Polyurethane coating as well as preparation method and application thereof

A polyurethane coating and isocyanate technology, applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problems of affecting the flatness of the coating film, difficult coating filling, low density, etc., to achieve good anti-slump performance, shorten production cycle, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

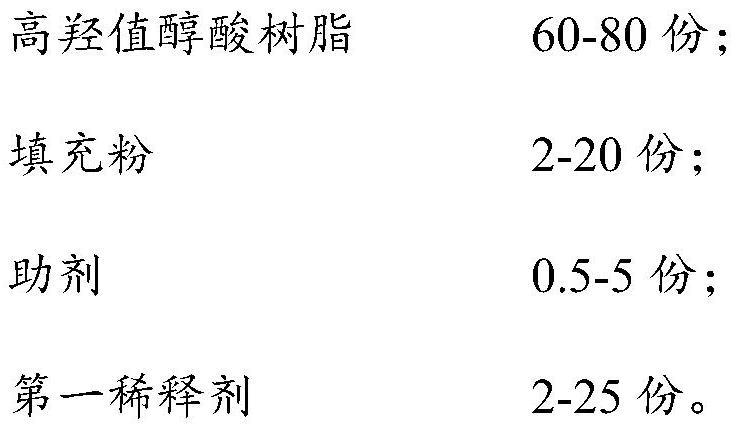

[0081] In Example 1, component A of polyurethane coating uses high hydroxyl number alkyd resin with A3, and in Comparative Examples 1-2, high hydroxyl number alkyd resin with A1-A2 is used. The high hydroxyl number alkyd resin with A1-A3 is prepared according to the formula in Table 1:

[0082] Table 1 Formula of alkyd resin with high hydroxyl value (unit: parts by weight)

[0083] Number of alkyd resin with high hydroxyl value A1 A2 A3 phthalic anhydride 18.2 35.5 M-phthalic anhydride 36.6 20.3 neopentyl glycol 12.5 22 21.2 trimethylolpropane 13.7 20 pentaerythritol 10 15.2 Lithium hydroxide 0.1 0.1 0.1 butyl acetate 20.3 19 15.3 Reflux solvent 7.8 5.2 7.9 solid content 72% 75% 78%

[0084] Add polyanhydride, polyol and reflux solvent in turn according to the formula in Table 1, and introduce N. 2 Heating the gas to 130℃, adding lithium hydroxide, heating to 170℃ for reflux esterification for 2.5h,...

Embodiment 1 and comparative example 1-5

[0097] 1, preparing component A.

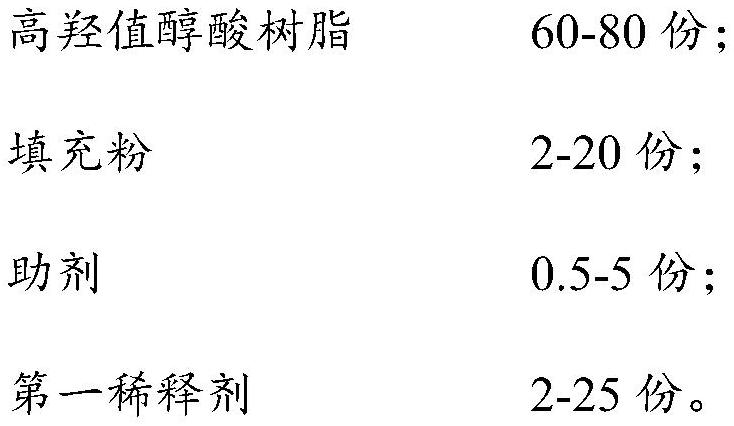

[0098] The difference between Example 1 and Comparative Examples 1-5 is that component A is different. Example 1 and Comparative Examples 1-5 respectively use the following raw materials in Table 3 and their proportions to prepare component A.

[0099] Table 3 Mass Ratio of Formula A in Examples 1-3 (unit: parts by weight)

[0100]

[0101]

[0102] According to Table 3, the alkyd resin with high hydroxyl value, filler powder, additives and butyl acetate prepared above are dispersed at a high speed of 1500r / min for 20 minutes until the fineness is less than 50μm, thus obtaining component A.

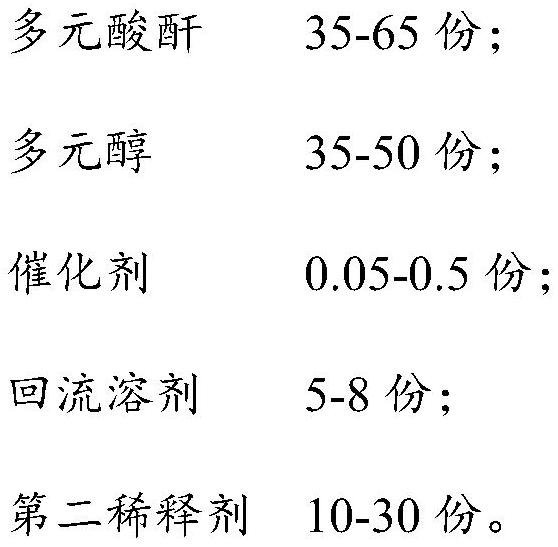

[0103] 2. Preparation of component B.

[0104] The raw materials of component B include:

[0105]

[0106] Add TDI-TMP polymer and TDI trimer into ethyl acetate diluent, mix well, and dilute with butyl acetate diluent to prepare component B, in which the solid content of component B is 45%, the viscosity is 13.2S (coated -4 cups), and the NCO value of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com