A kind of preparation method and application of transparent epoxy resin-silicone rubber modified material

A technology of epoxy resin and modified materials, applied in epoxy resin glue, epoxy resin coating, adhesive and other directions, can solve the problem of limited improvement in material strength, and achieve the effect of excellent mechanical properties and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The synthesis of embodiment 1, difunctional epoxy resin DABPA

[0055]

[0056] Solid alkali method: add epichlorohydrin (ECH, 1mol), diallyl bisphenol A (DADGEBA, 0.1mol), tetramethylammonium bromide (0.006mol) into a three-necked flask together, and stir at 100°C Reaction 2h. Then lower the temperature to 85°C, add 0.2mol sodium hydroxide solid, react at 85°C for 2h, and then use a rotary evaporator to distill off excess epichlorohydrin under reduced pressure. Pour the reaction solution into a separatory funnel, add an appropriate amount of 50mL xylene to dissolve the crude product, wash it with deionized water, remove the lower water layer, add 5% sodium hydroxide solution to the crude product, and react at 85°C for 2 hours. Hydrolyze chlorine, remove the water layer, check the acidity and alkalinity with ph test paper, then neutralize the organic phase with 2% sodium dihydrogen phosphate to neutrality, wash with water and remove the water layer, and finally remo...

Embodiment 2

[0057] Embodiment 2, the preparation of bifunctional epoxy resin-silicone rubber block network material of the present invention

[0058] According to the feed ratio shown in Table 1, the invented bifunctional epoxy resin-silicone rubber block network materials DADGEBA-1p, DADGEBA-3p, DADGEBA-5p, DADGEBA-10p were prepared. Specific steps are as follows:

[0059] Add the difunctional epoxy resin DABPA prepared in Example 1 into the silicone rubber, stir at 80°C for 1h, and after cooling to room temperature, add hydrogen-containing silicone oil (HS), catalyst (Pt) and catalytic retarder 2-methyl -3 butyne-2 alcohol (MBO), after stirring at room temperature for 15 minutes, remove air bubbles in vacuum for 10 minutes, then pour into the mold, and follow the conditions of 2 hours at 90°C, 2 hours at 120°C, 2 hours at 140°C, and 2 hours at 180°C After curing, the inventive bifunctional epoxy resin-silicone rubber block network material is obtained.

[0060] from Figure 10 It can...

experiment example 1

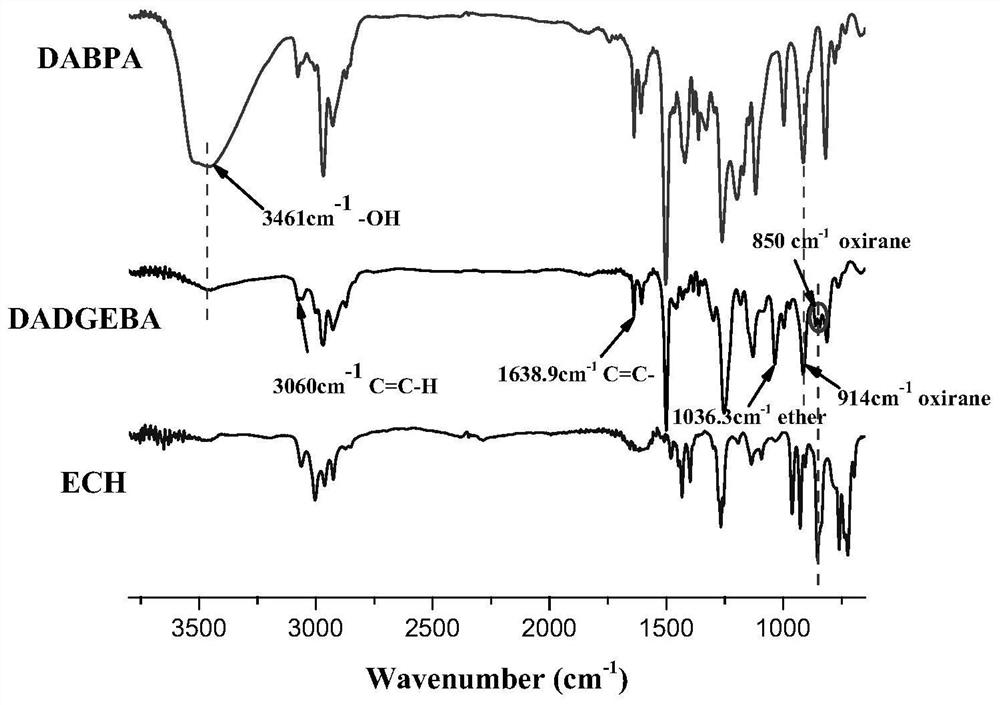

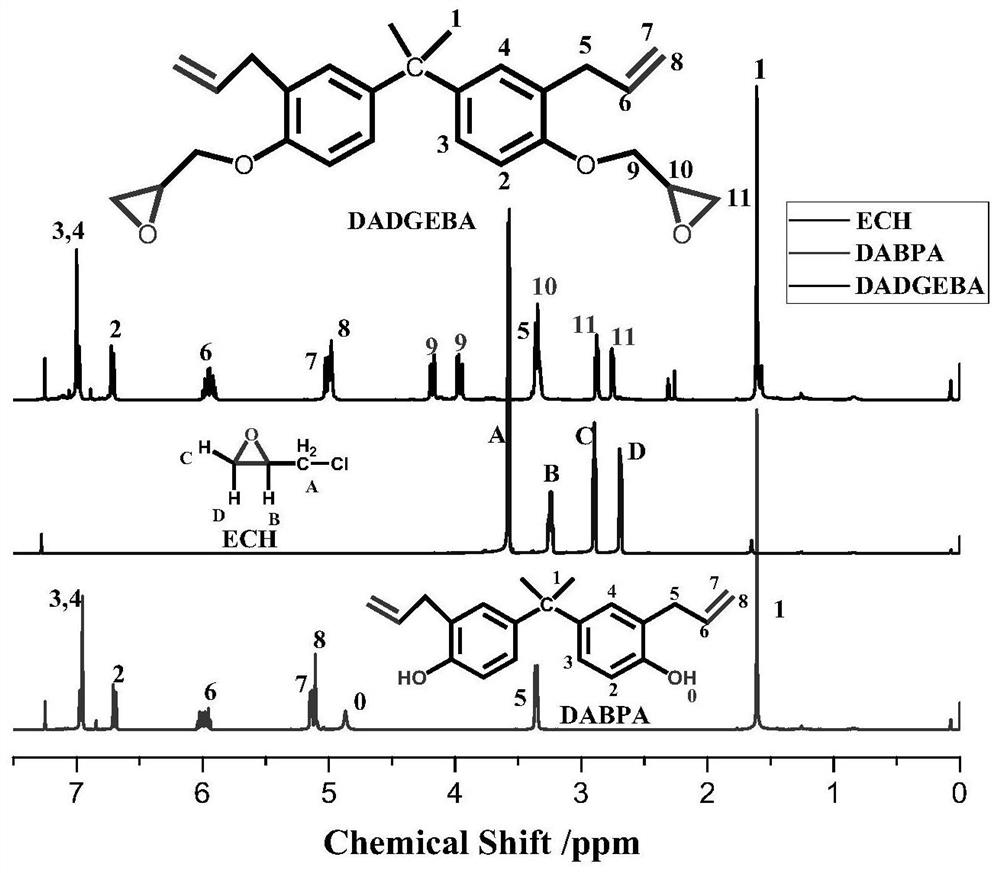

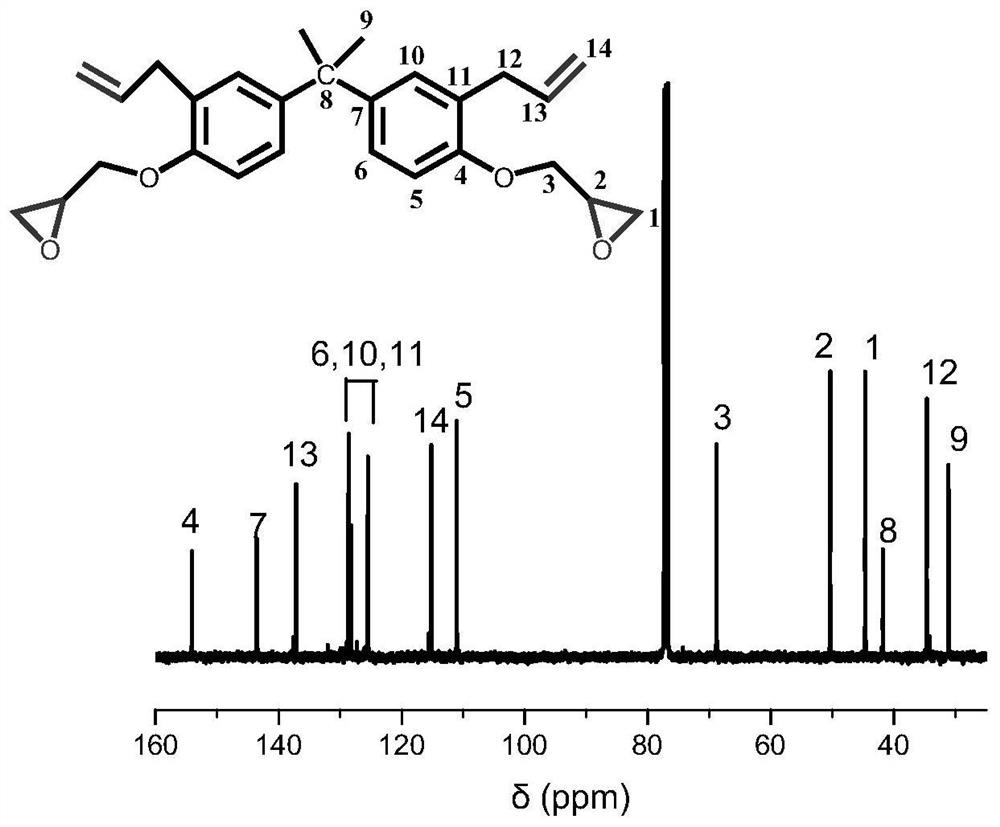

[0067] Experimental Example 1, Structural Characterization of Difunctional Epoxy Resin

[0068] (1) Experimental method

[0069] The bifunctional epoxy resin DABPA prepared in Example 1 was characterized by infrared, hydrogen nuclear magnetic spectrum and carbon nuclear magnetic spectrum respectively.

[0070] (2) Experimental results

[0071] The result is as Figure 1-3 shown. In the infrared spectrum ( figure 1 ), the hydroxyl peak of DADGEBA disappeared obviously, 850,914cm -1 The peak of the epoxy group at 723cm -1 The peak of carbon-chlorine bond disappeared, indicating that diallyl bisphenol A reacted with epichlorohydrin. In the H NMR and C NMR spectra ( figure 2 , image 3 ), the corresponding peaks of each hydrogen atom and carbon atom in DABPA can also be found respectively. The above results illustrate that the present invention has successfully prepared the difunctional epoxy resin DABPA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com