Titanium dioxide intercalation photocatalysed composite material and preparation method thereof

A composite material, titanium dioxide technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

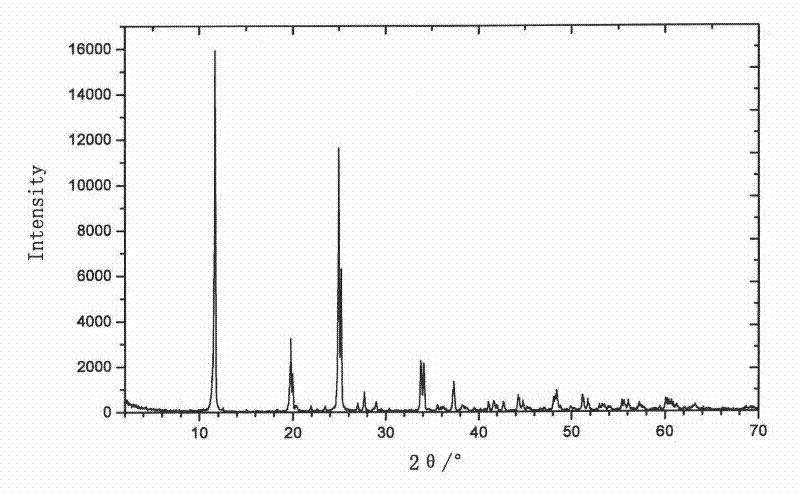

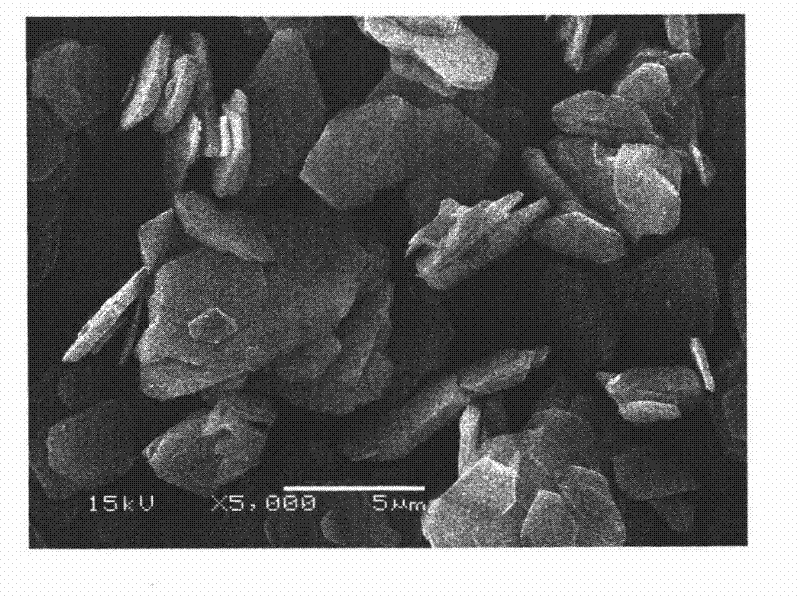

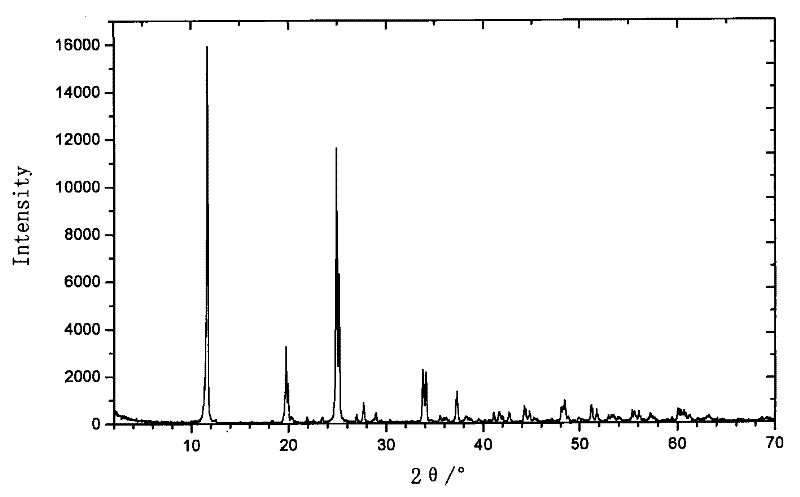

[0020] Example 1: Weigh about 20g of α-zirconium phosphate and put it into a 100ml beaker, add 100ml of 0.2mo.L NaCl solution, stir and react at room temperature for 4 hours, filter, fully wash with distilled water 3 times, separate liquid and solid, and store at 65°C After drying for 24 hours, the sample was ready for use (referred to as sample I). Add 25mL of 95% ethanol and 15mL of absolute ethanol to a 100ml beaker, add 10mL of n-butyl titanate under continuous stirring, stir for 3 hours for hydrolysis, then add 5g of sample I, and shake the resulting suspension at 50°C under a shaker After 3 hours, filter, wash with 50% ethanol aqueous solution for 3 times, then wash the solid phase with distilled water, dry in a 65°C oven for 24 hours, and set aside the solid phase for use (marked as sample II), take 3g of sample II and put it into the inner lining In a polytetrafluoroethylene stainless steel autoclave with a volume of 100mL, add deionized water to make the volume of the...

Embodiment 2

[0024] Example 2: Add 25mL of 95% ethanol and 15mL of absolute ethanol to a 100ml beaker, add 25mL of n-butyl titanate under continuous stirring, stir and hydrolyze for 2 hours, then add 5g of the sample I prepared in Example 1 to obtain The suspension was vibrated at 50° C. for 3 hours on a shaker, filtered, washed three times with 50% ethanol aqueous solution, and then the solid phase was washed with distilled water, dried in an oven at 65° C. for 24 hours, and the solid phase was ready for use (referred to as sample III). Take 3g of sample III and put it into a stainless steel high-pressure reactor lined with polytetrafluoroethylene. The volume of the reactor is 100mL. Add deionized water to make the volume of the solution reach 70% of the volume of the reactor. In the process, the temperature of the oven was adjusted to 240°C. After reacting for 2 hours, it was taken out of the oven, cooled naturally, opened, filtered with suction, separated from solid and liquid, washed wi...

Embodiment 3

[0026] Example 3: Add 25mL of 95% ethanol and 15mL of absolute ethanol to a 100ml beaker, add 20mL of n-butyl titanate under continuous stirring, stir and hydrolyze for 2 hours, then add 5g of the sample I prepared in Example 1 to obtain The suspension was vibrated at 50° C. for 3 hours on a shaker, filtered, washed three times with 50% aqueous ethanol, and then the solid phase was washed with distilled water, dried in an oven at 65° C. for 24 hours, and the solid phase was ready for use (referred to as sample IV). Take 3g of sample IV and put it into a stainless steel autoclave lined with polytetrafluoroethylene. The volume of the autoclave is 100mL. Add deionized water to make the volume of the solution reach 70% of the volume of the autoclave, and place the closed autoclave in an oven. , the oven temperature was adjusted to 1500°C, after 4 hours of reaction, it was taken out of the oven, cooled naturally, opened, filtered with suction, separated from solid and liquid, washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com