Ready-made clothes delivery code scanning system

A technology of scanning code and ready-to-wear, applied in data processing applications, instruments, calculations, etc., to achieve the best technical and practical effects, overcome the bottleneck of processing efficiency, and overcome the problem of missed detection and error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

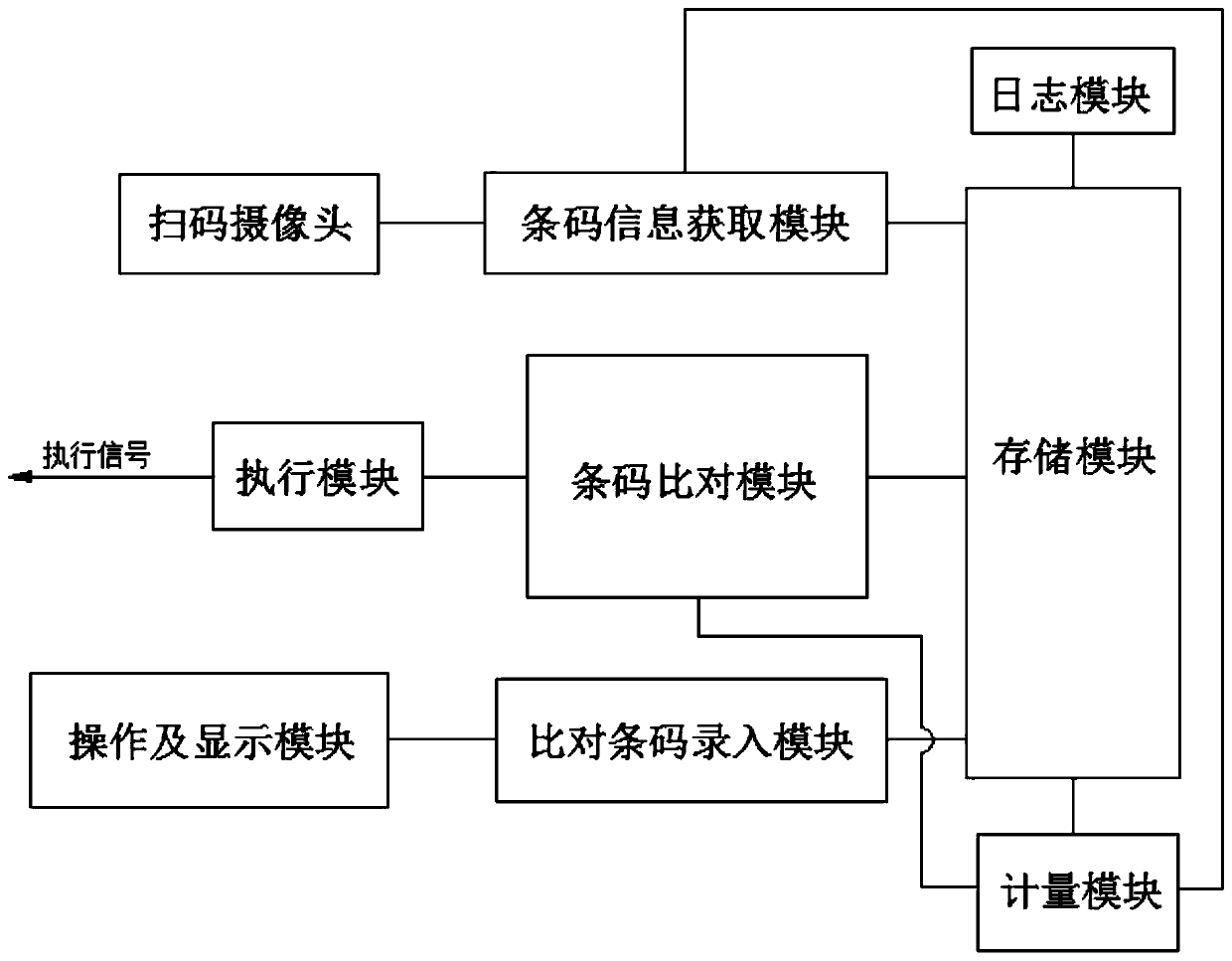

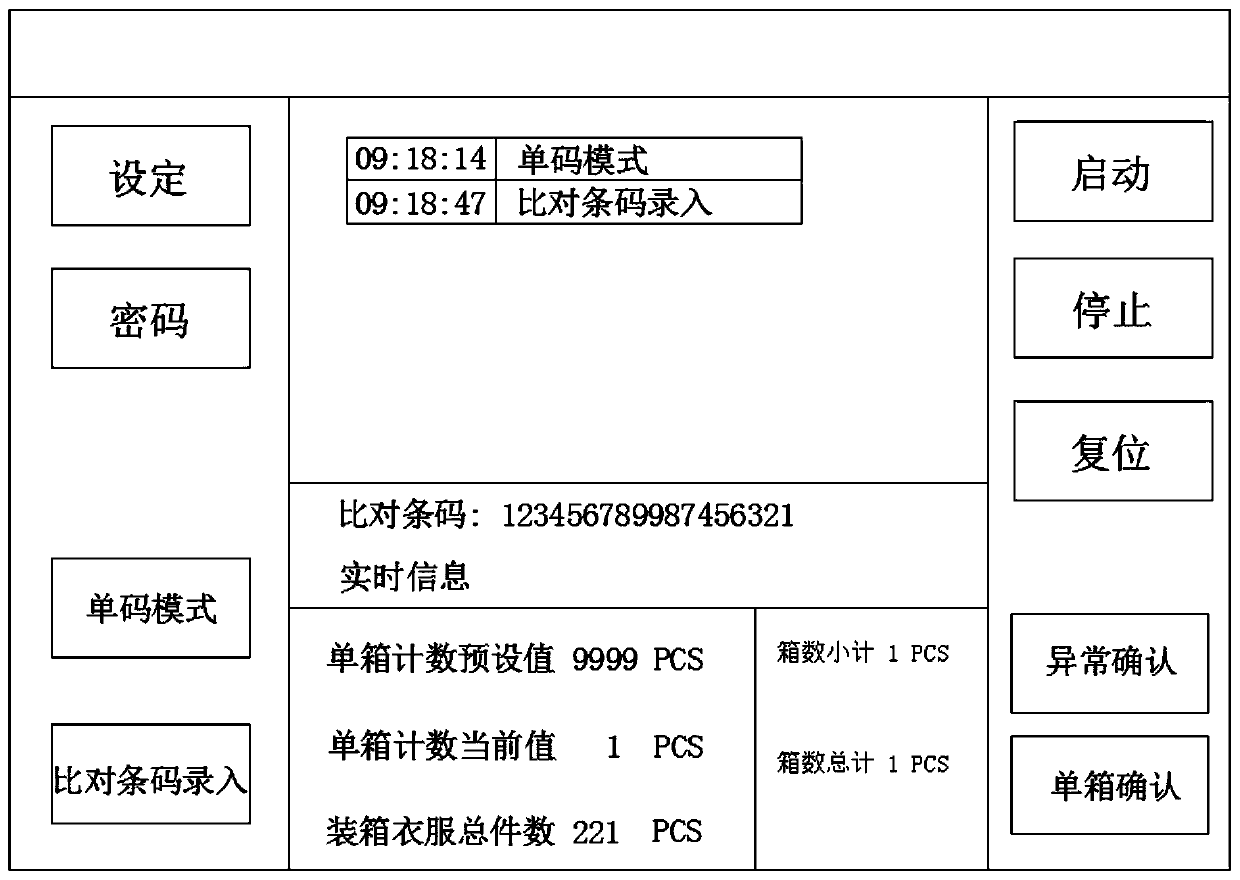

[0016] Attached as follows figure 1 and 2 , to further describe the application scheme:

[0017] A code scanning system for ready-to-wear shipments, comprising:

[0018] The barcode information acquisition module is used to connect with the code scanning camera and obtain the barcode information on the garment label through the code scanning camera;

[0019] The comparison barcode input module is used to obtain the comparison barcode input by the user;

[0020] The barcode comparison module is used to compare the preset comparison barcode with the obtained barcode information to generate a comparison result; the comparison result includes a first logo representing a consistent comparison and an inconsistent Second logo;

[0021] The metering module is used to count the number of barcode information recognized by scanning the code, and add one every time a barcode information is obtained or every time a first logo is obtained;

[0022] The operation and display module is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com