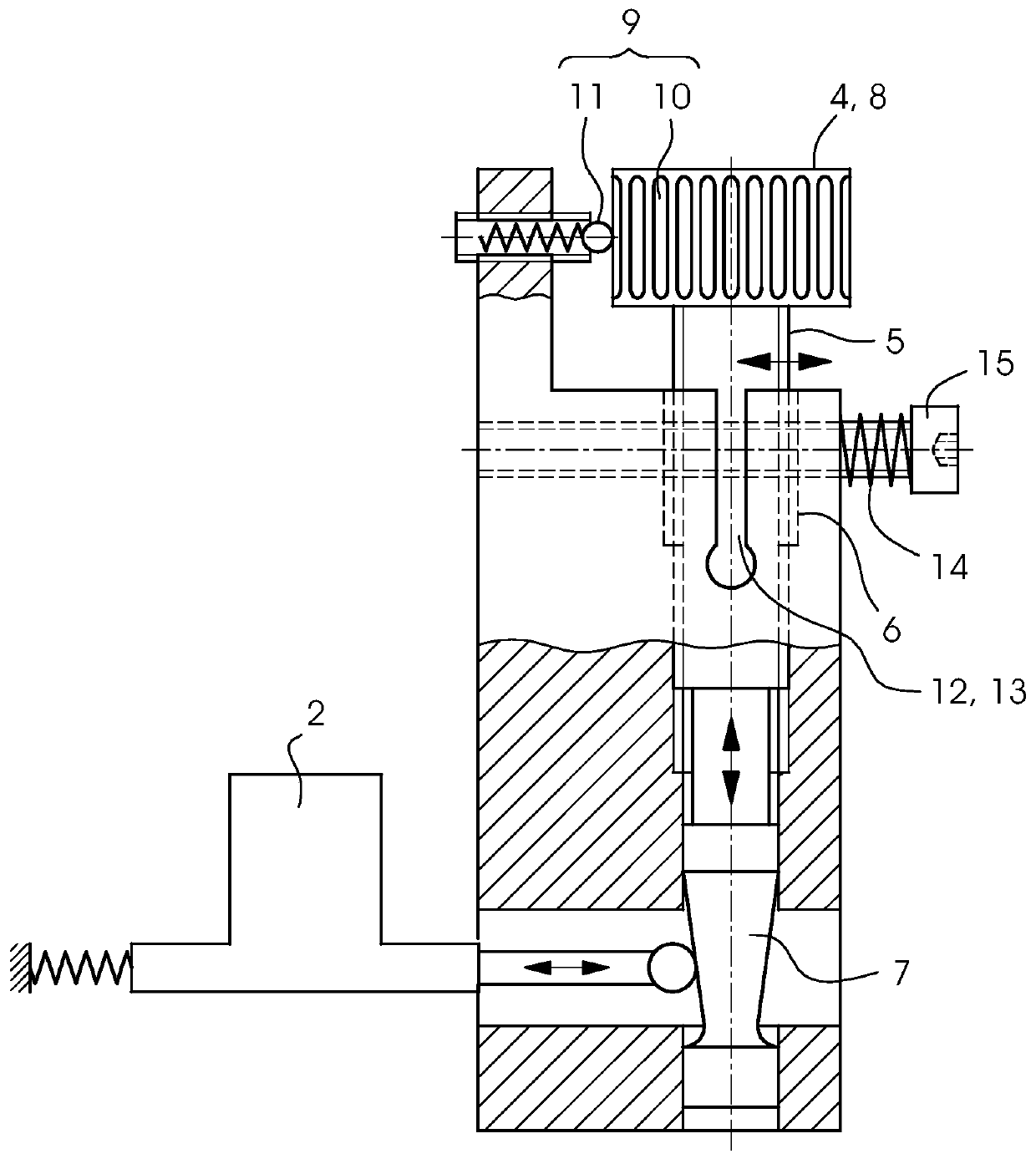

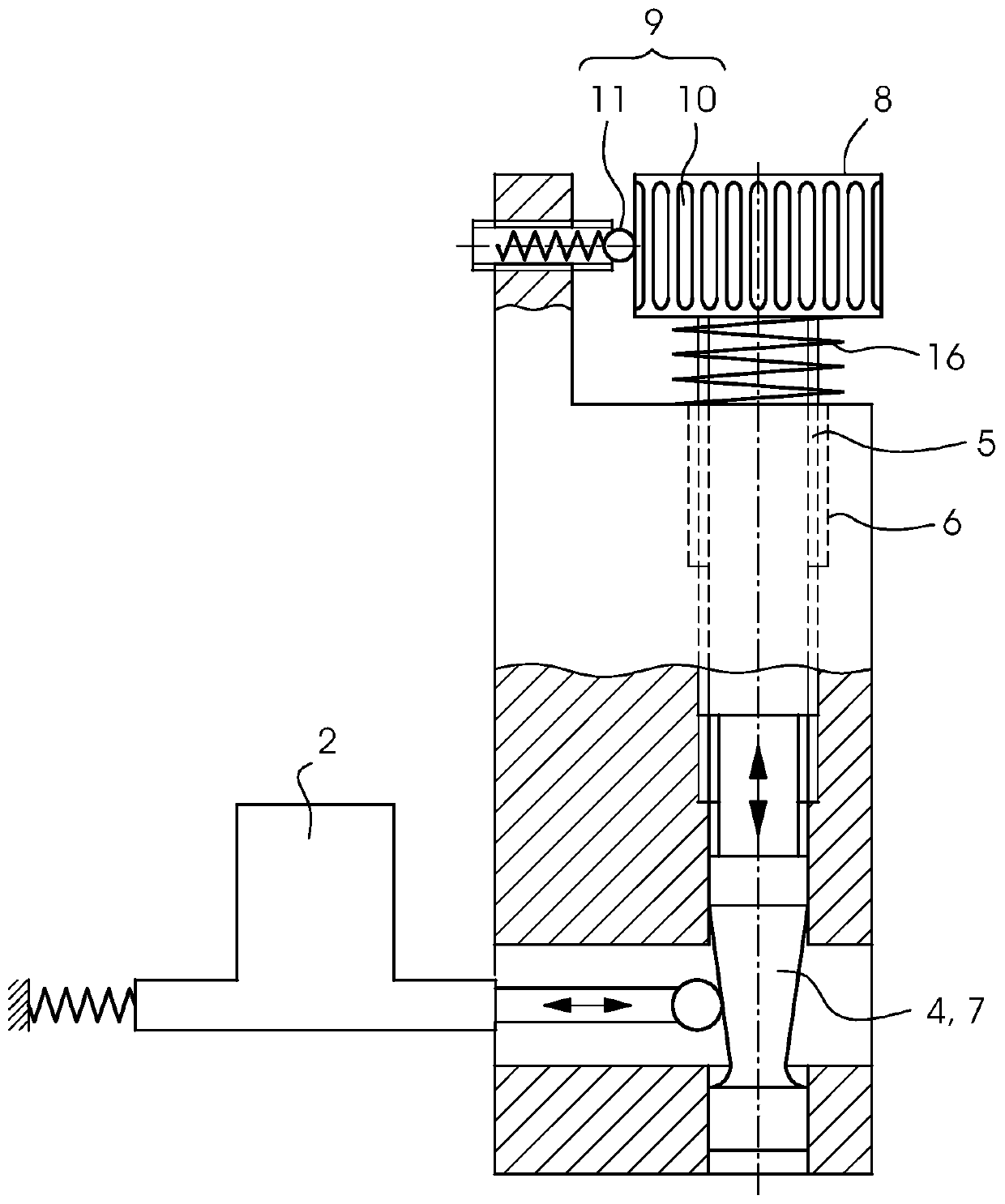

[0023] Each print head 2 is equipped with a calibration device by means of which a print head 2 can be adjusted relative to its adjacent print head 2 . This adjustment movement of the printing head 2 driven by the calibration device can be a translation or a rotation.

[0024] calibration equipment in figure 2 with image 3 The embodiments shown in have commo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com