Polyimide film as well as preparation method and application thereof

A technology of polyimide film and polyamic acid, which is used in identification devices, instruments, etc., can solve problems such as difficulty in taking into account film transparency and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The present invention will be described below with reference to specific embodiments. It should be noted that the following embodiments are examples of the present invention, and are only used to illustrate the present invention, but not to limit the present invention. Other combinations and various modifications within the inventive concept can be made without departing from the spirit or scope of the inventions.

[0059] experiment method

[0060] Solution Viscosity Test:

[0061] Solution viscosity was measured at 25°C using a Brookfield DV-I viscometer.

[0062] Dimensional Stability Test:

[0063] The change in film size with temperature was measured by a thermomechanical analyzer (TMA) model TA-Q400 with the sample heated at a rate of 10°C / min from 0°C to 500°C in a nitrogen atmosphere.

[0064] Film forming performance test:

[0065] The state of the polyimide film on the glass substrate and its bonding with the glass substrate were observed.

[0066] The...

Embodiment 1

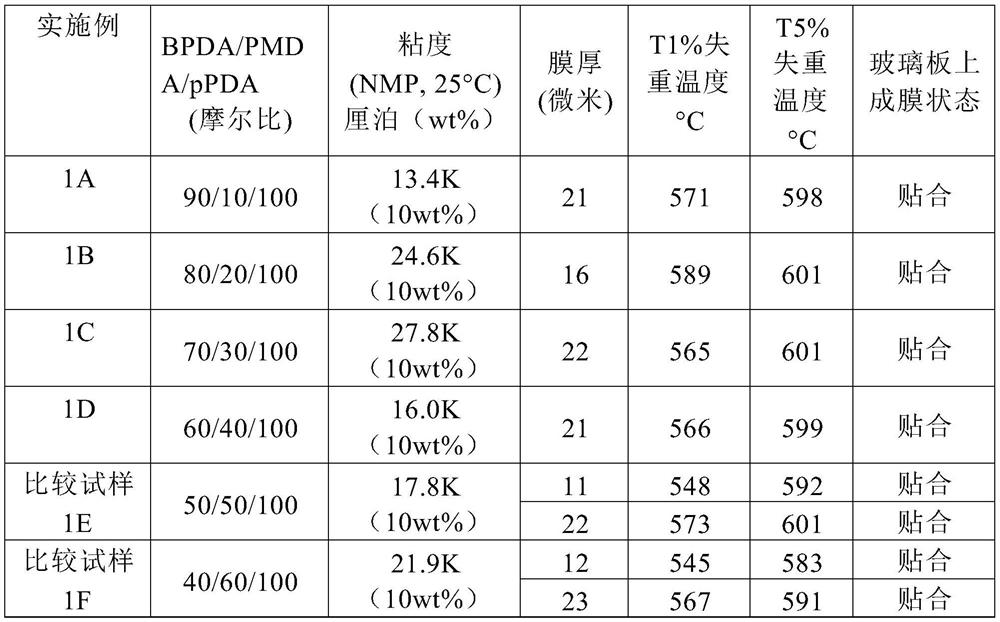

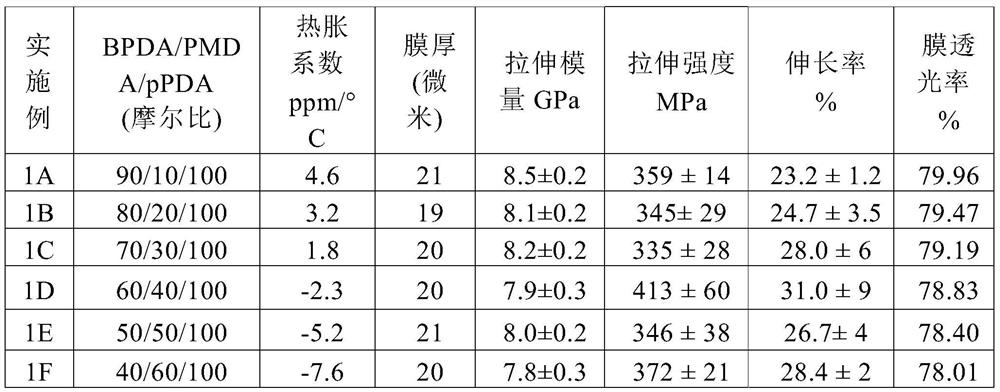

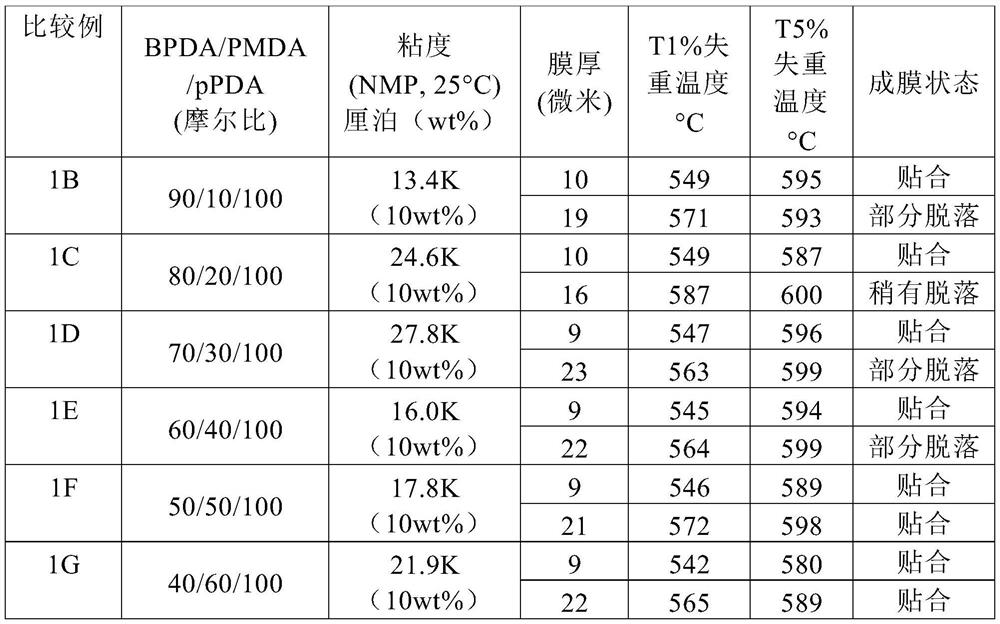

[0071] The polyimide film is prepared from the BPDA / PMDA / pPDA copolymer by the temperature-programmed method of the present invention

[0072] The solution of polyamic acid was prepared by normal feeding method, and BPDA and PMDA in corresponding molar amounts were added to a glass bottle filled with N-methylpyrrolidone (NMP) and infused with nitrogen atmosphere, and the corresponding molar amounts of BPDA and PMDA were added after stirring at room temperature for 15 minutes. pPDA monomer, continue to add NMP solvent to ensure that there is no residual monomer on the inner wall of the container, and dilute to a solid content of 10wt% in the solution. The molar ratio of each monomer is shown in Table 1.

[0073] The obtained polyamic acid solution was cast on a glass substrate, and the glass substrate with the polyamic acid film was placed in an oven at 75°C, 230°C, and 400°C for 1.0h, 1.0h, and 1.5h, respectively.

[0074] The performance of the polyimide film was tested, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com