Belt drive type dense rack hand-cranking mechanism

A compact rack and belt drive technology, which is applied in the direction of transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of poor adaptability to the operating environment, high operating costs, and inconvenient maintenance and repairs, and achieve strong adaptability to the operating environment, Wide range of transmission ratio and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

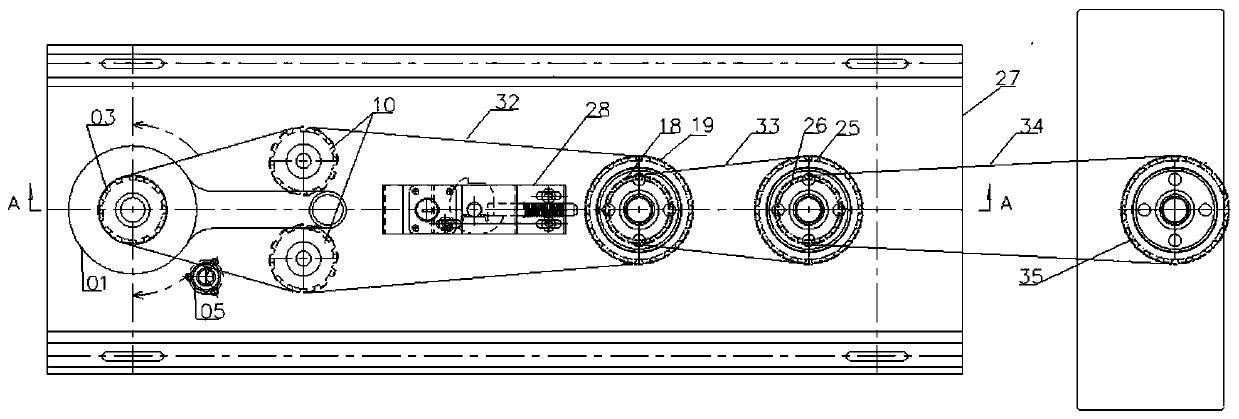

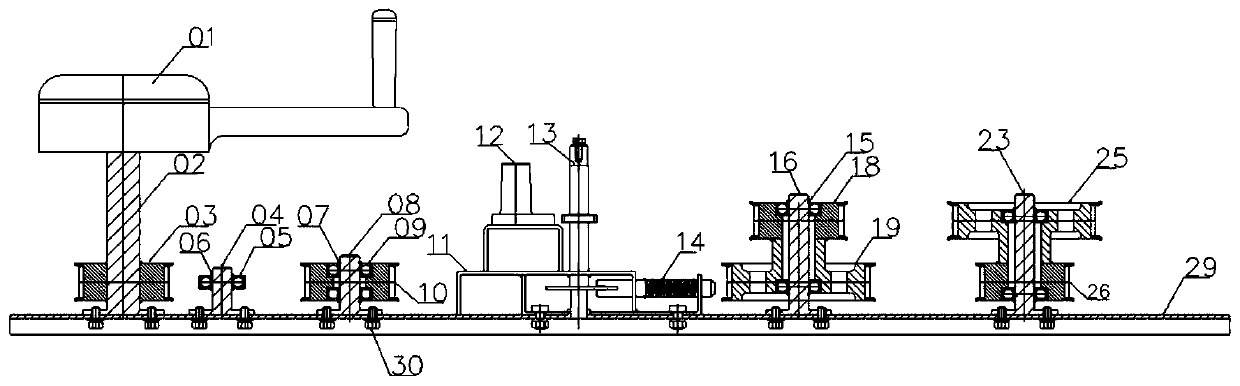

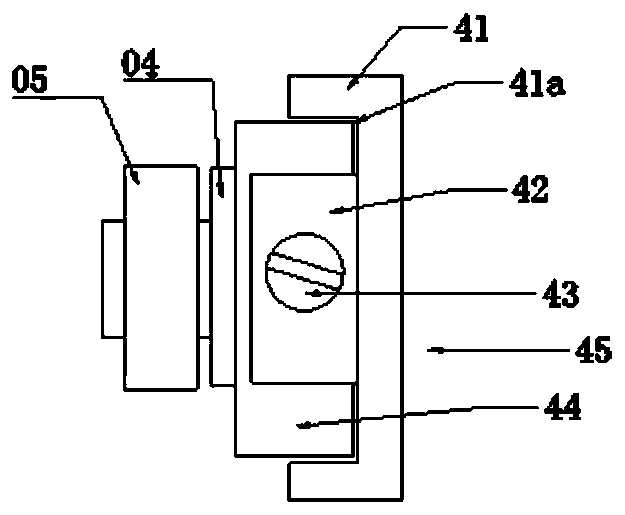

[0010] In order to further understand the technical solution of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings. Such as Figure 1-2 The belt-driven compact rack hand mechanism of the present invention includes the main pulley 03, the transition pulley, the output pulley, and the balance tension pulley that are arranged on the integrated frame 27 by corresponding T shafts and mutually driven by corresponding synchronous belts. , and locking braking device 28 etc., its each pulley is corresponding synchronous pulley.

[0011] Its transition pulley comprises the transition large pulley 19 and the transition small pulley 18 that are located on the corresponding transition T shaft 16 and the wheel diameters are different, and the output pulley includes a wheel diameter that is located on the corresponding output T shaft 23. The large output pulley 25 and the small output pulley 26 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com