A Concrete Ultra-flat Floor Cut-Free Construction Structure

A concrete and floor technology, which is applied to the coagulation pavement, roads, buildings and other directions of on-site paving, can solve problems such as failure to meet building quality requirements, difficulty in grasping the time of cutting seams, and inability to cut seams in time, so as to avoid two problems. Secondary kerf, reduced shrinkage stress cracks, reduced uncontrollability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

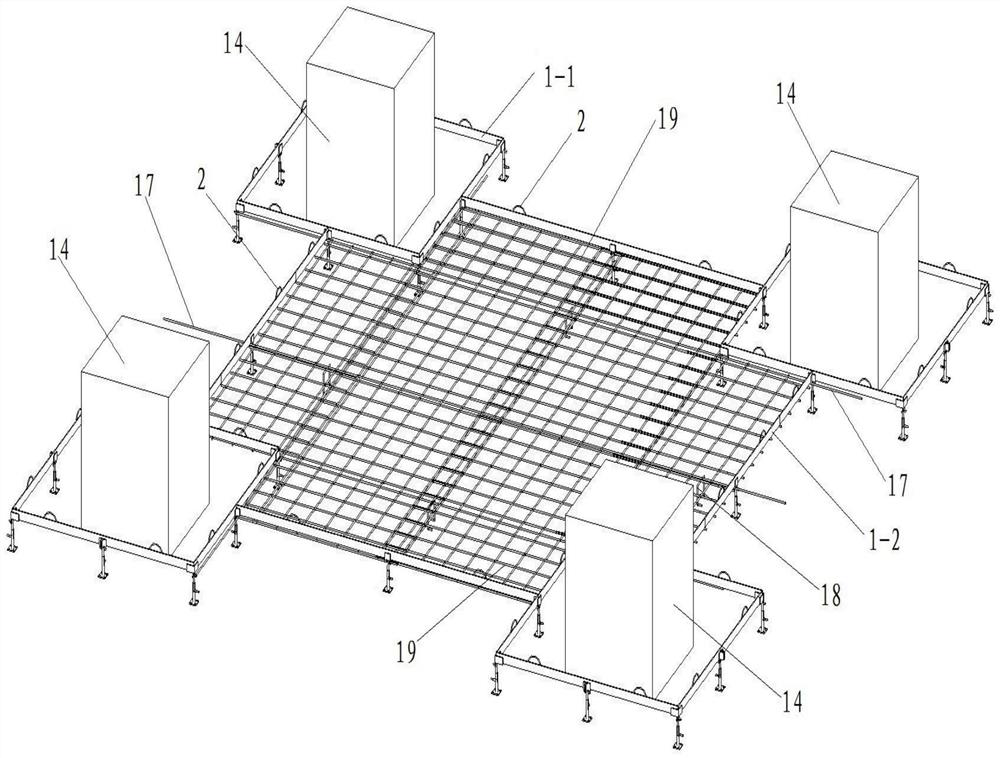

[0034] Such as Figure 1 to Figure 4 As shown, the present invention includes a concrete floor and a floor foundation poured in the concrete floor, the floor foundation includes a partition network and a floor reinforcement layer, and is used to support the partition network and The support mechanism of the floor reinforcement layer, the support mechanism includes a plurality of support rings arranged in an array, and in the support mechanism, between two adjacent support rings arranged in the same row and between two adjacent support rings arranged in the same row An auxiliary support frame is arranged between the support rings;

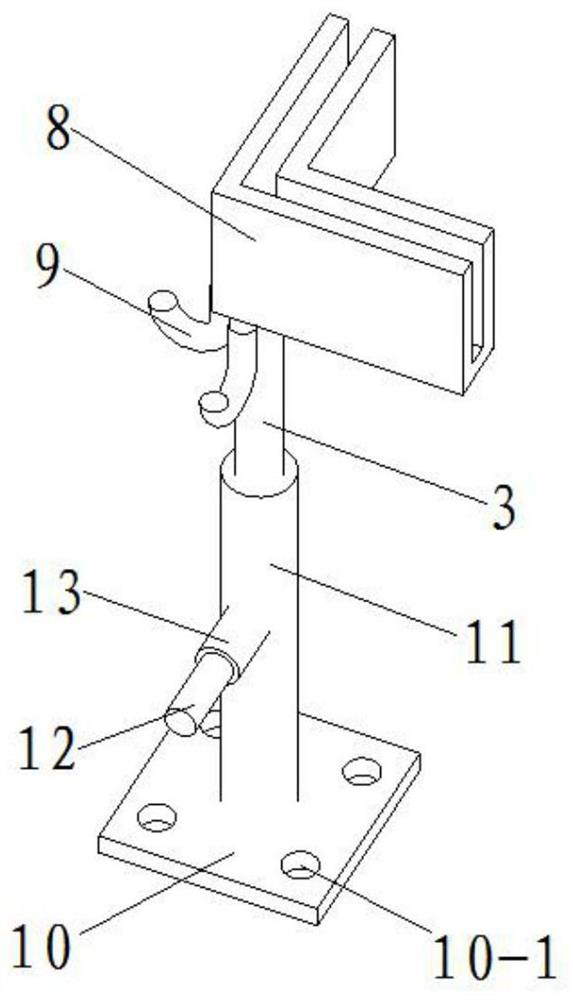

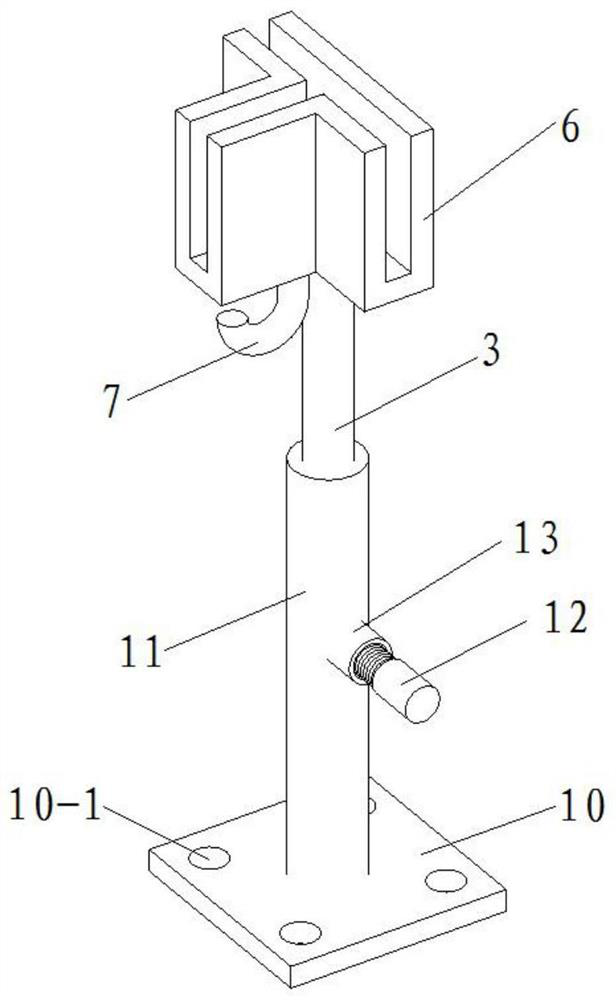

[0035] The support ring includes four matching main support frames, the four main support frames enclose a rectangular area, and a transition support frame is arranged between the two main support frames on the same side of the rectangular area, The main support frame includes an L-shaped clip 8 and a main adjustment base arranged below the L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com