Screen protection film and electronic equipment

A screen protection film and preset threshold technology, applied in the direction of film/sheet adhesive, adhesive, etc., can solve the problems of weakened screen protection function, easy attenuation, and decline in the comprehensive performance of the screen protection film, so as to ensure the ultrasonic fingerprint Recognition effect, reduce ultrasonic attenuation, enhance the effect of propagation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

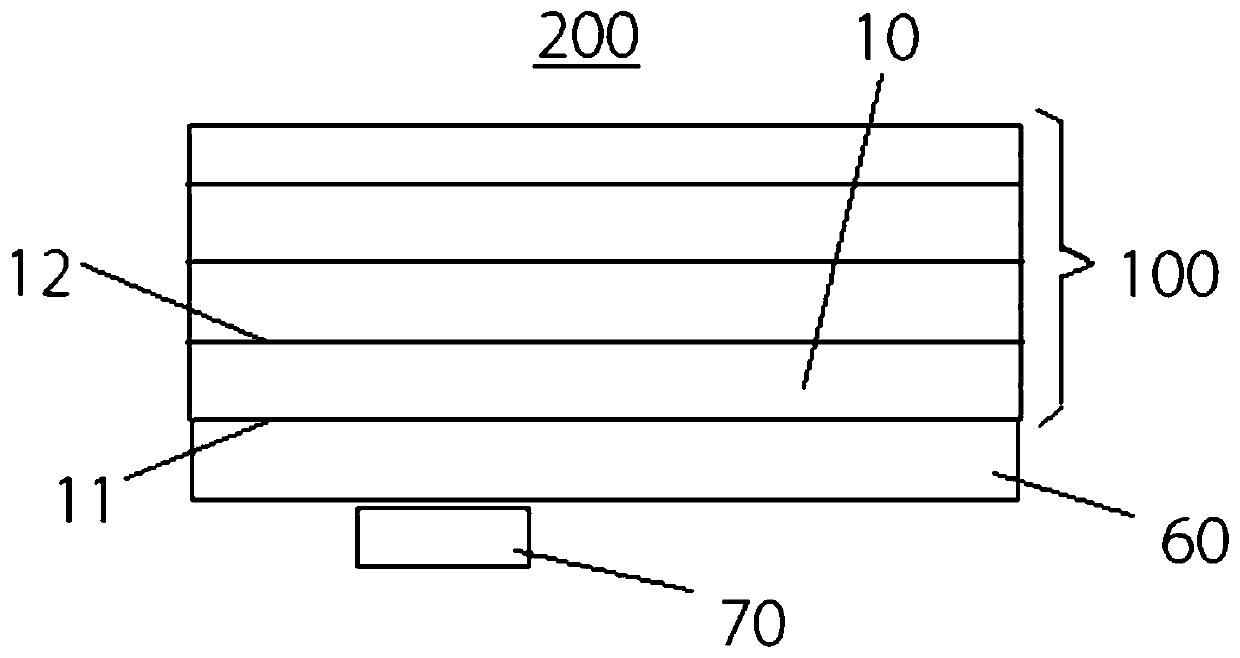

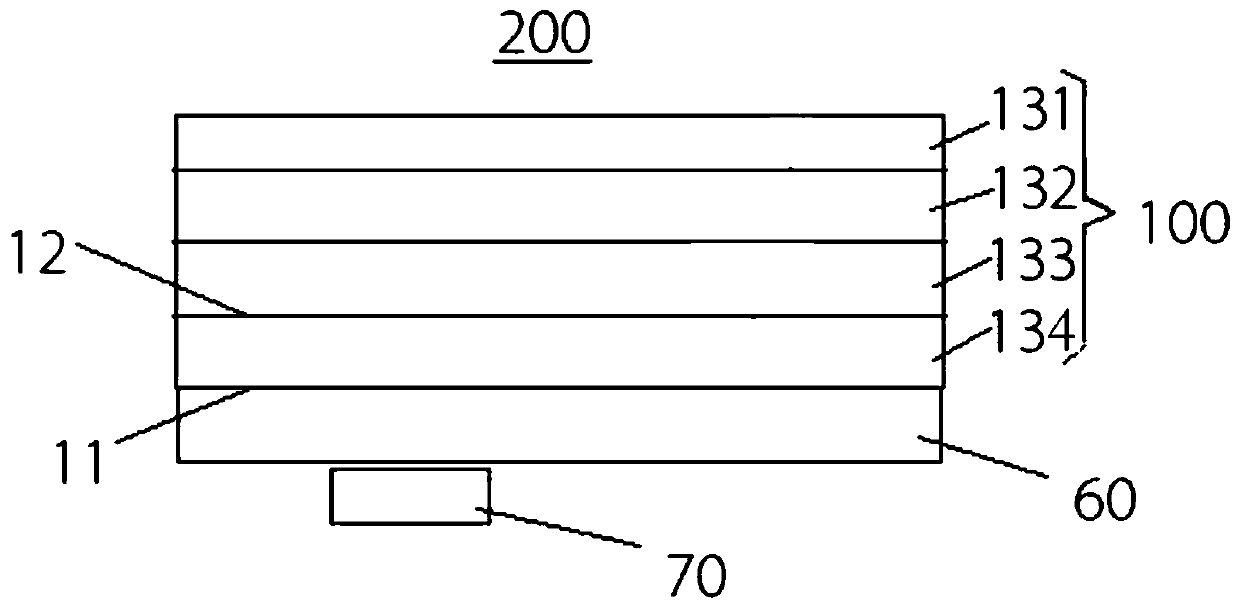

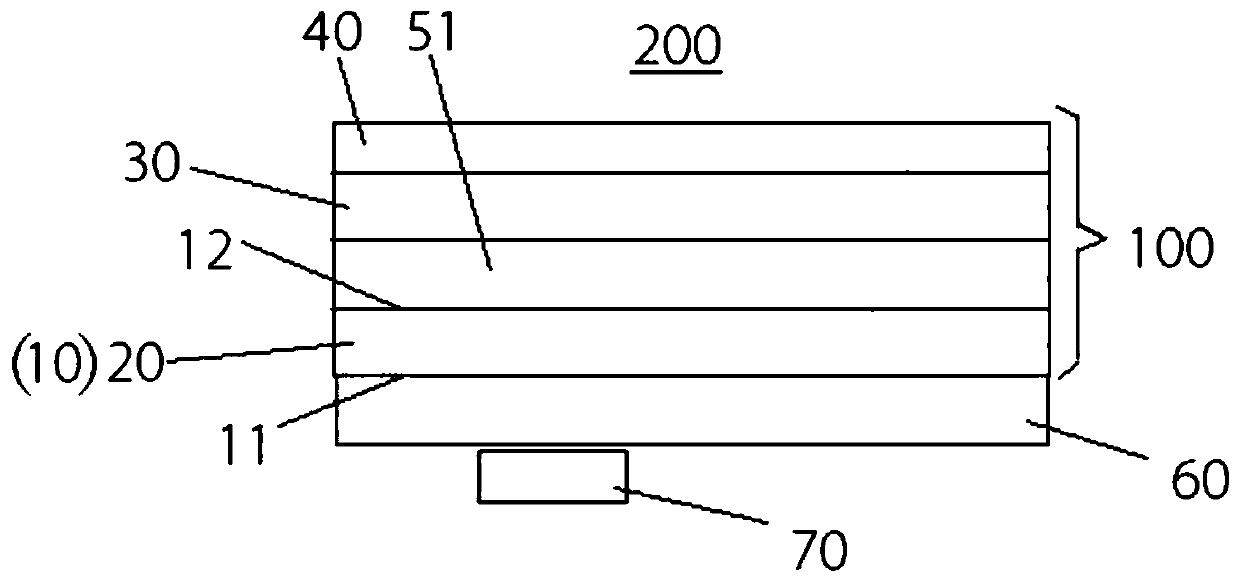

[0015] see figure 1 , the embodiment of the present application provides a screen protection film 100, the screen protection film 100 is used to fit the display module 60, and the side of the display module 60 facing away from the screen protection film 100 is provided with an ultrasonic fingerprint sensor. Group 70, the screen protection film 100 can pass through the ultrasonic waves emitted by the ultrasonic fingerprint module 70, the screen protection film 100 is provided with a resonant layer 10, and the resonant layer 10 is provided with a The first surface 11 of the first surface 11 and the second surface 12 opposite to the first surface 11, the resonance layer 10 can make the ultrasonic waves emitted from the first surface 11 toward the second surface 12 and from the second surface 12 The ultrasonic waves reflected toward the first surface 11 are superimposed to generate resonance.

[0016] A resonant layer 10 is provided through the screen protective film 100, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com