Medical waste incineration treatment device

A technology for processing equipment and medical waste, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as air pollution, long incineration time, large garbage, etc., achieve recycling, improve incineration efficiency, reduce The effect of filter load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

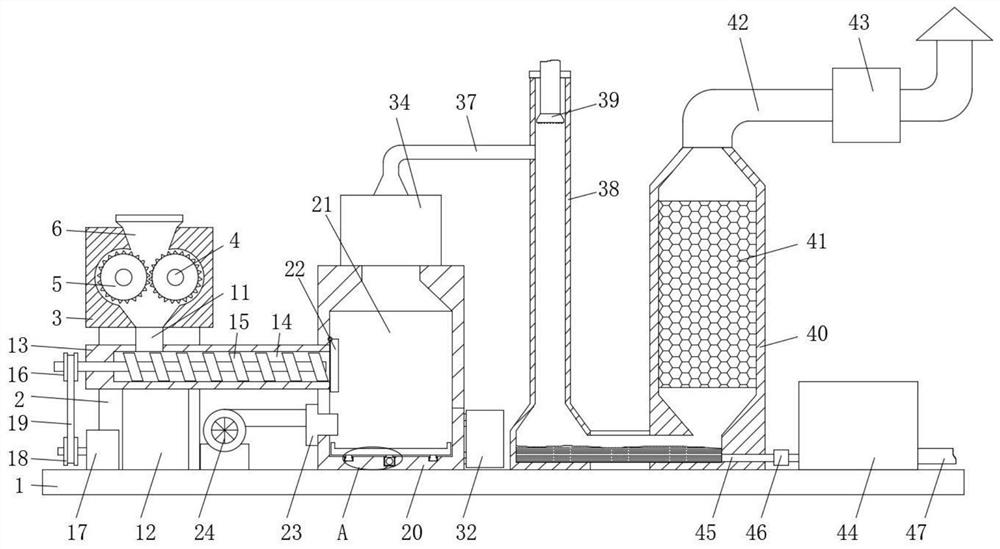

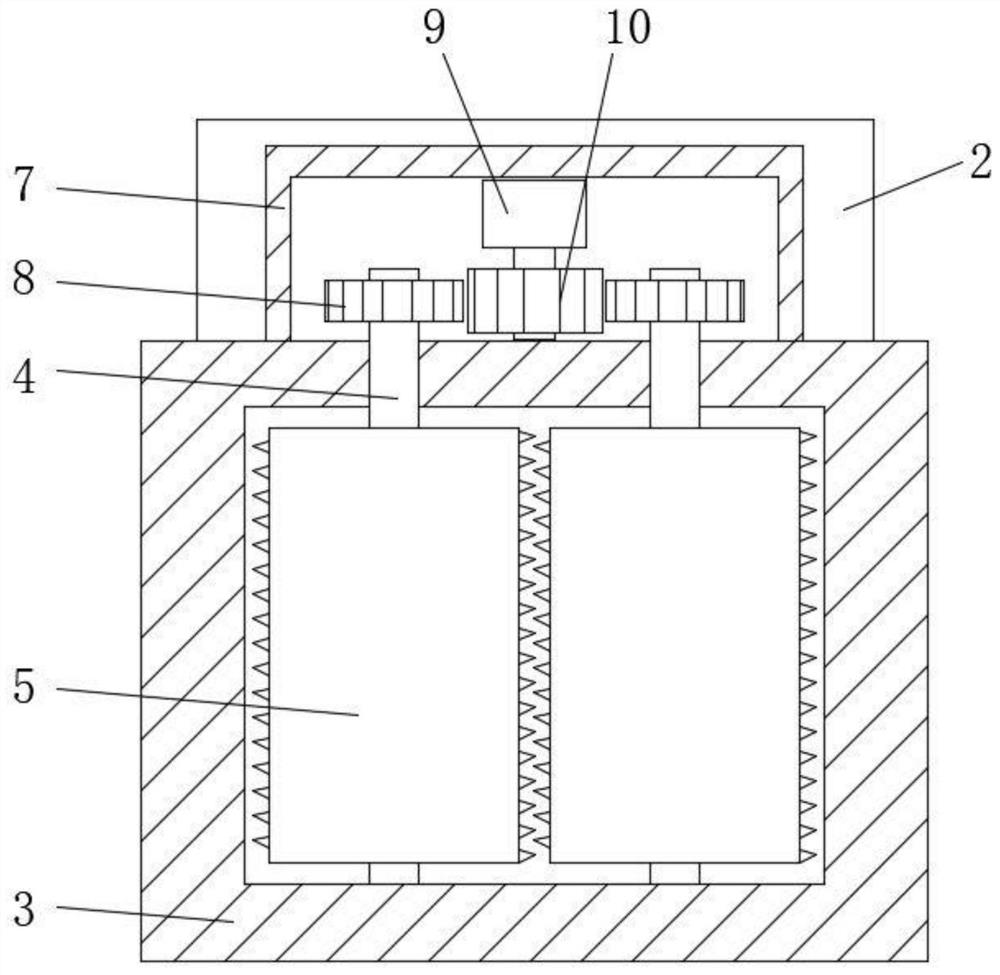

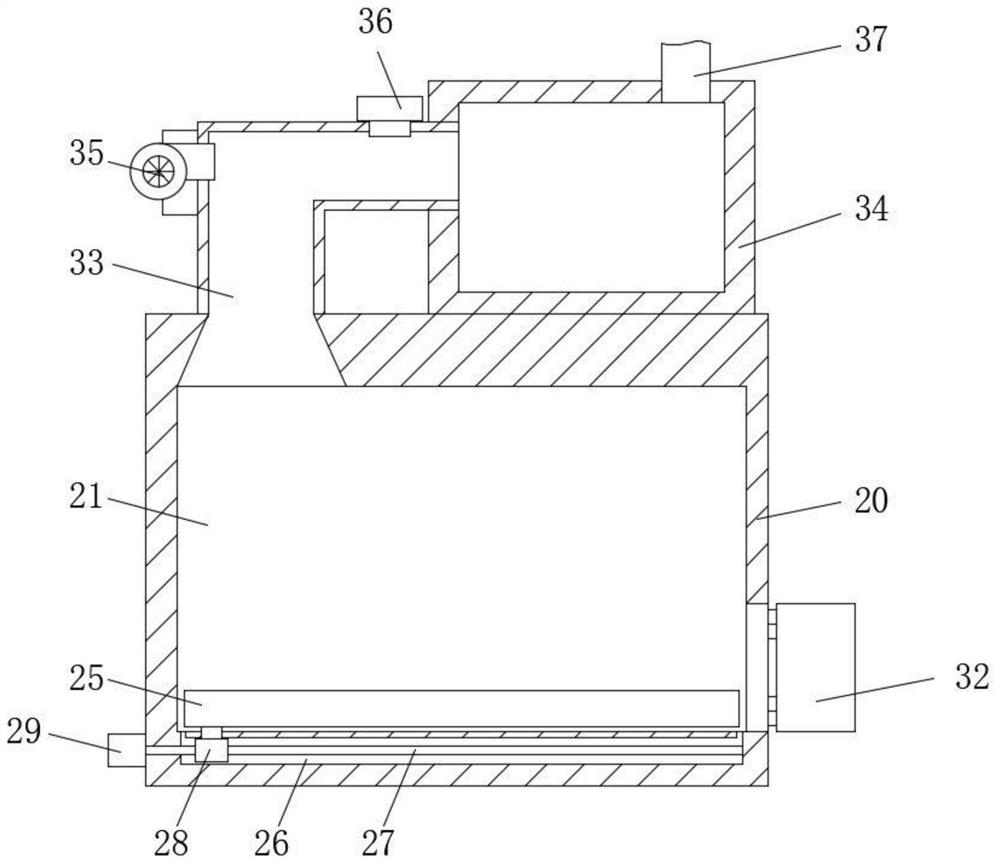

[0025] Such as Figure 1-4As shown, the embodiment of the present invention provides a medical waste incineration treatment equipment, including a base 1, the top side of the base 1 is fixedly connected with a first fixed platform 2, the first fixed platform 2 is provided with a crushing box 3, and the crushing box 3 is provided with two rotating shafts 4, and crushing rollers 5 are nested and fixedly connected to the two rotating shafts 4. The top of the crushing box 3 is provided with a feed port 6, and the top of the first fixed table 2 is located outside the crushing box 3. One side of the surface is provided with a protection box 7, and one end of the two rotating shafts 4 is provided with a driven gear 8 in the protection box 7, and a first motor 9 is arranged in the protection box 7, and the driving end of the first motor 9 is provided with The driving gear 10 meshing with the two driven gears 8, the top side of the base 1 is fixedly connected with a second fixed platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com