Manual and electric dual-purpose omni-directional moving opposite-wheel control mechanism of carrier mobile equipment

A technology that moves and moves equipment in all directions. It is used in vehicle cleaning equipment, lifting devices, etc., and can solve the problem of not being able to fit in a small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

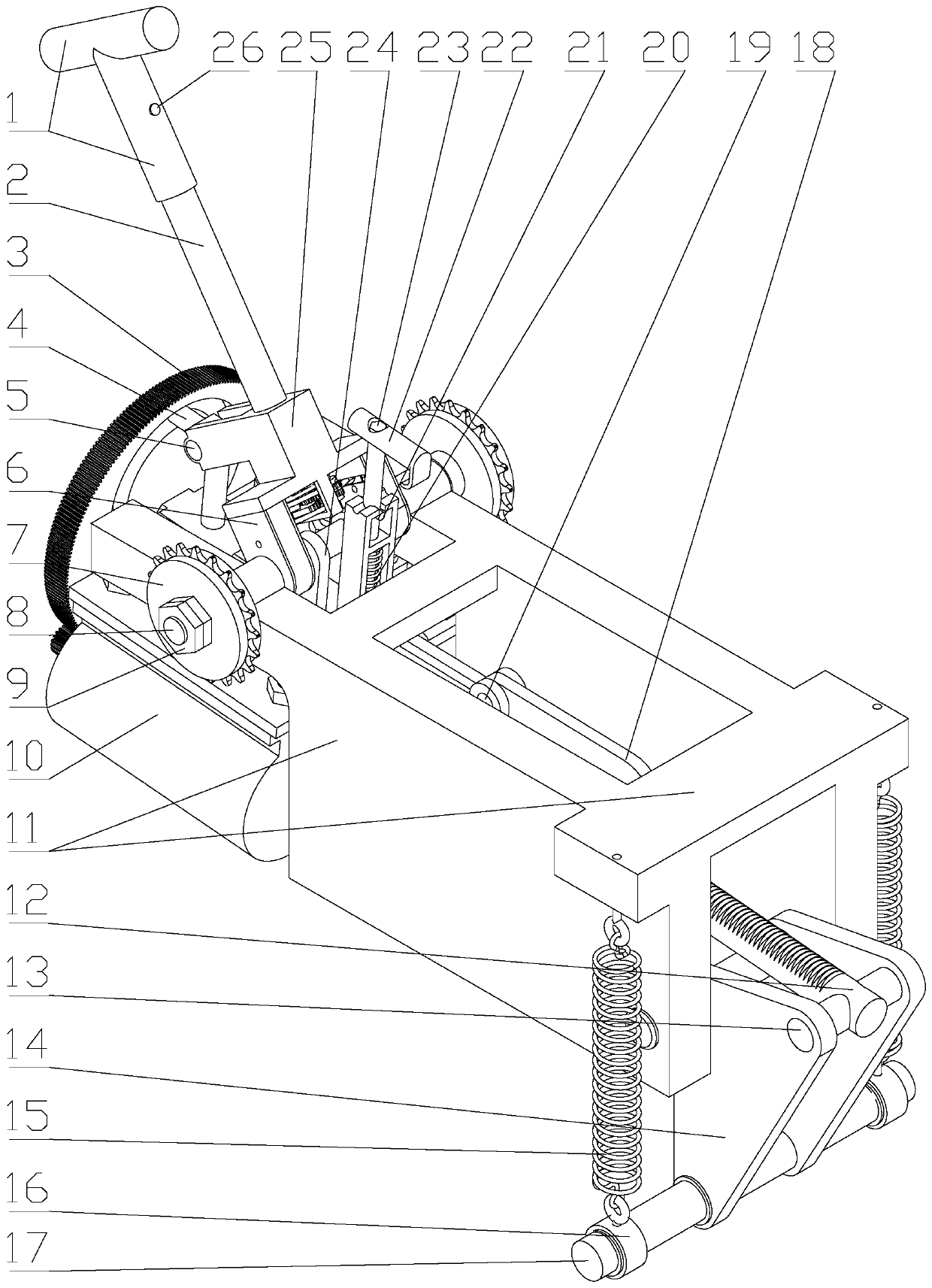

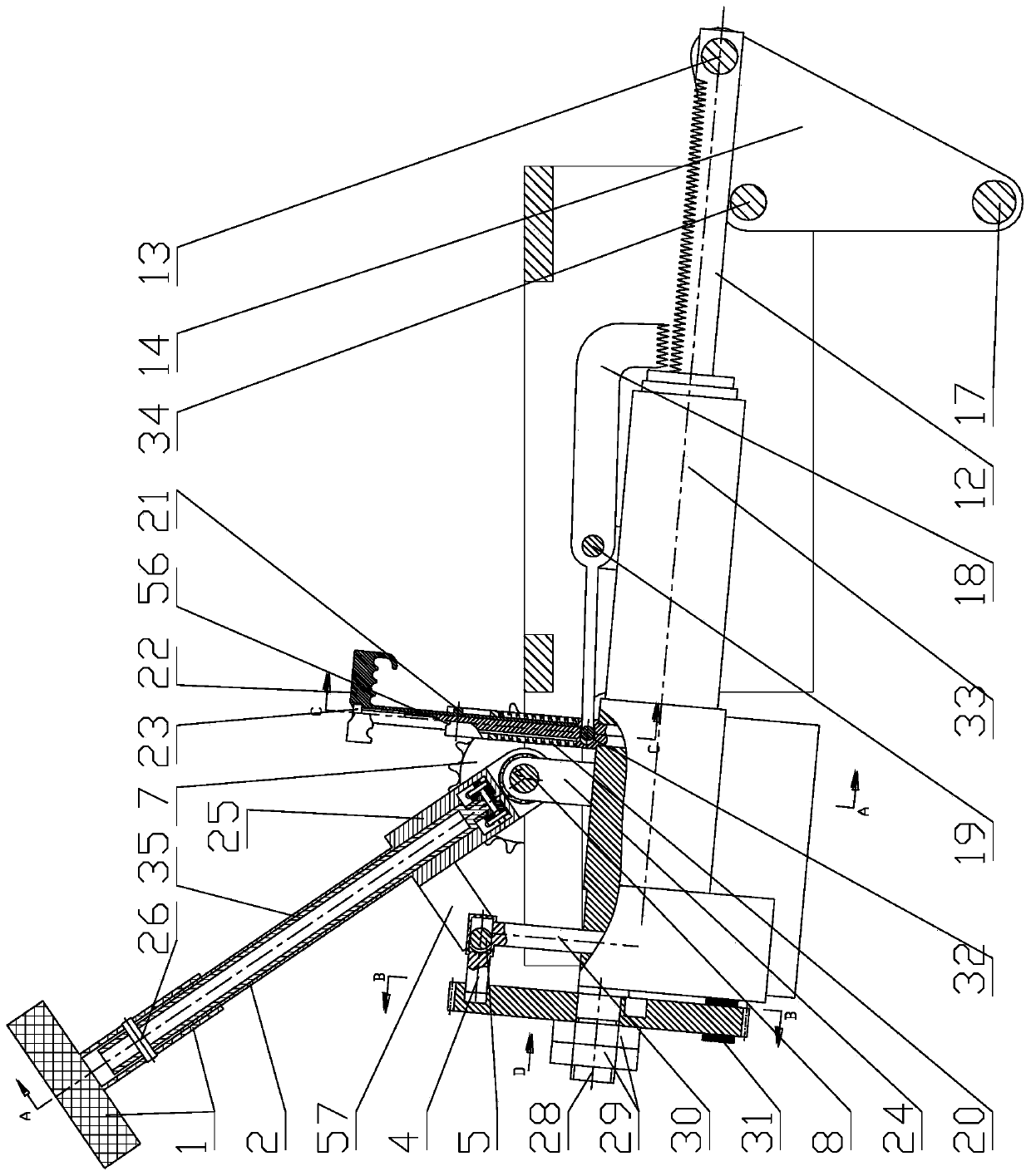

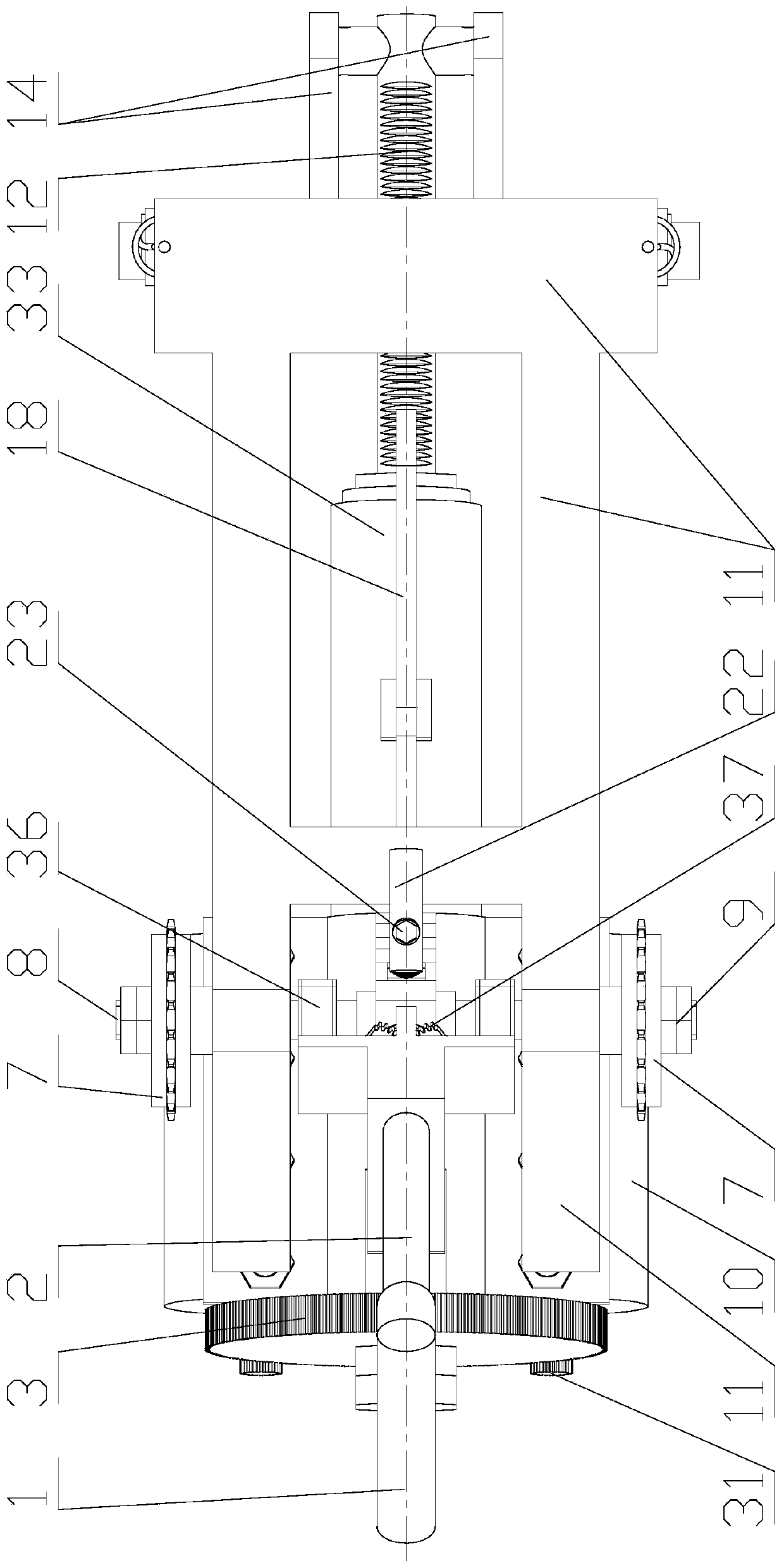

[0027] exist Figure 1 to Figure 10 In , it represents the structural composition of the mechanism and the connection and positional relationship of the components. Including the total control mechanism, the landing control mechanism, the travel control mechanism, the locking mechanism and the electric mechanism. This mechanism is basically a symmetrical structure.

[0028] Figure 1 to Figure 5 Indicates the structural composition of the total operating mechanism and the connection and positional relationship of parts. The total control mechanism is composed of frame body 11, handle 1, sleeve rod 2, sleeve rod seat 25, fixed pin 26, rotating rod 35, ratchet seat 36, ratchet seat outer cover 6, ratchet seat inner cover 39, screw 40, central axis 8 Composition; the frame body 11 is a hollow cuboid shape, which is the supporting frame of the mechanism; the handle 1 is composed of two T-shaped cylinders, and the cylinder at the lower end of the handle 1 is a round tube, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com