Rear-mounted feeding digital controlled lathe

A CNC lathe, post-mounted technology, applied in the field of machinery, can solve problems such as low work efficiency, pollution, and hydraulic oil in the fuel tank, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

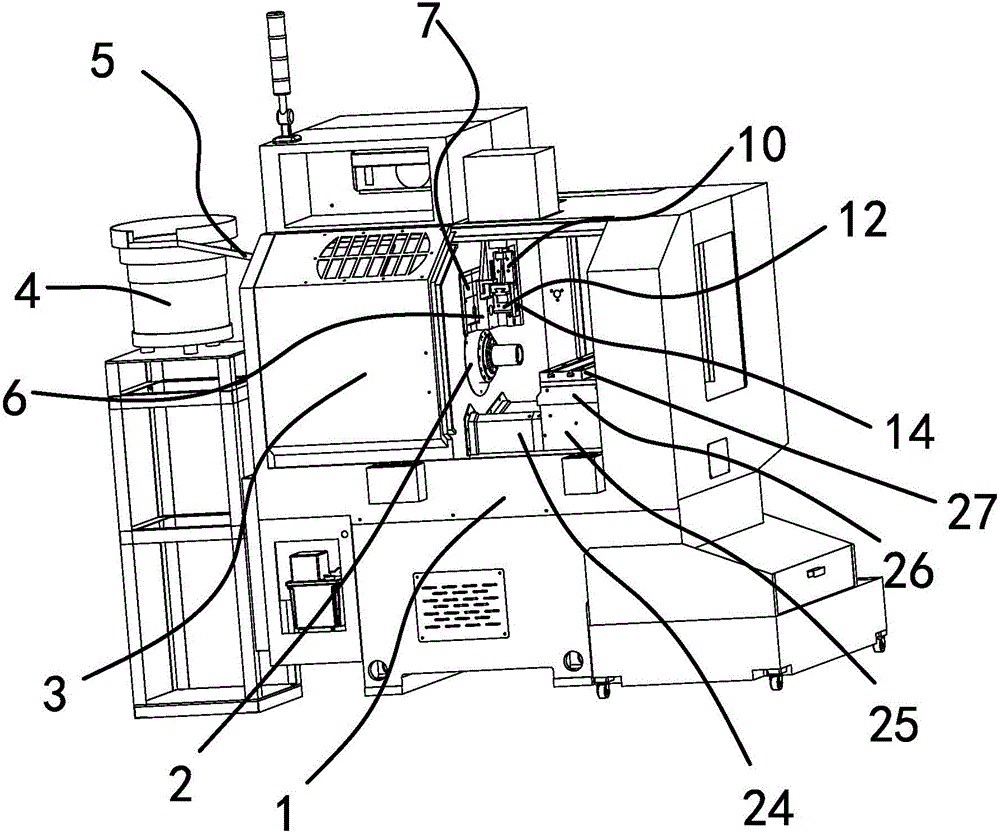

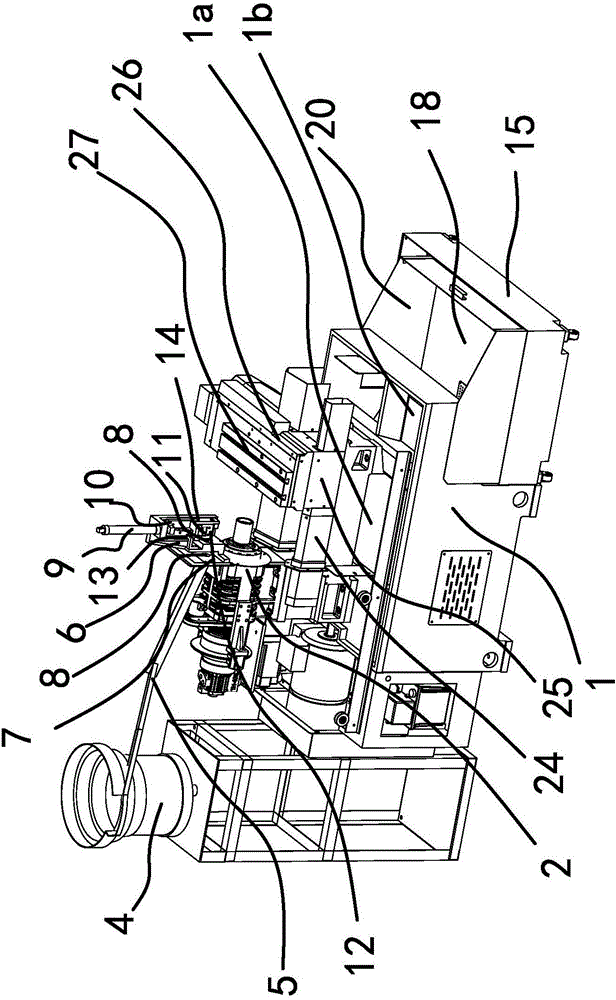

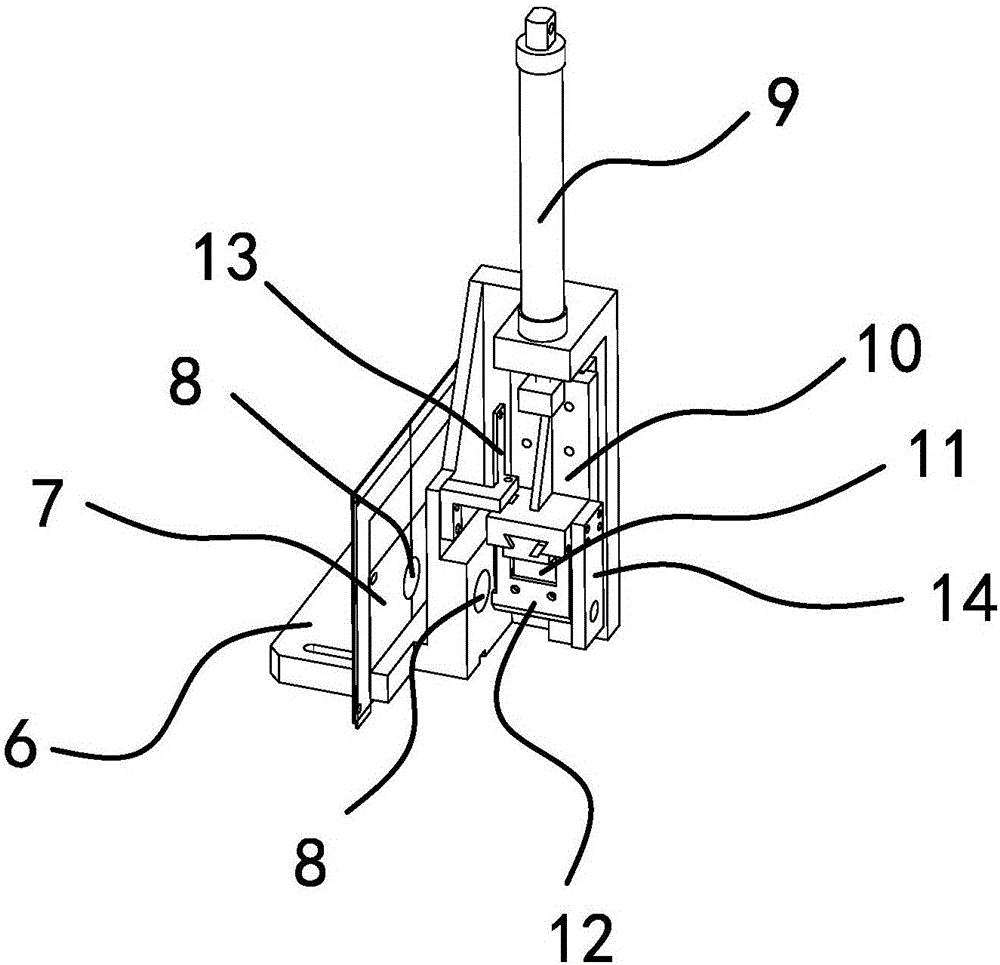

[0023] Such as Figure 1 to Figure 7 As shown, the rear-mounted feeding CNC lathe includes a frame 1, a machine cover 3 and a main shaft 2 located in the machine cover 3 are installed on the frame 1, and a slide rail 24 is also provided on the frame 1, and the slide rail 24 is located on the main shaft 2. In the front, a horizontal support plate 25 is slidably connected to the slide rail 24, a longitudinal support plate 26 is slidably connected to the transverse horizontal plate 18, and a workbench 27 is installed on the longitudinal support plate 26. On the vibrating plate 4 where the workpiece is placed and the vibrating plate 4 is located behind the main shaft 2, the outlet end of the vibrating plate 4 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com