Cloth hanging carton

A carton and indentation technology, applied to rigid containers, clothing, clothing packaging, etc., can solve the problems of environmental protection and resource recycling, excessive material consumption, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

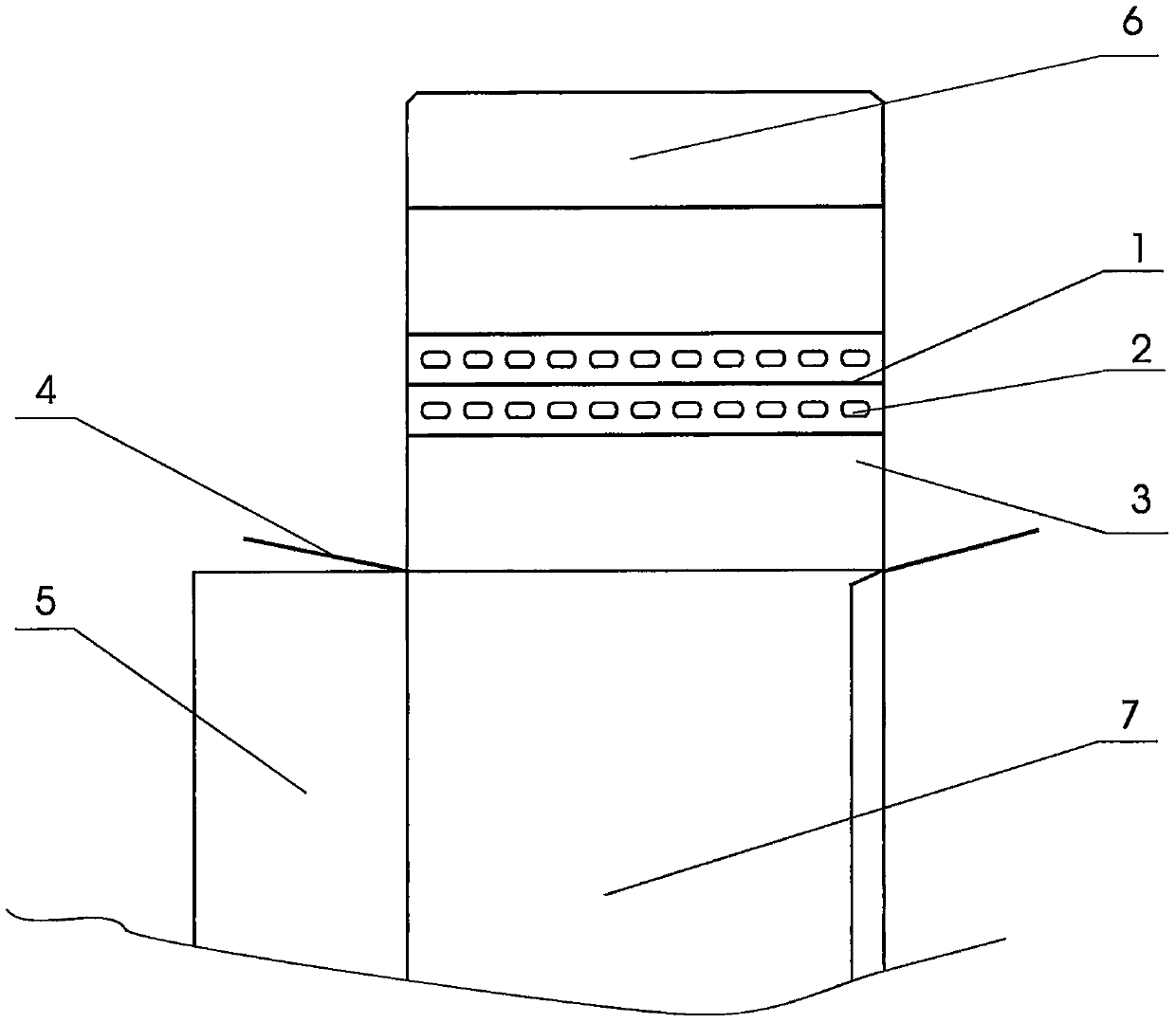

[0028] figure 1 Among them, one long side box wall is used as the sealing door panel (5) of the hanging clothes box, and the other long side box wall (7) is integrated with the long side top cover (3), and the long side top cover (3) There are three bending indentations (1) in the middle of the box, the middle bending indentation (1) is the inner bending indentation of the box, and the other two are outer bending indentations with a distance of 80mm, and the middle bending indentation ( There are 11 clothes hanging holes (2) on both sides of 1), and the clothes hanging holes (2) are evenly distributed with the bending indentation (1) in the middle as the axis of symmetry. The longitudinal length of the top cover (3) on the long side is equal to the width of the carton after deducting the extension of the top cover (6) and the three bending indentations (1).

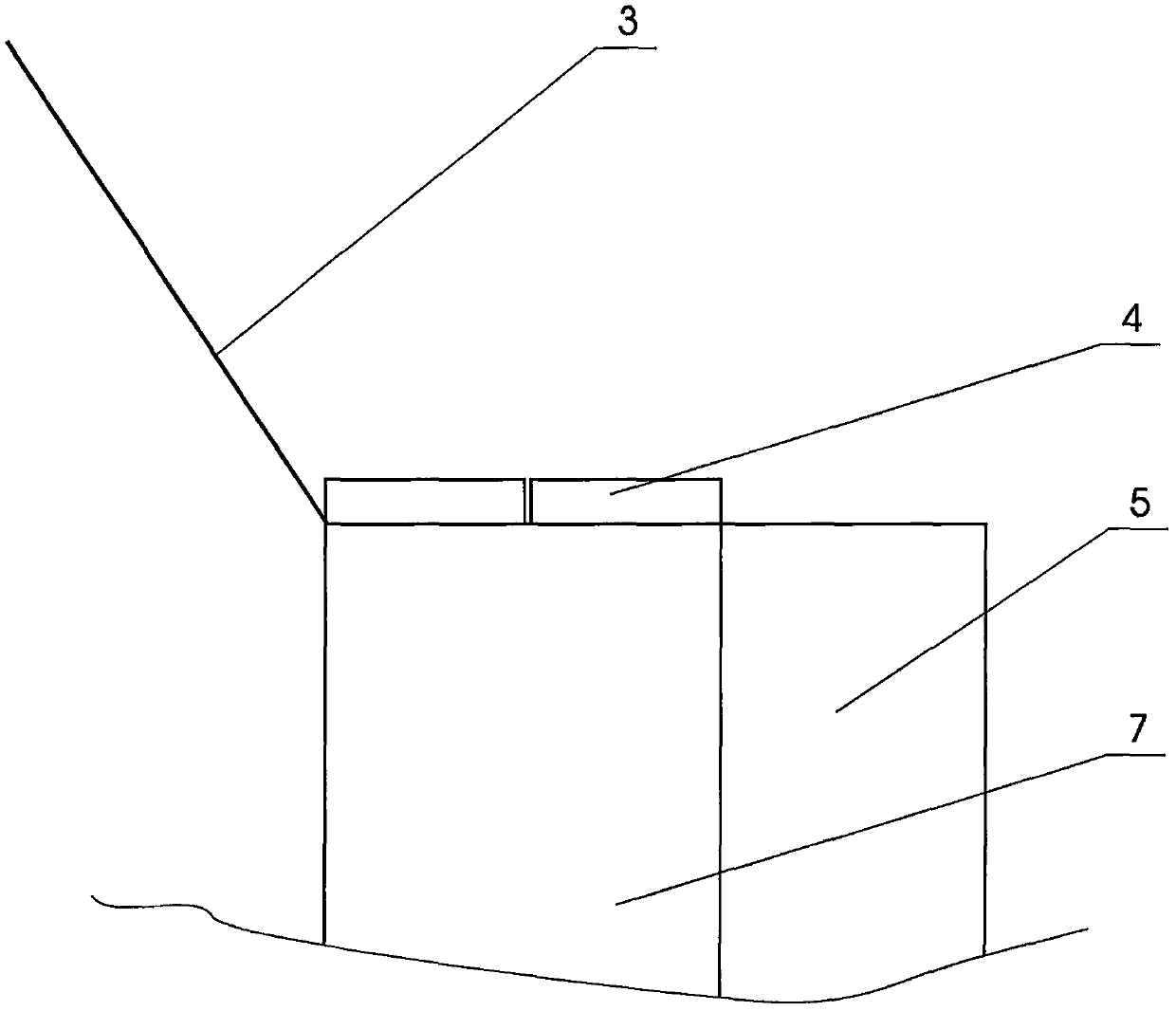

[0029] image 3 Among them, the middle part of the short side top cover (4) has a disconnected slot along the long si...

Embodiment 2

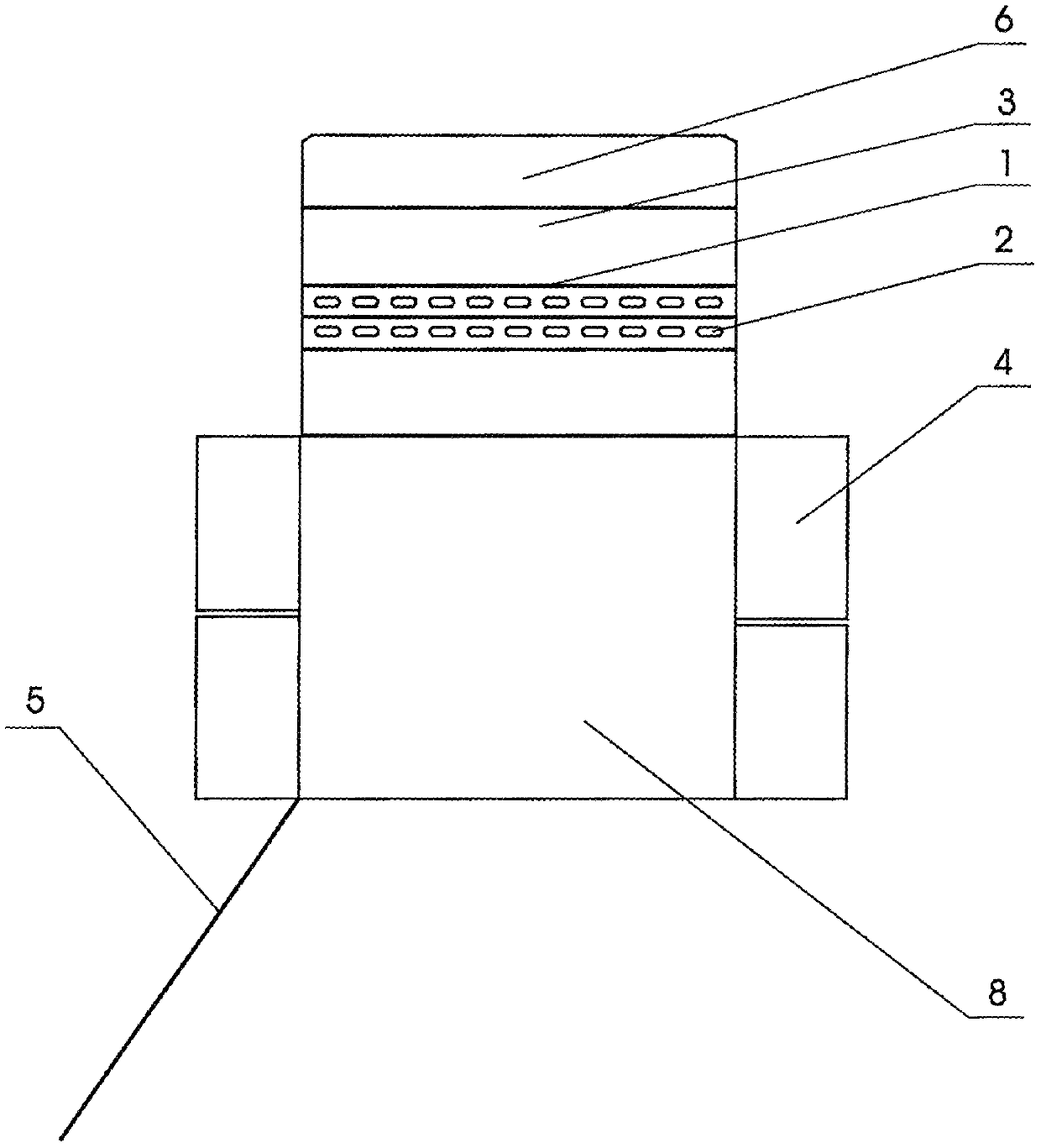

[0034] One long side box wall is used as the sealing door panel (5) of the hanging clothes box, and the other long side box wall (7) is connected with the long side top cover (3), and the middle part of the long side top cover (3) There are three bending indentations (1), the middle bending indentation (1) is the inner bending indentation of the box, and the other two are outer bending indentations with a distance of 80 mm, and the middle bending indentation (1) 11 clothes-hanging holes (2) are respectively arranged on both sides of the body, and the clothes-hanging holes (2) are evenly distributed with the middle road bending indentation (1) as the axis of symmetry. The longitudinal length of the top cover (3) on the long side is equal to the width of the carton after deducting the extension of the top cover (6) and the three bending indentations (1).

[0035] Figure 8 Among them, the middle part of the short side top cover (4) has a disconnected slot along the long side di...

Embodiment 3

[0041] Figure 12 Among them, make a breach on a long side box wall (7), so that the entry and exit of clothes, another long side box wall (7) is connected with the long side top cover (3), and the long side top cover (3) ) has three bending indentations (1) in the middle. (1) There are 11 clothes hanging holes (2) on both sides, and the clothes hanging holes (2) are evenly distributed with the bending indentation (1) in the middle as the axis of symmetry. The longitudinal length of the top cover (3) on the long side is equal to the width of the carton after deducting the extension of the top cover (6) and the three bending indentations (1).

[0042] The middle part of the short side top cover (4) has a disconnected slot along the long side direction of the box. The width of the slot needs to ensure that the corrugated cardboard used in the carton can be inserted after being folded in half.

[0043] The long-side top cover (3) is bent along the three bending indentations (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com